A lifting mechanism for a punching die in a sticky die set

A die and die base technology, which is applied in the field of patch-adhesive hybrid embroidery machines, can solve problems such as waste, waste of processed fabrics, and insufficient lifting height of the die, and achieve the effects of convenient installation and debugging, saving fabrics, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

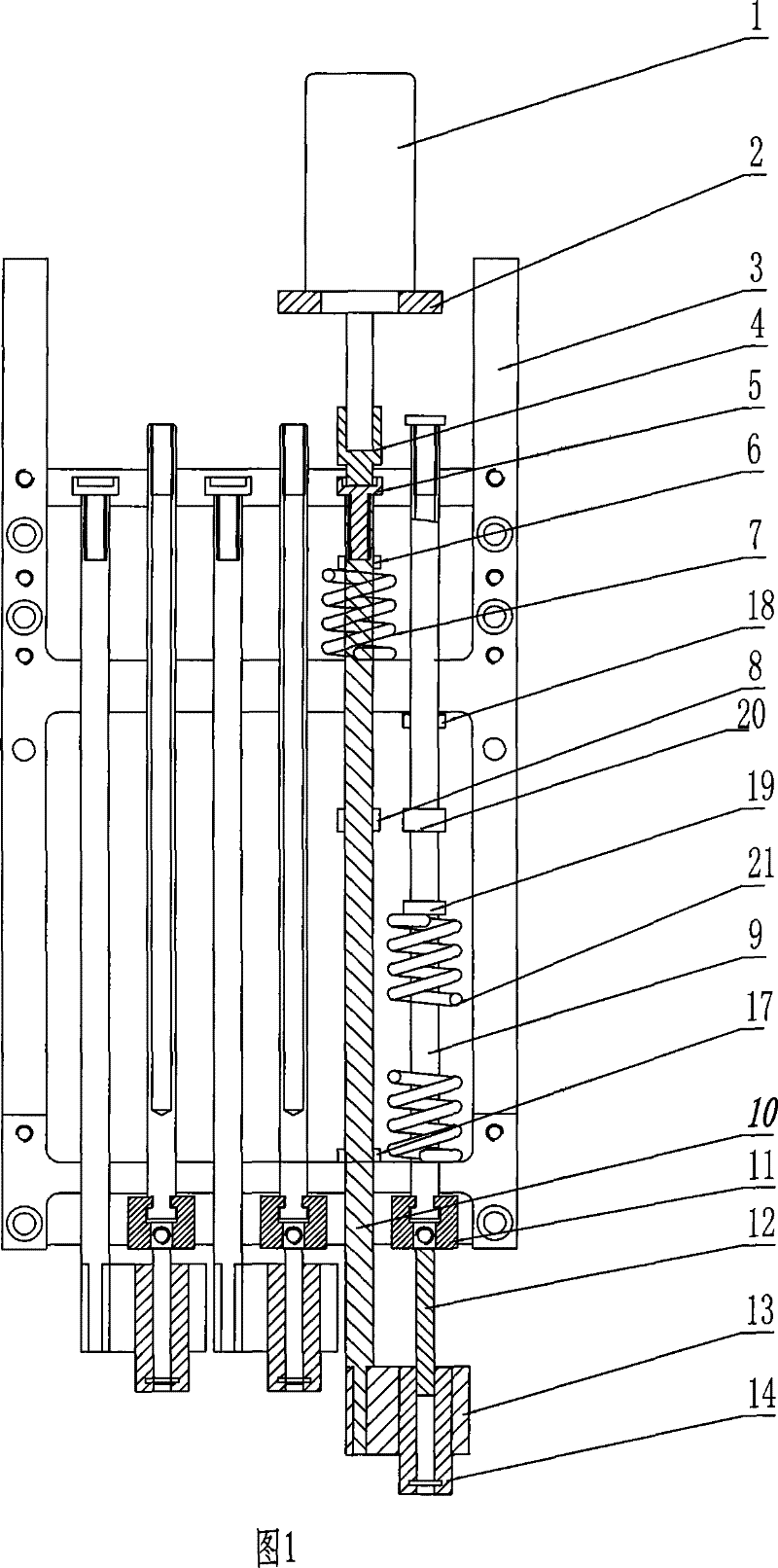

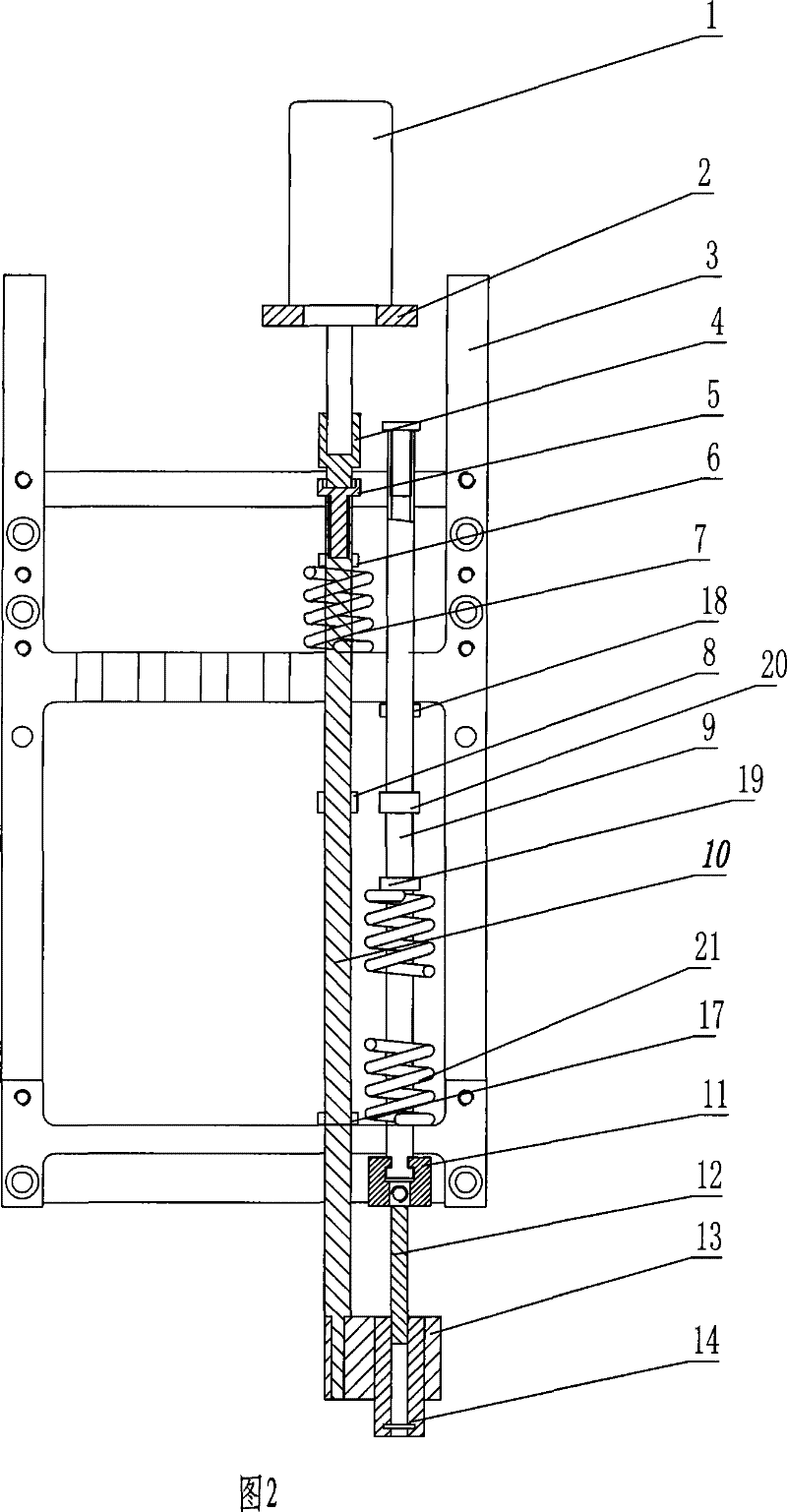

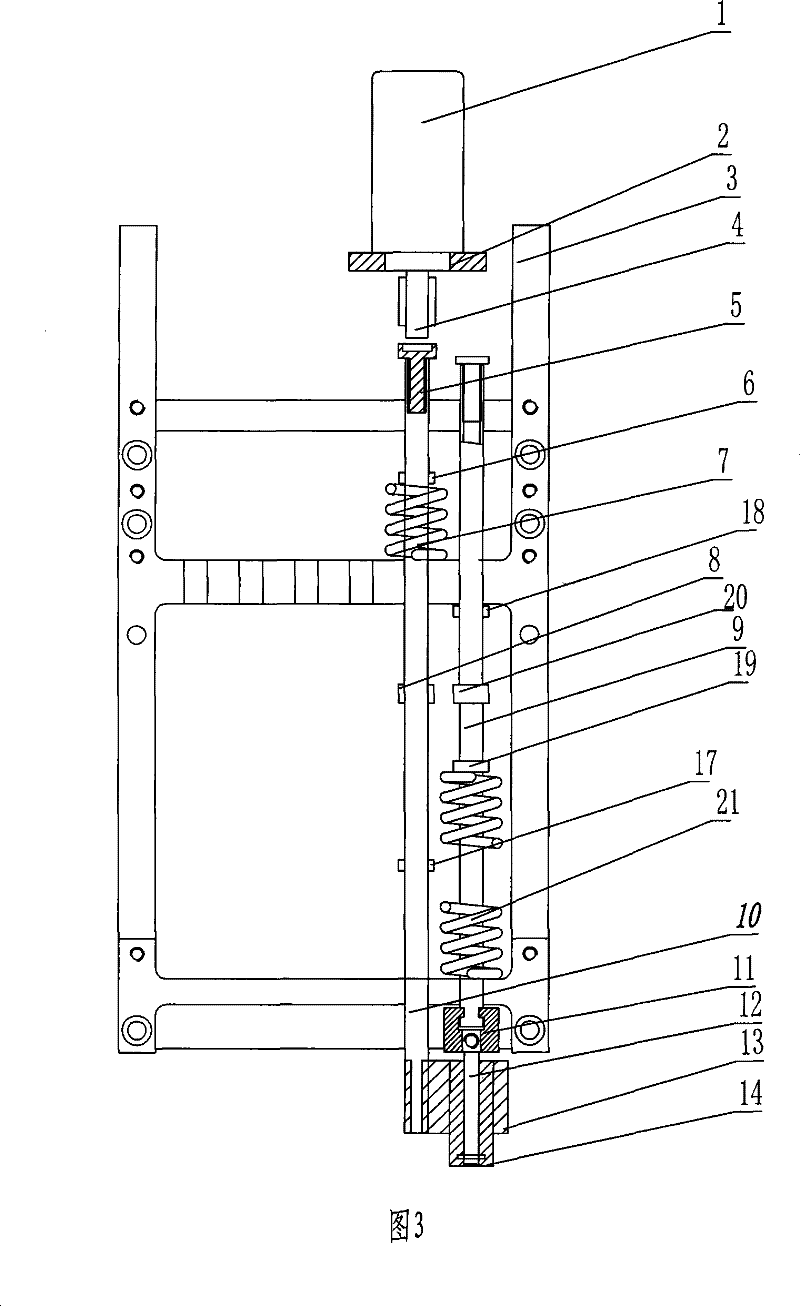

[0017] Depend on Figure 1-4 As shown, the lifting mechanism for the punching die in this adhesive die set includes a transmission mechanism, a connecting rod mechanism, and a punching needle mechanism. The transmission mechanism includes a linear cylinder 1, a cylinder bracket 2 connected to it, and a positioning block that is threaded. 4. The link mechanism includes a lifting needle bar 10 and a central block 5 connected with it. The lifting needle bar 10 is provided with a first rebound spring 7, a first guide block 8, a first limit block 6 and a second limit block 17, connected with the die 14 through the die connector 13, the second limit block 17 is used as the bottom dead center of the lifting needle bar 10; 20. The third limiting block 18 and the fourth limiting block 19 are connected with the punching needle 12 through the punching needle coupling 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com