Axial flow barrel for combined harvester

A combine harvester, axial flow technology, applied in the application, agricultural machinery and implements, threshing equipment, etc., can solve the problems of many rotation cycles, easy to cause blockage, long residence time and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

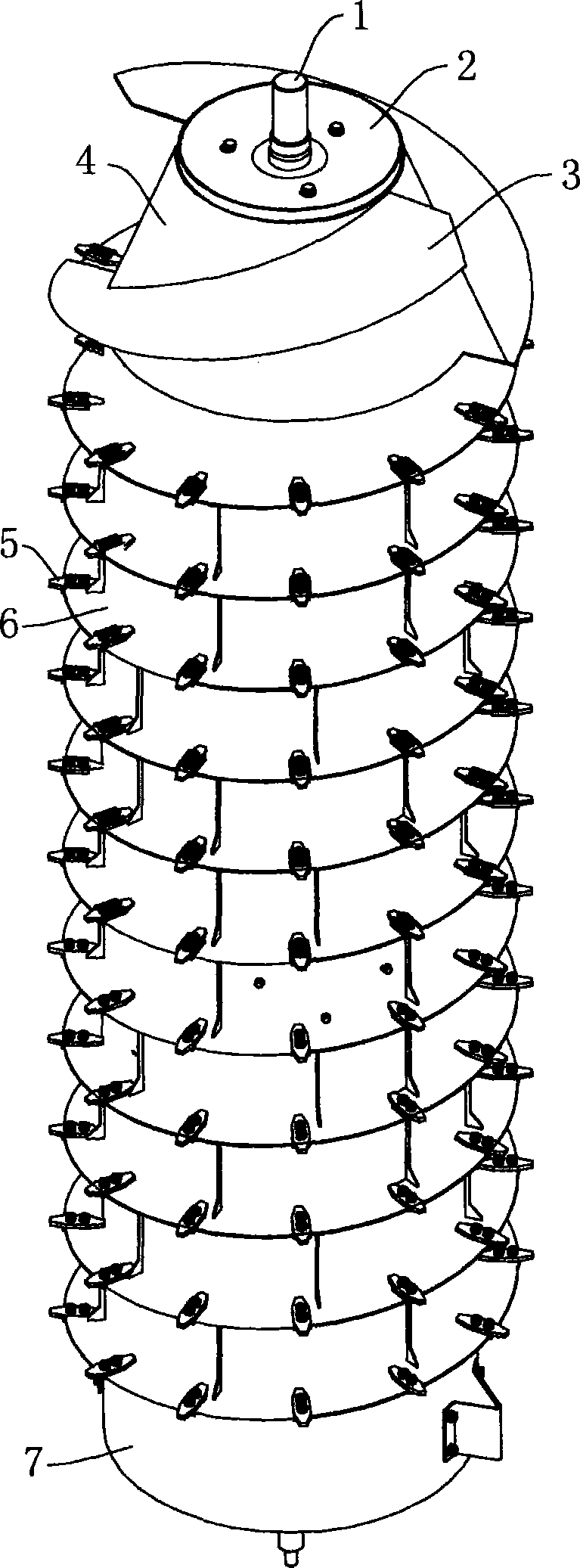

[0013] As shown in the accompanying drawings, an axial flow drum for a combine harvester includes a drum shaft 1, a drum body fixed on the drum shaft 1, and the drum body includes a cylindrical body portion 7 and a truncated cone The cylindrical feeding end 4; the feeding screw blade 3 fixed on the surface of the conical frustum of the feeding end is used to grab the material and then feed the material into the drum chamber. The feeding screw blade 3 consists of two pieces The short helical blades form a double-headed helical structure, which can speed up the feeding speed and reduce the possibility of material clogging; the conveying helical blades 6 fixed on the cylindrical surface of the cylinder body are used to realize the conveying of materials in the drum chamber. Guide, the conveying helical blade 7 is composed of a single-headed helical blade.

[0014] The threshing and separating teeth 5 are fixedly connected to the outer peripheral portion of the conveying screw bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com