A flat car for railway transportation

A technology of railway transportation and wheels, which is applied in the field of railway ore-carrying gondola cars and railway transportation vehicles. It can solve the problems of reducing the running stability of the vehicles, not being able to fully utilize the limit, and the volume of the car body can not be achieved, so as to meet the requirements of heavy load and speed increase. Development, suitable for popularization and application, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

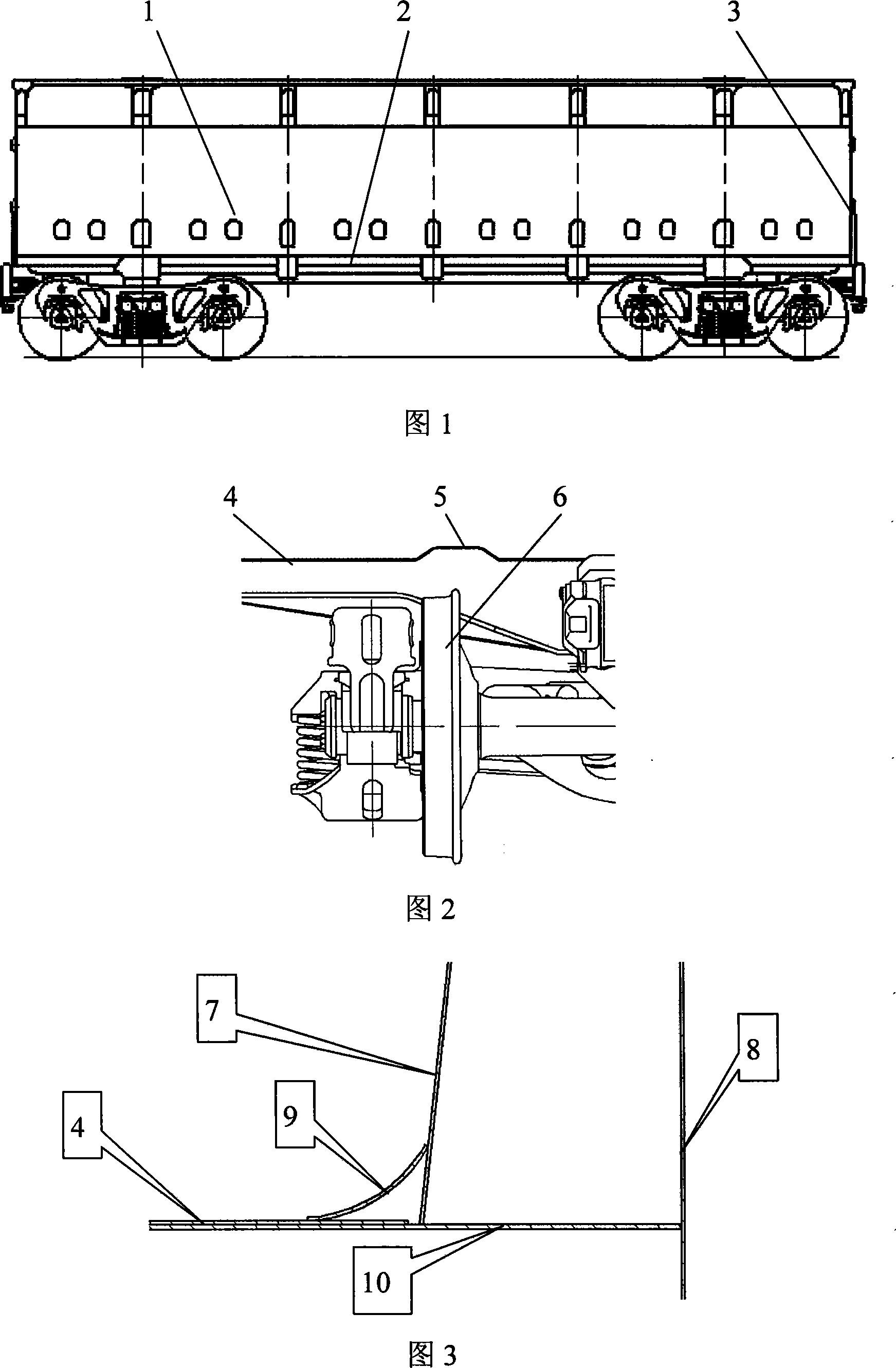

[0010] The accompanying drawing shows a specific embodiment of the present invention, and the present invention will be further described below in conjunction with the accompanying drawing and the embodiment.

[0011] It can be seen from Fig. 1 that the present invention is a heavy-duty railway gondola car. The car body includes an end wall 3, a side wall 1 and an underframe 2. The side post 7 of the gondola car is a pressed side post and adopts a built-in structure. The floor 4 adopts a pressed The gondola car body structure with type protrusions to give way to the wheels. The vehicle has a simple appearance and a simple structure, and the entire side wall is very flat, which reduces the resistance during operation and improves the stability of the vehicle.

[0012] It can be seen from Fig. 2 that the floor 4 of the gondola car adopts a profiled structure, and two protrusions 5 avoiding the wheels 6 are provided at the position close to the floor 4 and the wheels 6. The protr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com