Retracting device

A tension spring, stop position technology, applied in furniture parts, home utensils, drawers, etc., can solve the problem of expensive pull-back automatic devices, and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

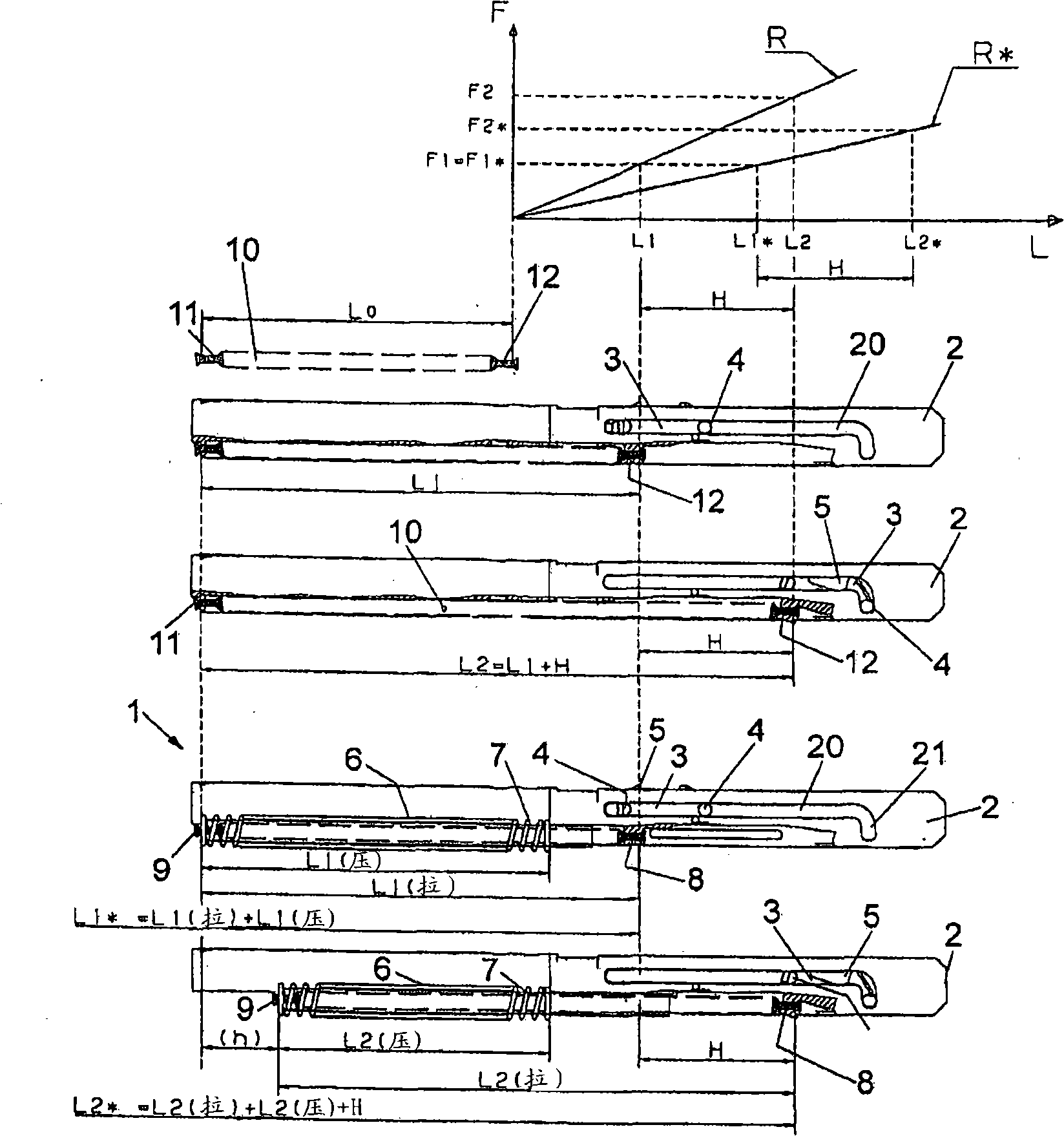

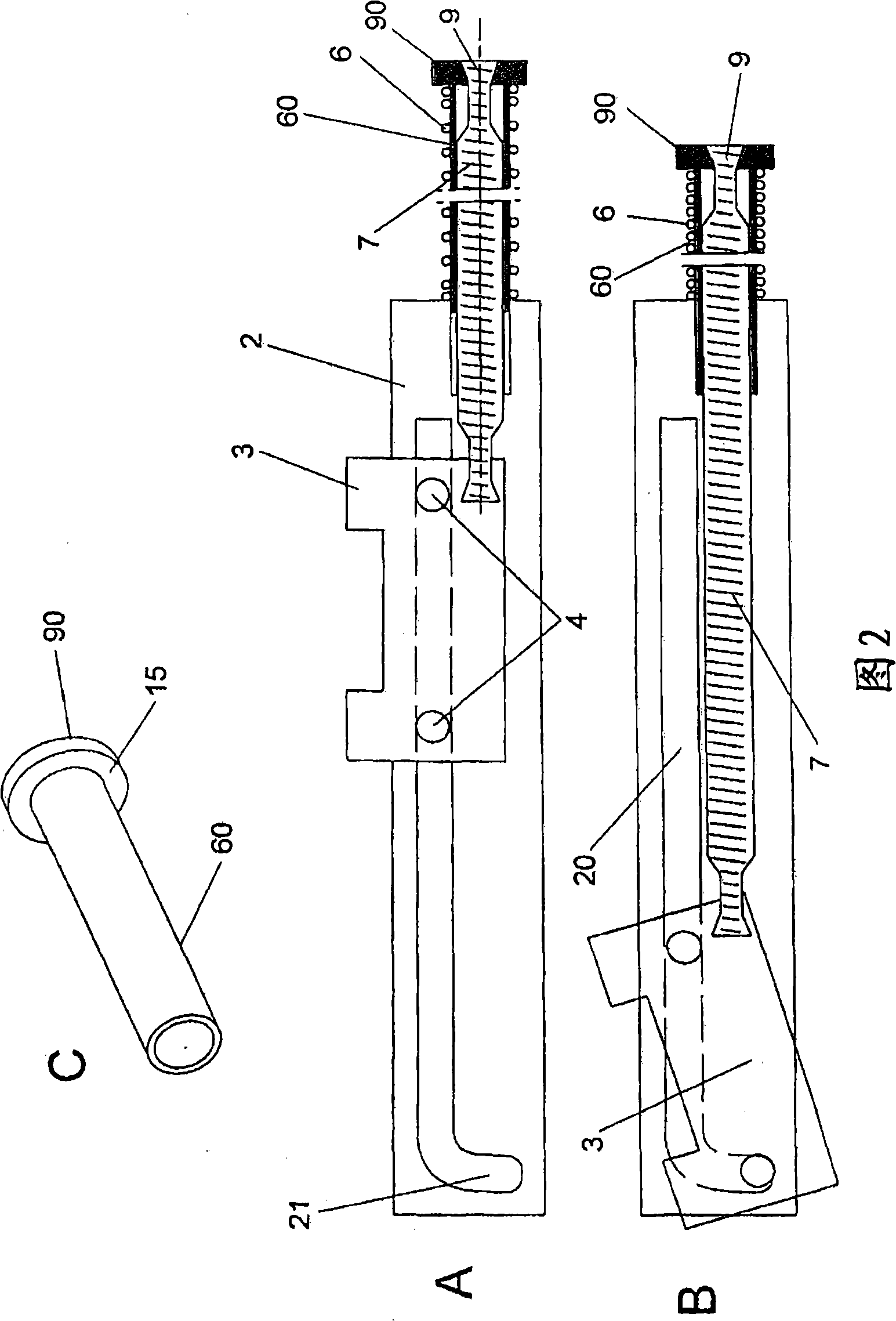

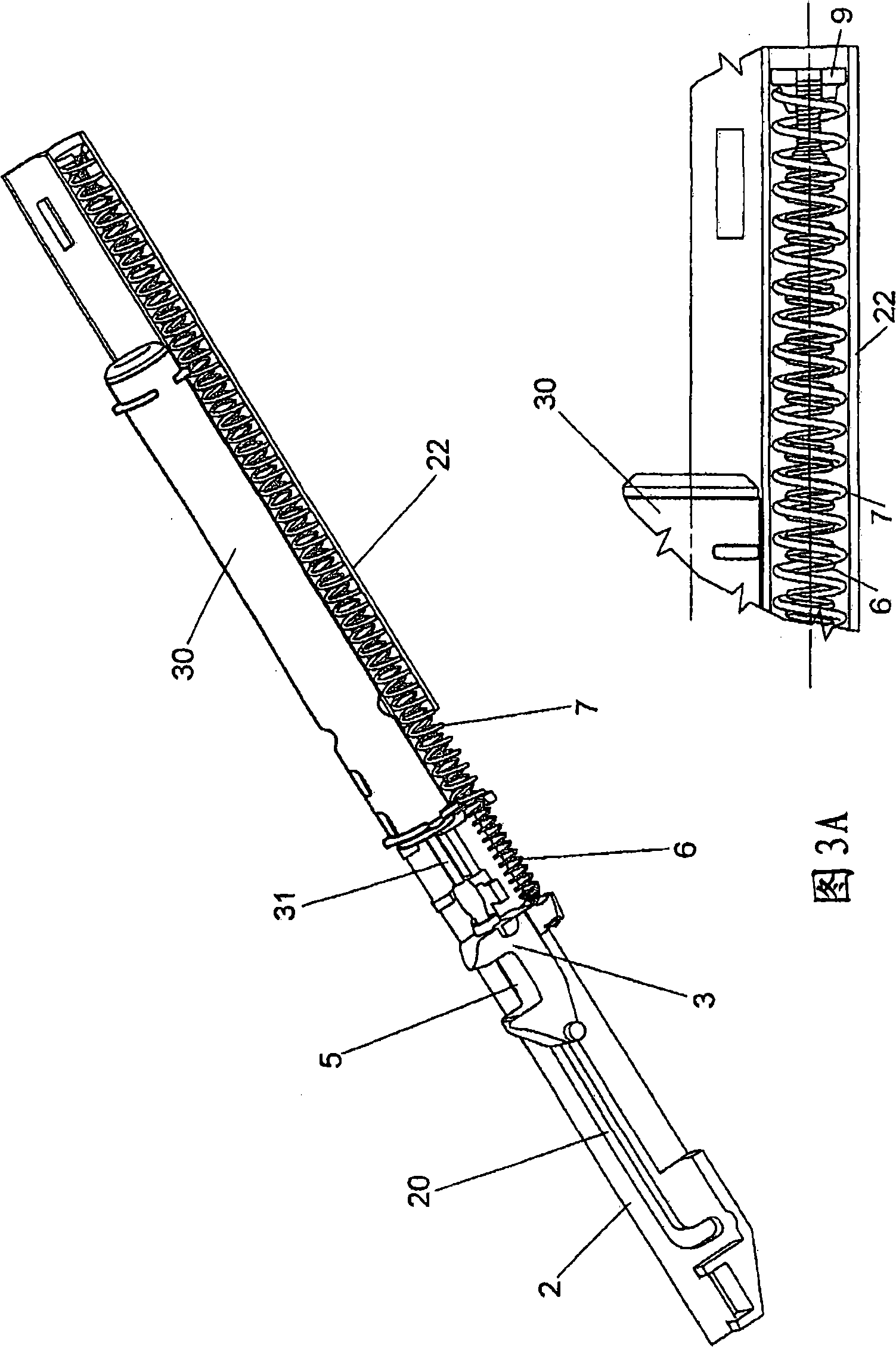

[0018] one in figure 1 The retraction device 1 shown in the lower region of , comprises a housing 2 which can be mounted on a furniture cabinet or on a fixed rail of the extension guide. A curve guide 20 with a curved end section 21 is formed in the housing 2 . A driver 3 is guided in the curve guide 20 and has two pins 4 which engage in the curve guide 20 . A recess 5 is formed on the carrier 3 for a trigger which can be inserted into the recess 5 in order to couple the carrier 3 to a movable furniture part in the region of the curve guide 20 .

[0019] The driver 3 is pretensioned to the left by a compression spring 6 and a tension spring 7 . The compression spring 6 is supported on one side of the housing 2 and is coupled on the opposite side to a connecting piece 9 which in turn is connected to the tension spring 7 . The tension spring 7 is connected to the connecting part 8 with the driver 3 on the side opposite the connecting part 9 .

[0020] figure 1 The upper two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com