Thermal lump and its application in combustion chamber

A heat insulation block and combustion chamber technology, applied in the direction of combustion chambers, continuous combustion chambers, combustion methods, etc., can solve problems such as adverse force input, achieve the effects of increasing passive safety, extending inspection and maintenance intervals, and avoiding subsequent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

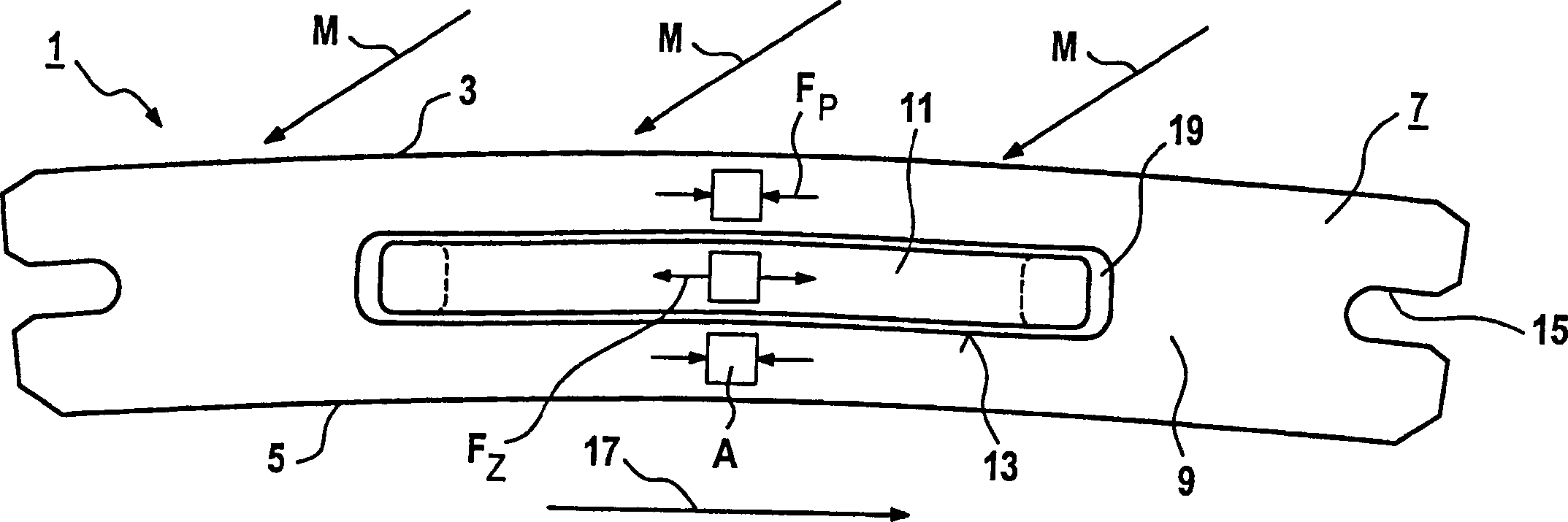

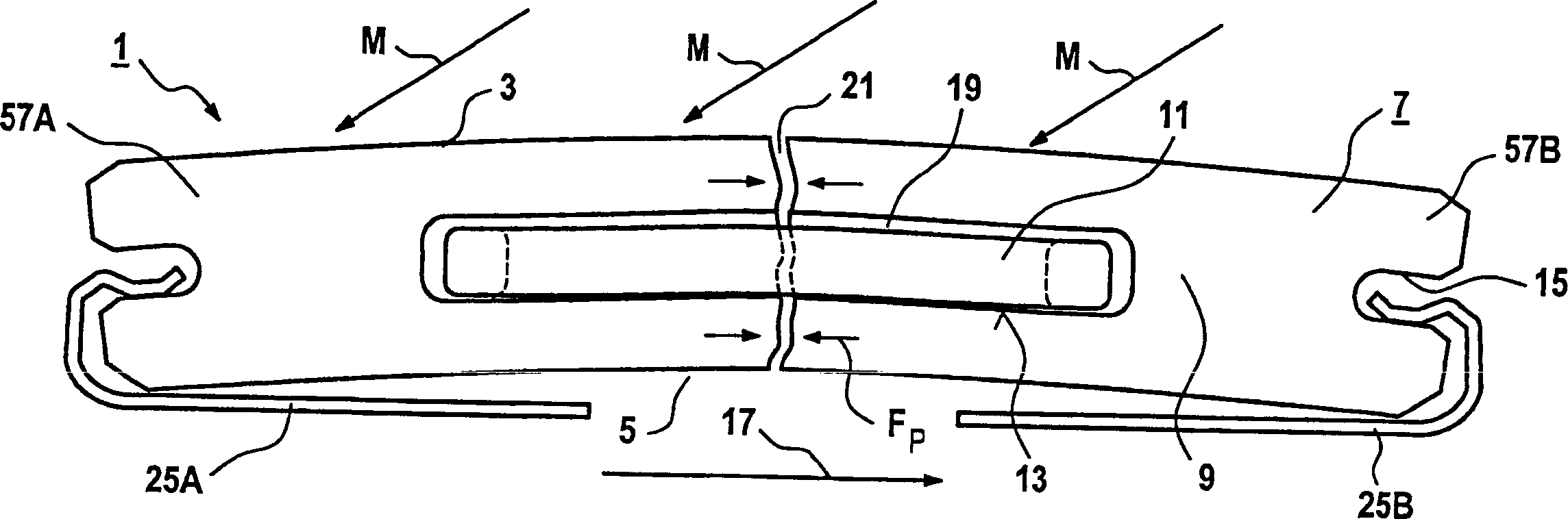

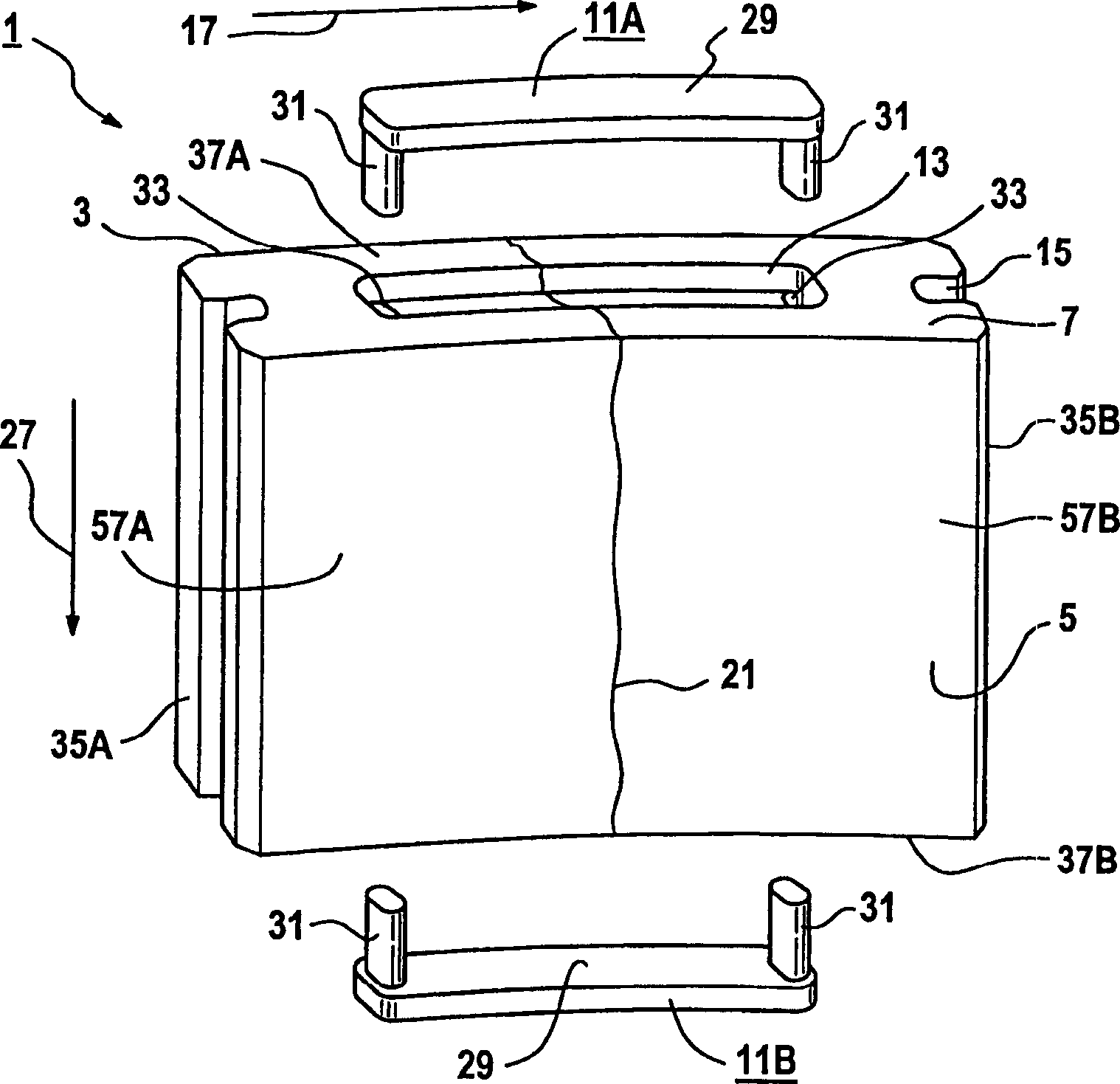

[0043] figure 1 The insulating block 1 is shown in side view. The insulating block 1 has a hot side 3 and a wall side 5 opposite the hot side 3 . The peripheral side 7 of the insulating block 1 connects the hot side 3 and the wall side 5 . The peripheral side 7 has a peripheral side surface 9 . A thermal medium M (eg hot gas) acts on the hot side 3 during use of the insulating block 1 . The tensile element 11 , which is prestressed in the peripheral direction 17 , is arranged on the peripheral side 7 of the insulating block 1 . In this case the tensile element 11 is prestressed to the prestress F Z . The peripheral side 7 has a peripheral groove 13 in which the tensile element 11 engages. Due to the prestress F of the tensile member 11 Z , generating compressive stress F on the material of the insulation block 1 P , the compressive stress F P (for example) acting on surface element A. In this case, the tensile member 11 is pre-stressed to: compressive stress F Z The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com