Double-sided adhesive sheet

An adhesive sheet, double-sided technology, applied in the direction of adhesive type, acid copolymer adhesive, film/sheet adhesive, etc., can solve problems such as insufficient and reduced adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

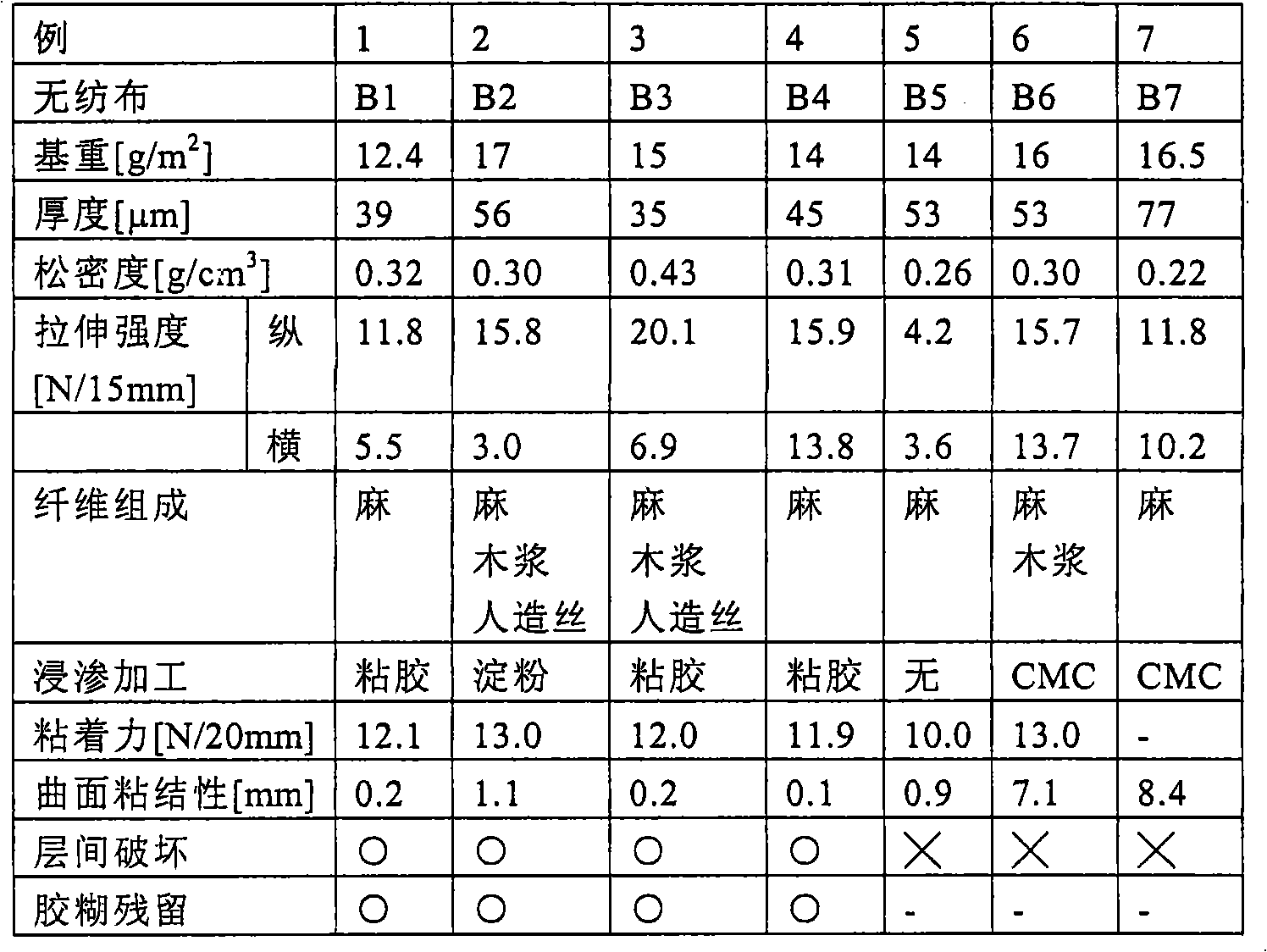

[0041] Hereinafter, several examples related to the present invention will be described, but the present invention is not limited to the examples described above. In addition, in the following description, "part" and "%" are mass basis unless otherwise indicated.

[0042]

[0043] In the reaction vessel that has condensation pipe, nitrogen inlet pipe, thermometer and stirrer, drop into 2,2'-azobis[N-(2-carboxyethyl)-2-methylpropionamidine] hydrate (initiator ) (product of Wako Pure Chemical Industries, Ltd., trade name "VA-057") 0.279 g and ion-exchanged water 100 g, and stirred for 1 hour while introducing nitrogen gas. The reaction system was kept at 60°C, and 29 parts of butyl acrylate, 67 parts of 2-ethylhexyl acrylate, 4 parts of acrylic acid, 3-methacryloxypropyltrimethoxy Add 0.02 parts of silane (manufactured by Shin-Etsu Chemical Co., Ltd., trade name "KBM-503"), 0.033 parts of dodecanethiol (chain transfer agent) and 2 parts of polyoxyethylene sodium lauryl sulfat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap