Method for determining the rotation speed of rotating shaft

A speed, rated technology used in the field of computer programming to solve problems such as inaccurate beats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

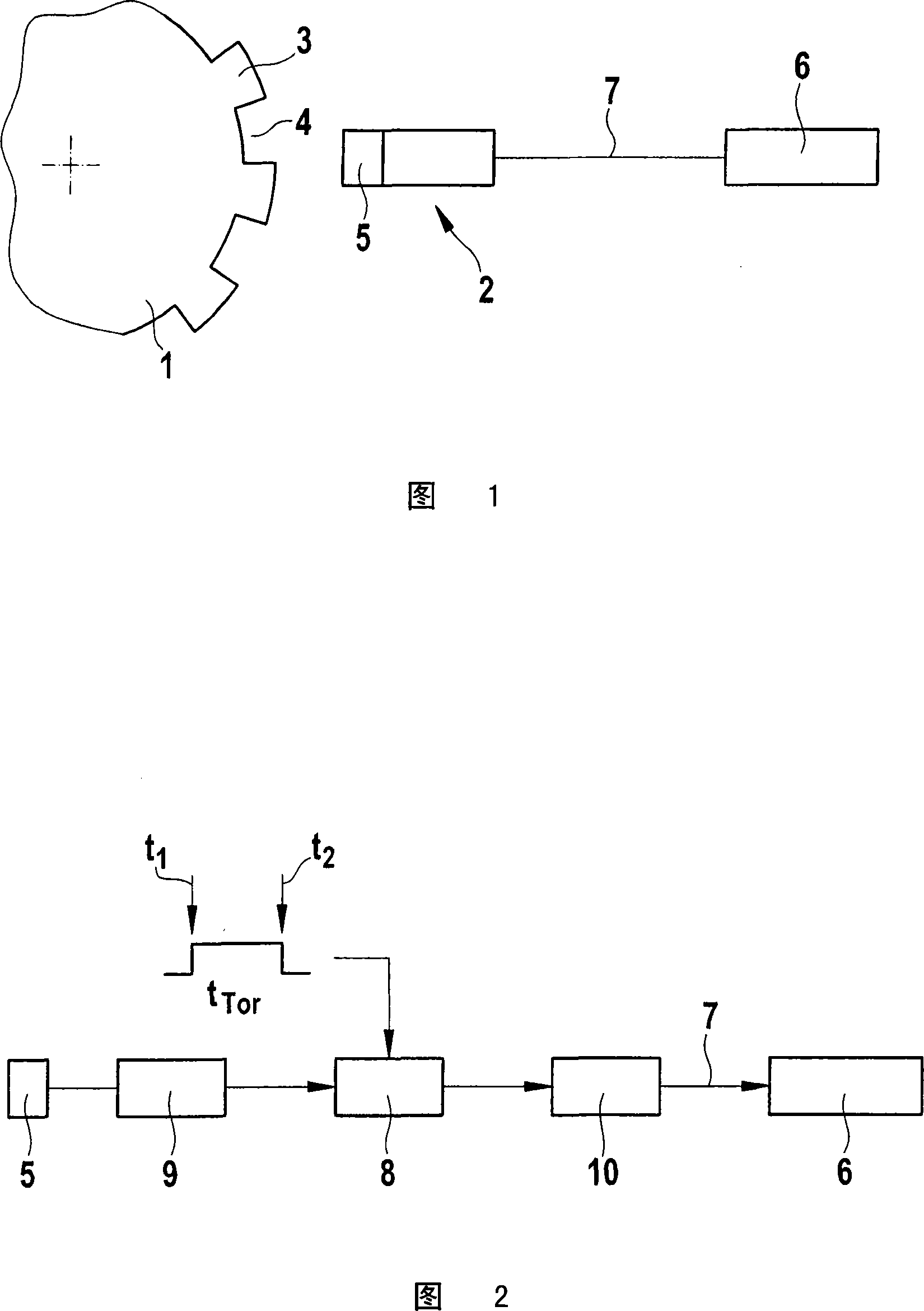

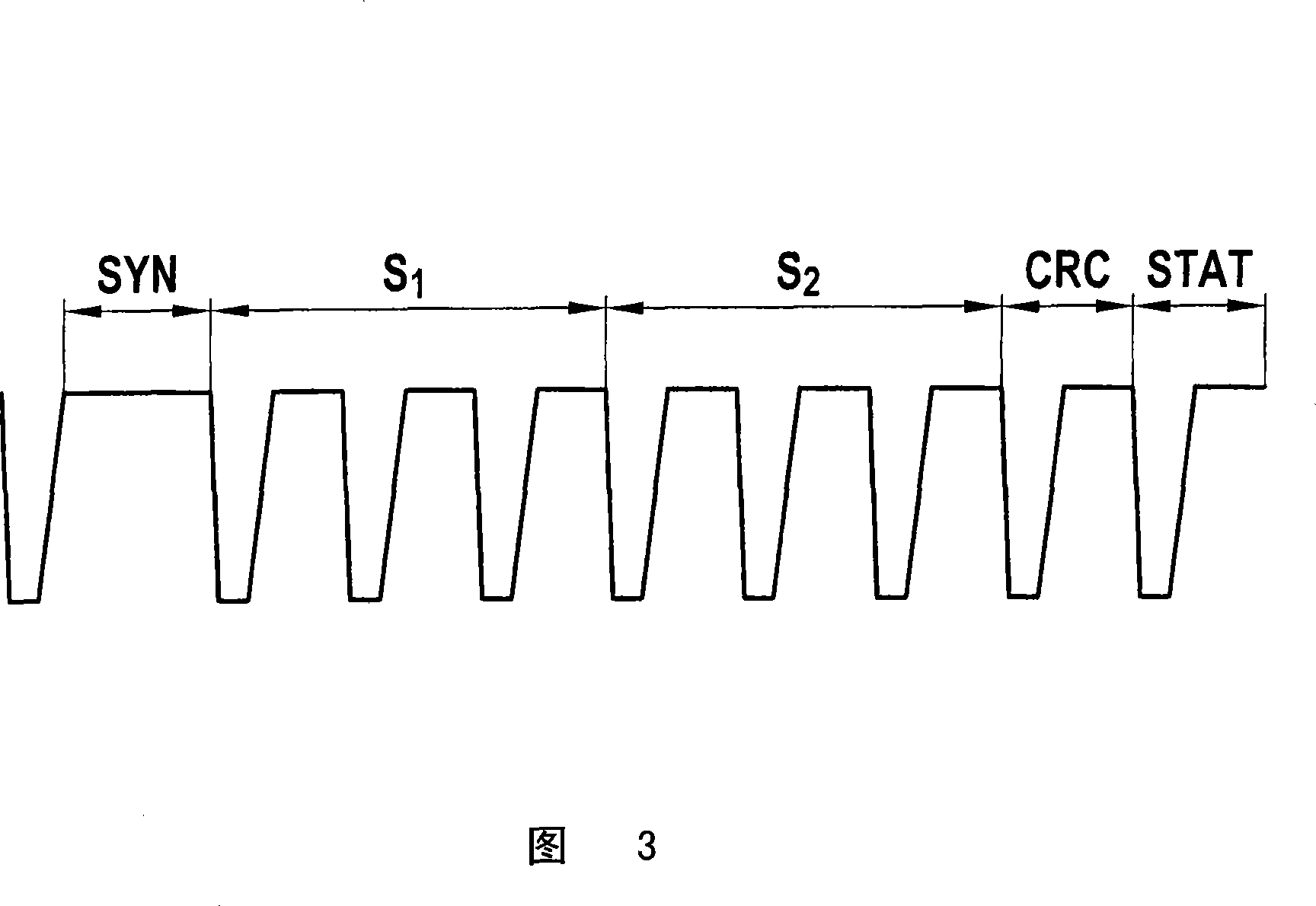

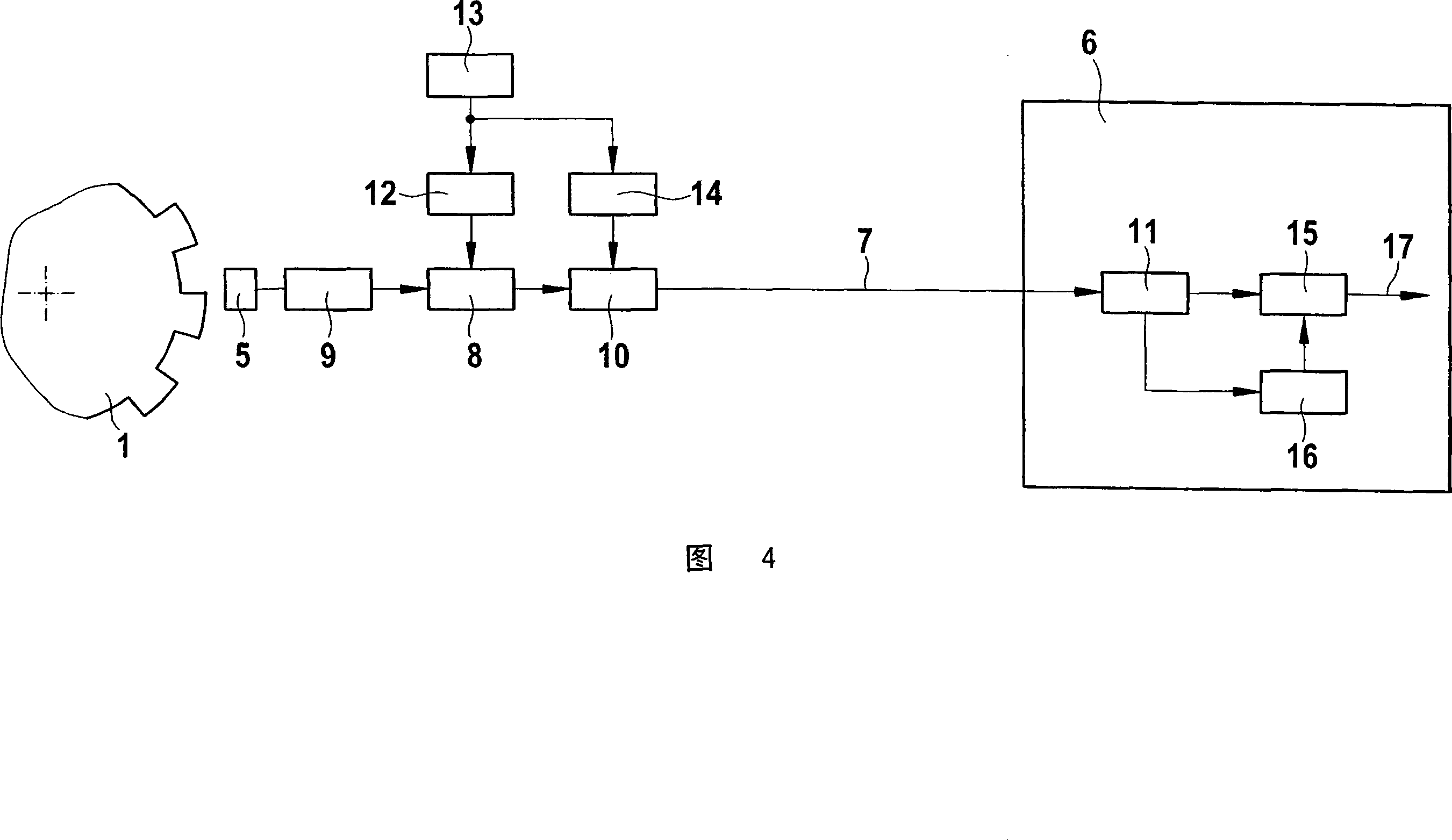

[0014] Figure 1 shows the arrangement of a sensor wheel 1 and a sensor 2. The sensor wheel 1 is connected to an unshown crankshaft of an internal combustion engine, so that the sensor wheel 1 and the crankshaft rotate together. The sensor shaft 1 includes marks, for example marks in the form of teeth 3 and tooth slots 4 arranged alternately. When these marks pass by the sensor 2, these marks cause an electrical signal of the sensing element 5. The sensing element 5 may be, for example, a Hall-sensor, an inductive sensor or the like. In this way, the electrical signal of the sensing element 5 is a rectangular voltage. This rectangular voltage corresponds to the sequential expansion of the teeth 3 and the cogging 4 of the sensor wheel 1. The tooth 3 and the tooth slot 4 produce two different states in the sensor 2. These states are transmitted to an electronic controller 6 at two levels of voltage (rectangular voltage) or current, for example, as a series of pulses. Data is transmit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com