Pallet stretching-out device for refrigerator

A technology for pulling out devices and trays, which can be used in household refrigeration devices, applications, household appliances, etc., and can solve problems such as access interference, and achieve the effect of preventing interference and making access easier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

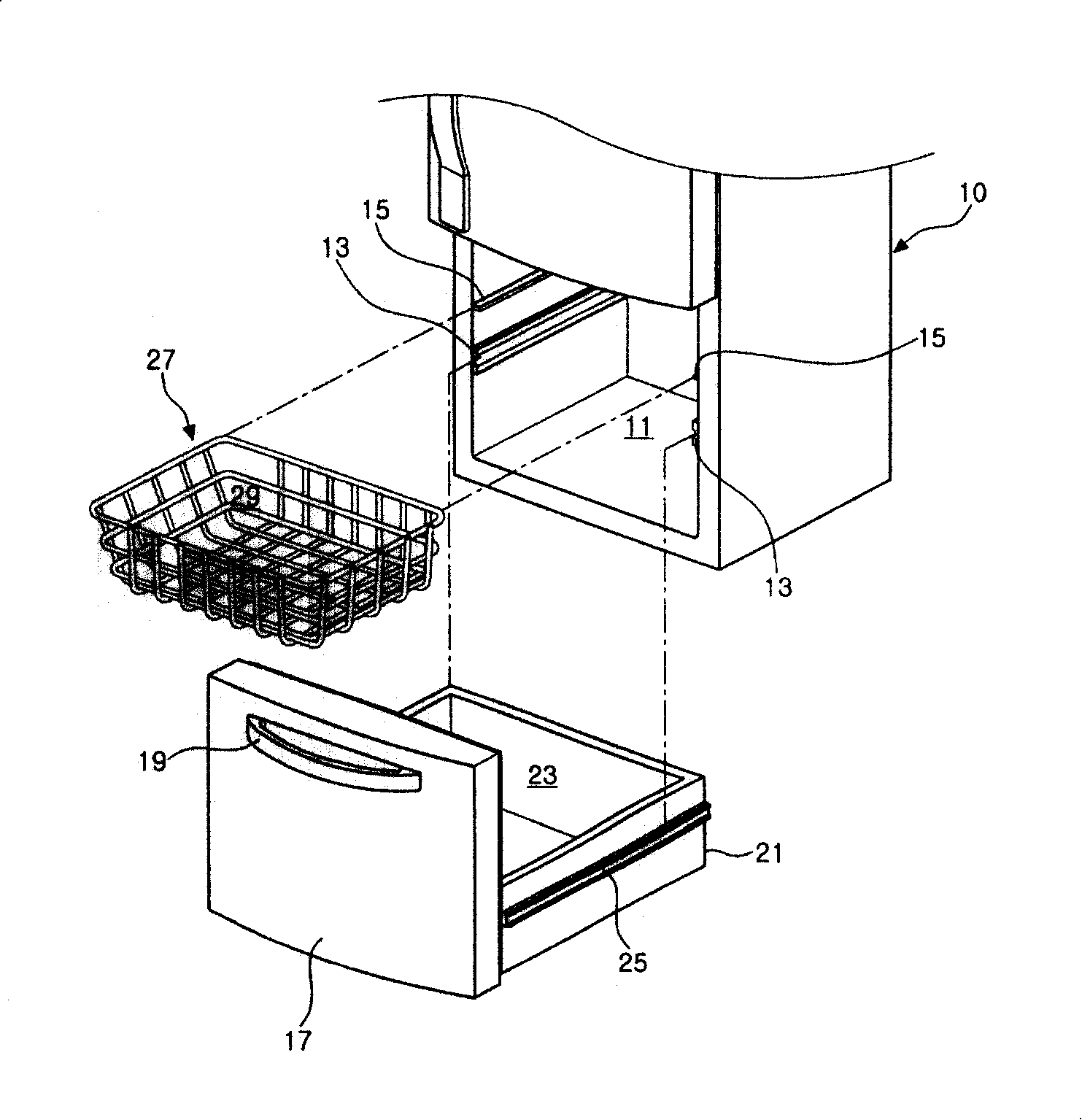

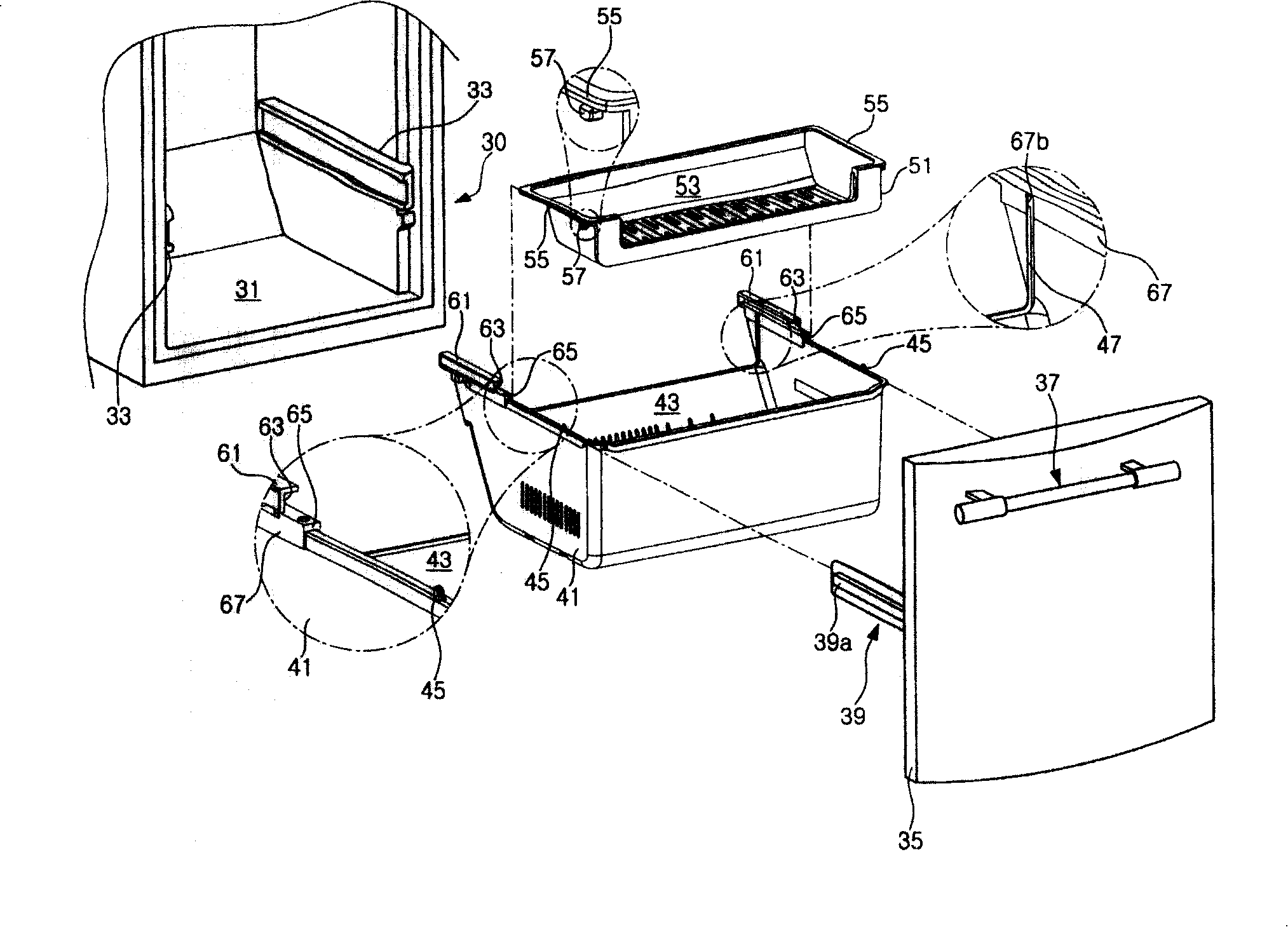

[0040] Such as figure 2 , 3 As shown, the two sides of the storage space 31 of the refrigerator body 30 are provided with guide rails 33 . The guide rails 33 are used to guide the entry and exit of the first tray 41, and the first tray 41 will be described below. The guide rail 33 is formed elongated in the direction in which the first tray 41 goes in and out, that is, in the front-rear direction of the storage space 31 .

[0041] Furthermore, the present invention is provided with a door 35 for selectively opening and closing the storage space 31 . A door handle 37 for the user to hold is provided on the upper front end of the door 35 . A guide frame 39 is provided on the inside of the door 35, and the function of the guide frame 39 is to enable the first tray 41 to be drawn in and out. The first pallet will be described below.

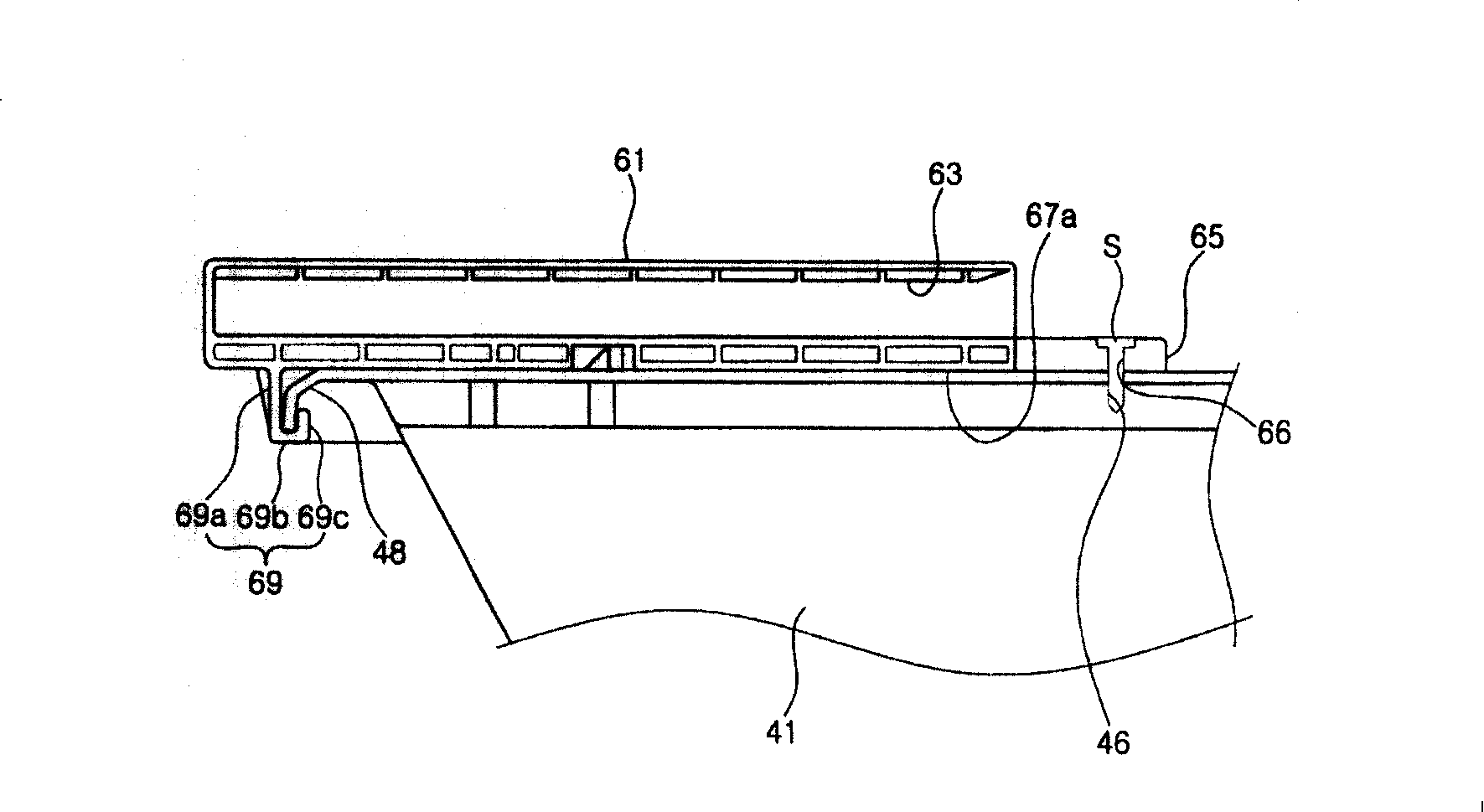

[0042] The guide frame 39 is composed of the following parts: a fixed portion (not shown) fixed to the inside of the door 35; a pair of connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com