Structure for reinforcing rigidity of vehicle body

A rigid, car body technology, applied in the superstructure, superstructure sub-assemblies, vehicle components, etc., to solve problems such as encountering difficulties and difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

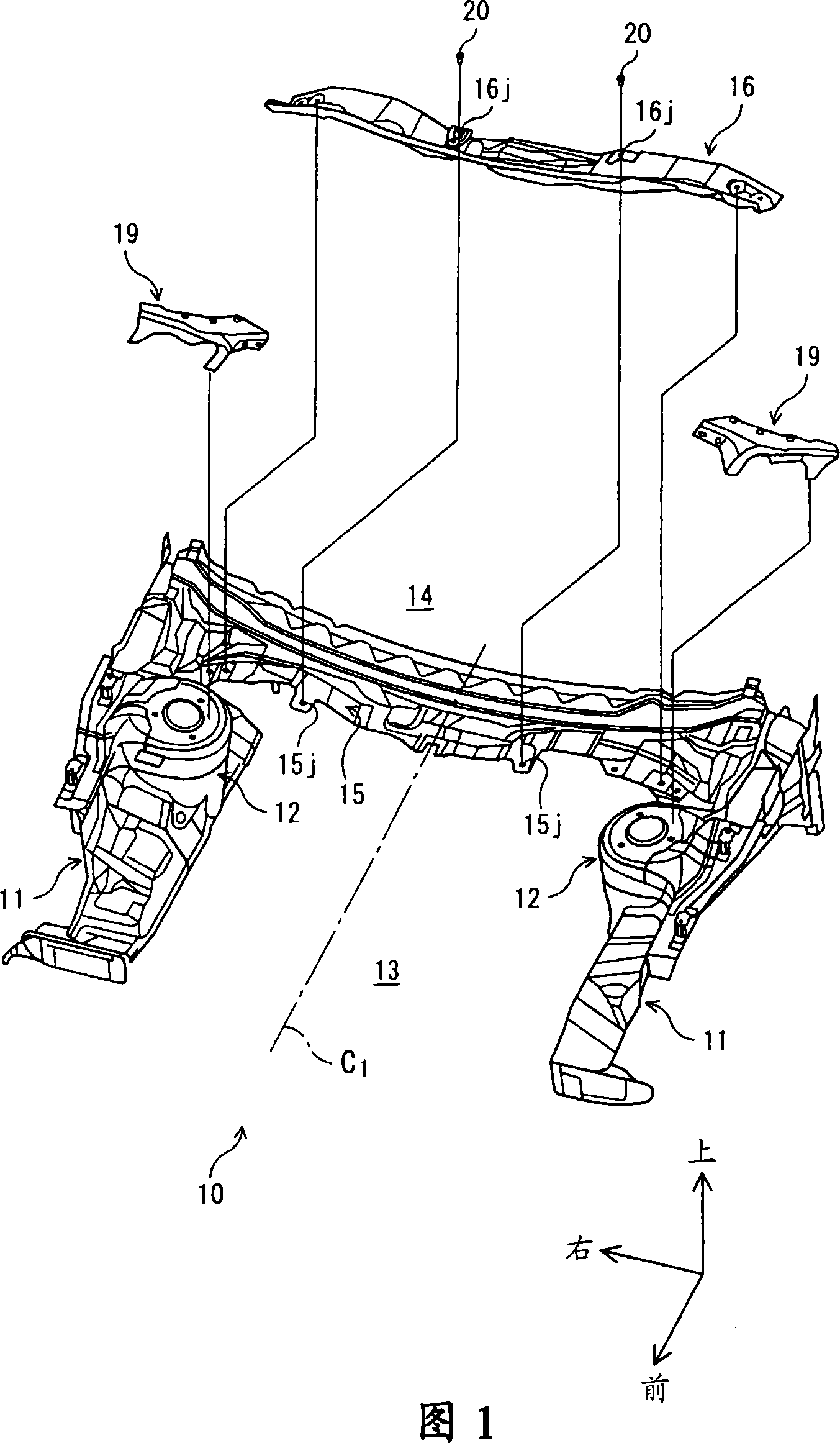

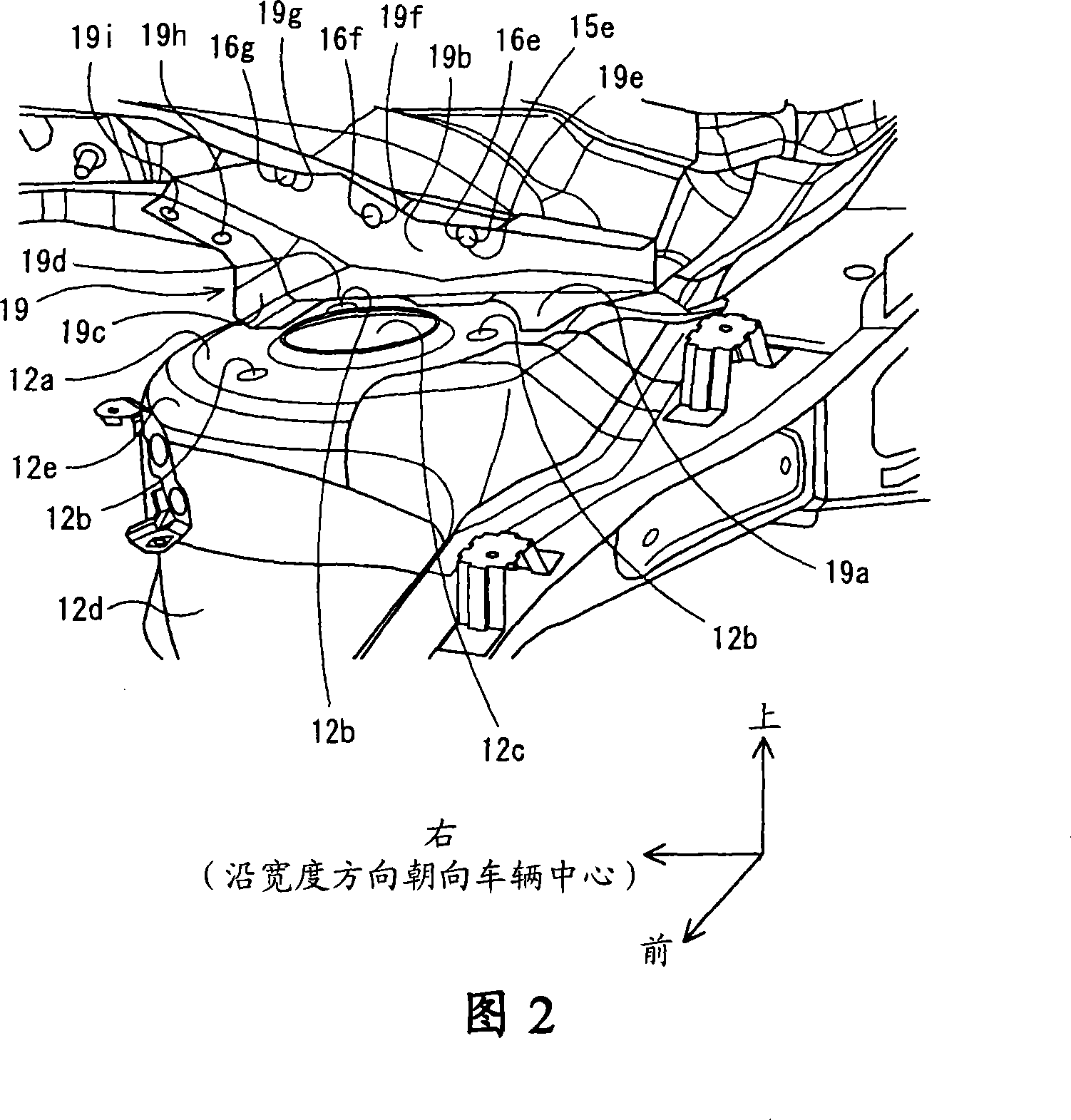

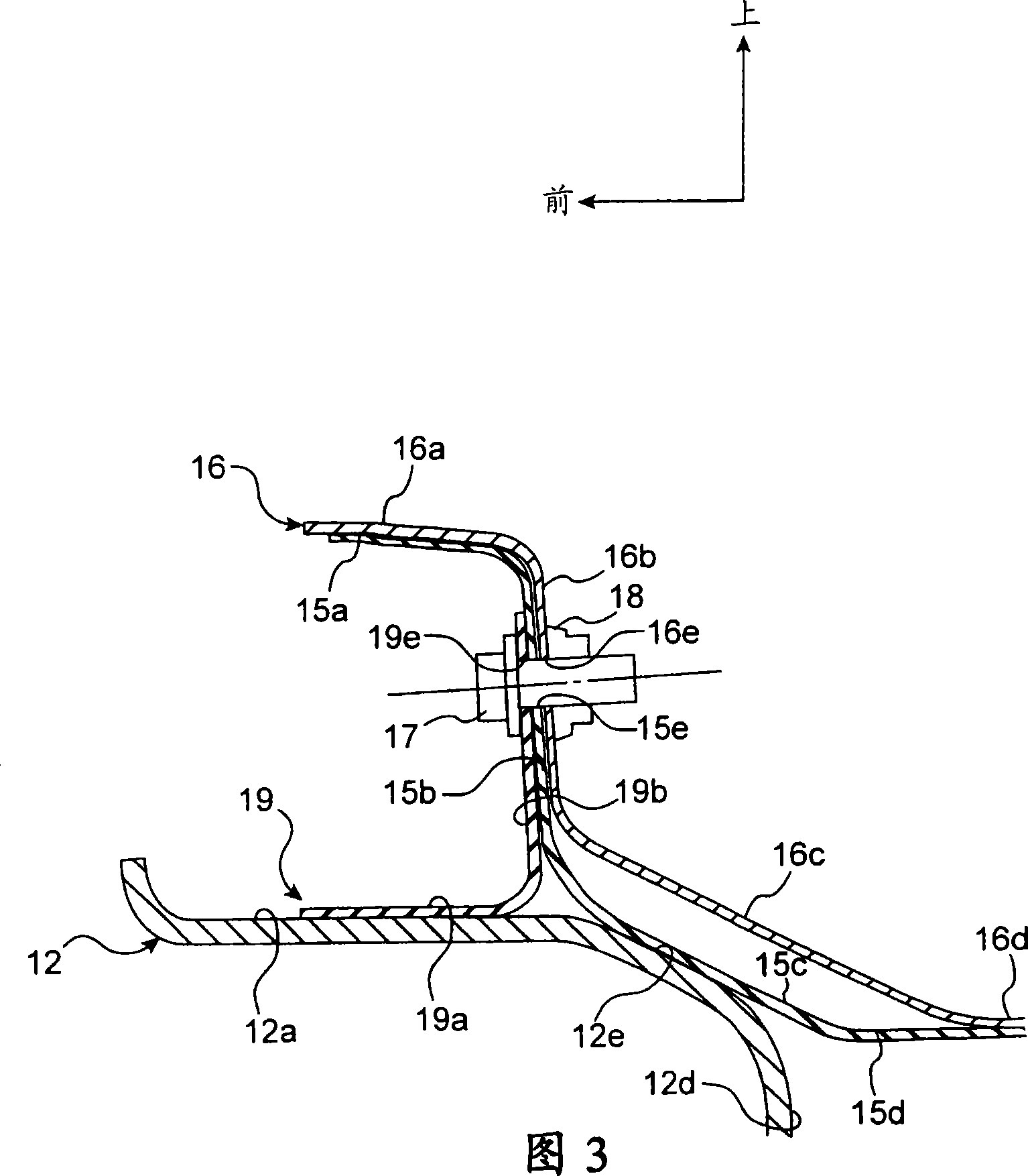

[0026] A structure for enhancing rigidity of a vehicle body of an embodiment of the present invention will be described below with reference to the accompanying drawings. 1 is a schematic perspective view showing a vehicle body constituting a front part of a vehicle; FIG. 2 is a schematic perspective view showing a configuration in the vicinity of a spring cover; and FIG. 3 is a schematic cross section showing a configuration in the vicinity of the spring cover view.

[0027] As shown in FIG. 1, the front of the vehicle 10 is mounted with an upper frame 11 extending in the longitudinal direction of the vehicle body 10 such that one upper frame is provided on the left side and the other upper frame is provided on the right side, Thereby forming part of the vehicle body.

[0028] The upper frames 11 are respectively provided with spring covers 12 .

[0029] Each spring cover 12 is a member formed in a cylindrical shape. The spring cover accommodates and supports the upper por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com