Total-travel reciprocating mechanism driven by hydraulic cylinders

A technology of hydraulic oil cylinder and reciprocating mechanism, applied in the direction of lifting device, can solve the problems of installation and use, can not be changed, and achieve the effect of convenient assembly, effective stroke guarantee, stable and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

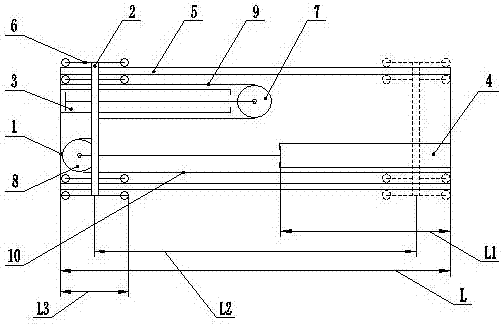

[0013] The implementation of the full-stroke reciprocating mechanism driven by the hydraulic cylinder will be further described in detail below in conjunction with the accompanying drawings:

[0014] The full stroke reciprocating mechanism driven by the hydraulic cylinder is composed of frame 1, synchronous support 2, hydraulic cylinder I3, hydraulic cylinder II4, slide rail 5, sliding trolley 6, pulley I7, pulley II8, chain I9, chain II10; the full stroke reciprocating mechanism The frame 1 is a rectangular structure, the upper and lower frames of the frame 1 are installed and connected with the synchronous support 2, the slide rail 5 is symmetrically installed on the upper and lower frames of the frame 1, and the sliding trolley 6 is symmetrically installed on the slide rail 5 through the synchronous support 2; the left side of the frame 1 Hydraulic cylinder Ⅰ3 is installed on the frame, hydraulic cylinder Ⅱ4 is installed on the right frame of frame 1, pulley Ⅰ7 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com