Measuring apparatus for fabric dynamic heat and moisture transmission characteristic

A measuring device and technology for heat and moisture transfer, applied in measuring devices, textile testing, material thermal development, etc., can solve problems such as the inability to adjust the temperature of the human body and the inability to determine the heat and moisture transfer performance of fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

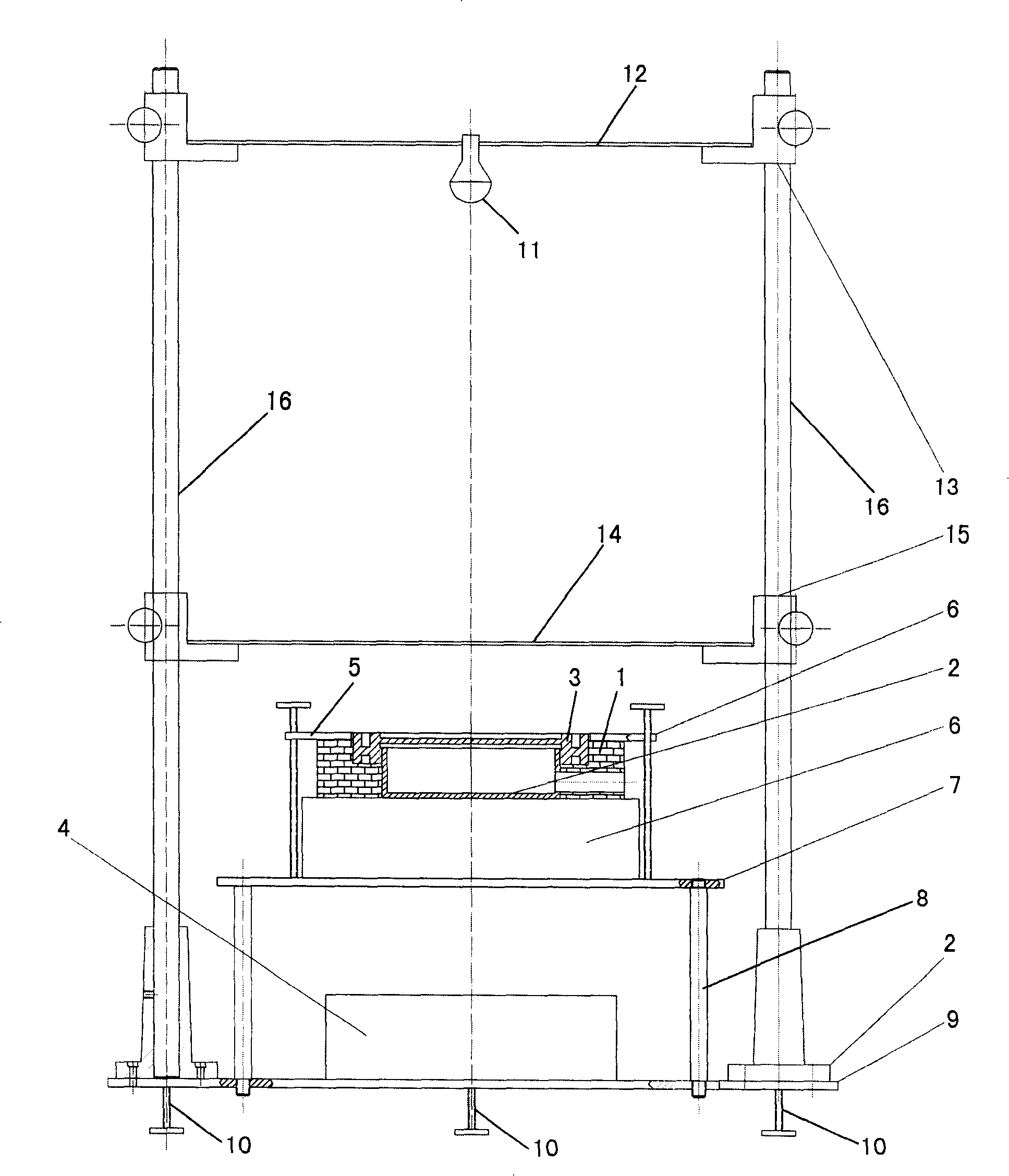

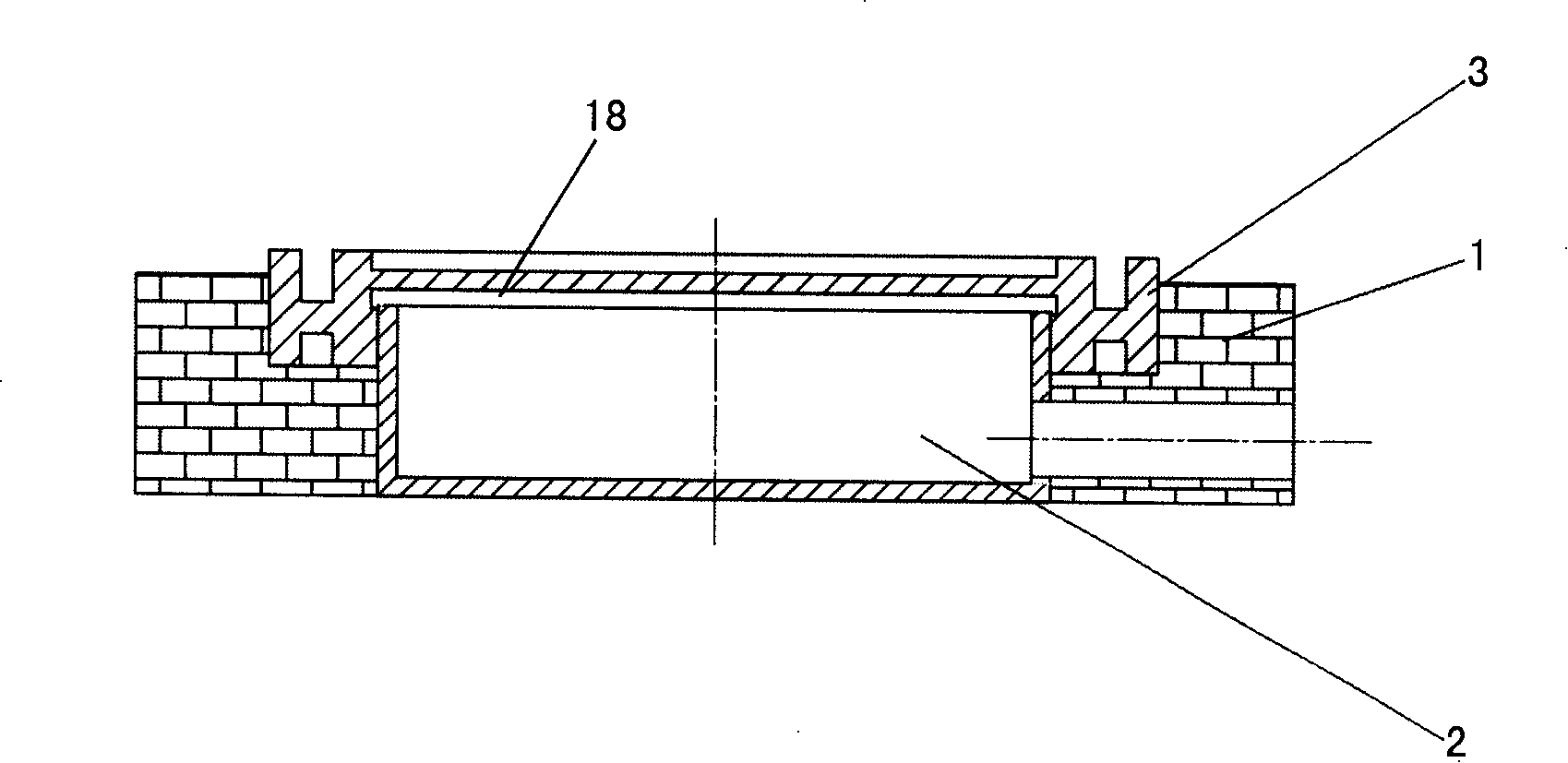

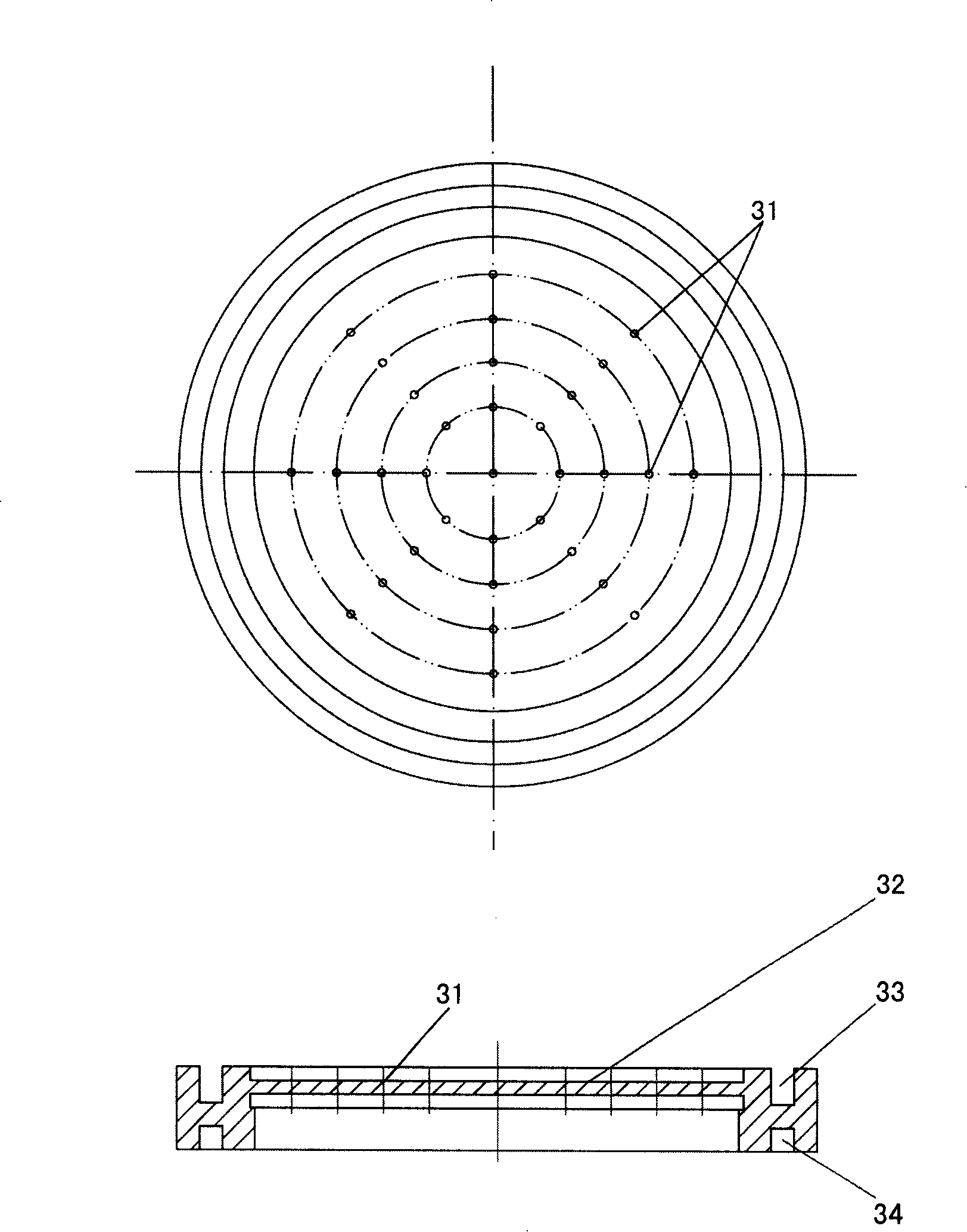

Method used

Image

Examples

example 1

[0094] Typical measurement curves are summarized in Figures 5 to 7, respectively. Figure 5 shows the measurement results of the upper surface of the biomimetic skin layer; Figure 6 shows the measurement results of the bottom surface of the fabric next to the biomimetic skin layer; Figure 7 shows the measurement results of the upper surface of the fabric in contact with the environment. The whole measurement process is divided into six sections, detailed as follows:

[0095] The first stage: dynamic contact process (0→t 1 ): The temperature from when the sample is placed on the measuring disc until the temperature on the skin reaches a stable temperature (t1) at the time of involuntary perspiration. At this stage, it is used to simulate the process of wearing clothes. Since the ambient temperature is generally lower than the skin temperature, the temperature of the skin surface first gradually decreases and then gradually increases to a steady state, while the temperature of ...

example 2

[0145] Examples of measurement results on different fabric samples

[0146] To determine device performance, nanofunctional material-treated liquid water management functional fabrics will be used as samples. Based on the basic physical parameters of the fabrics found in Table 2, the general measurement results are shown in Fig. 7.

[0147] The basic physical properties of table 2MMF

[0148] fabric number

inclusions

structure

Thickness under 98 Pa pressure

(mm)

weight

(g / m 2 )

A

100% nano-processed

cotton denim

0.796

182

[0149] Figure 8 is the measurement results of typical liquid water transfer characteristics of pure cotton twill fabric treated with nanomaterials. As shown in Figure 8, after liquid water reaches the bottom surface of the fabric, it can be quickly and easily transported to the upper surface and evaporated into the environment, so the water co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com