Tyre burst auxiliary wheel

A technology for assisting wheels and punctures, applied in vehicle parts, tire parts, transportation and packaging, etc., can solve problems such as tail flicking, vehicles cannot continue to drive normally, and hidden dangers of unsafe driving, so as to extend service life and protect Damaged, strong impact resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

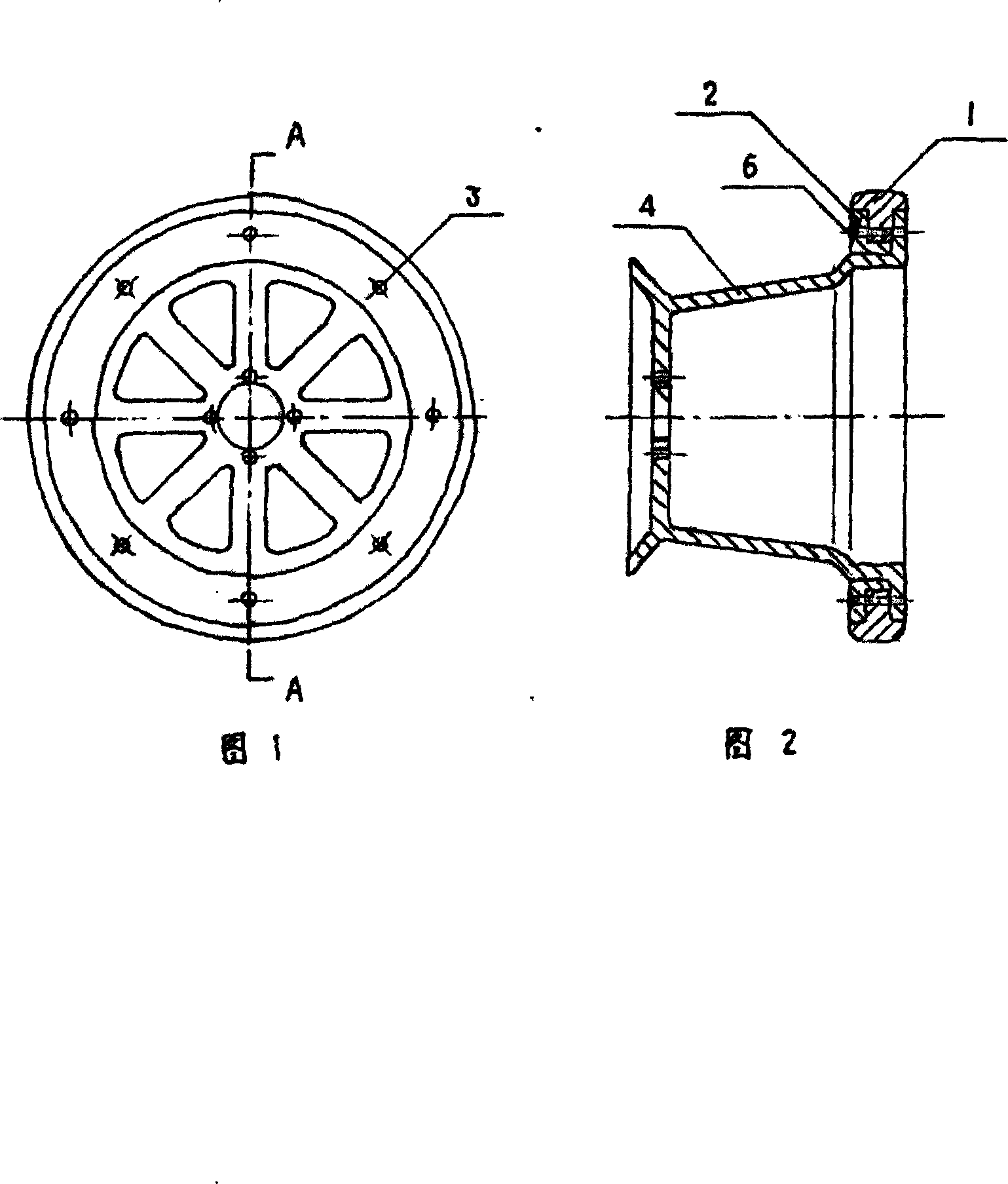

[0017] In the embodiment shown in Fig. 2, the rim 4 is provided with an auxiliary tire 1, the supporting steel ring 2 is fixed by welding with screws 6 (evenly distributed), and the auxiliary tire is arranged on one side of the rim to form the main body of the present invention. .

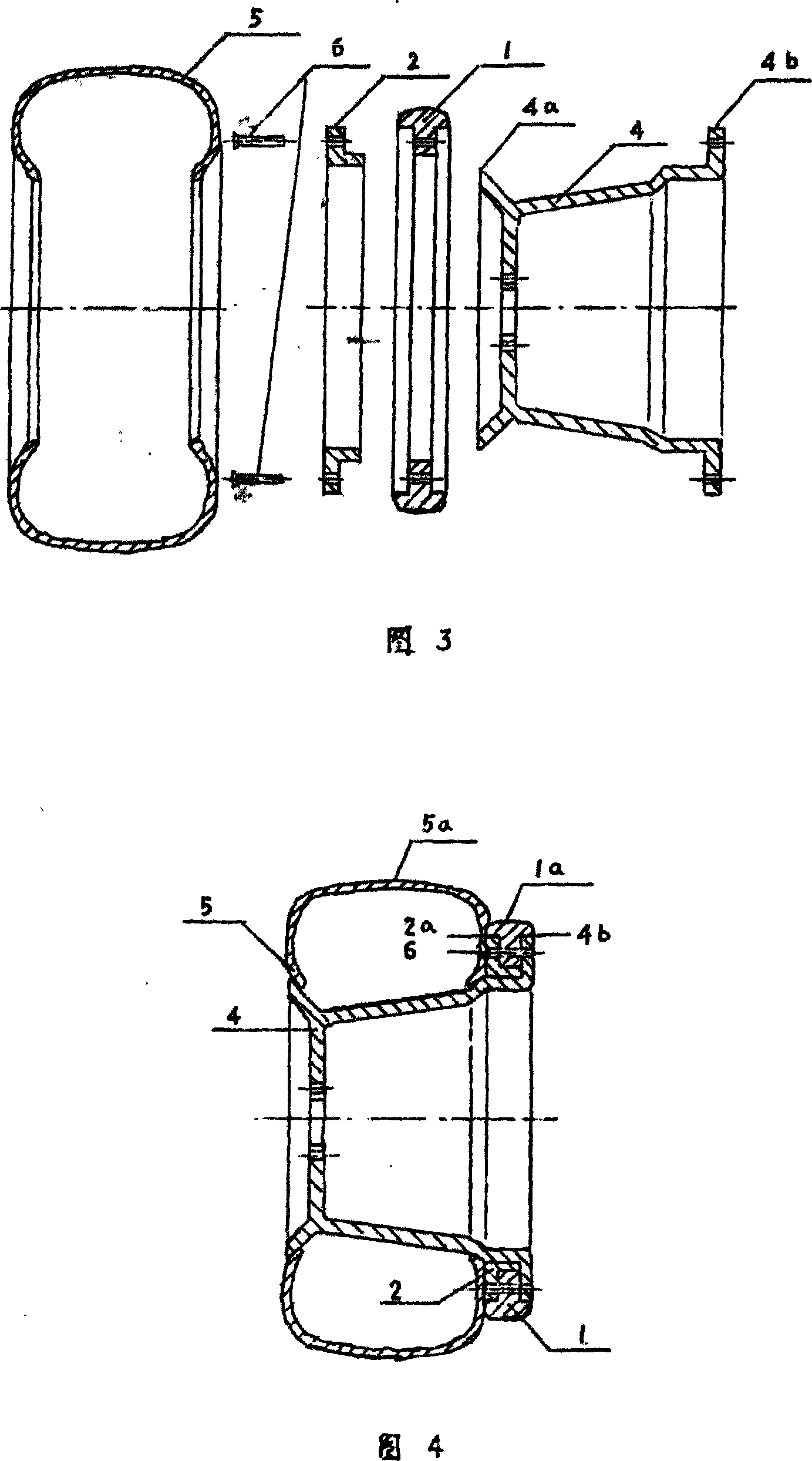

[0018] In the embodiment shown in Figure 3, the circumference 4b of the rim edge on one side of the auxiliary tire is larger than the circumference 4a of the other side edge of the rim, and the screws 6 are evenly distributed to fix the supporting steel ring 2 and the auxiliary tire 1 on the rim 4 , constituting the solution of the present invention.

[0019] In the embodiment shown in Figure 4, the auxiliary tire 1 is an air-free synthetic rubber material, and the supporting steel ring circumference 2a is the same as the rim circumference 4b on one side of the auxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com