Rotary encoding switch

A rotary coding switch, switch-level technology, applied in the direction of code conversion, analog-to-digital converter, analog-to-digital conversion, etc., can solve the problems of limited accuracy, complex set value and cost, and achieve high-resolution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

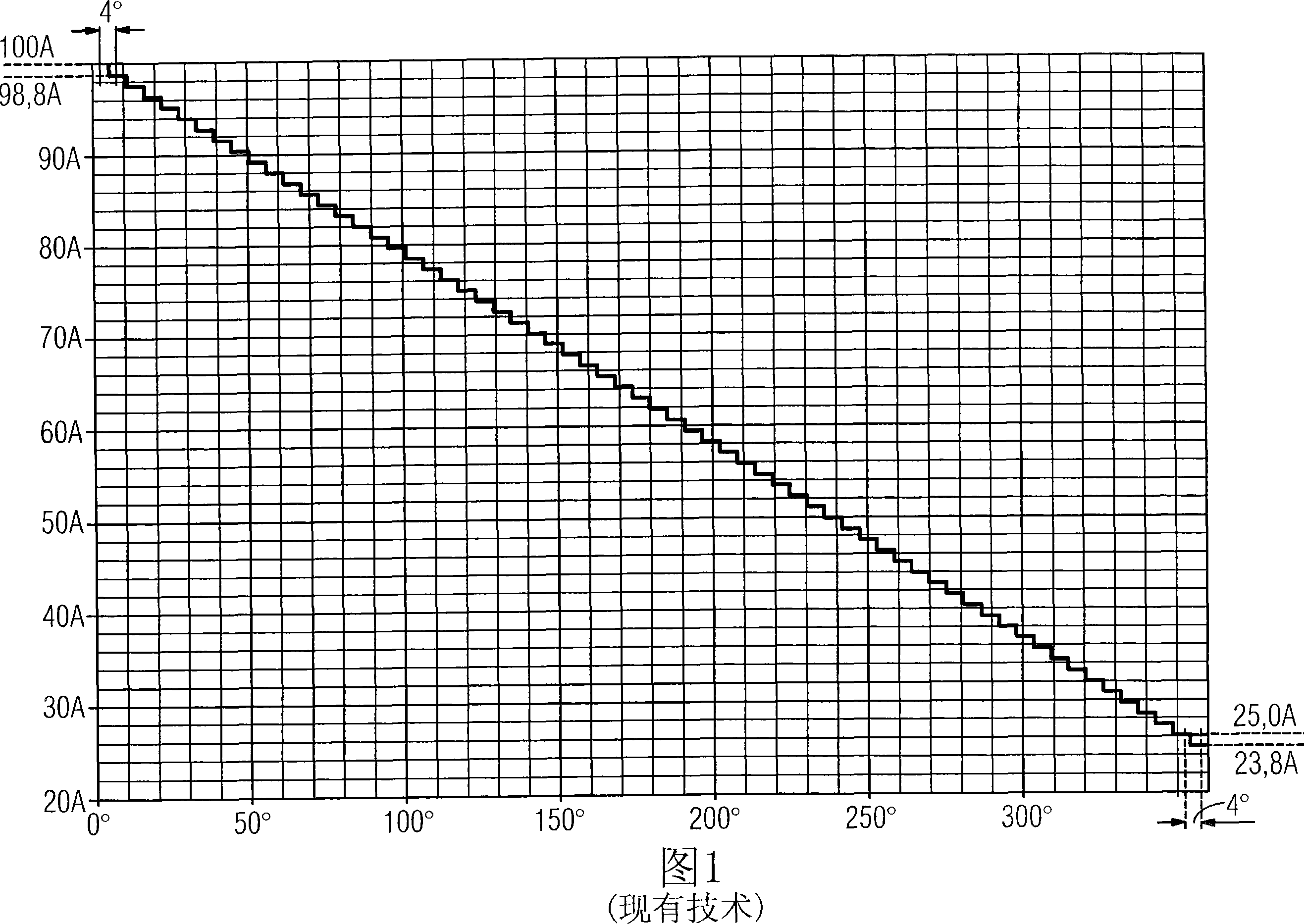

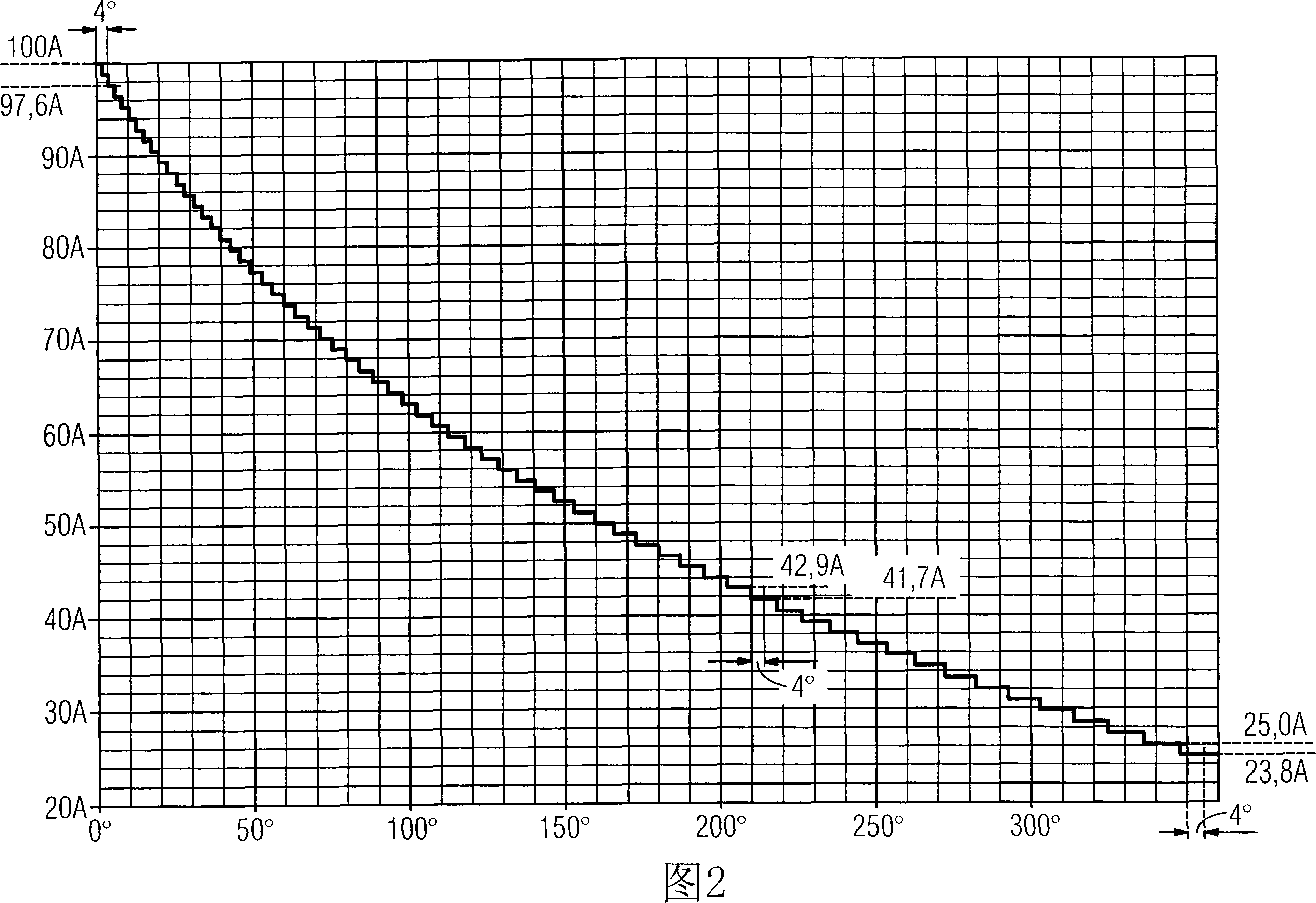

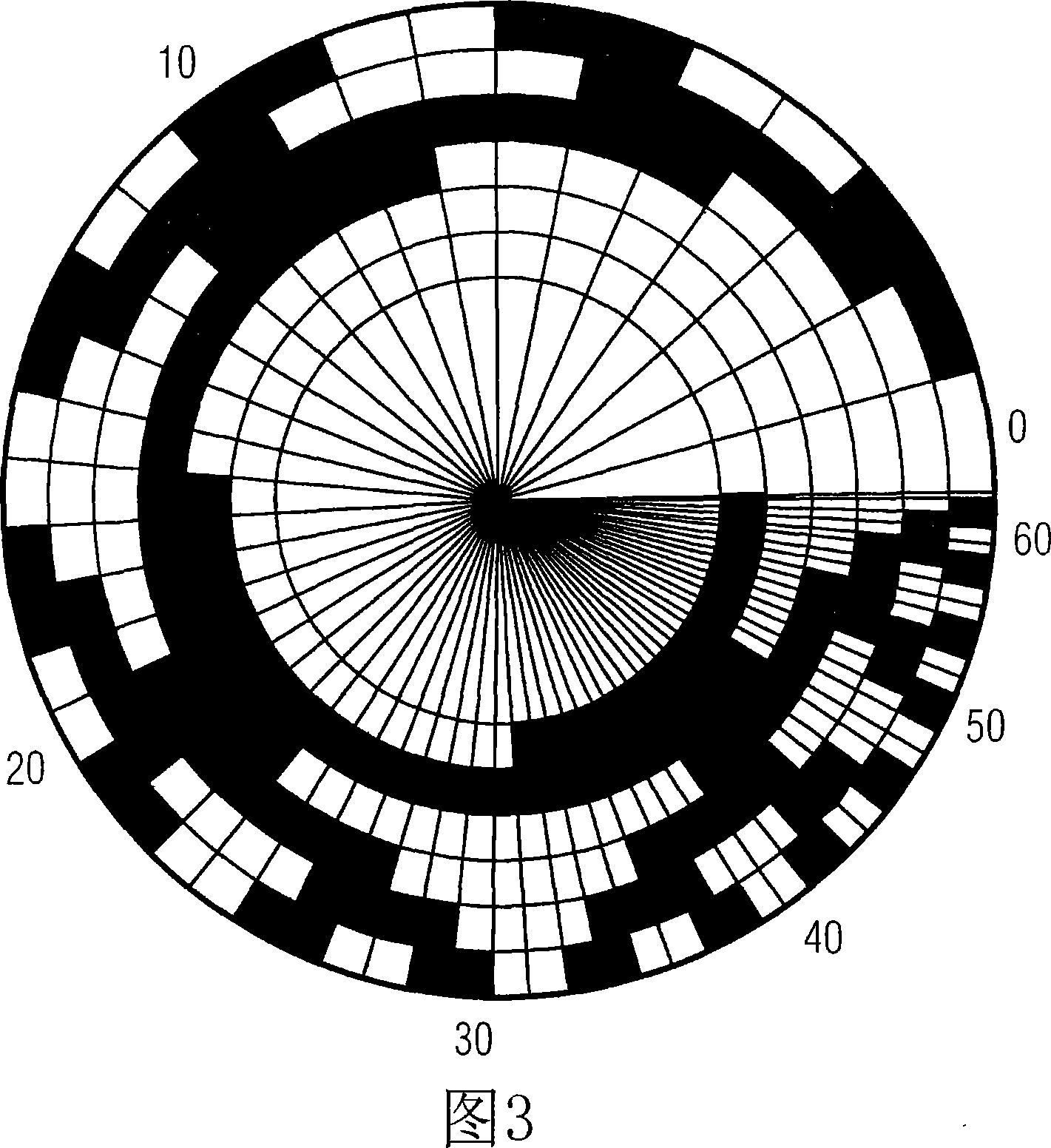

[0018] The difference between n-stage (for example n=16) rotary encoding switches disclosed in the prior art is that the distance between each switch stage is constant. The example shown in FIG. 1 employs such conventional rotary-encoded switches, where 64 switching stages have been used here for better comparison with the solution of the invention. A rotary-encoded switch comprising 64 switching stages has not been disclosed so far.

[0019] In a 64-stage rotary-encoded switch including a circular code disc, the constant spacing between each switching stage is approximately 5.63°. If this rotary encoding switch is used as a current setting element in an overload relay, a dial with current markings and a setting arrow are required. The installation of dials and setting arrows on rotary coding switches is always subject to manufacturing tolerances. Experience shows that manufacturing tolerances lie within a range of not more than + / - 4°.

[0020] In this example (see Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com