Phase insulator

A technology of interphase insulators and insulating sheets, which is applied in the direction of winding insulation materials, winding insulation shape/style/structure, etc., and can solve problems such as inability to ensure interphase insulation at coil ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

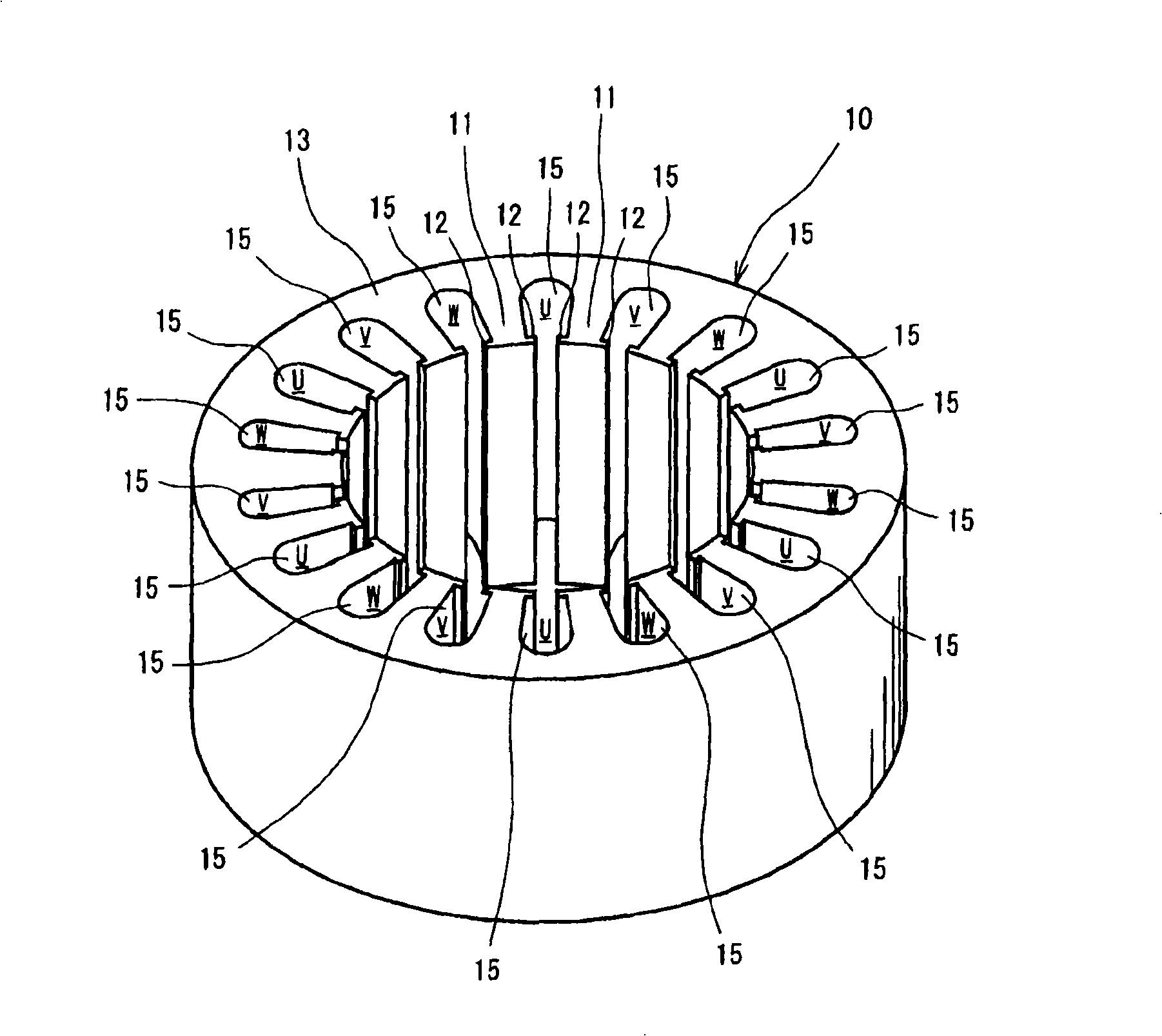

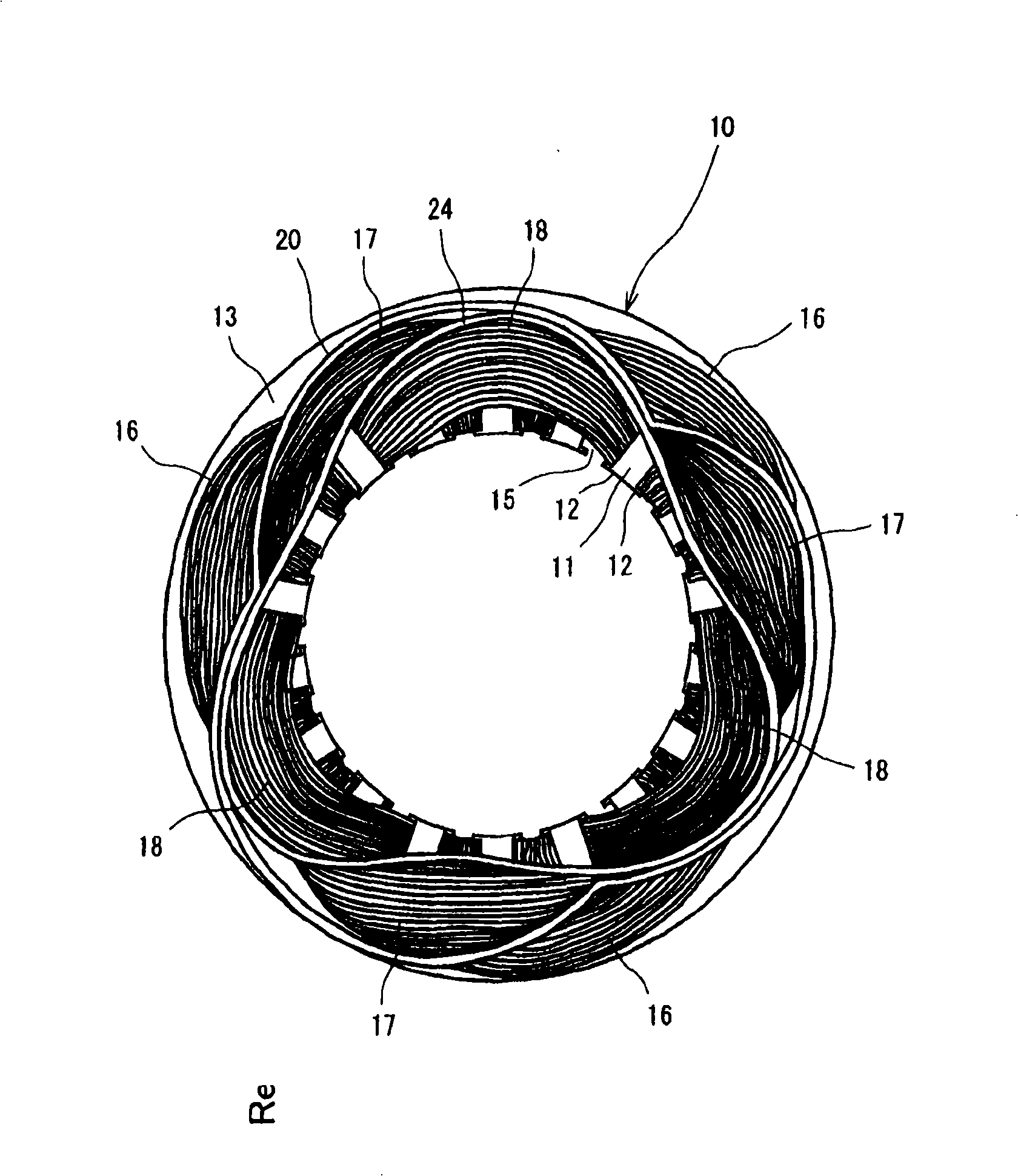

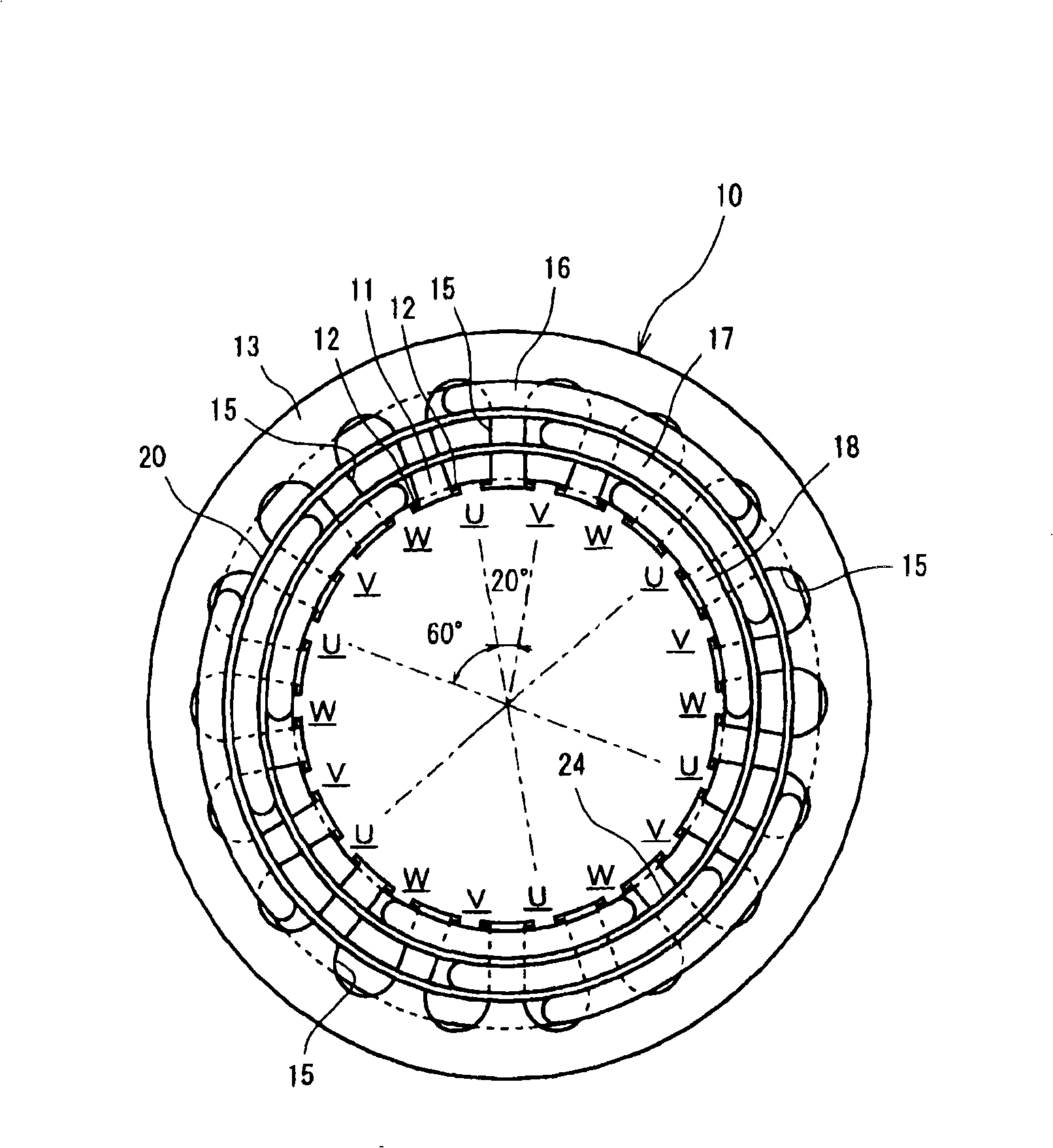

[0016] The following will refer to Figures 1 to 6 A preferred embodiment according to the present invention is described. In this preferred embodiment, the stator core of the stator is incorporated into an electric motor with three-phase distributed windings for an electric compressor. Such as figure 1 As shown, the stator core 10 is formed in a substantially cylindrical shape. The stator core 10 has end surfaces 13 , 14 at both axial end sections, respectively. The end surfaces 13 , 14 are perpendicular to the axial direction of the stator core 10 . figure 1 is a perspective view, and figure 1 The end surface 13 is shown in . The teeth 11 are formed on the inner peripheral surface of the stator core 10 and are arranged in the circumferential direction of the stator core 10 . The teeth 11 protrude toward the axial center of the stator core 10 .

[0017] Each tooth 11 has a protruding portion 12 on both sides of its tip. The protruding portion 12 protrudes in the circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com