Wire-protecting and de-icing method of unit type high tension power line

A technology of high-voltage transmission lines and ice-melting methods, which is applied to the installation of electrical components, cables, and output power conversion devices. It can solve problems such as high power supply capacity requirements, difficult voltage withstand insulation, and complicated operations, and achieve easy dispersion. Installation and long-term online operation, low insulation cost, and the effect of meeting the requirements of ice protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

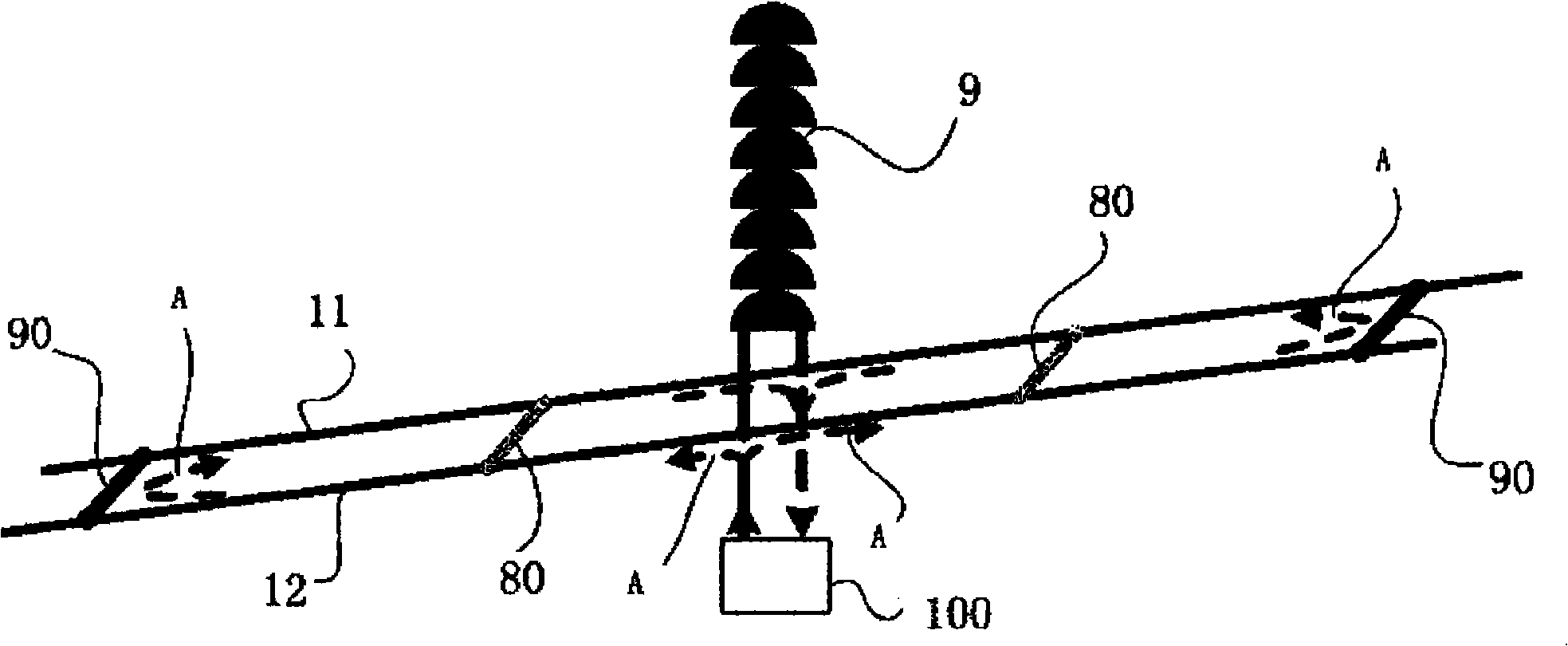

[0032] In the present invention, the unitary high-voltage transmission line protection and ice melting method combines Figure 1 to Figure 4 shown, including the following steps:

[0033] A. Define the same-phase split wires 11 and 12 in a certain section as the line-guaranteed ice-melting unit, and use conductive spacers 90 at both ends of the unit;

[0034] B. Install a wire-guaranteed ice-melting device 100 in the unit, and the wire-guaranteed ice-melting current output by the wire-guaranteed ice-melting device 100 forms a loop between the two conductive spacers 90 and the split conductors 11, 12 and generates The heat realizes line-guaranteed melting of ice.

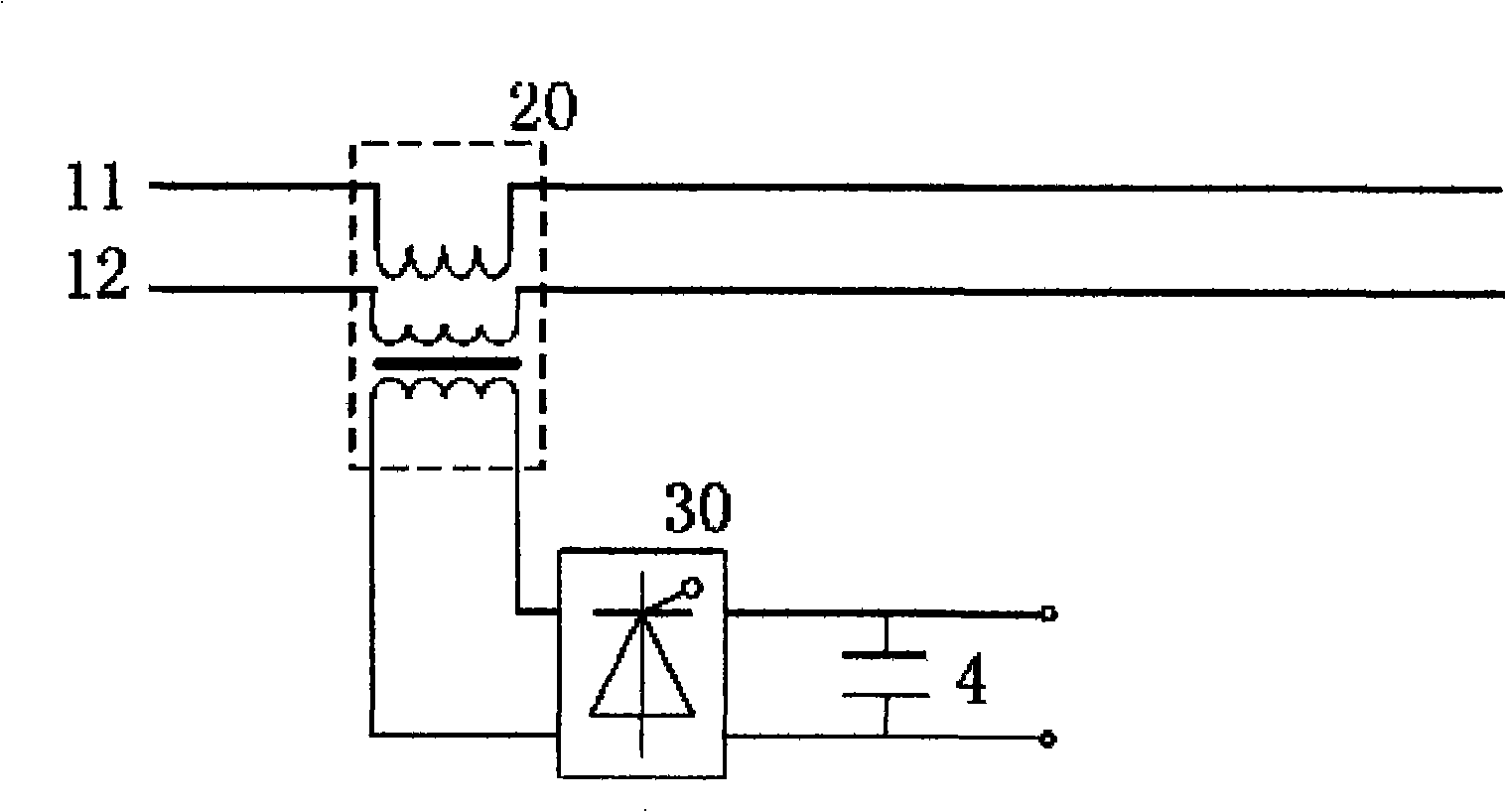

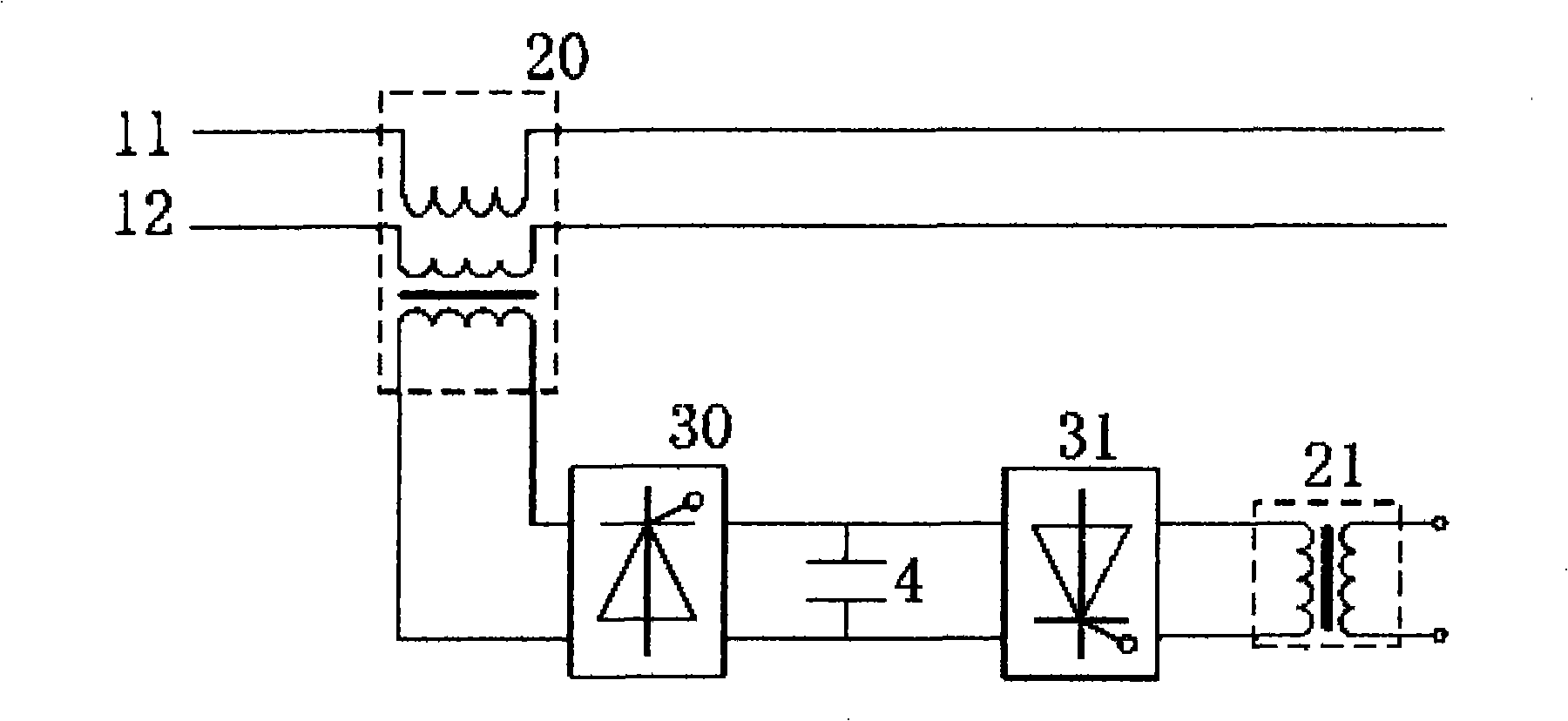

[0035] The line-guaranteed ice-melting device 100 includes a line-guaranteed ice-melting power supply and a line-guaranteed ice-melting current control system.

[0036] The line-guaranteed ice-melting power supply output of the line-guaranteed ice-melting device 100 adopts a DC mode or an AC mode:

[0037] When th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com