A milling cutter head and a milling cutter tool with holow spaces for receiving a male element

A technology of milling cutters, cutter heads, applied in the field of milling cutter heads and milling cutter tools with a hollow space for receiving male elements, capable of solving the problems of lack of milling cutter heads, lack of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

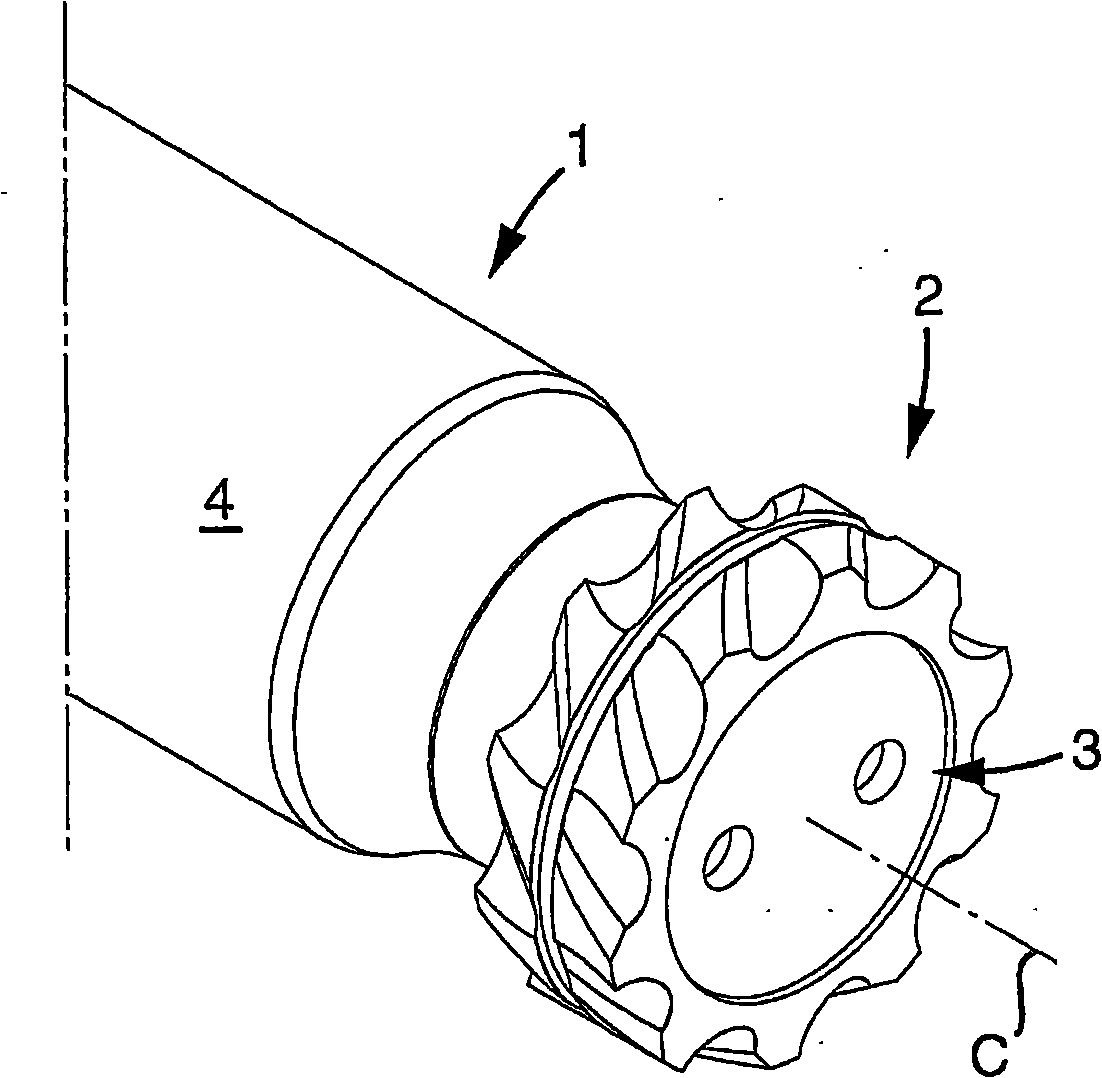

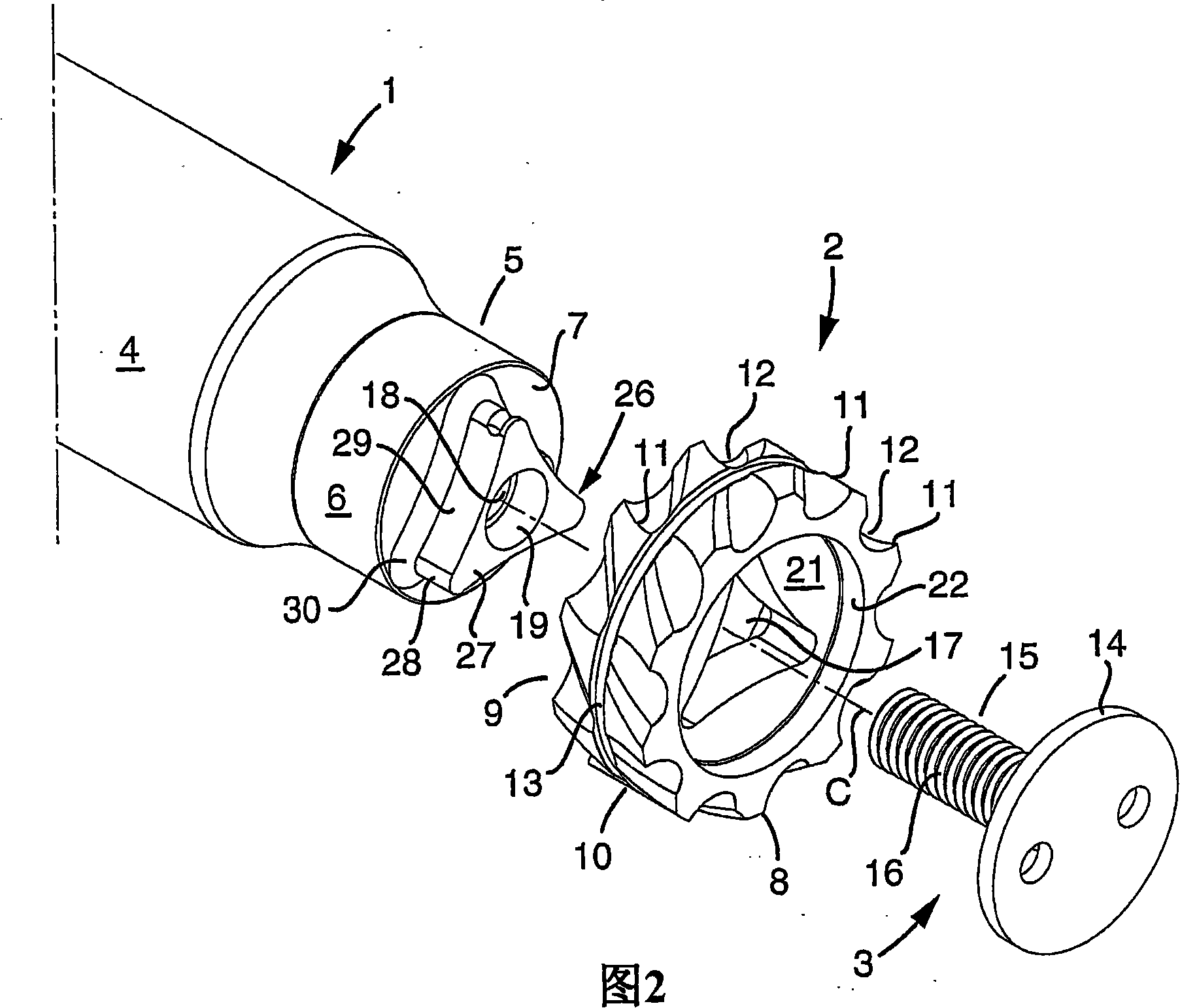

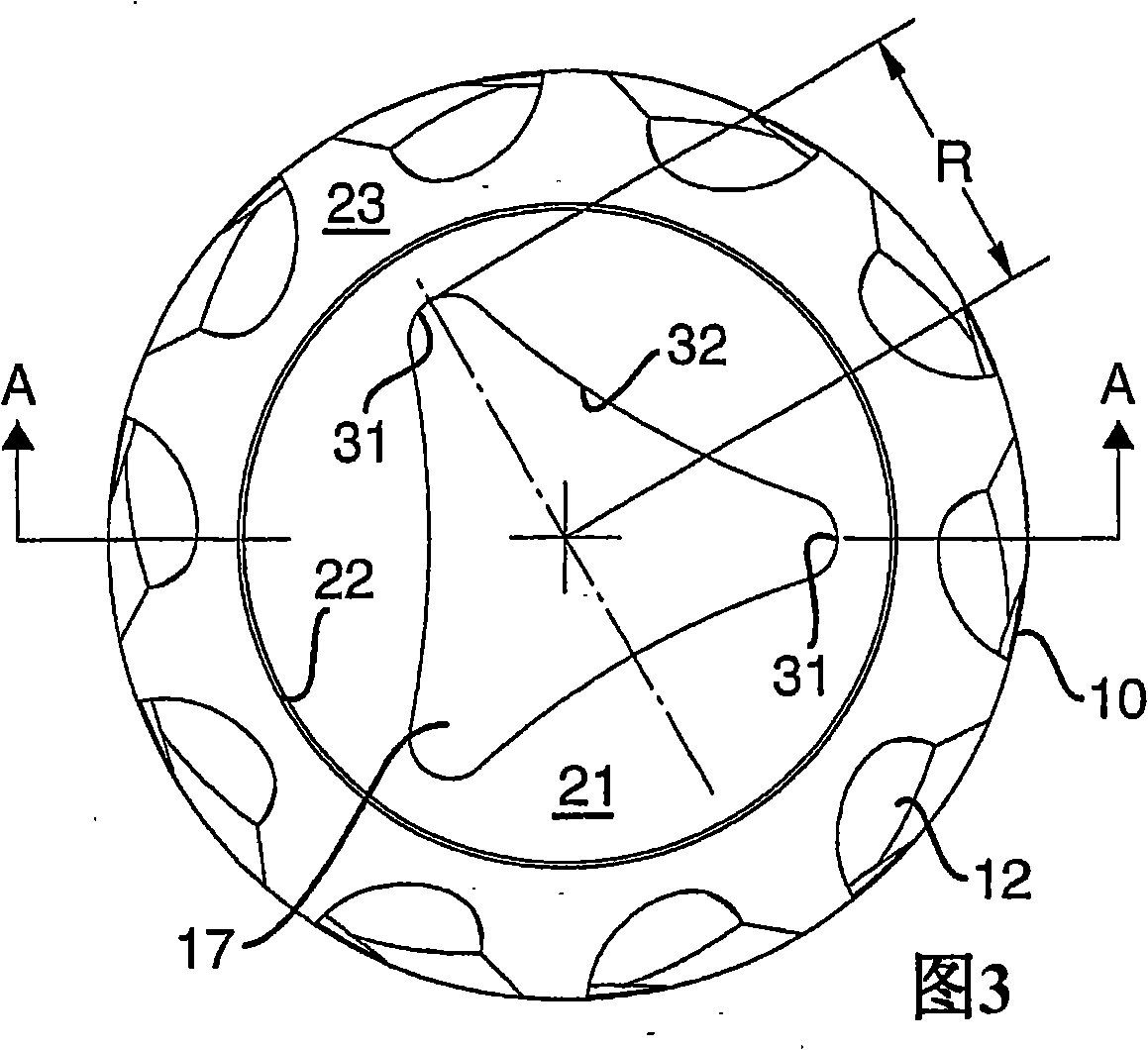

[0018] exist figure 1 And in FIG. 2 , a milling cutter tool made according to the invention is shown, which consists of a rotatable base body 1 and a replaceable milling cutter head 2 . For fastening the milling cutter head to the basic body, fastening means 3 are used, which in the exemplary embodiment shown are in the form of front-mounted screws. In this example, not only the milling cutter head 2 but also the basic body 1 has a rotationally symmetrical basic shape defined by a central axis C about which the tool can rotate. Advantageously, but not necessarily, the base body 1 has an elongated shape, and in this example this shape is defined by the cylindrical envelope surface 4 along the main part of the base body's length. At its front free end, the basic body transforms into a thinner, male element or member 5 , which is delimited by a rotationally symmetrical envelope surface 6 and a planar end face 7 . Most suitably, the envelope surface 6 is cylindrical.

[0019] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com