Composite-bottom cast aluminum cooker

A technology of cooking utensils and cast aluminum, which is applied in the direction of household utensils, kitchen utensils, and special materials for cooking utensils, etc., can solve the problems of low yield rate, achieve high yield rate, high practical value, and improve the effect of connection firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

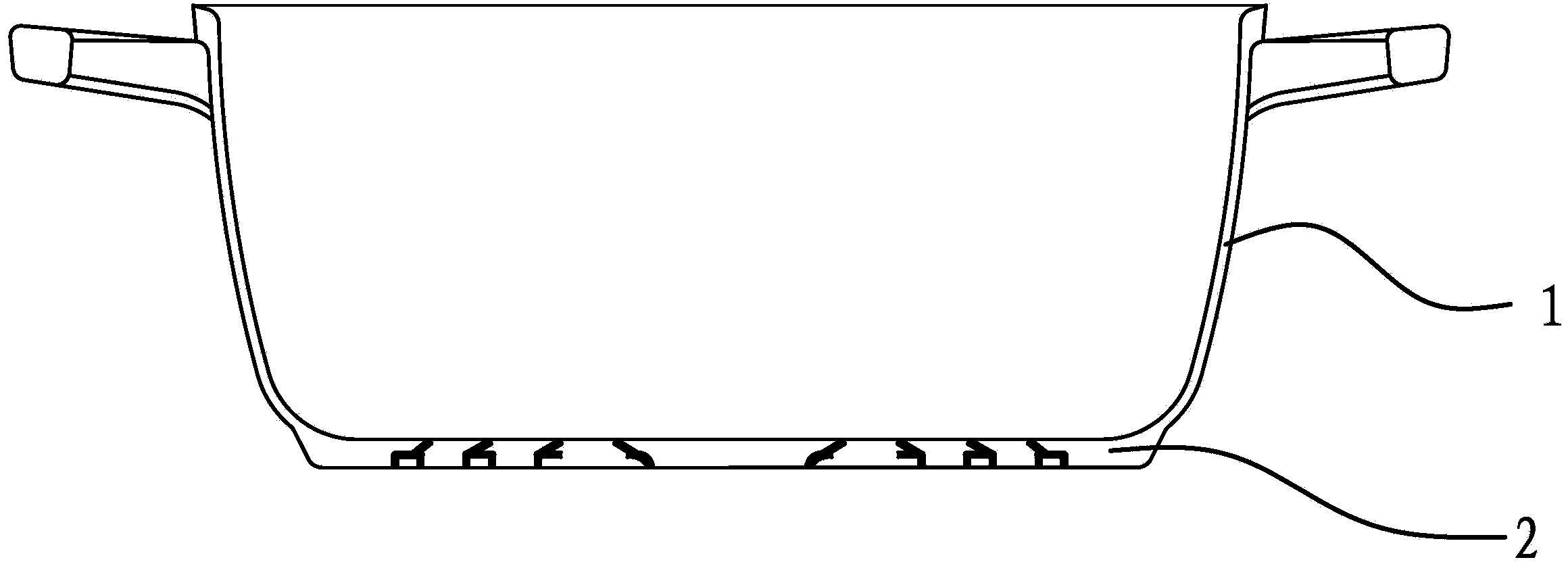

[0035] like figure 1 As shown, the double-bottom cast aluminum cooker can be used as an ordinary cooker at an open flame, and it can also be used on an induction cooker.

[0036] The double-bottom cast aluminum cooker includes an open body 1 made of aluminum material. The bottom of the body 1 has a chassis 2, and the chassis 2 has a metal sheet 3, and the metal sheet 3 is a magnetically conductive material.

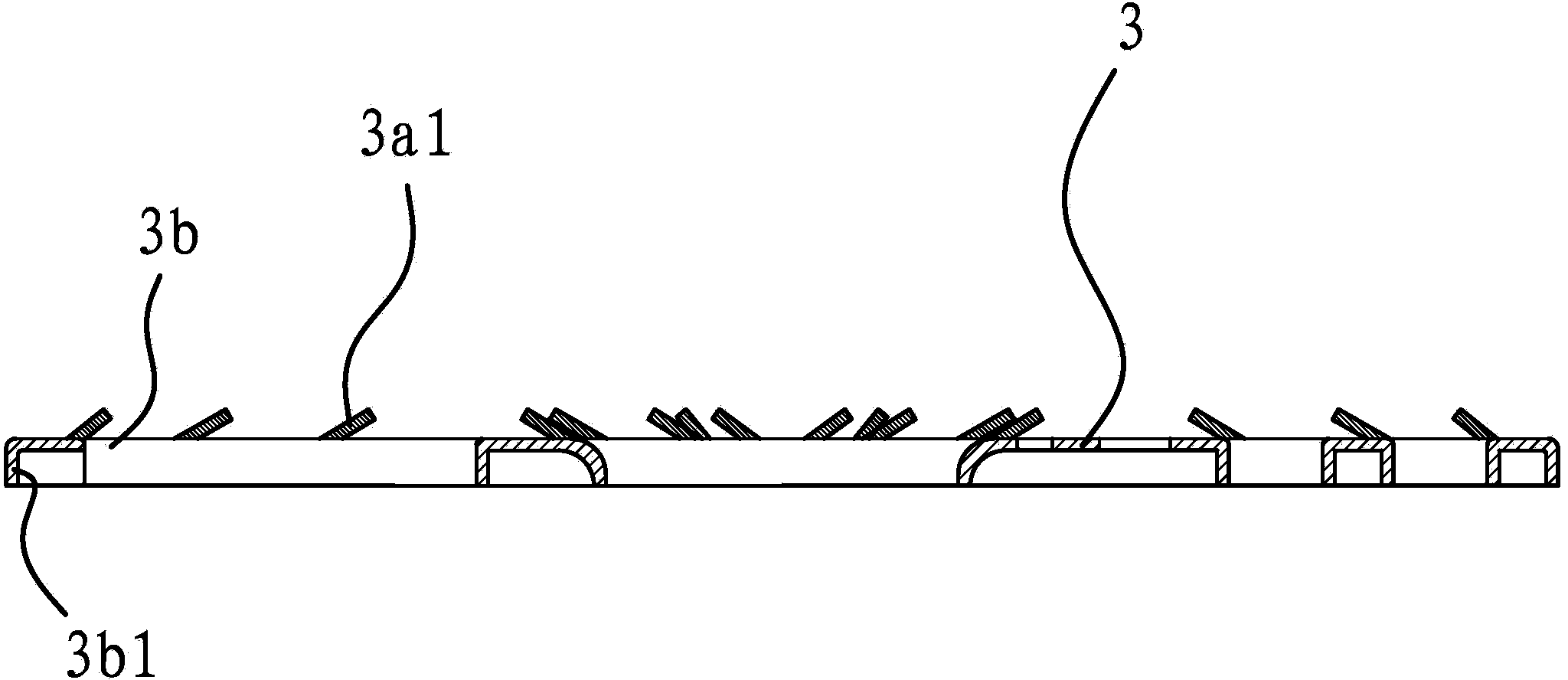

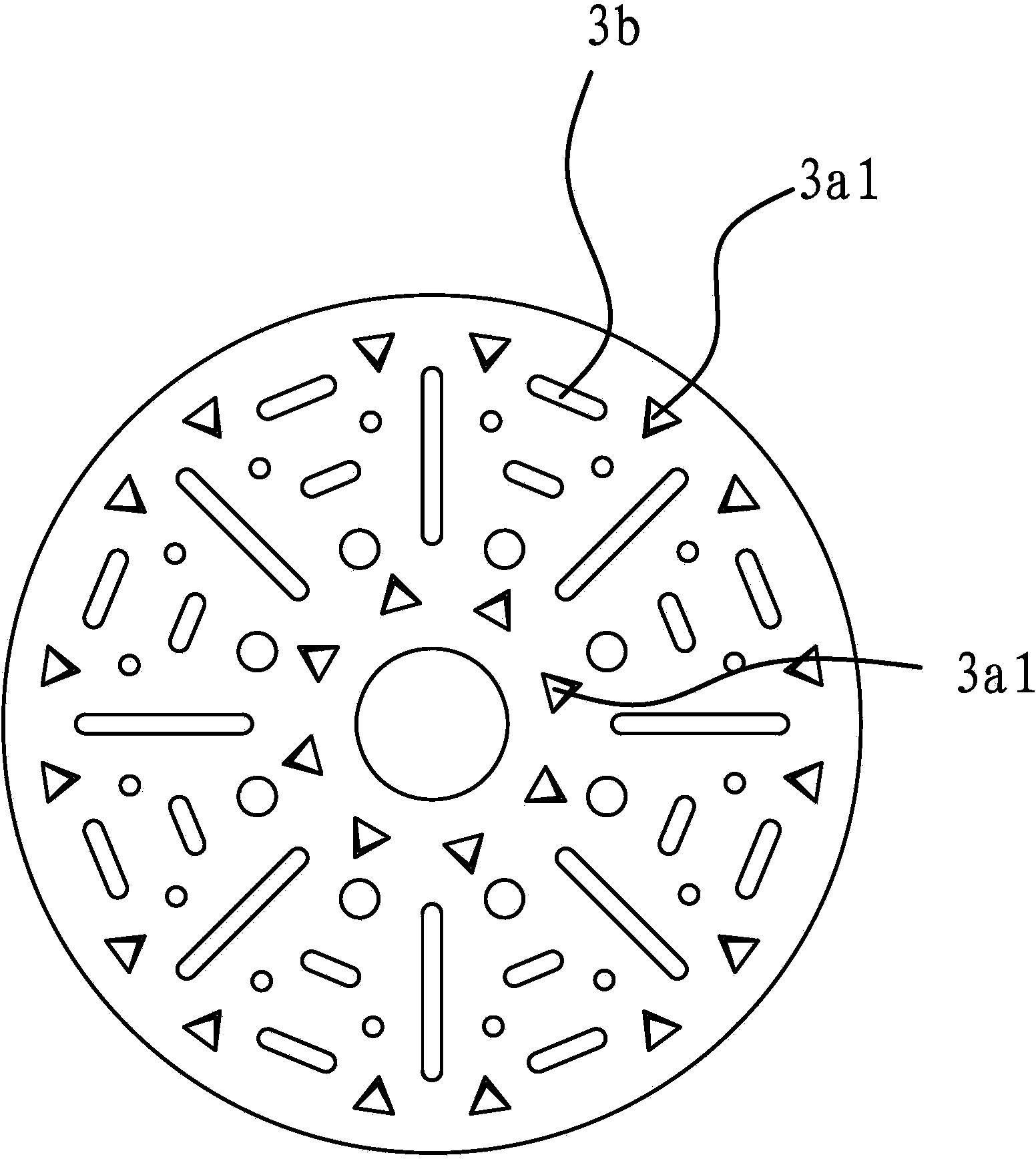

[0037] like figure 1 and figure 2 As shown, the metal sheet 3 is embedded in the above-mentioned chassis 2 , and the side of the metal sheet 3 has an inner flange 3a1 close to the inner surface of the chassis 2 , and the inner flange 3a1 extends to the inner surface of the chassis 2 . The side of the metal sheet 3 has an outer flange 3b1 close to the outer surface of the chassis 2 , and the outer flange 3b1 extends to the outer surface of the chassis 2 .

[0038] like figure 2 and image 3 and Figure 4 As shown, one end of the inner flange 3a1 is connected to th...

Embodiment 2

[0044] The structure and principle of this embodiment are basically the same as those of the first embodiment, except that the angle between the inner flange 3a1 and the metal sheet 3 is 50°. At the same time, the number of inner flanging units is two, and the number of outer flanging units is three. The three outer flanging units are located between the two inner flanging units.

Embodiment 3

[0046] The structure and principle of this embodiment are basically the same as those of the first embodiment, except that the angle between the inner flange 3a1 and the metal sheet 3 is 60°. At the same time, the number of inner flanging units is two, and the number of outer flanging units is two. The two inner flanging units are located between the two outer flanging units.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com