Tensioning system

A tensioning system and tool technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problem of large lubricant flow and achieve the effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

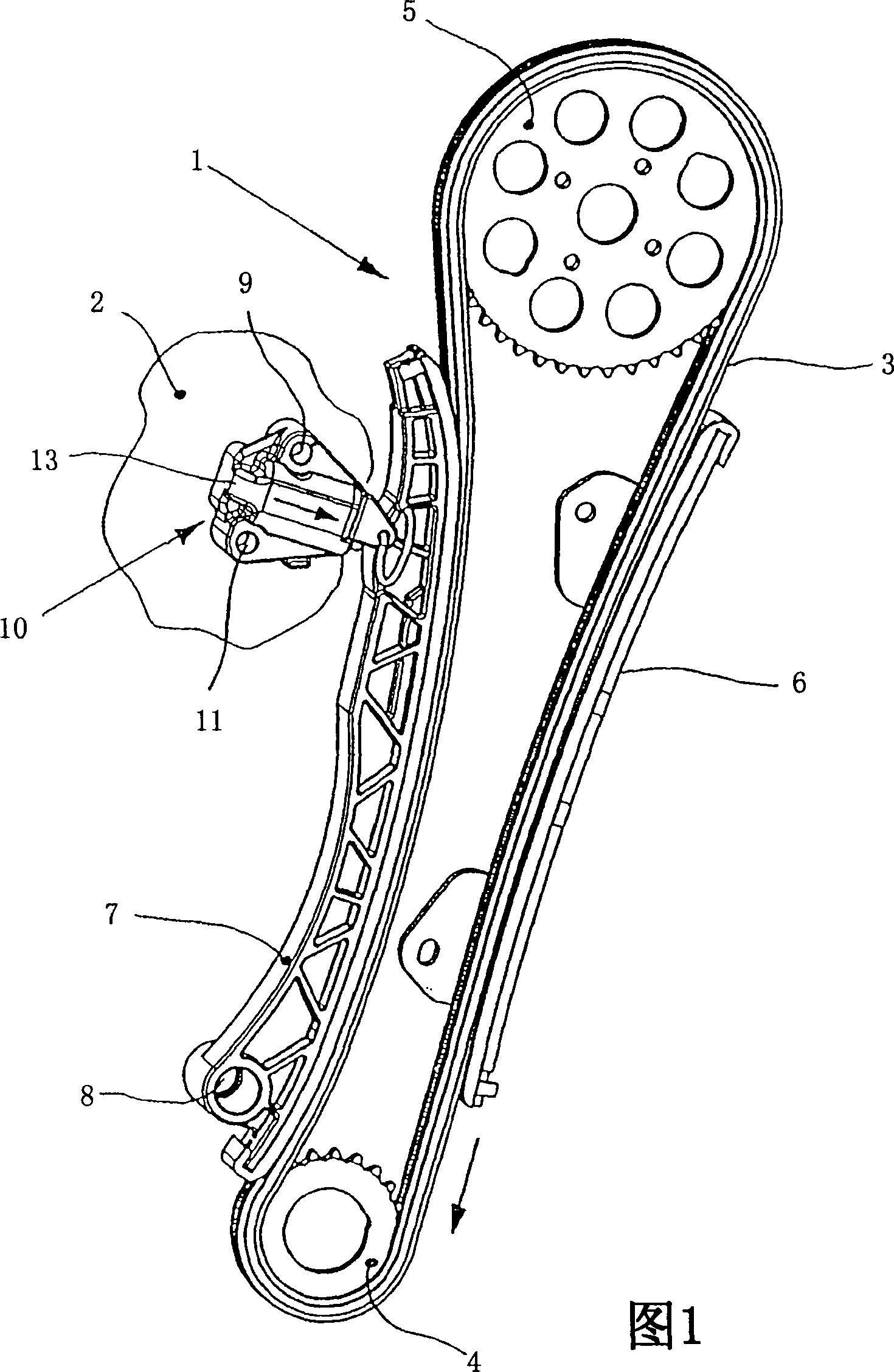

[0024] FIG. 1 shows a traction gear transmission 1 of an internal combustion engine 2 . Here, traction means 3 designed as a chain connects output gear 4 , which is rotationally rigidly connected to the crankshaft of internal combustion engine 2 , with drive gear 5 , via which a camshaft (not shown) of internal combustion engine 2 is driven. The traction means 3 running in the clockwise direction is guided on guide rails 6 in the region of the traction section. Furthermore, the traction means 3 is operatively connected in the idle section to a tensioning rail 7 arranged so as to be rotatably limited around a pivot axis 8 . At the end remote from the pivot axis 8 , the tensioning rail 7 is assigned a hydraulically acting tensioning system 10 which is detachably fastened to the internal combustion engine 2 via fastening elements 9 , 11 , in particular screw connections. In the operating state, tensioning system 10 is acted upon by a hydraulic fluid, in particular a lubricant wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com