Multi-way valve operation mechanism for fork lift

A control mechanism and multi-way valve technology, applied in the direction of lifting devices, etc., can solve the problems of operator fatigue and achieve the effect of increasing the operating space under the feet, precise elastic force design and automatic lock structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

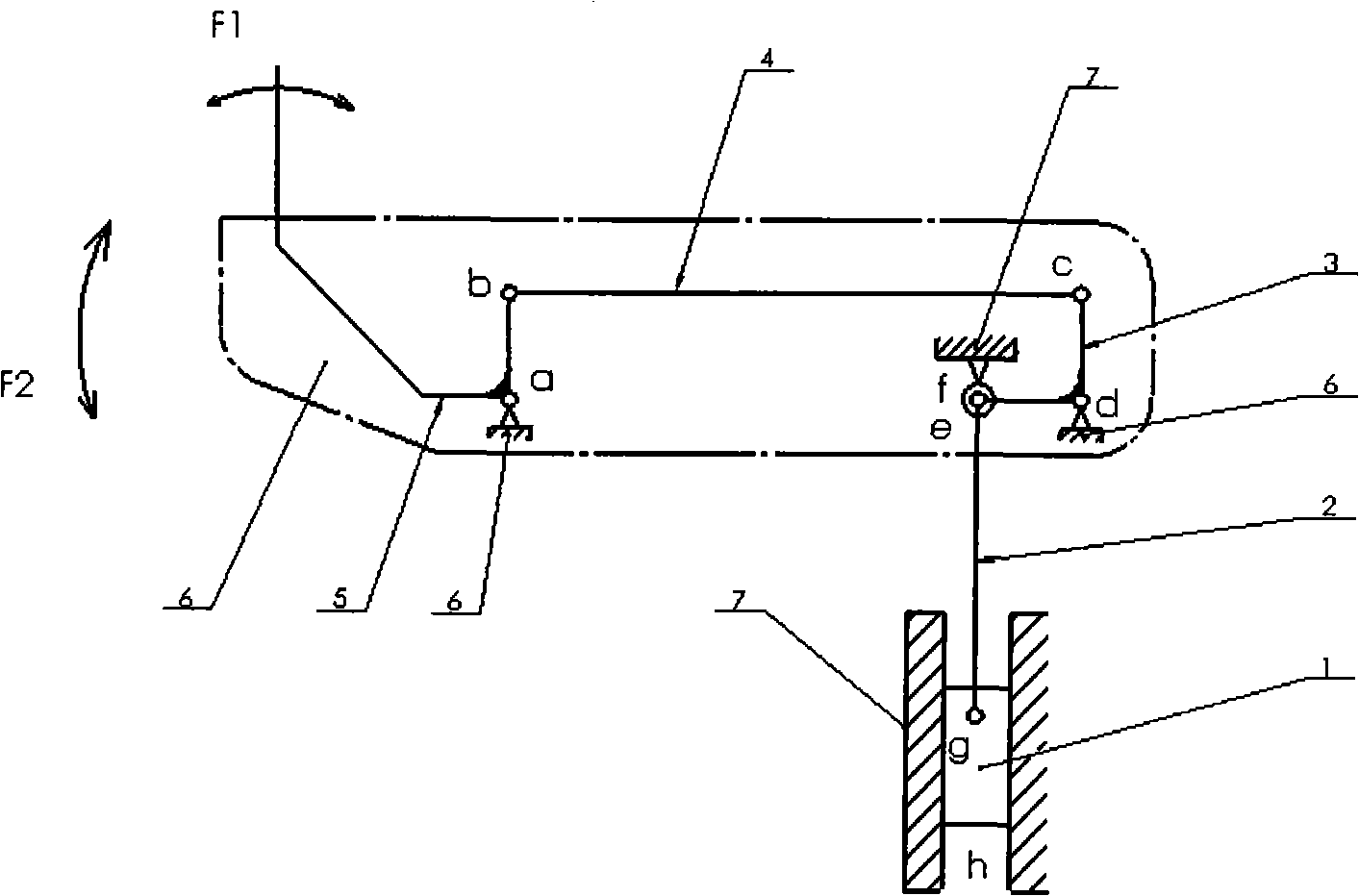

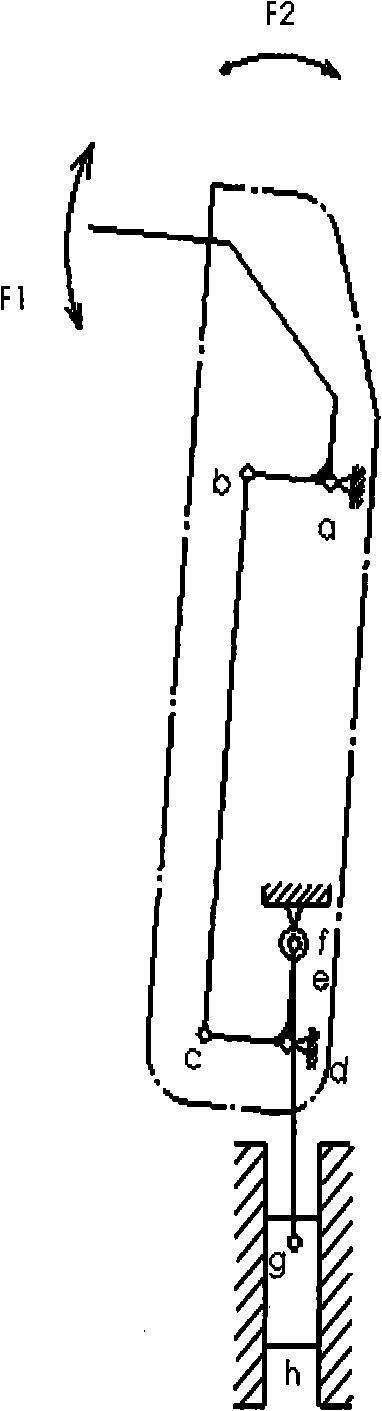

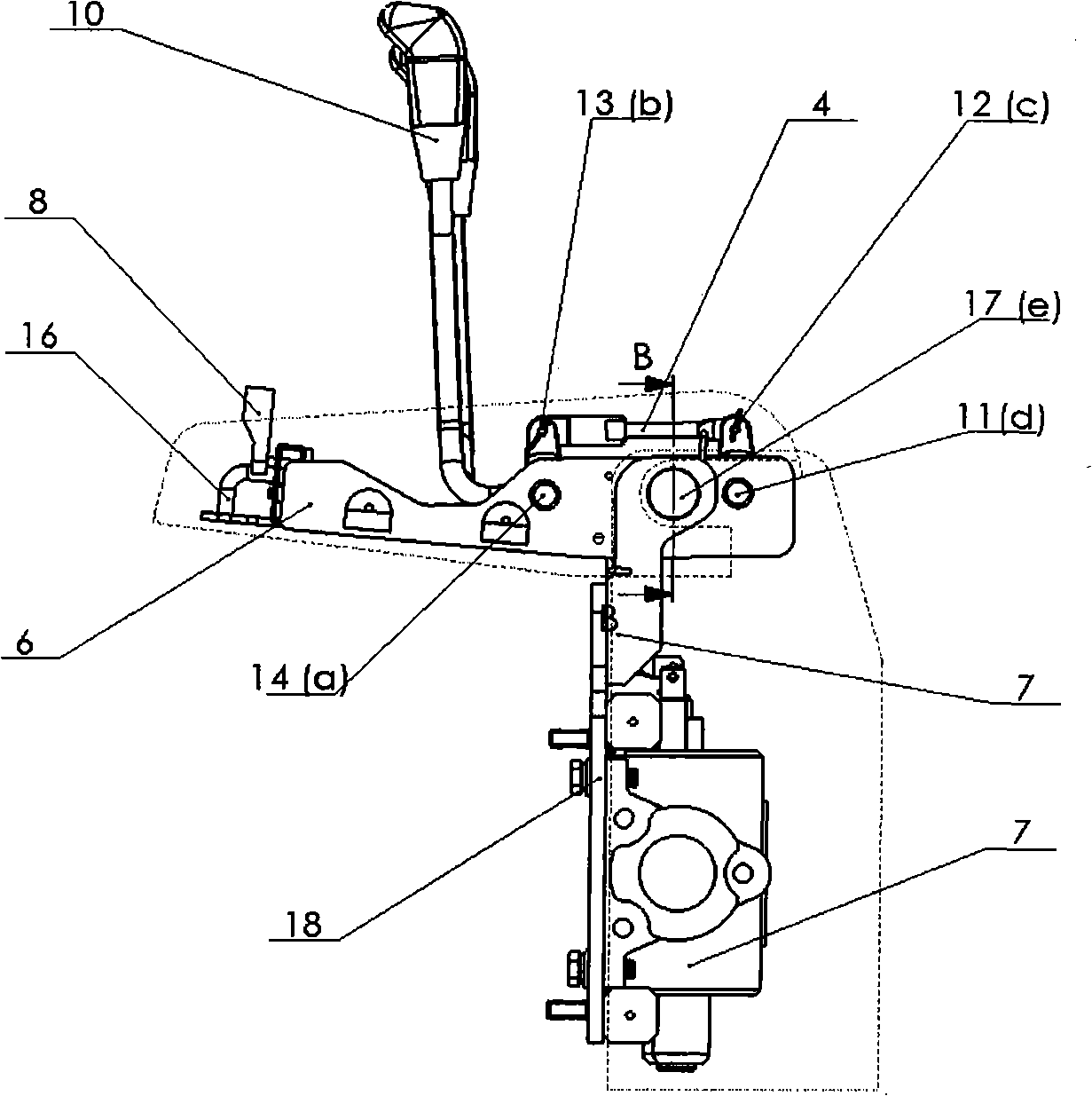

[0024] see Figure 1-7 , The new multi-way valve operating mechanism of the forklift includes a multi-way valve 7, and the multi-way valve 7 is arranged on the forklift body through a multi-way valve bracket 18. It also includes a rectangular frame bracket 6, the corresponding ends of the rectangular frame bracket 6 and the multi-way valve 7 are connected to the hinge frame 3 through the shaft 11, the cross section of the hinge frame 3 is angle steel, and the horizontal sides of the hinge frame 3 are respectively passed through short pins 15 is movably connected with two piston connecting rods 2, and the two piston connecting rods 2 are respectively a forward and backward tilting piston connecting rod and a lifting piston connecting rod. Rod 4, the other ends of the two connecting rods 4 are respectively connected to the front and rear tilt control lever 10 and the lift control lever 5 through the link pin 13, and the front and rear tilt control lever 10 and the lift control l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com