Tire manufacturing method for improving the uniformity of a tire

A uniformity and tire technology, applied in tires, household appliances, other household appliances, etc., can solve problems such as severe vehicle vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

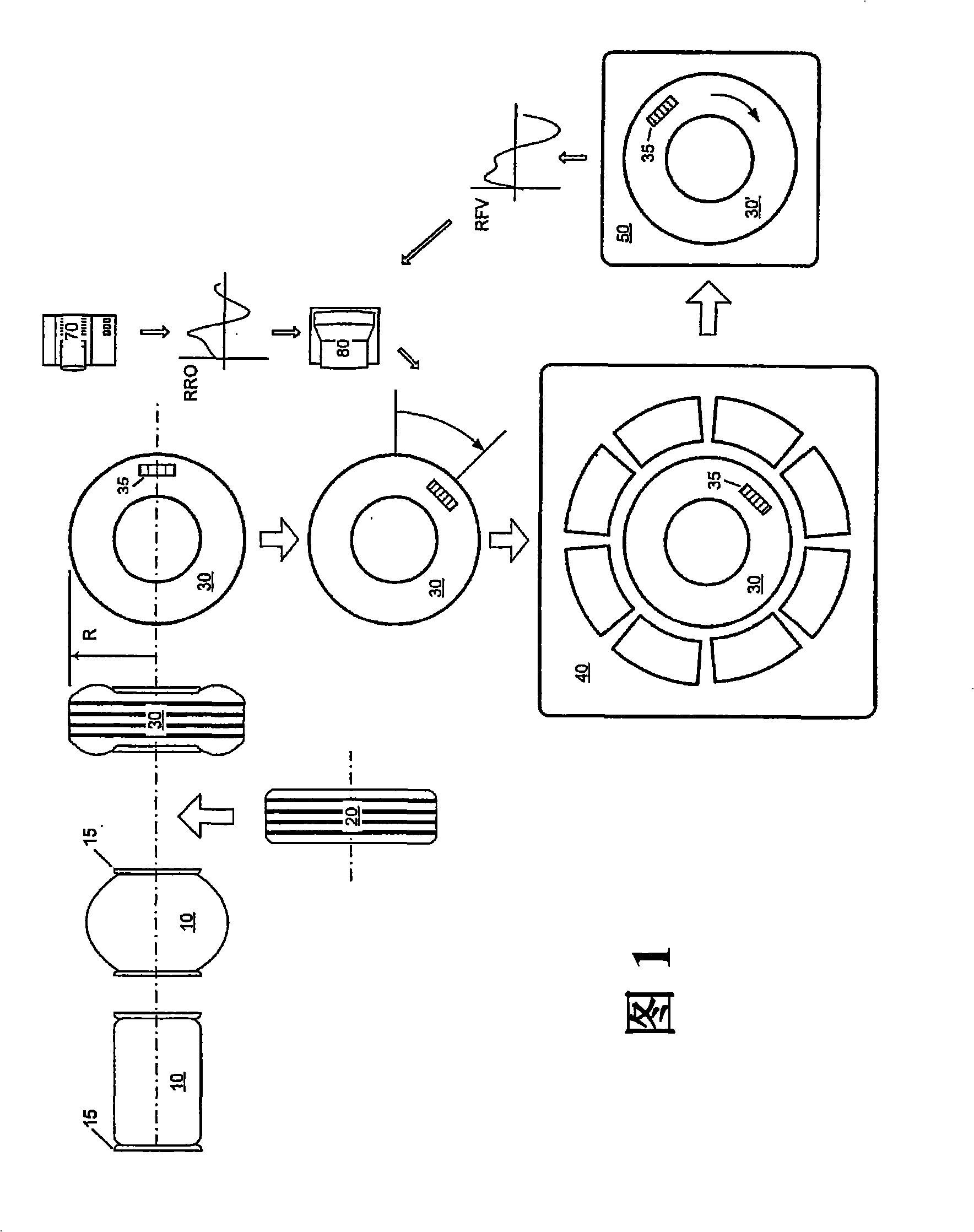

[0020] Reference will now be made in detail to typical modes of the invention, which are one or more of the modes shown in the drawings. Each example described is an explanation of the invention, but does not mean that the invention is limited thereto. Throughout this specification, features illustrated or described in one introduction may be used in other descriptions. Common features explained in whole or in part are denoted by like reference numerals in the figures.

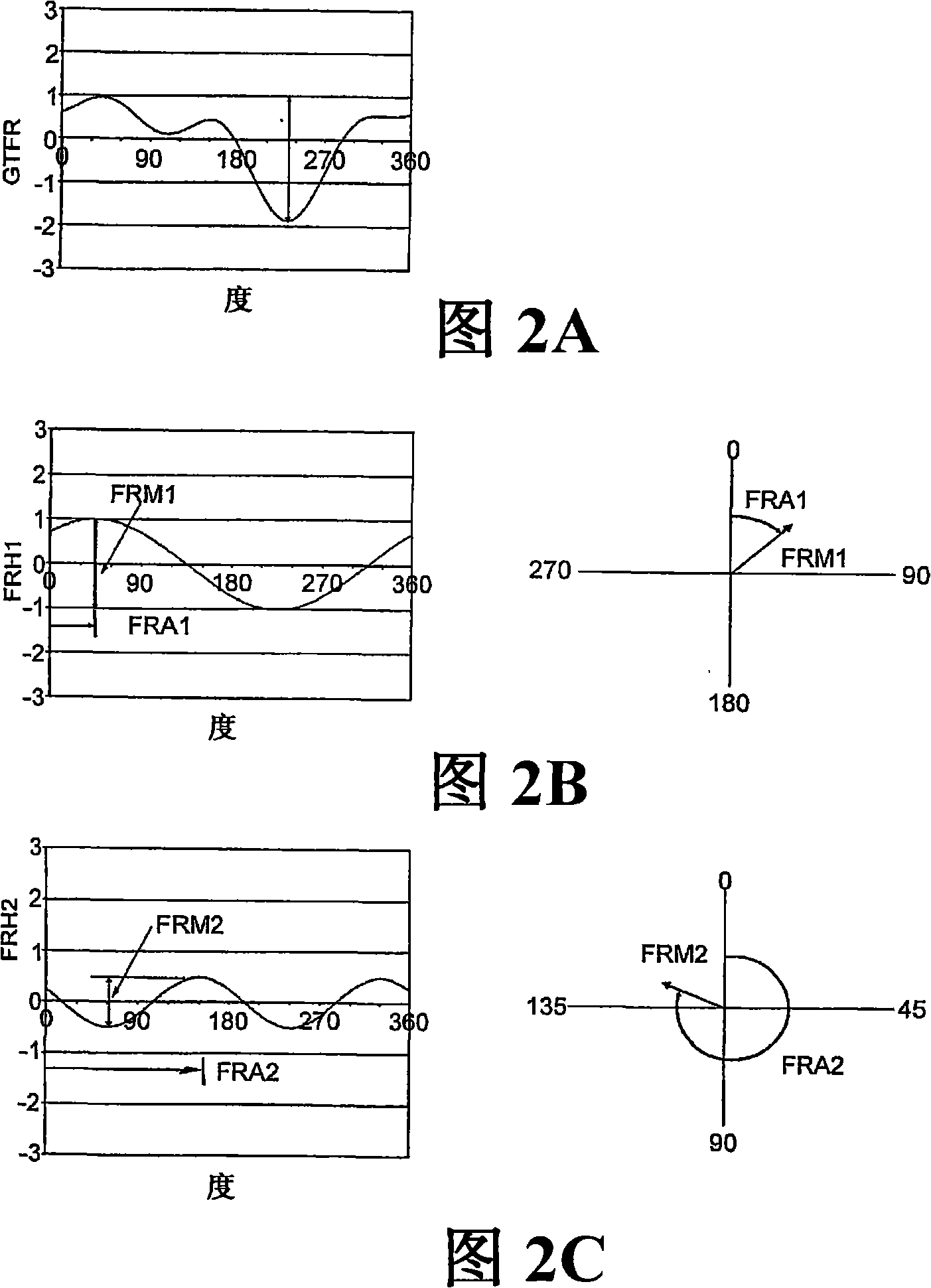

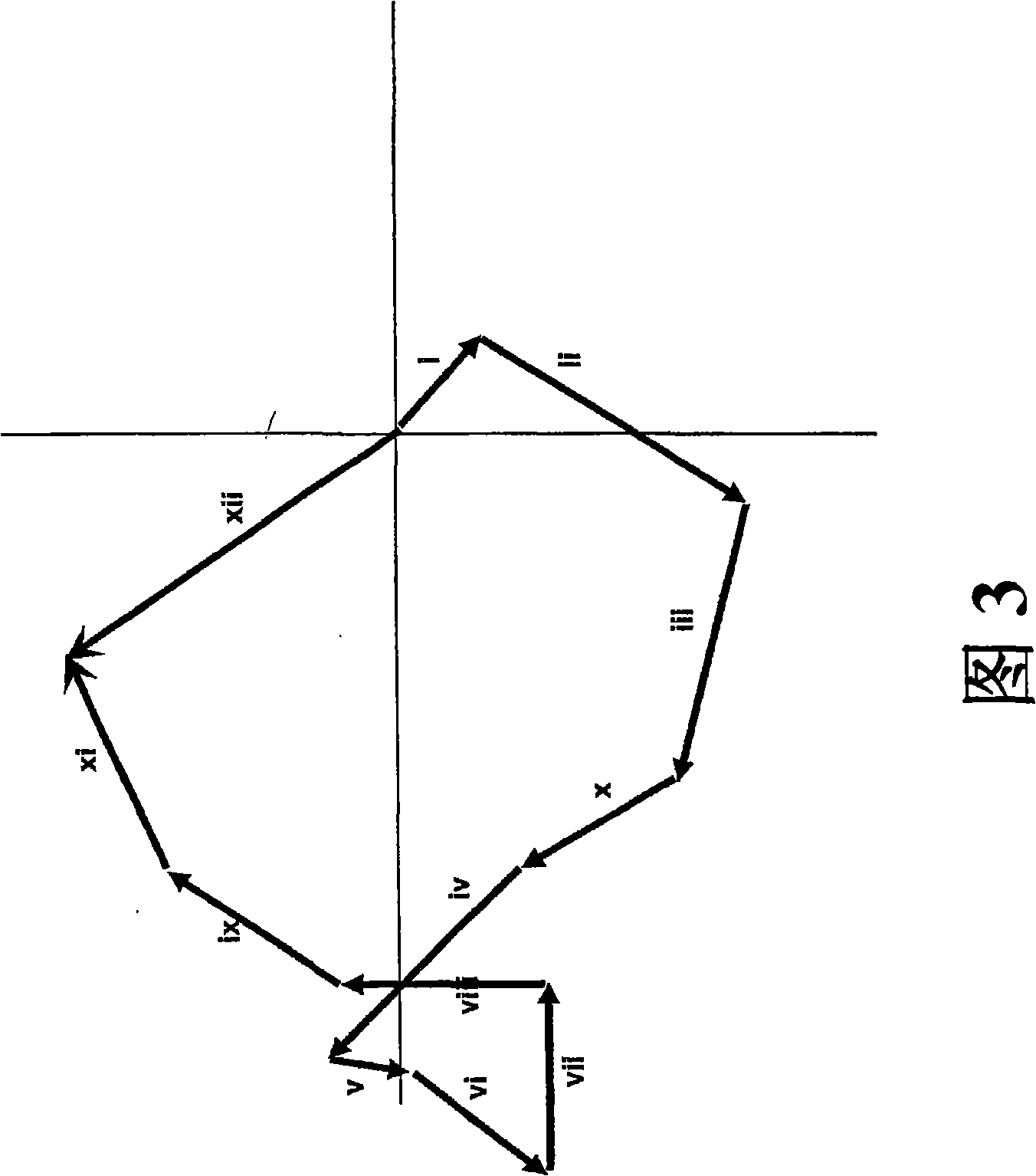

[0021] Modern pneumatic tires are usually manufactured with great care and accuracy. The goal of the tire designer is to produce a tire free of circumferential and tangential non-uniformity. However, despite the best intentions of the designer, since the tire production process involves many steps, these steps can lead to various non-uniformities. One obvious non-uniformity is that the tire may not be perfectly round (radial run-out or RRO). Another form of non-uniformity is radial force fluctuation (RFV)....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com