Method for measuring high furnace burden face appearance and material flow track using laser ranging technique

A blast furnace material surface, laser ranging technology, used in measuring devices, optical devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

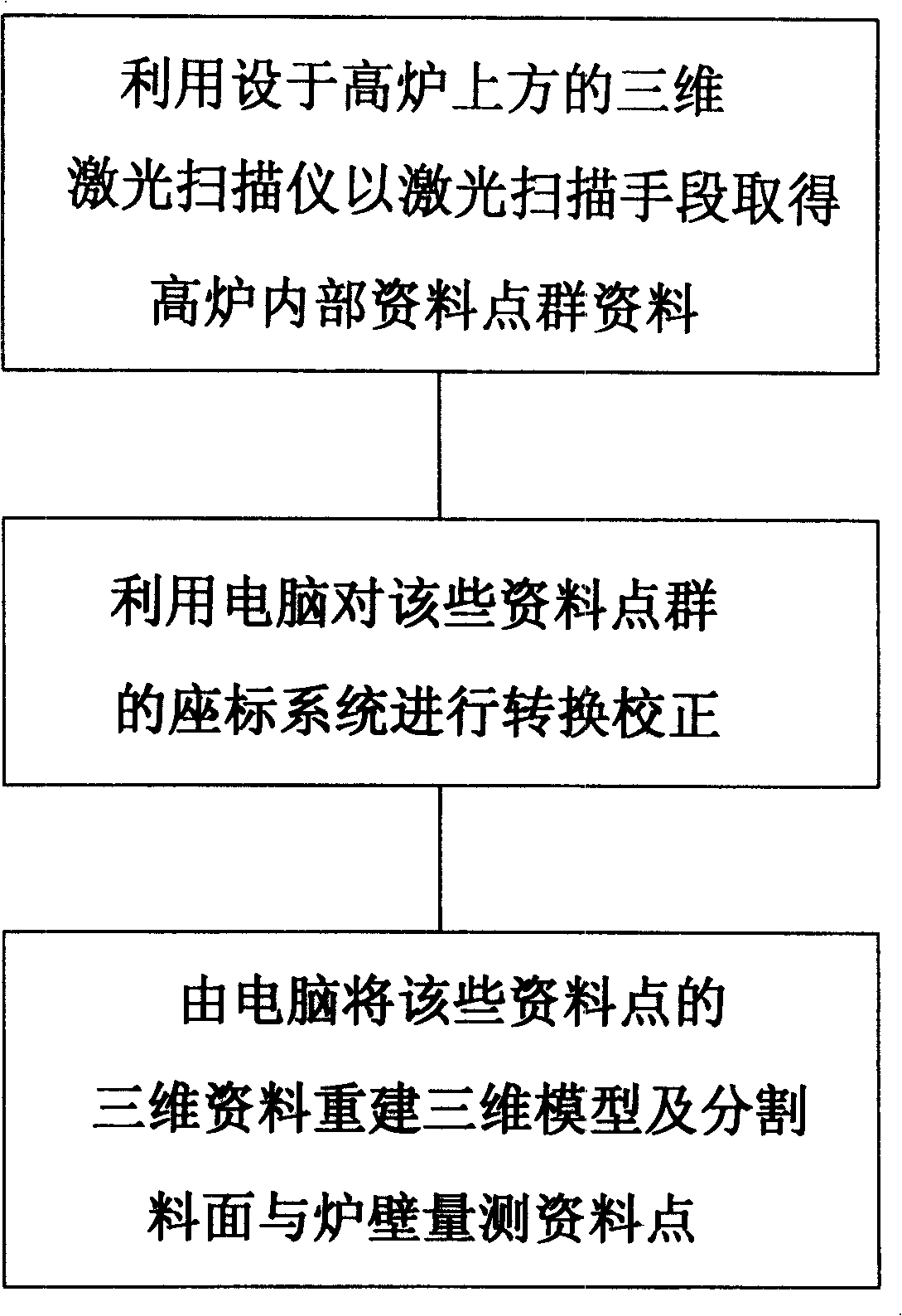

[0038] For further elaborating the technical means and effect that the present invention adopts for reaching the predetermined invention purpose, below in conjunction with accompanying drawing and preferred embodiment, measure blast furnace material surface shape and material flow trajectory with laser ranging technology that proposes according to the present invention The specific implementation, method, steps, features and effects of the method are described in detail below.

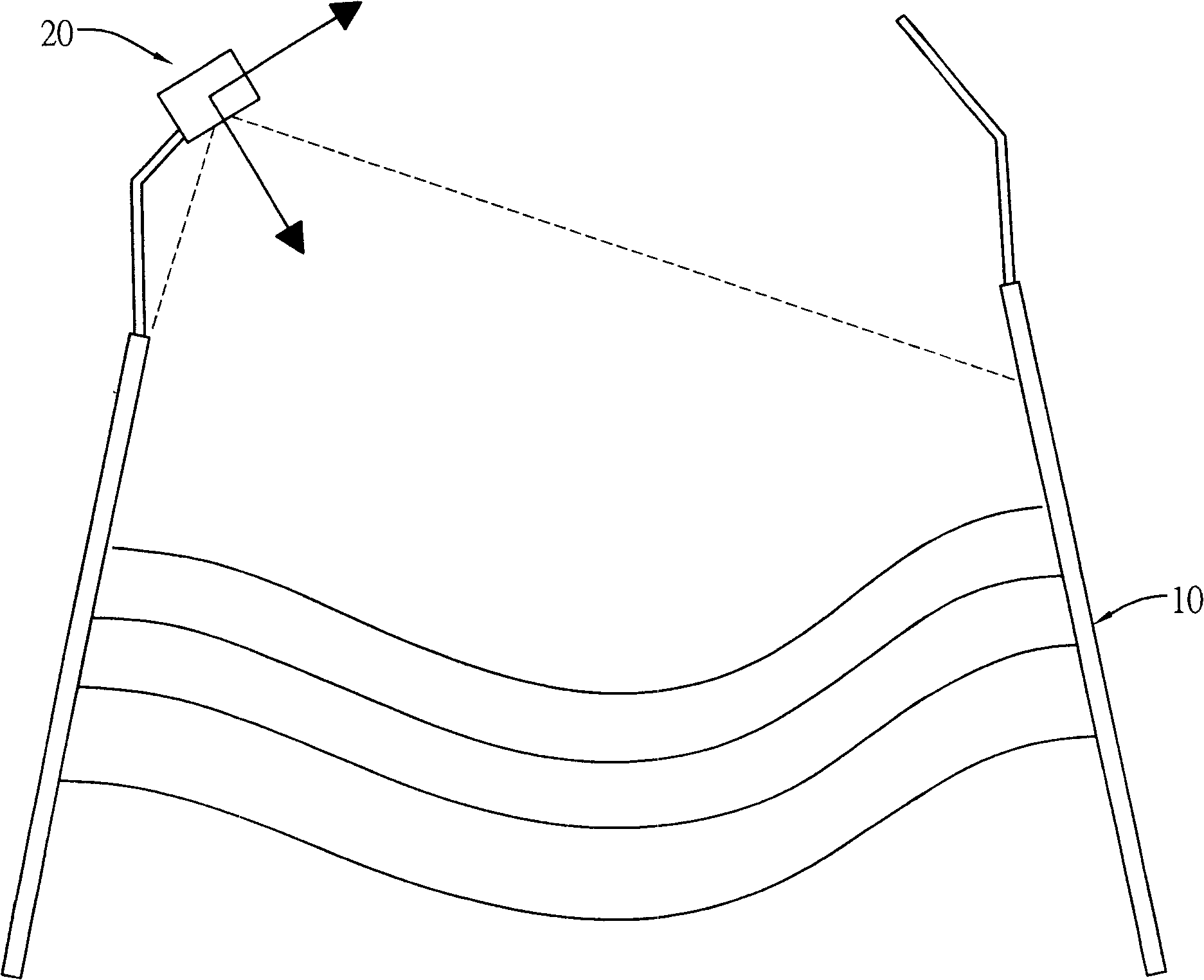

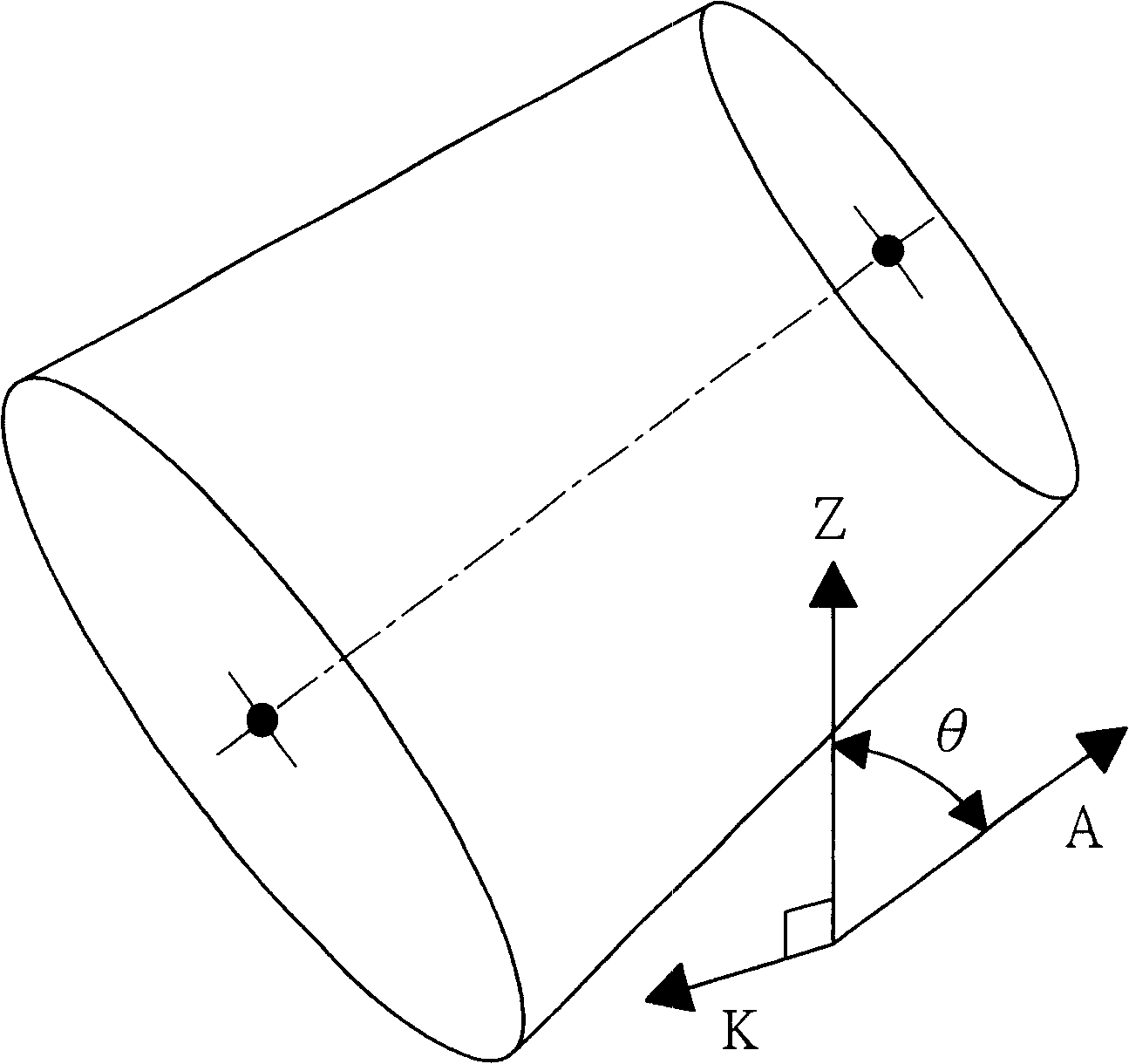

[0039] Relevant to the specific implementation design of the method for measuring the profile of the blast furnace charge surface with laser ranging technology in the present invention, as figure 1 As shown, it mainly uses a three-dimensional laser scanner to be installed above the material surface of the blast furnace. In this preferred embodiment, the laser scanner is installed obliquely at the entrance hole above the throat of the blast furnace. Such as figure 2 As shown in the figure, since the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com