Roof ventilating fan

A technology for exhaust fans and shutters, which is applied to components of pumping devices for elastic fluids, non-variable-capacity pumps, pump devices, etc., can solve the problems of small opening angle and inability to obtain large exhaust volume, etc. To achieve the effect of increasing the exhaust air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] Hereinafter, examples of the present invention will be described.

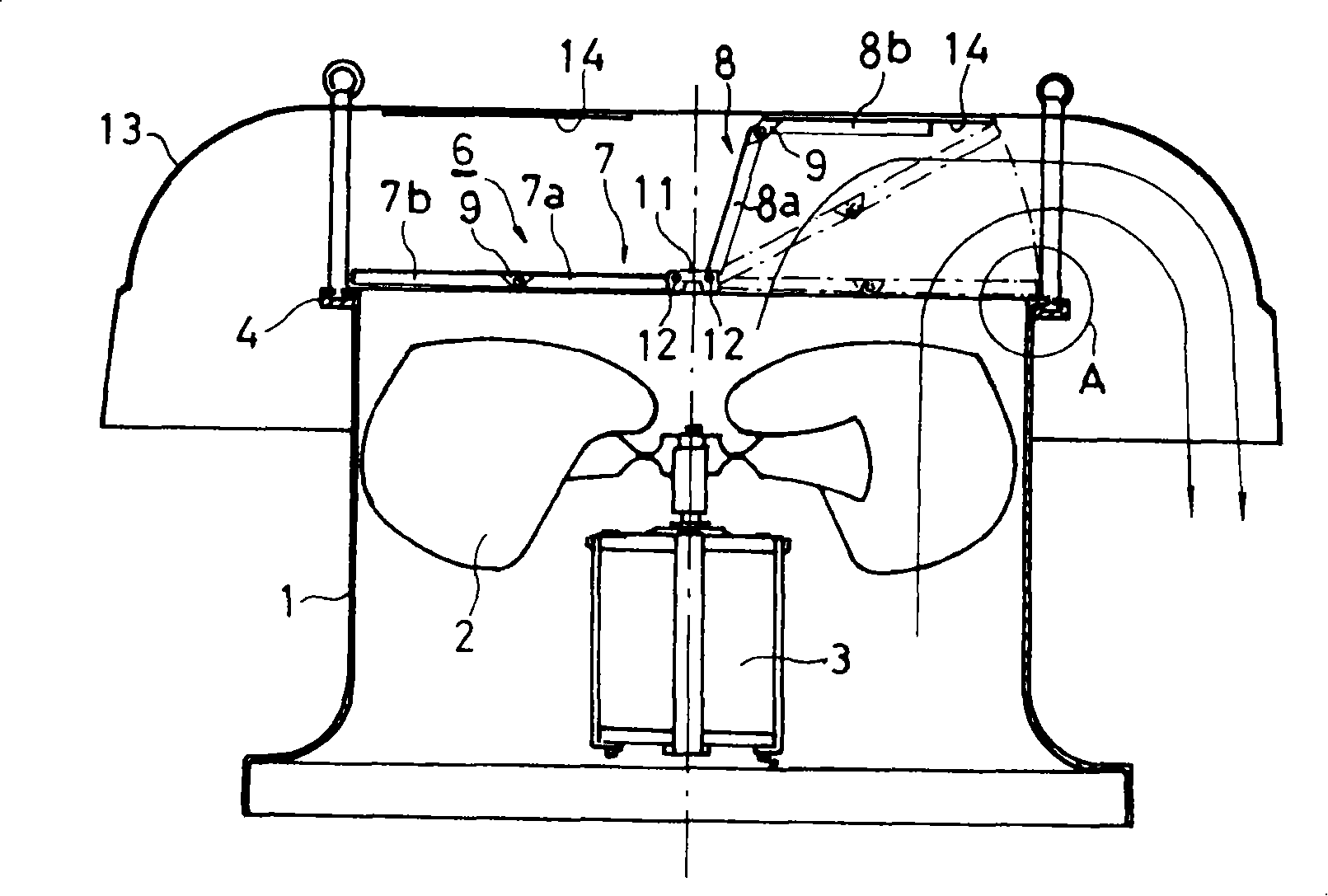

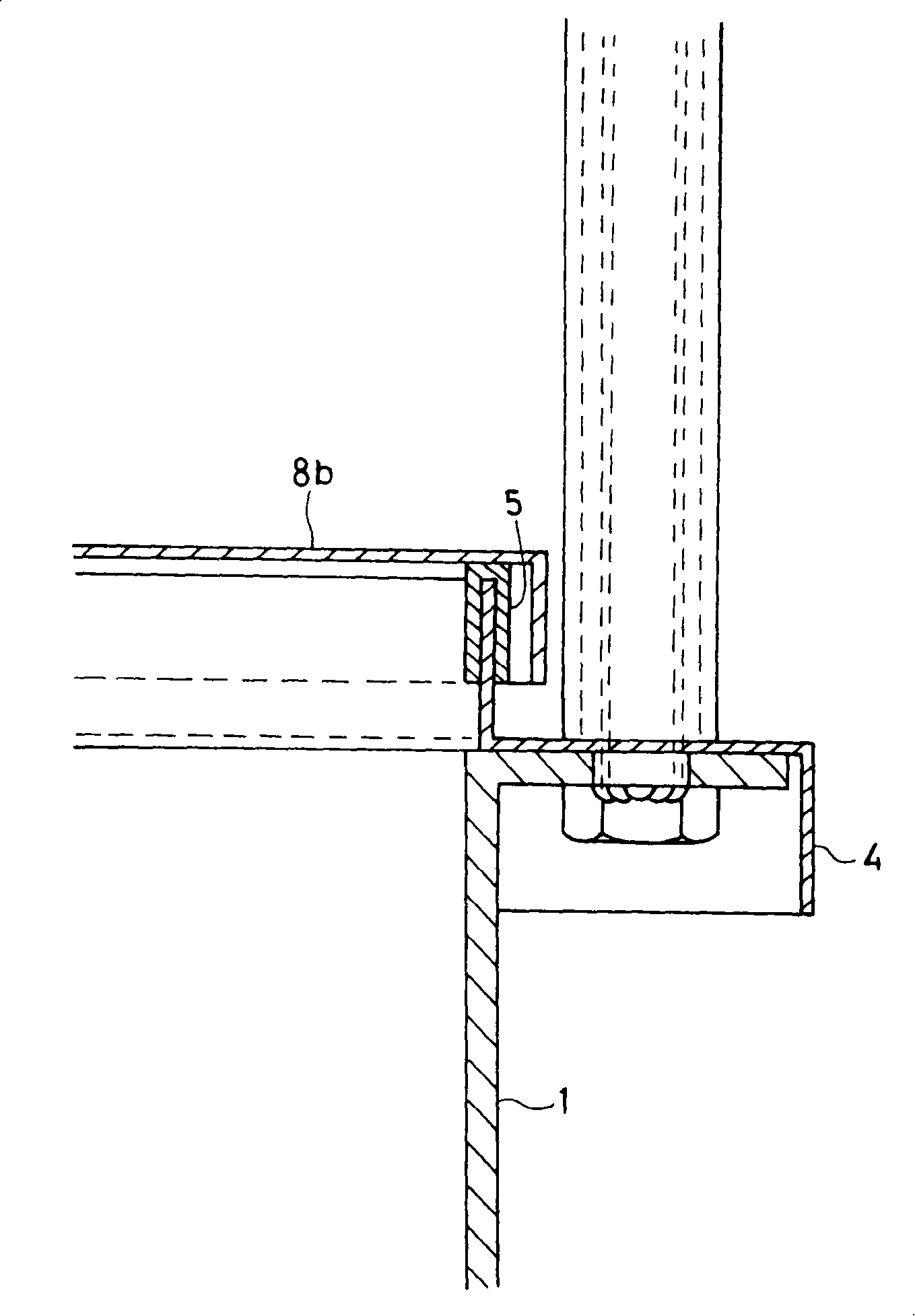

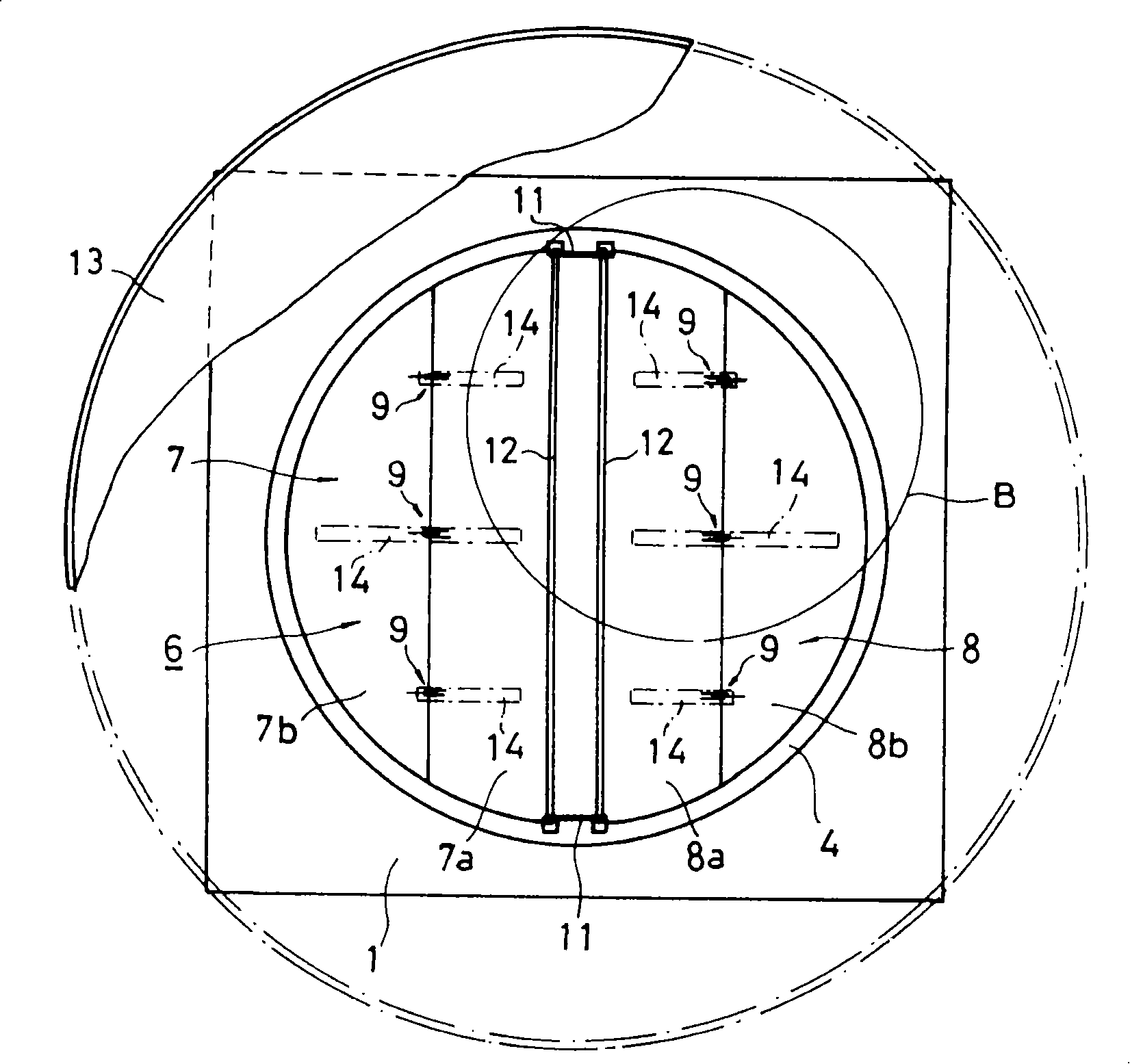

[0020] figure 1 It is the front view of the middle longitudinal section of the embodiment of the present invention, figure 2 yes figure 1 Enlarged view of part A in, image 3 It is a partially cutaway top view showing an embodiment of the present invention, Figure 4 yes image 3 Enlarged view of part B in, Figure 5 is an enlarged view of the pivoting part of the base of the plate shutter, Figure 6 It is a top view of hinges and springs for flexion and extension of plate shutters, Figure 7 It is an explanatory diagram of the opening and closing operation of the plate-shaped shutter.

[0021] Among the figure, 1 is the cylindrical main body that is opened up and down. 2 is the fan that is arranged in the inside of the above-mentioned main body 1 and rotates by the motor 3 .

[0022] Reference numeral 4 denotes a louver mounting frame fixed to the upper opening of the main body 1 . In additi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com