Method and device for processing particulates material bed layer

A particulate material, air flow technology, applied in the field of cooling an air-supported particulate material bed, can solve problems such as the inability to obtain heat exchange benefits, the unsatisfactory operation of the clinker bed, and the reduction of flow characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

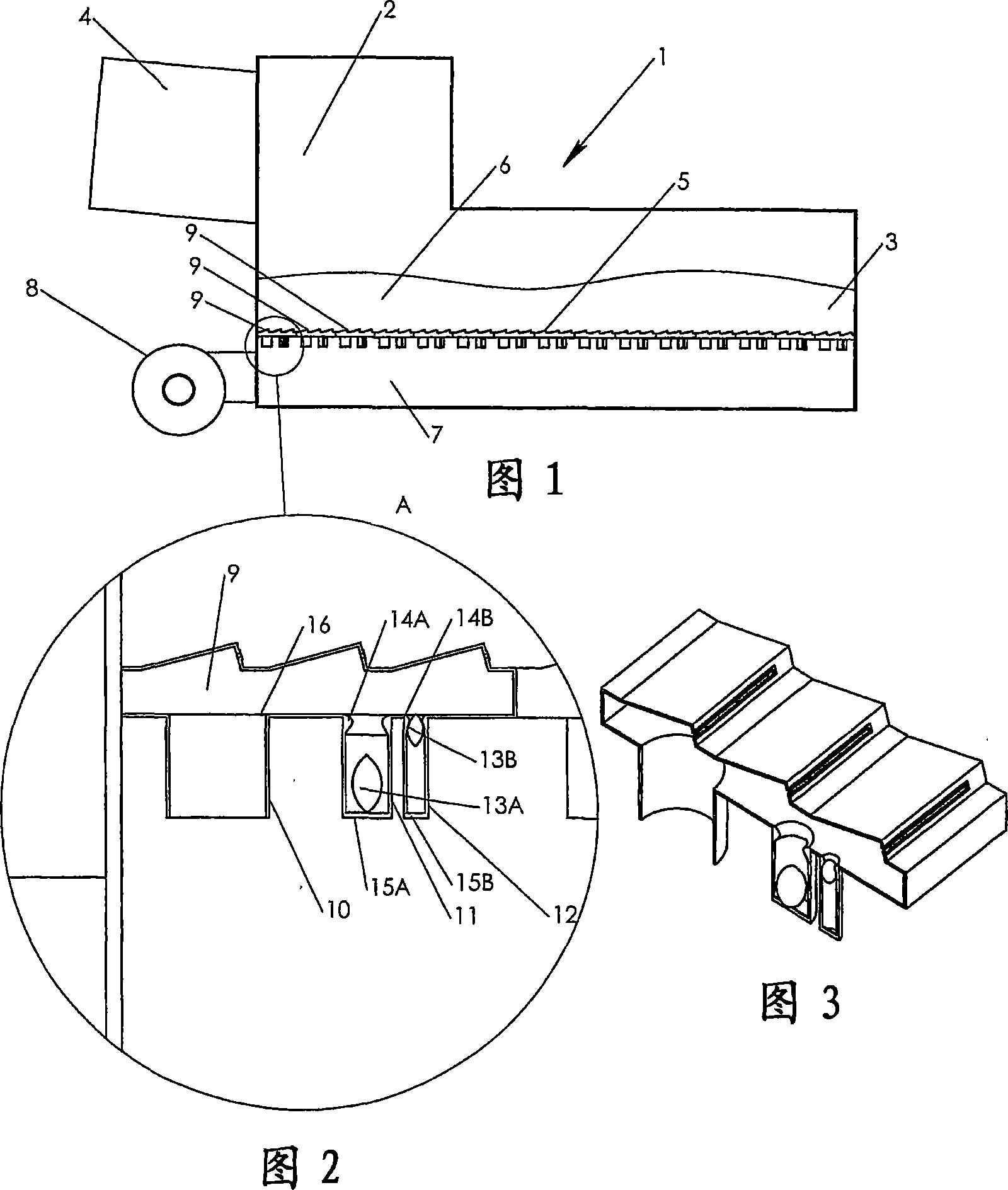

[0039] FIG. 1 shows a cooler 1 comprising an inlet port 2 and an outlet port 3 . The cooler is connected to the rotary kiln 4 and receives the hot material to be cooled from the rotary kiln 4 . The material from the rotary kiln falls onto a distribution floor 5 provided in the cooler 1 and is conveyed as a layer 6 of material on the distribution floor 5 from the inlet end 2 of the cooler 1 to the outlet by a conveying device (not shown) End 3. The transport device may be, but not limited to, a reciprocating grate, a reciprocating grate or a walking floor principle. Below the distribution floor 5, the cooler 1 comprises one or more compartments 7, each compartment being supplied with cooling air from a blower device. The compartment 7 may be divided into a number of small compartments (not shown) in the longitudinal and transverse directions of the cooler, in which case each individual compartment is supplied with cooling air. The distribution base 5 is divided into a number...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com