Frame used for corrugating machine roller train

A technology of roller group and corrugating machine, applied in the direction of machining/deformation, etc., can solve the problems of time-consuming, increased operation time, heavy roller group, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to fully understand the purpose, features and effects of the present invention, now through the following specific embodiments, and in conjunction with the accompanying drawings, the present invention is described in detail, as follows:

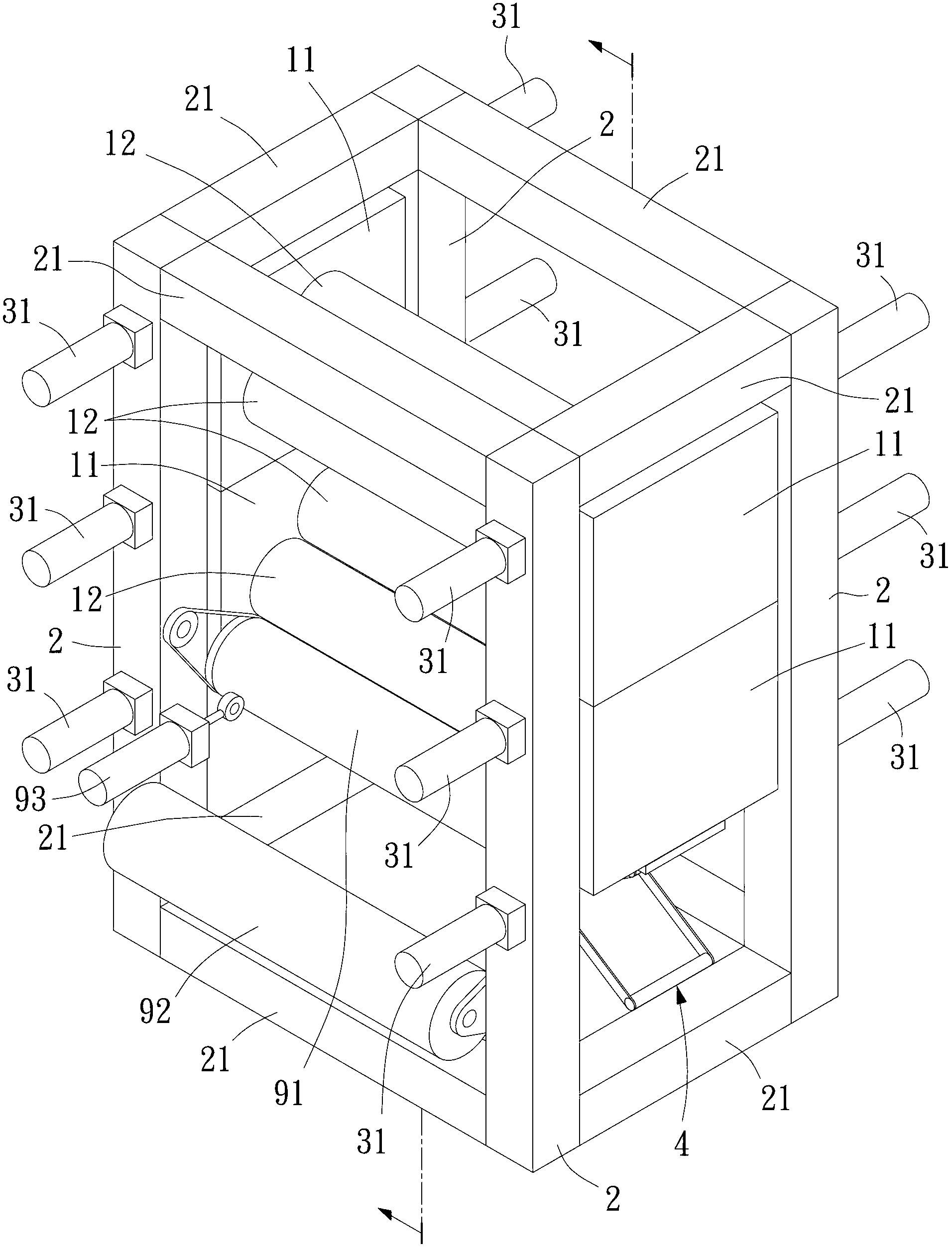

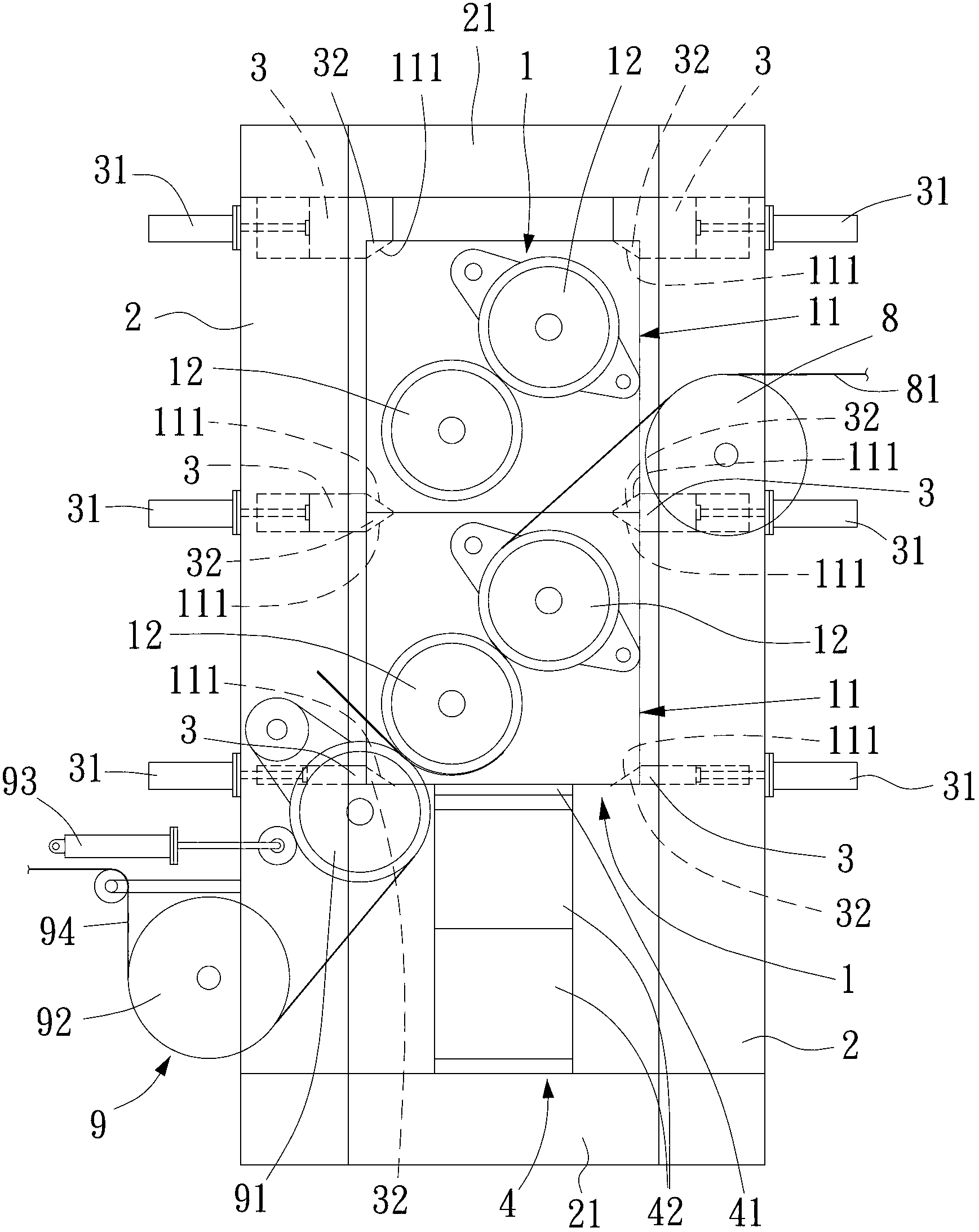

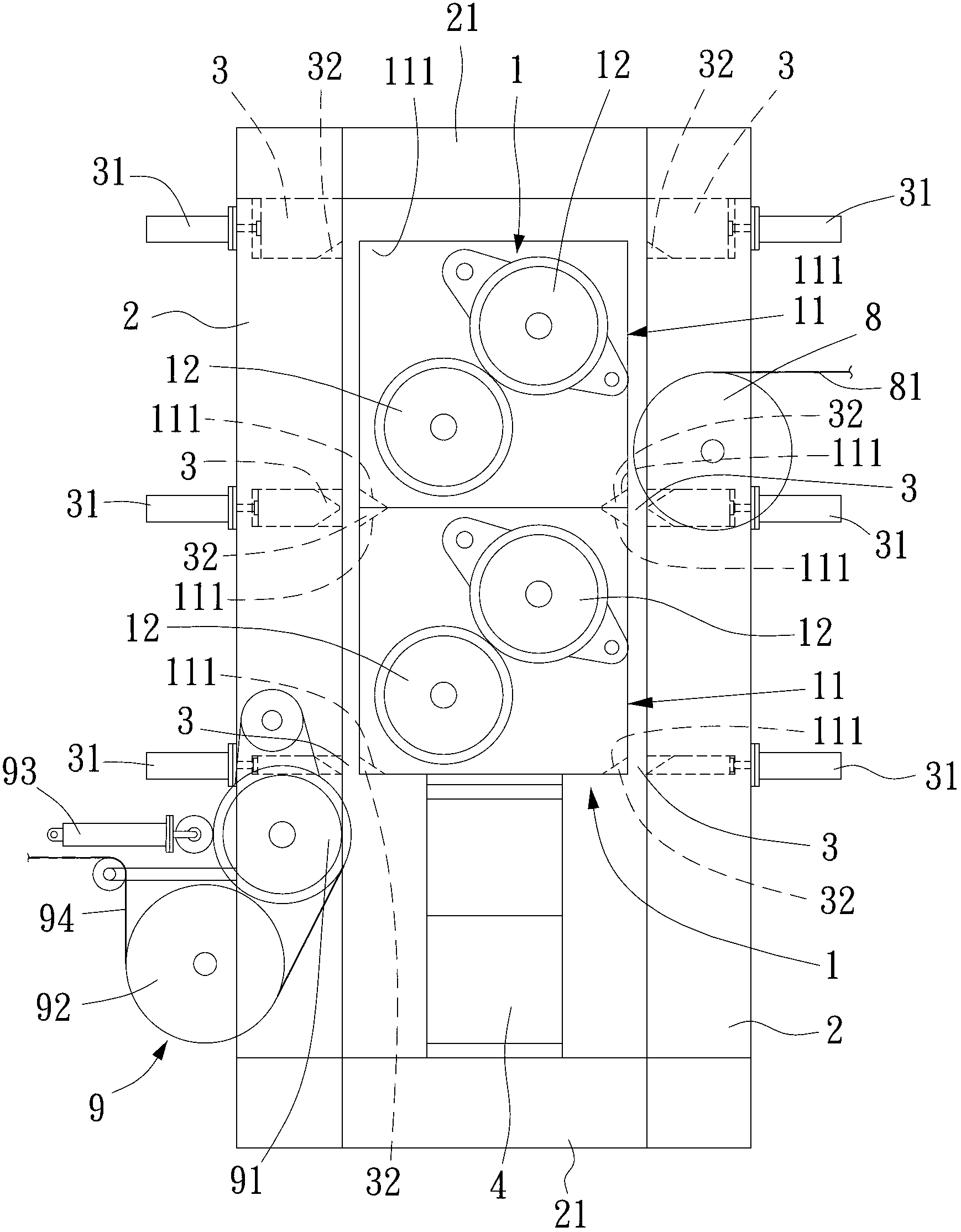

[0049] figure 1 and figure 2 They are schematic diagrams of specific embodiments of the present invention and schematic diagrams of applications Figure 1 , which shows the frame body used for the corrugating machine roller set according to the present invention, the frame body is left-right symmetrical, figure 2 yes figure 1 The cross-sectional view of the middle position of the frame body, which shows the left side of the frame body from the middle of the frame body, which mainly shows the left side of the frame body. The frame body used for the corrugating machine roller set of the present invention is used to fix and release at least One group of roller sets 1, two groups of roller sets 1 are shown in the figure, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com