Windshield wiper blade assembly with axial translation prevention system

A windshield and wiper technology, which is applied in vehicle cleaning, vehicle maintenance, transportation and packaging, etc. It can solve problems such as loose and disassembled wiper components, connector slippage, and damage to the windshield of a locomotive.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The following description of the preferred embodiments is merely illustrative in nature and is not intended to limit the invention and its application or uses.

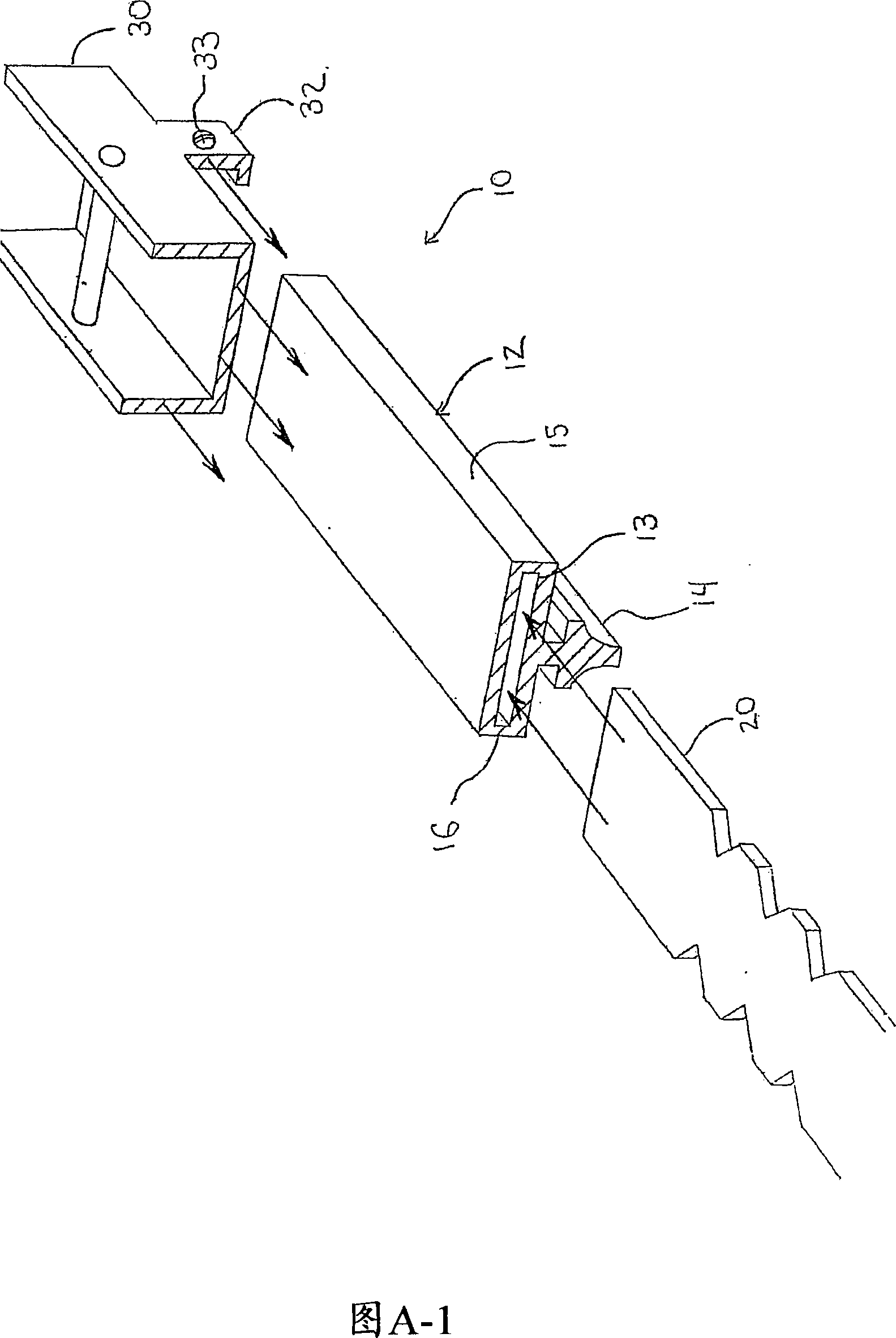

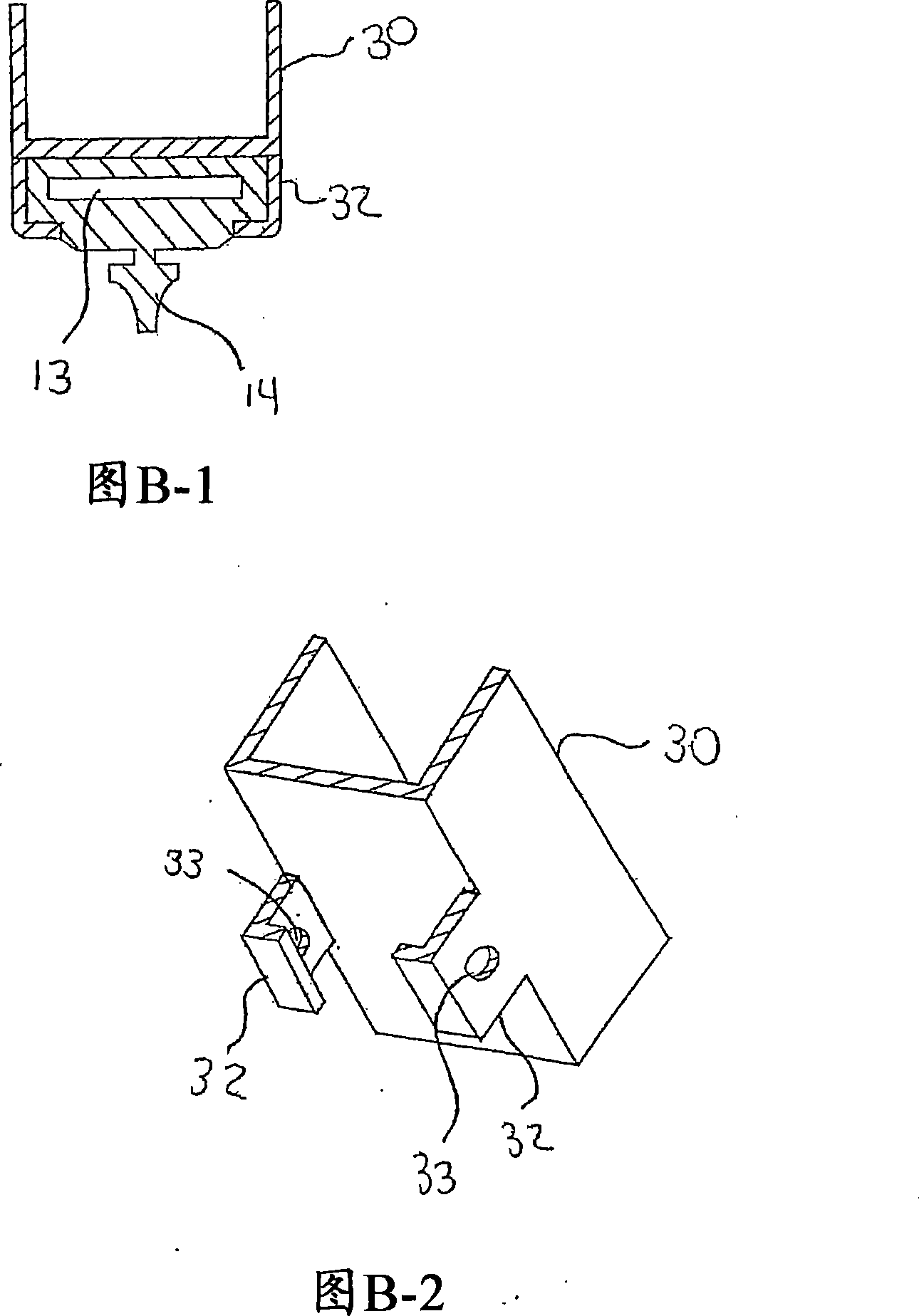

[0078] Referring now to the drawings, and in particular to FIG. A1 , a first embodiment of a windshield wiper assembly 10 is shown. The assembly 10 includes an elongated resilient wiper blade 12 having a resilient windshield wiper element 14 and a longitudinal beam receiving channel 13 extending through the blade 12 for receiving a support beam 20 therein. The support beam 20 is held in the wiper sheet 12 by a releasable connector element 30 which is secured to each other by one or more pairs of crimping tabs 32 (shown with additional fastening holes 33). Fasten the above components.

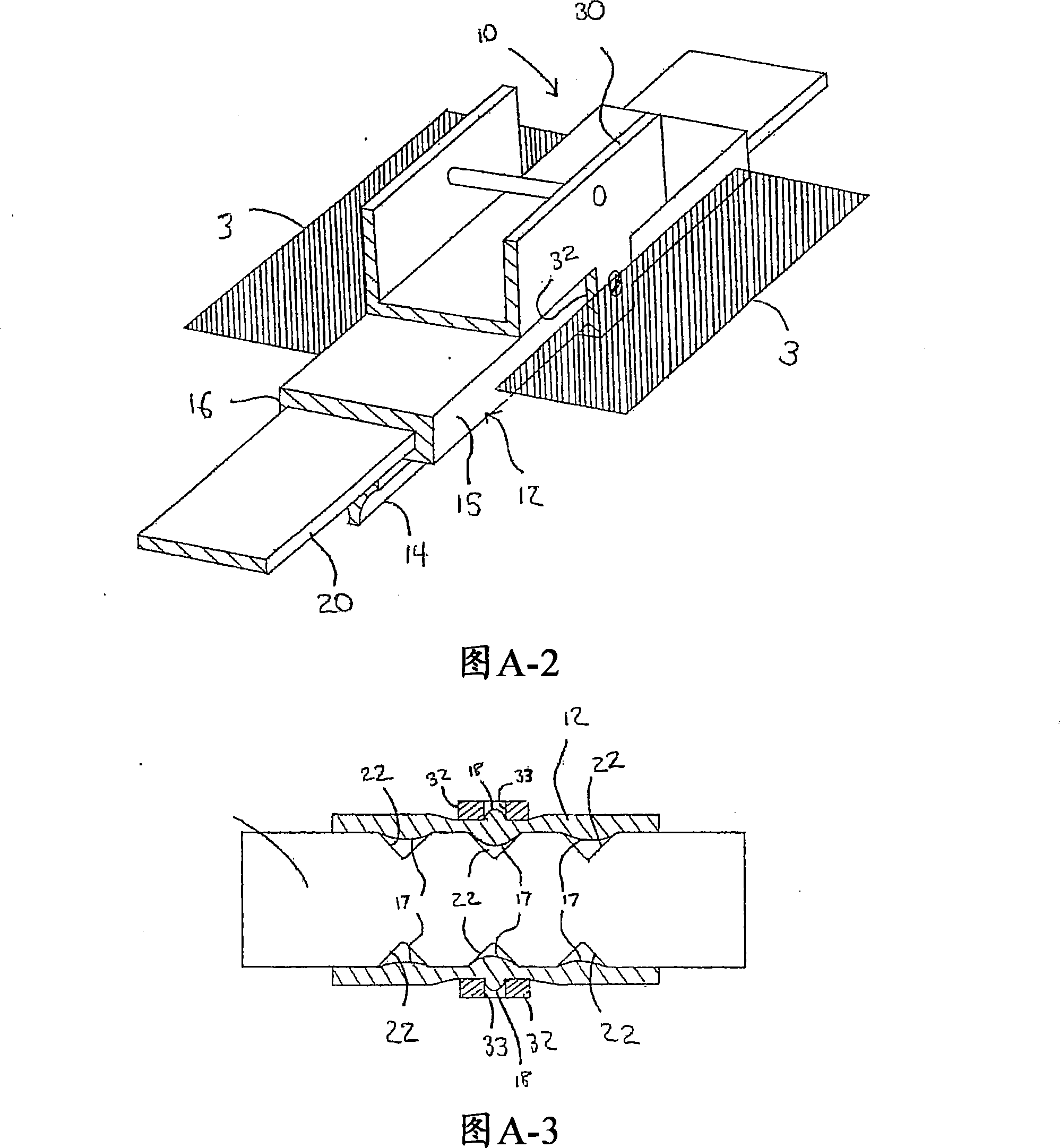

[0079] Figures A2 and A3 illustrate the wiping assembly 10 of Figure A1, wherein the wiping sheet 12, the support beam 20 and the connector element 30 are assembled together, showing that the support beam is located within the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com