Materials overturning and bidirectional pushing equipment

A material and equipment technology, applied in the field of material conveying equipment, can solve problems such as difficulty, waste of time and power, and achieve the effect of shortening the operation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

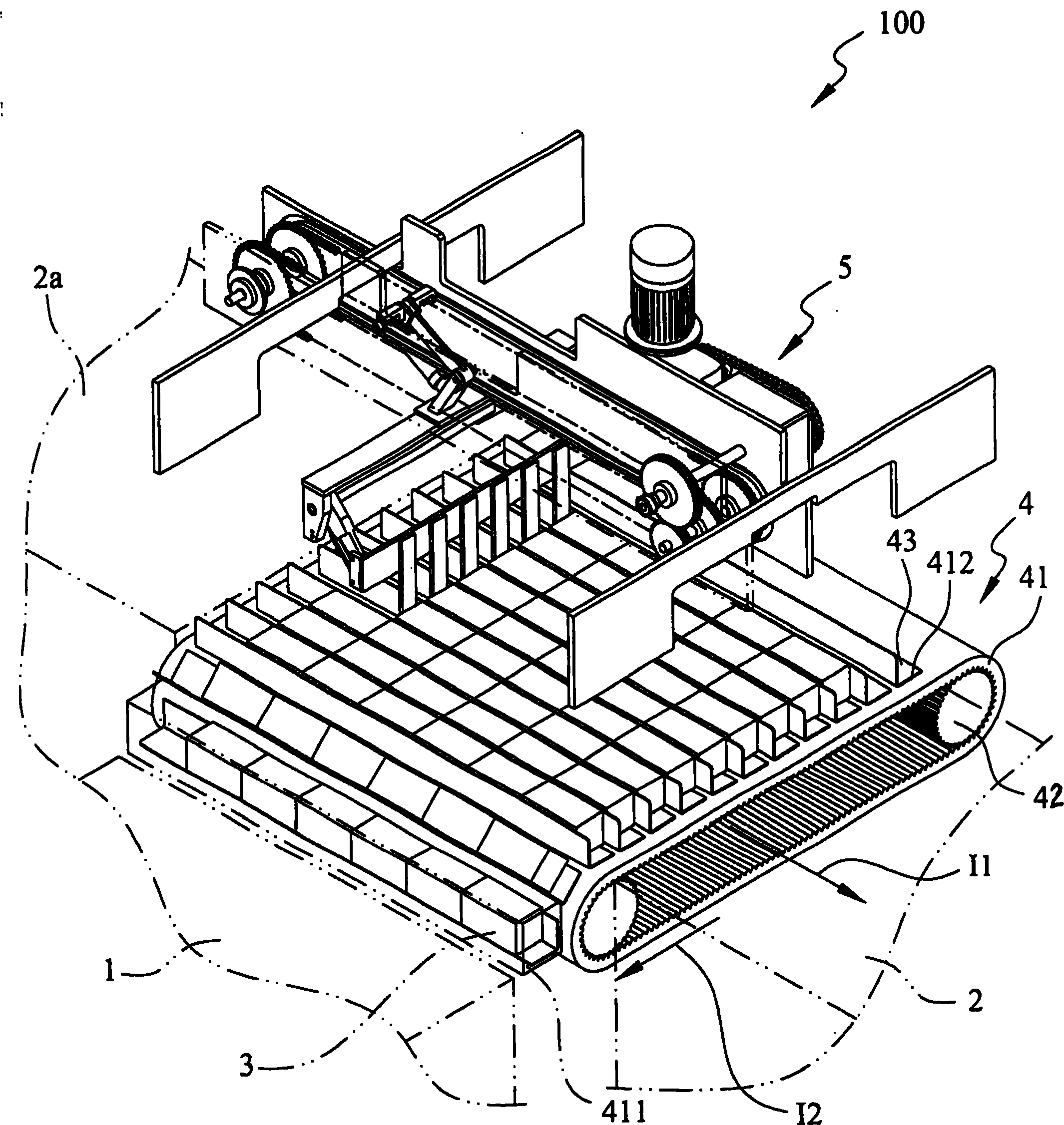

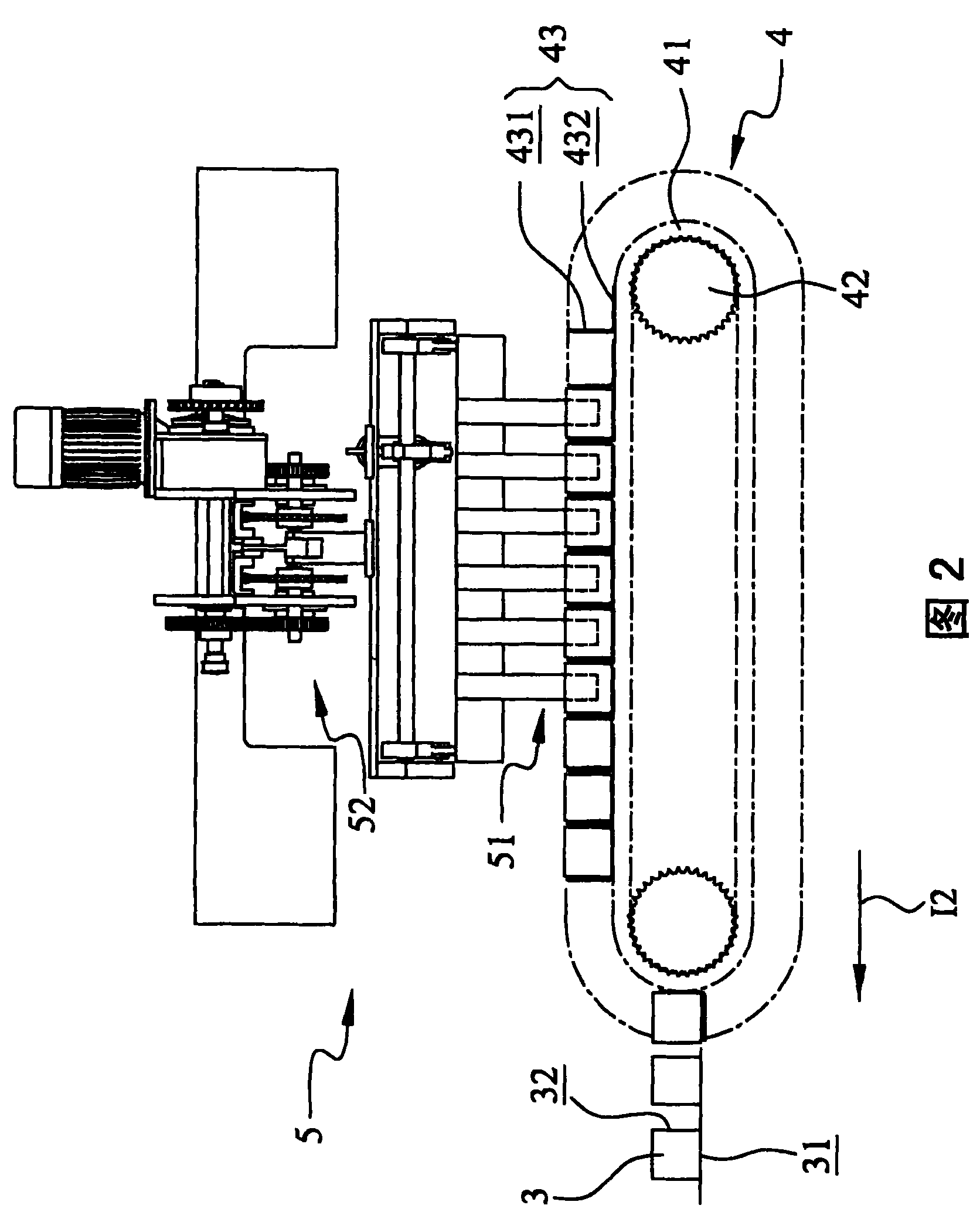

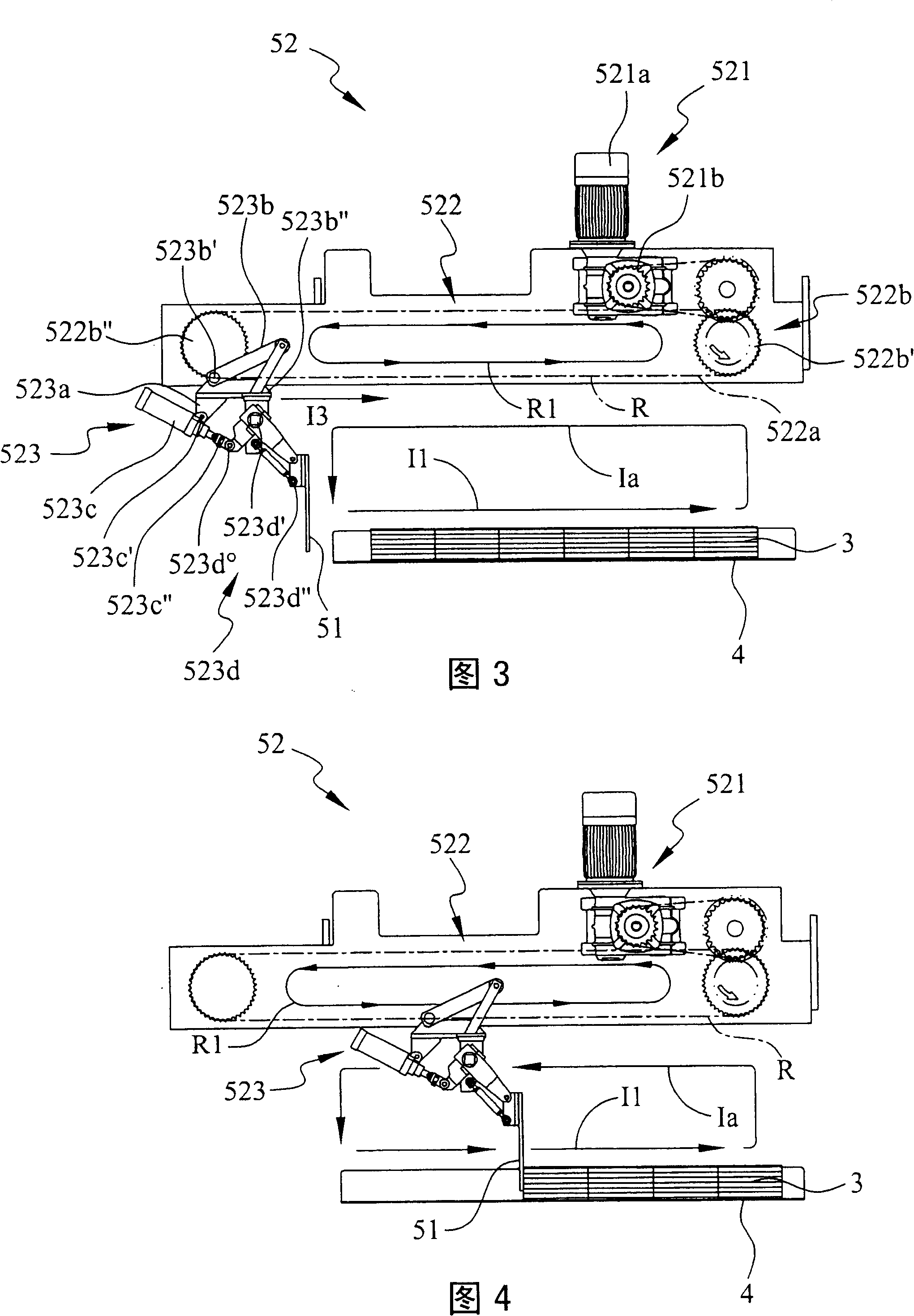

[0047] see figure 1 , which is a schematic perspective view showing a preferred embodiment of the present invention. As shown in the figure, a material turning and two-way pushing device 100 is adjacent to a material input area 1 and two material input areas 2 and 2a, so as to first turn over a plurality of materials 3 entering from the material input area 1, and then Push to the material output areas 2 and 2a along at least one output direction I1. Wherein, the material turning and two-way pushing equipment 100 includes a turning conveying device 4 and a pushing device 5 .

[0048] The overturning conveying device 4 includes a transmission component 41 , a driving component 42 and a plurality of separate loading mechanisms 43 . Wherein, the transmission component 41 is installed in the adjacent position of the material input area 1 and the material output area 2, the driving component 42 is connected to the transmission component 41, and drives the transmission component 41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com