Hook vibration prevention hammer

An anti-vibration hammer and hook type technology, applied in the direction of mechanical vibration damping device, etc., can solve the problems of affecting the service life of the normal operation of the transmission and transformation line, the anti-vibration hammer can not achieve the anti-vibration effect, and the cable pressure is large. Meet the special anti-vibration power requirements, highlight the anti-fatigue performance, and reduce the effect of local compressive stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

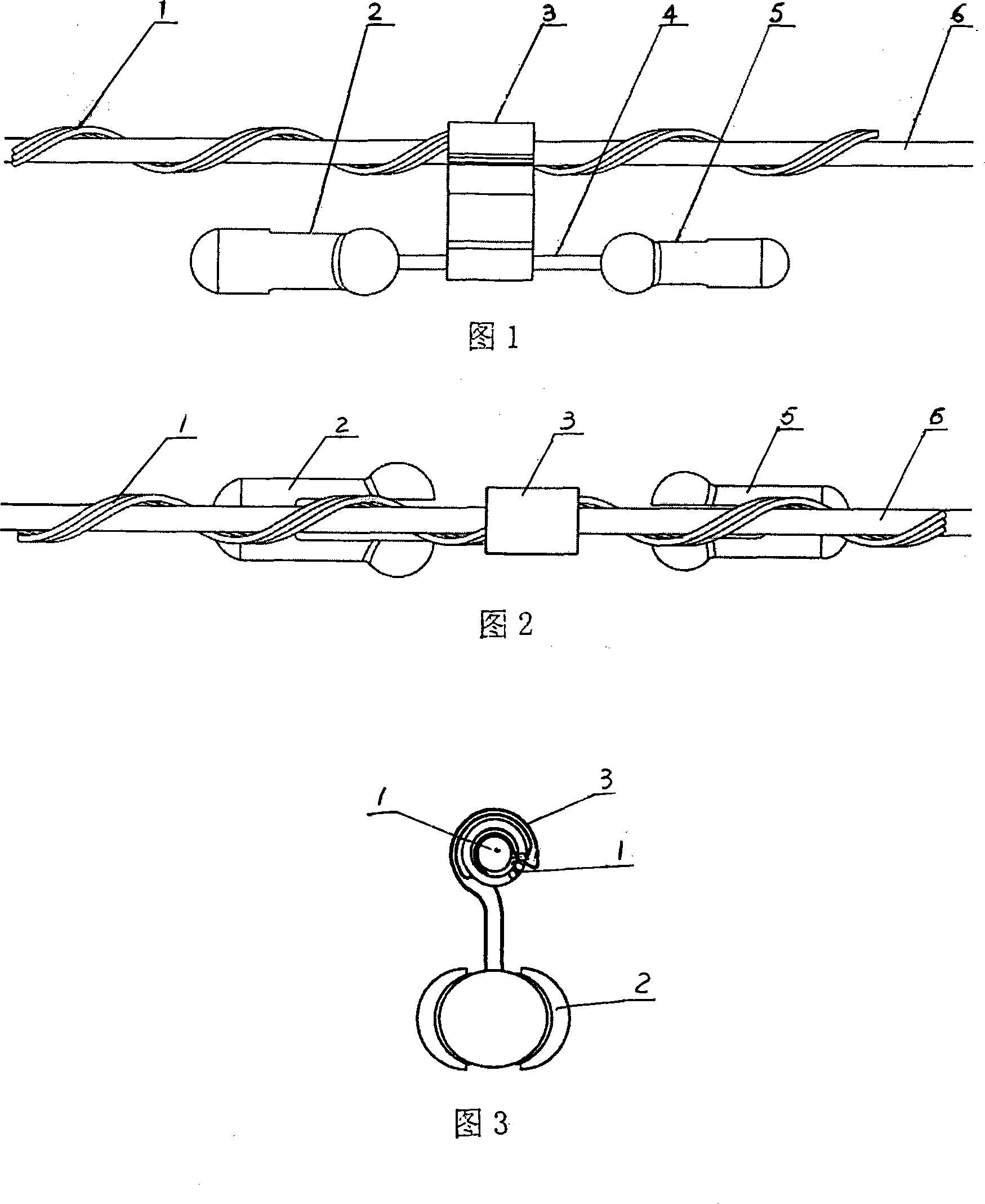

[0010] Referring to accompanying drawings 1-3, the hook-type anti-vibration hammer structure includes a hook 3, a pre-twisted wire 1, a steel strand 4, a large hammer head 2 and a small hammer head 5, and the hook body on the upper part of the hook 3 is set on the cable 6, The upper part of the hook body of the hook 3 is provided with a through hole, and the pre-twisted wire 1 is passed through the upper through hole of the hook 3 and is fixedly connected with the cable 6 . The lower part of the hook is provided with a through hole, and the steel strand 4 is inserted in the through hole, forming a tight fit between the two, so that the steel strand 4 cannot move in the through hole. The two outer ends of the steel strand 4 passing through the through hole are one long and the other short, and the long end extends into the bottom hole of the large hammer head 2, and its short end extends into the bottom hole of the small hammer head 5, and is bonded by connecting glue . The pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com