Steroscopic display and manufacturing method thereof

A technology of a stereoscopic display and a manufacturing method, which is applied to stereoscopic systems, static indicators, instruments, etc., can solve the problems of limited observer positions and high dependence of stereoscopic image viewing angles, and improve display quality, save manufacturing costs, and increase viewing angles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

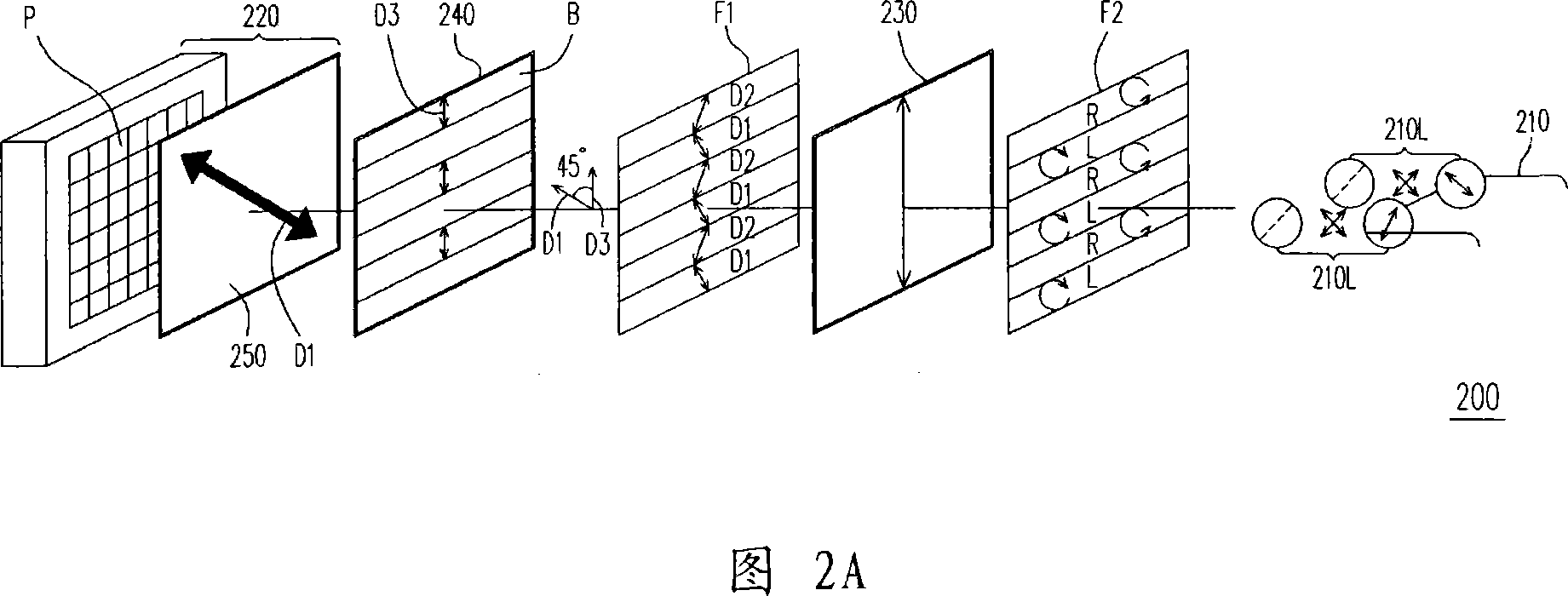

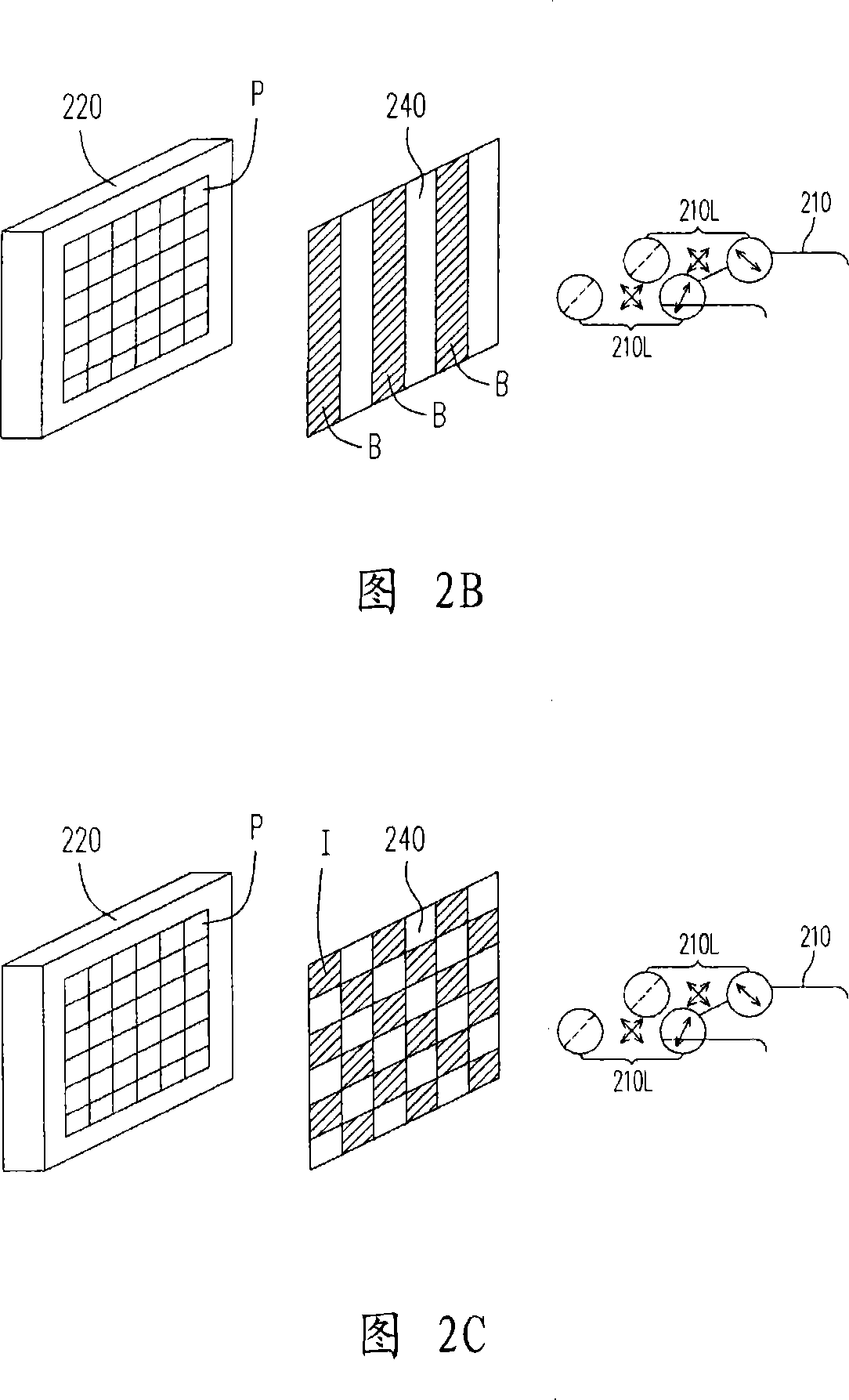

[0059] FIG. 2A is a schematic diagram of the first embodiment of the stereoscopic display of the present invention. Please refer to FIG. 2A , the stereoscopic display 200 is suitable for the viewer to watch while wearing circular polarized glasses 210, wherein the circular polarized glasses 210 have two circular polarized lenses 210L with left-handed and right-handed polarized characteristics, and the circular polarized lens 210L is as As shown in Figure 2A, it can be regarded as a combination of a quarter-wave plate and a linear polarizer. In addition, the stereoscopic display 200 includes a flat display panel 220 , a quarter-wave plate 230 and a patterned half-wave plate 240 . In this embodiment, the patterned half-wave plate 240 is disposed on the flat display panel 220, and the quarter-wave plate 230 is disposed on the patterned half-wave plate 240, and the patterned half-wave plate 240 is located in a quarter between the wave plate 230 and the flat display panel 220 . T...

no. 2 example

[0071] FIG. 5 is a schematic diagram of a second embodiment of the stereoscopic display of the present invention. Referring to FIG. 5 , the stereoscopic display 400 is similar to the stereoscopic display 200 described in the first embodiment, but the configuration positions of the quarter-wave plate 230 and the patterned half-wave plate 240 of the stereoscopic display 400 are different from the stereoscopic display 200 . The quarter-wave plate 230 of the stereoscopic display 400 is disposed on the flat display panel 220, and the patterned half-wave plate 240 is disposed on the quarter-wave plate 230, and the quarter-wave plate 230 is located on the patterned half-wave plate 230. between the sheet 240 and the flat display panel 220 .

[0072]In this embodiment, the flat display panel 220 has an upper polarizer 250, wherein the optical axis of the upper polarizer 250 extends in a direction D1, so that the flat display panel 220 is suitable for displaying a linearly polarized ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com