Continuous sand flushing technique and continuous sand flushing device thereof

A technology of sand washing and process, which is applied in the direction of flushing wellbore, wellbore/well parts, earthwork drilling and production, etc. It can solve the problem of low-density nitrogen foam operation effect discounting, restricting the popularization and use of nitrogen foam sand washing technology, nitrogen foam Long fluid release time and other problems, to reduce the chance of downhole accidents, facilitate the promotion of use, save the effect of sand washing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

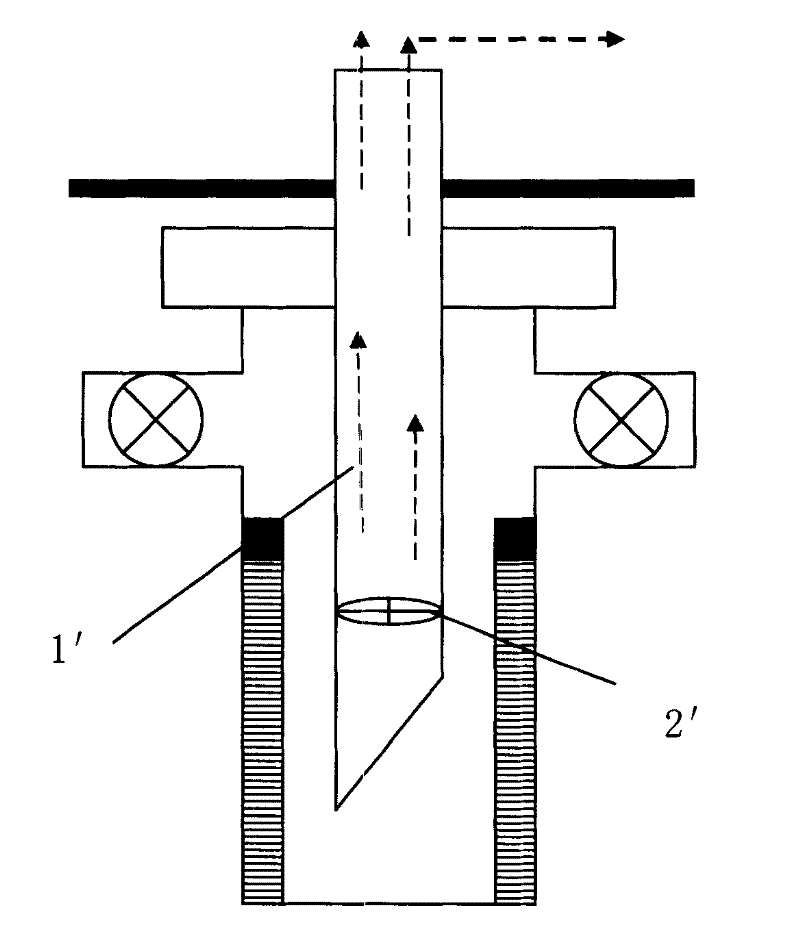

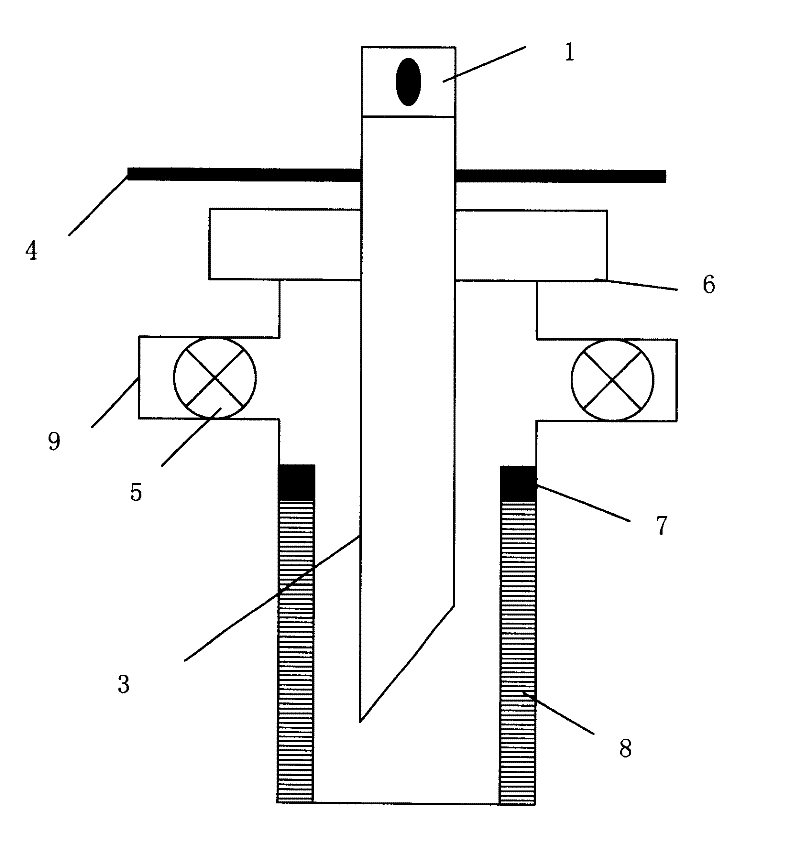

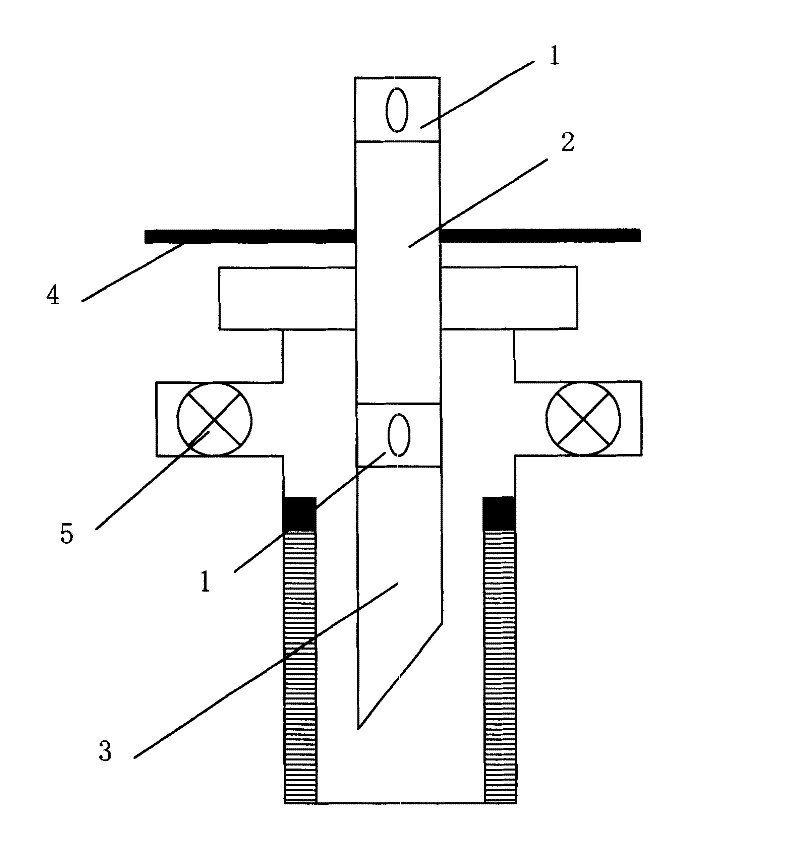

[0033] In order to further illustrate the operation procedure of the continuous sand washing process of the present invention, here we describe it in conjunction with the accompanying drawings and the actual sand washing operation on site.

[0034] On-site continuous sand washing operation is carried out according to the following steps:

[0035] Before the sand washing operation, it is recommended that the user estimate the length of the sand washing section according to the production oil well. Before sending it to the operation site, it is best to pre-set each control valve 1 with the opening function (in the open state) in the land workshop (processing factory) or the pipe station. state) is connected with the single sand washing pipe string 2 and the sand washing pipe string 3, and is in a standby state. The spare quantity is greater than the estimated length of sand flushing section. The control valve 1 used in this embodiment is as Figure 6 As indicated, the inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com