Molding metal mold and method for manufacturing molding product

A technology for forming metal and metal molds, which is applied to home appliances, other home appliances, optical components, etc., can solve problems such as positioning errors, and achieve the effect of accurately determining the axial position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0037] Referring to the accompanying drawings, embodiments of the present invention will be described in detail below.

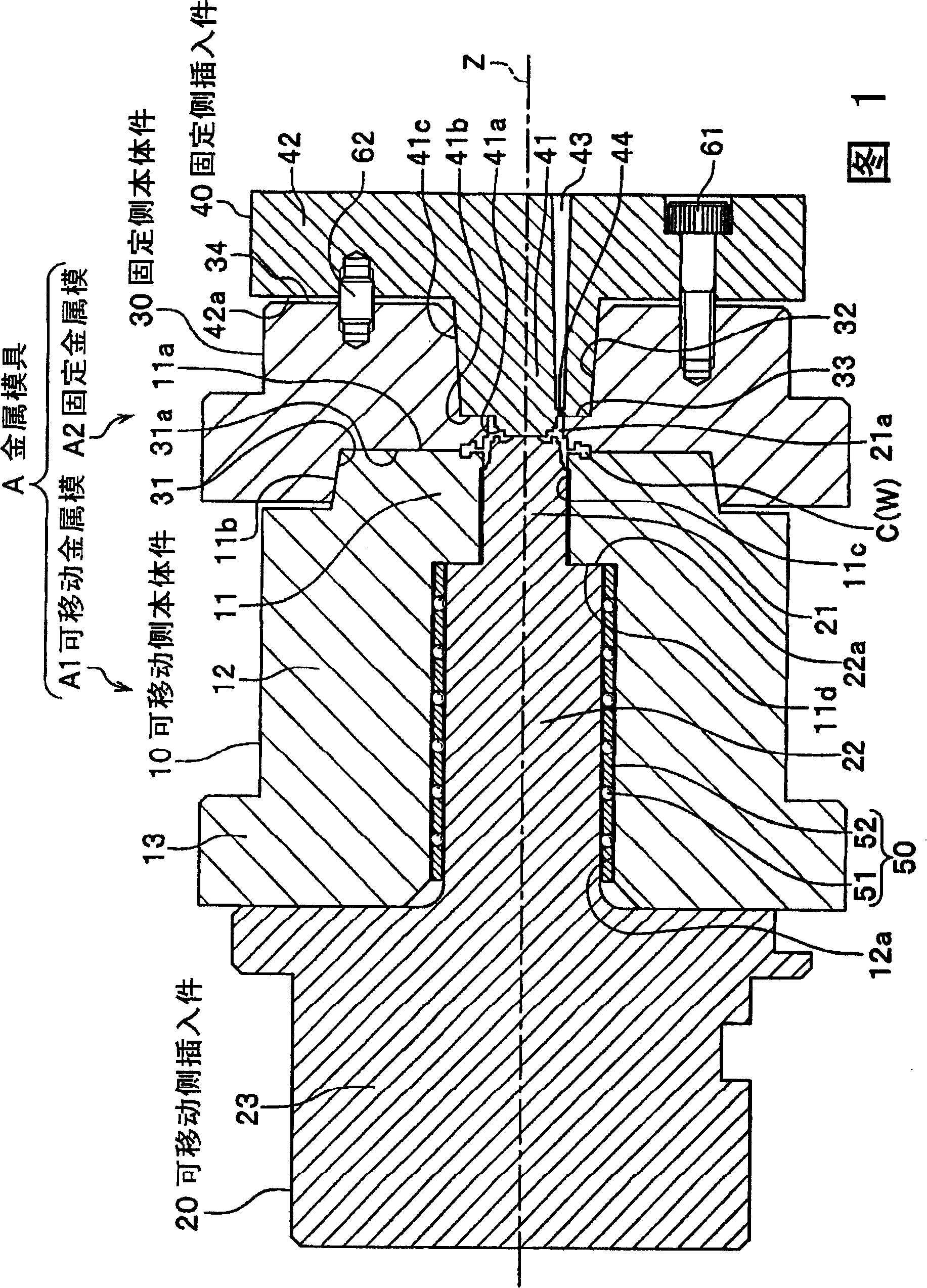

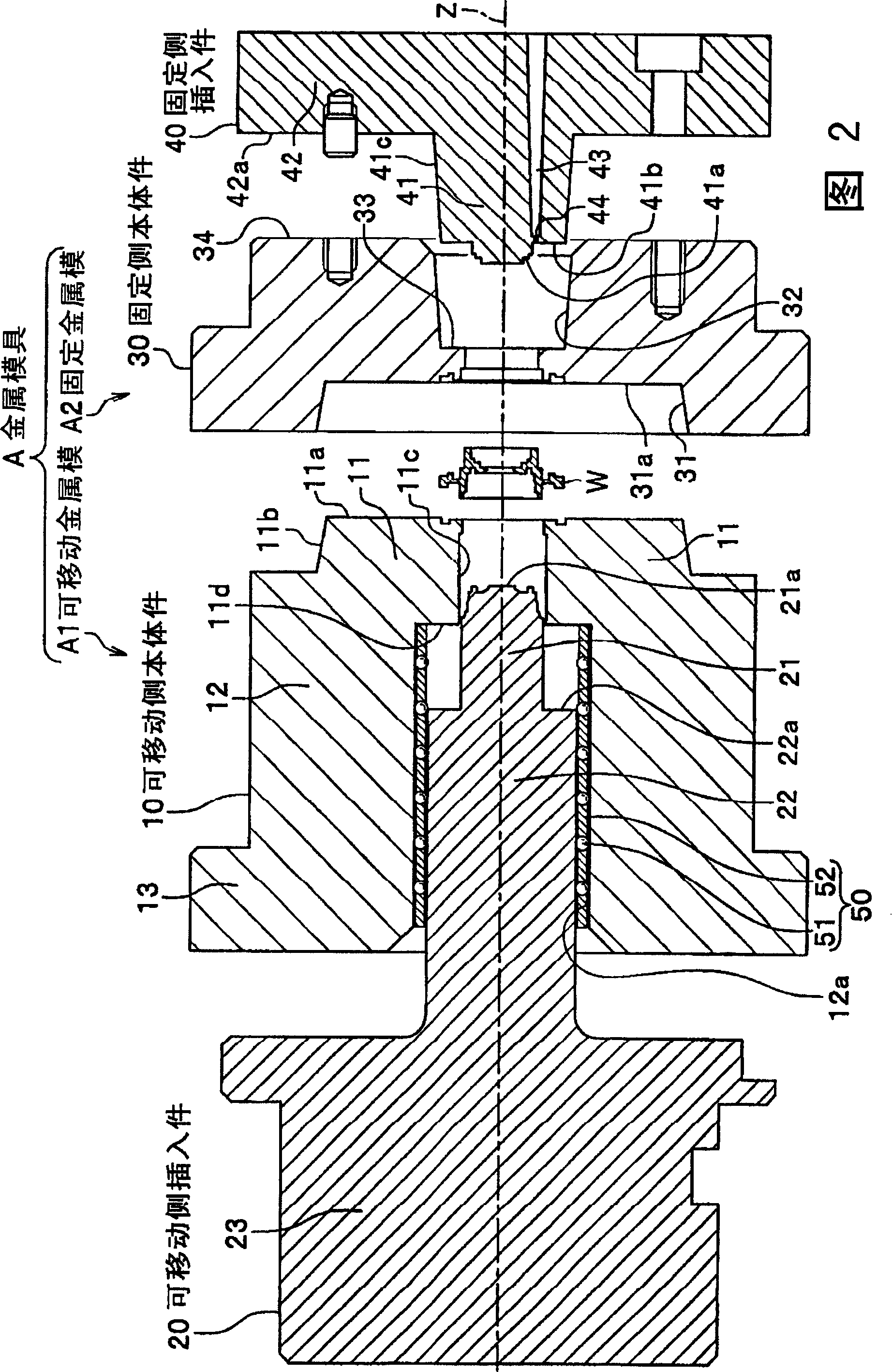

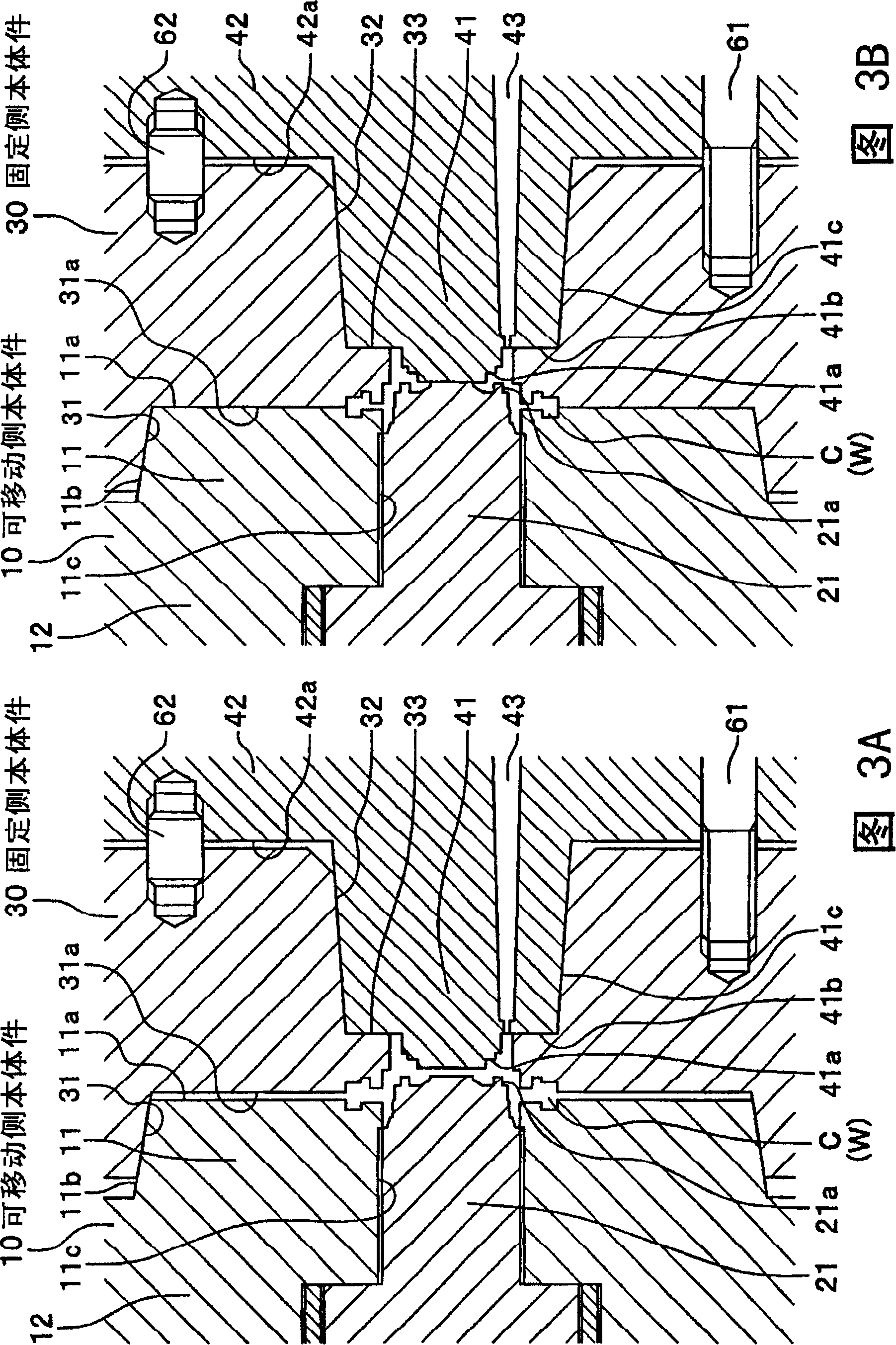

[0038] As shown in FIGS. 1 and 2 , a forming metal mold A according to the first embodiment includes a movable metal mold A1 as a first metal mold and a fixed metal mold A2 as a second metal mold. The molding metal mold A is a mold used for injection molding such as but not limited to a tubular molded article W. The molding metal mold A of the present invention can be particularly preferably used to manufacture molded articles requiring high shape accuracy, such as optical lenses and optical parts such as mirror frames for supporting optical lenses, and in this case, the movable metal mold The mutual positional relationship between A1 and fixed metal mold A2 is particularly important.

[0039] The movable metal mold A1 includes a movable side body member 10 as a first body member and a movable side insert 20 as a first insert. The fixed metal mold A2 inclu...

no. 2 example

[0064] Below, see Figure 4 A second embodiment of the present invention is described as a modified example of the first embodiment. Figure 4 is a sectional view of a forming metal mold according to the second embodiment. The same parts as those of the first embodiment are denoted by the same reference numerals, and their descriptions are omitted.

[0065] Such as Figure 4 As shown, the forming metal mold B according to the second embodiment includes a movable metal mold B1 and a fixed metal mold B2.

[0066] The movable metal mold B1 includes a movable side body part 10' and a movable side insert part 70. In the molding metal mold A of the first embodiment, the movable-side body member 10 and the movable-side insert 20 are relatively positioned by means of linear bearings 50 to be slidably (movable) assembled with each other. In contrast, in the moving metal mold B1, the relative positioning between the movable side body member 10' and the movable side insert 70 is achieve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com