Drives and exhaust gas recirculation valves for assemblies of internal combustion engines

A technology of exhaust gas recirculation valve and driving device, which is applied in the direction of exhaust gas recirculation, electromechanical devices, engine starting, etc., can solve the problems of high assembly cost, difficult gasket fixing, etc., and achieve improved life, weakened transmission, strong spring action or elastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Identical features are provided with the same reference numerals in all figures.

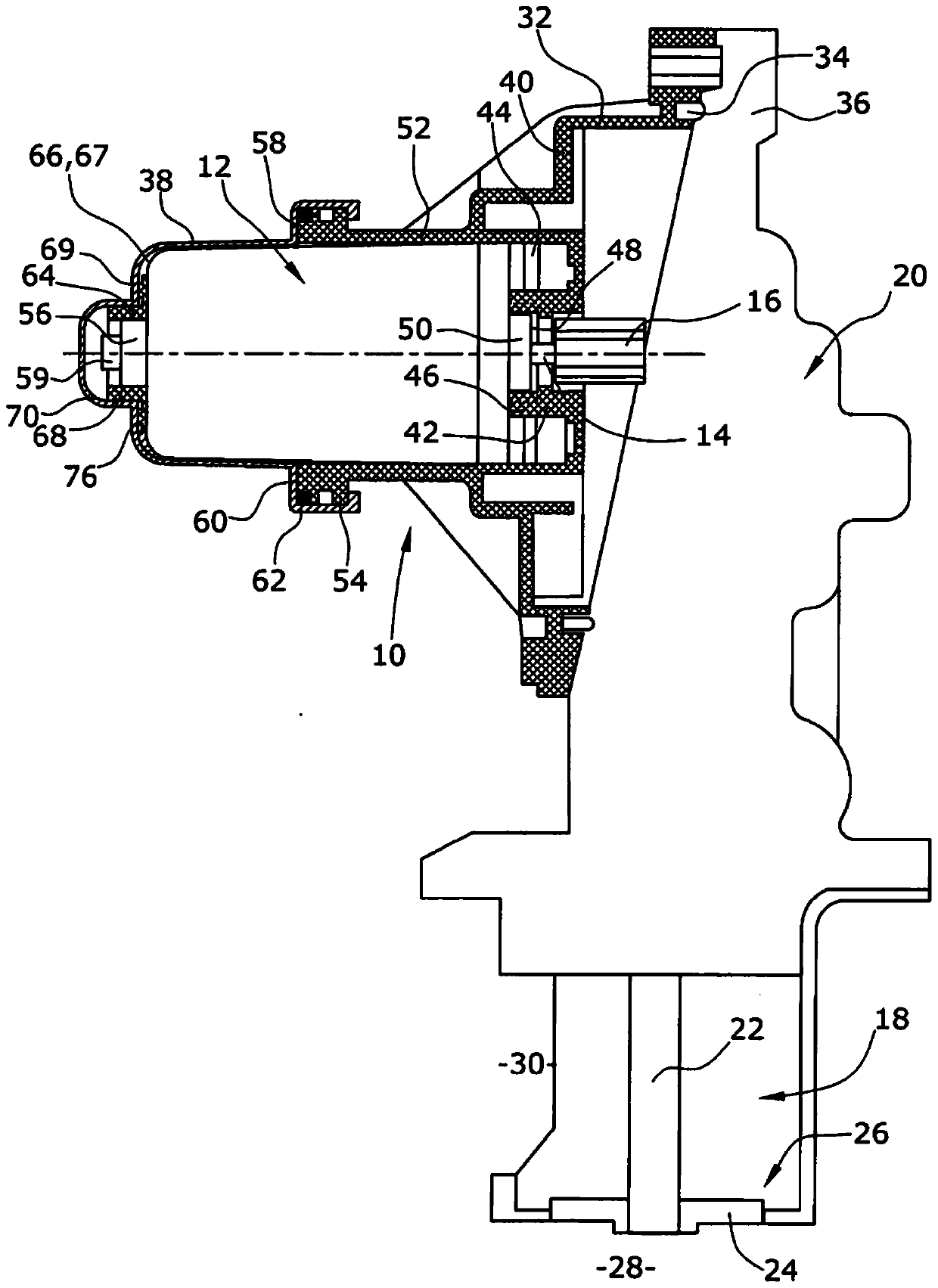

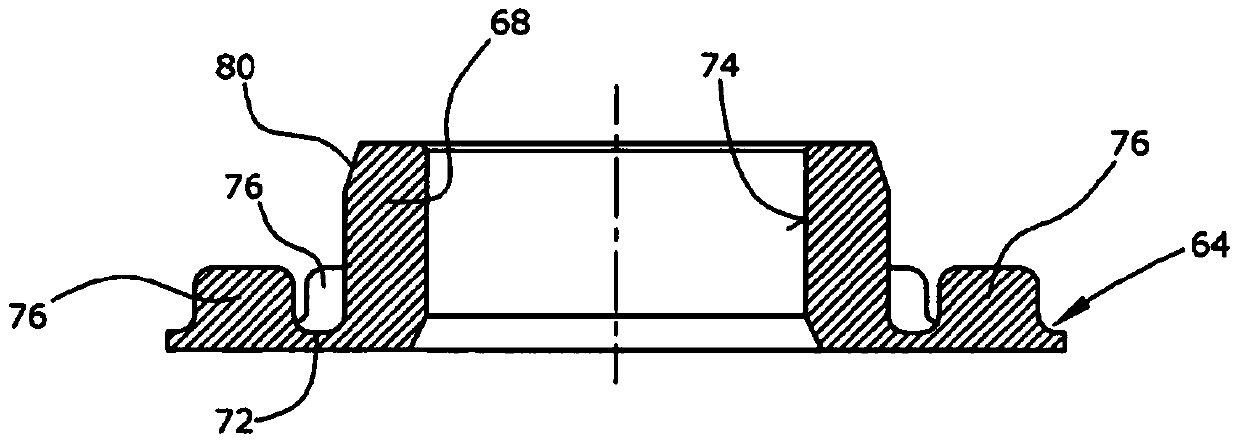

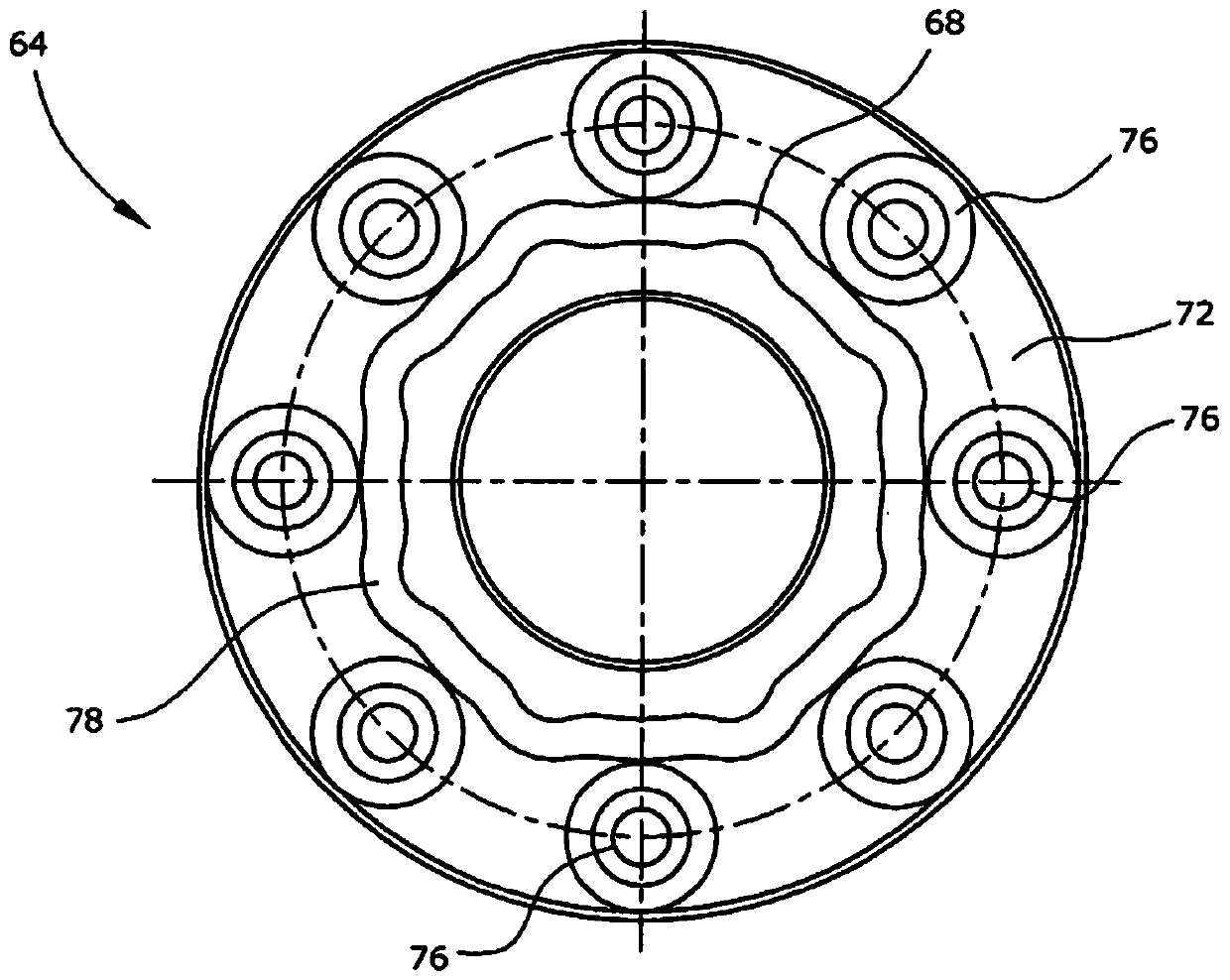

[0029] exist figure 1 In , a drive device is shown which has a housing 10 in which a drive element 12 in the form of an electric motor is arranged. In the present exemplary embodiment, a drive pinion 16 for actuating the exhaust gas recirculation valve 18 via the transmission 20 is provided in a rotationally fixed manner on the drive shaft 14 of the electric motor 12 . The exhaust gas recirculation valve 18 has a valve disk 24 arranged on a valve stem 22 which controls a passage 26 between an inlet 28 and an outlet 30 in a known manner. However, the drive device can also be used for operation or for driving pumps or valves.

[0030] The housing 10 shown is composed of several parts and comprises a fixed receiving part 32 , shown in section, and a cover 38 fixed on the receiving part 32 , which is fixed with a seal 34 in between. on the transmission housing portion 36 . The receiving p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com