Microtextured fuel cell elements for improved water management

A technology of fuel cell and microstructure, which is applied to fuel cell parts, fuel cells, solid electrolyte fuel cells, etc., can solve the problem that the reaction ratio cannot be guaranteed, and achieve the effect of increasing hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following descriptions of the subject matter, preparation, and utilization of the teachings disclosed herein are merely exemplary in nature and are not intended to limit the claims of this application or other applications claiming priority from this application or of patents issued therefrom. The scope, application and use of any particular invention.

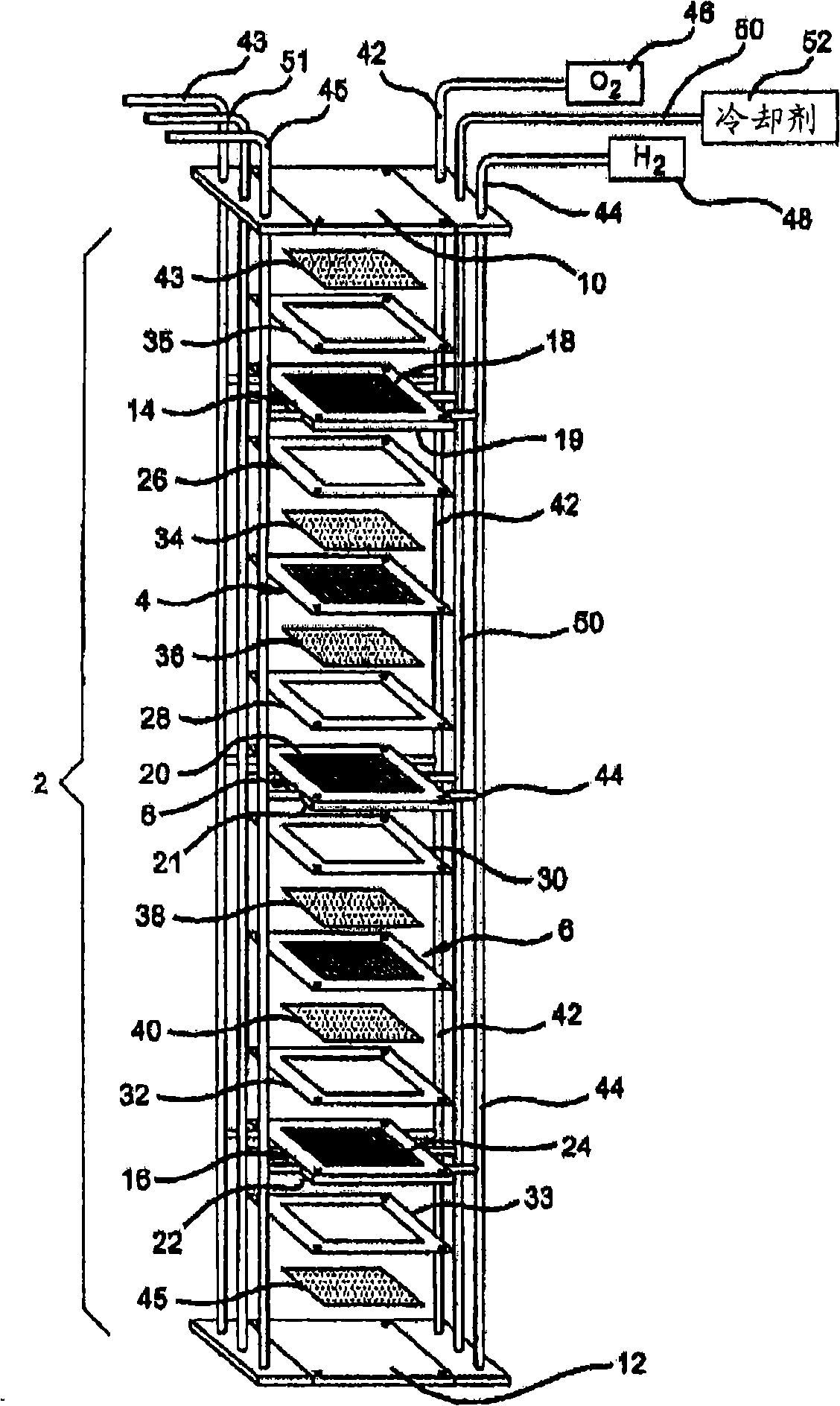

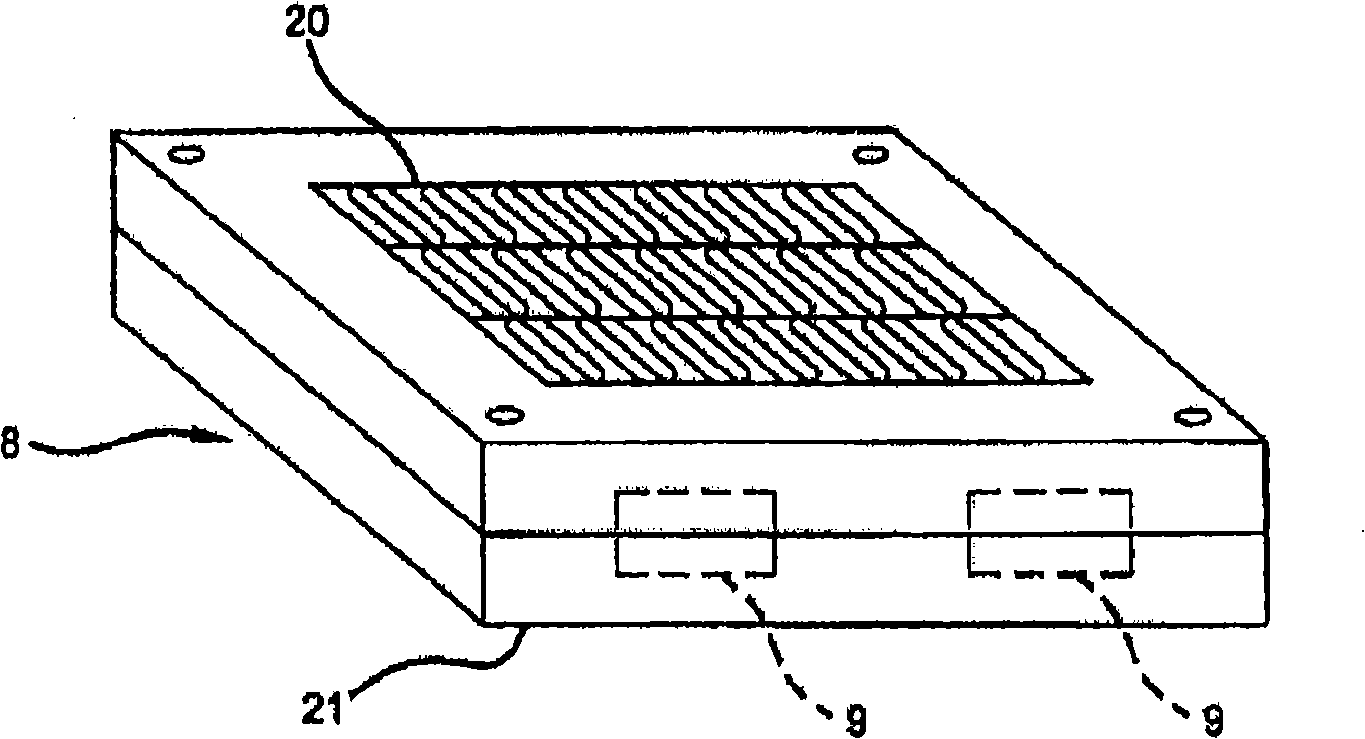

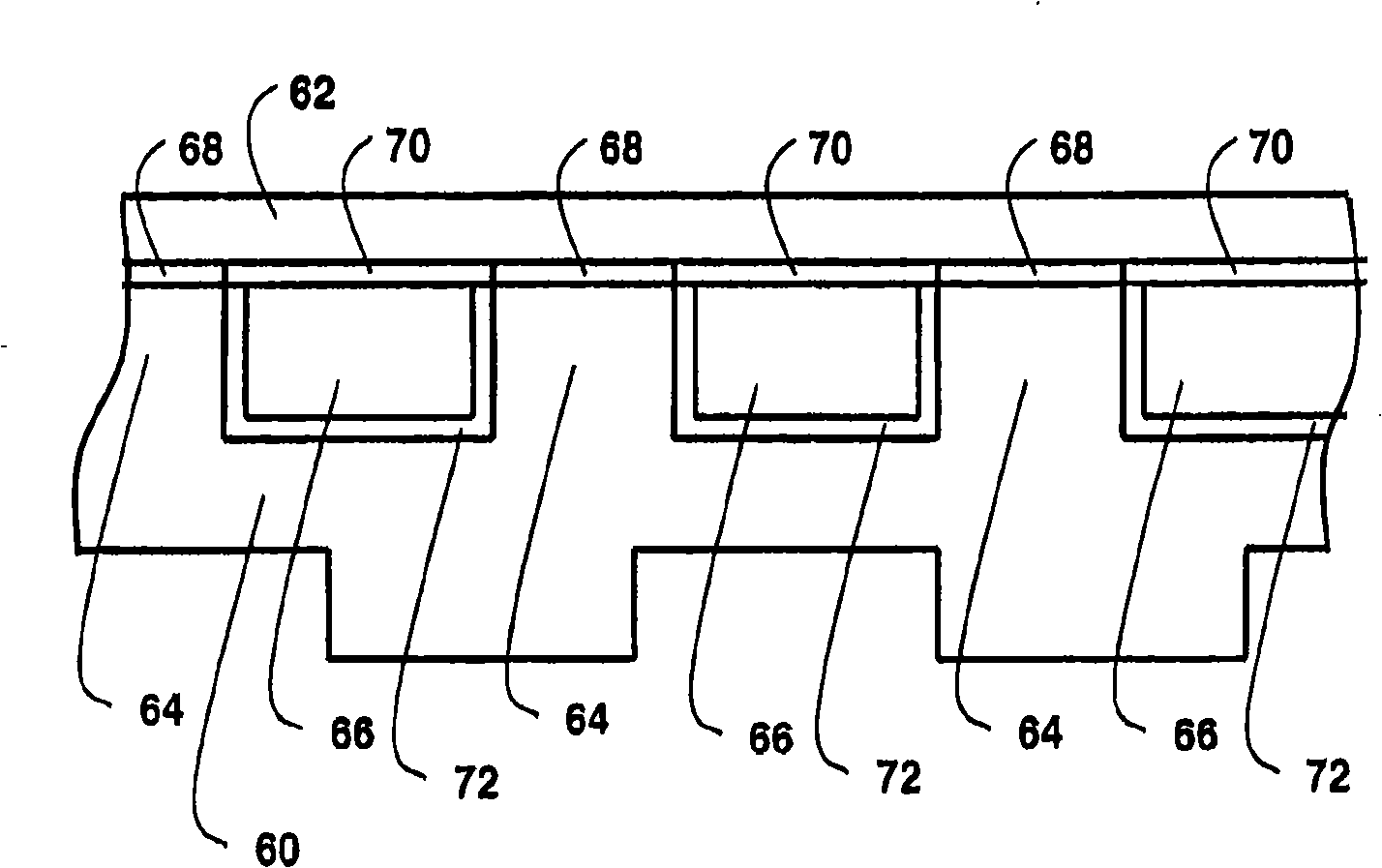

[0029] The present invention provides methods and materials for improving water management in fuel cells by microstructuring fuel cell components including separators and / or gas diffusion media. A method of making a fuel cell includes contacting a separator with a gas diffusion medium to form a covered gas flow field. The separator includes a plurality of lands defining a plurality of flow channels to form a reactant gas flow field, and the gas diffusion media includes a first surface area complementary to the plurality of lands of the separator, and a plurality of flow channels of the separator. and a complementar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com