Clapping tunable electromagnetic release

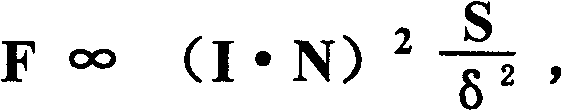

An electromagnetic release and snap-fit technology, which is applied in the direction of protection switch operation/release mechanism, etc., can solve the problems of limited adjustment ability, inability to play a protective role, insensitive tripping of electromagnetic release, etc., to achieve sensitive tripping. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

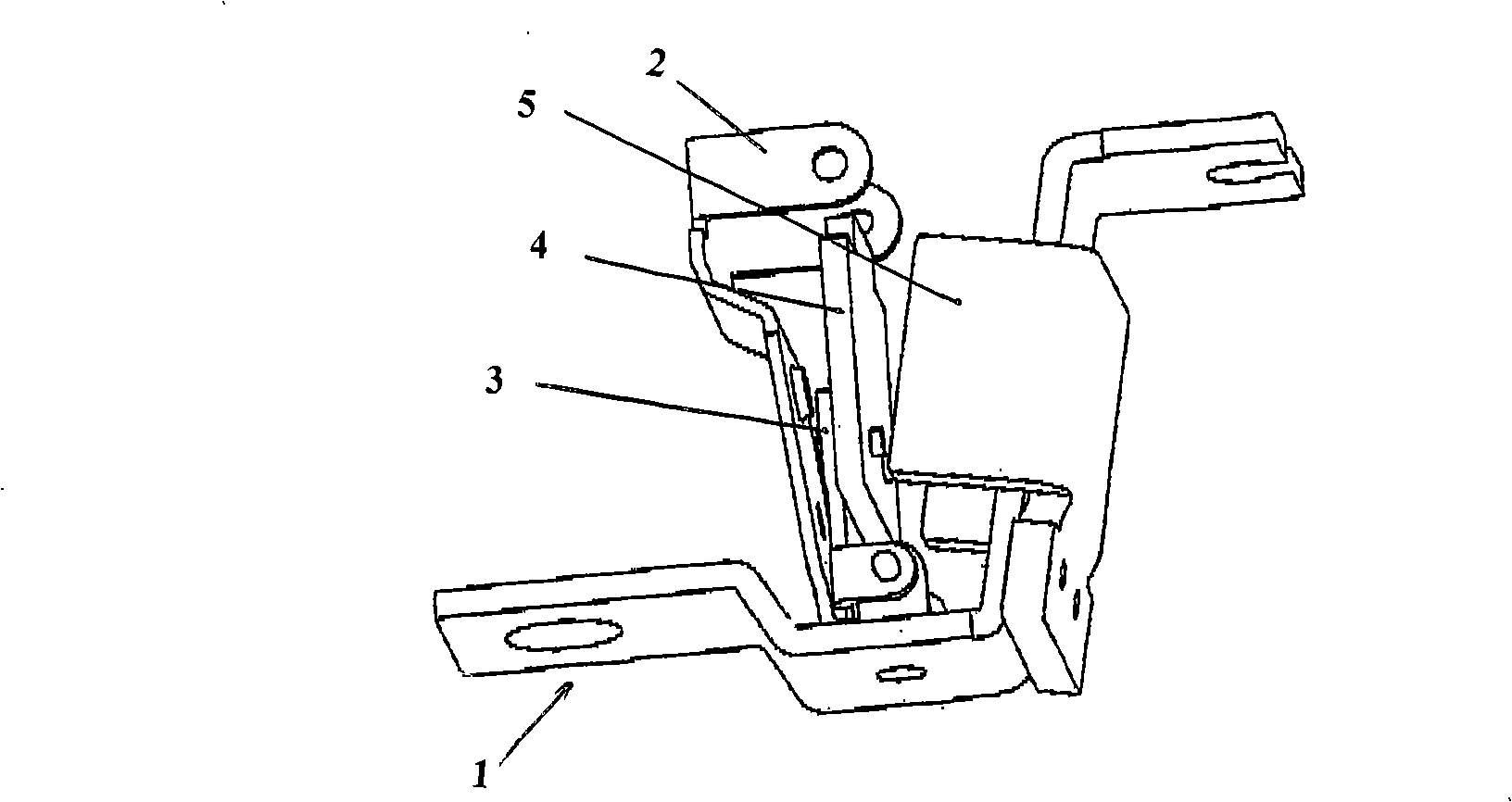

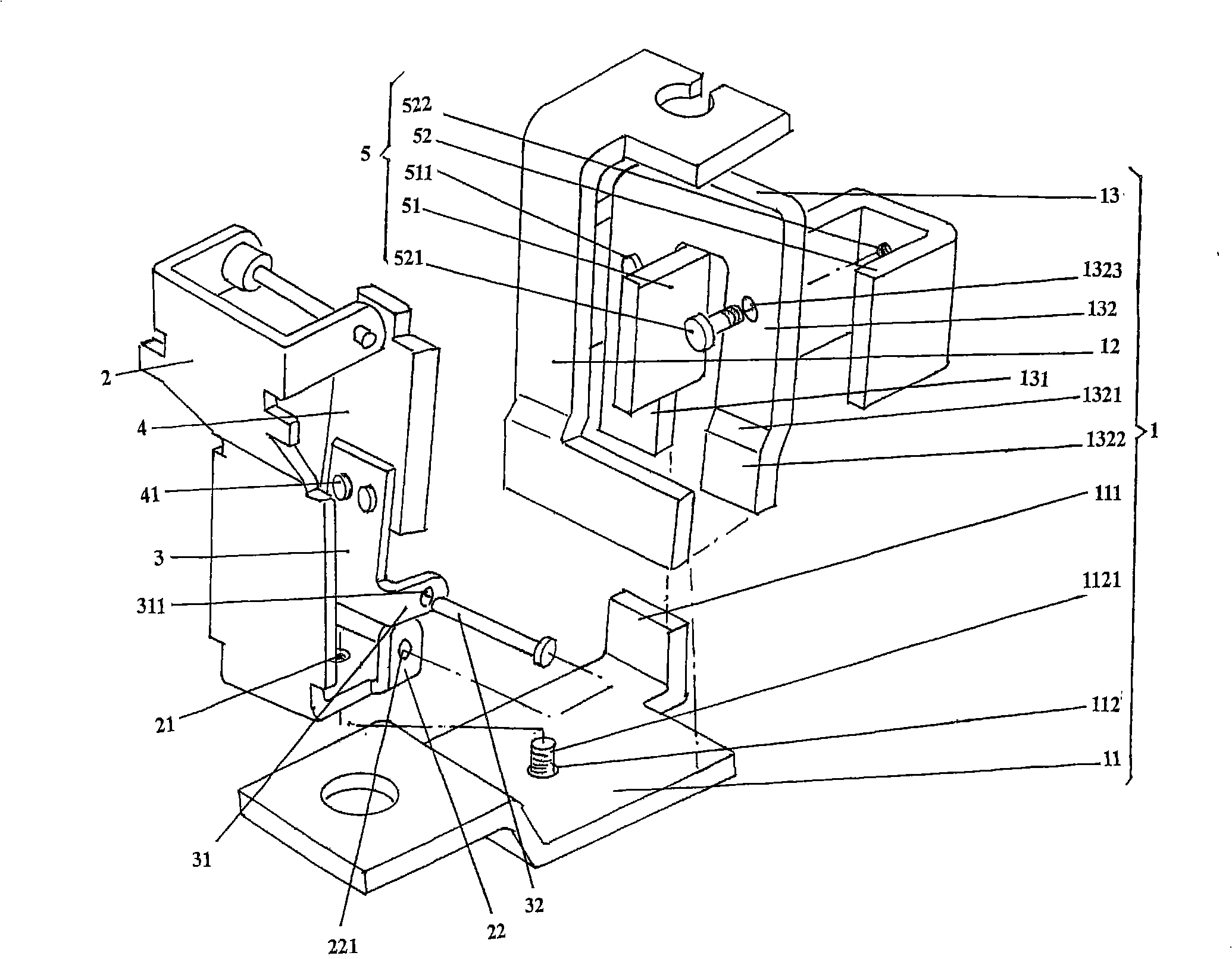

[0015] please see figure 2 , the current-carrying wire 1 composed of the first, second, and third conductive rods 11, 12, 13 is given. Taking the current position shown in the figure as an example, a first screw is provided in the near middle of the first conductive rod 11 hole 112, and the right end of the first conductive rod 11 is processed with a first bent portion 111 on one side, and the first bent portion 111 and the first conductive rod 11 preferably form a right angle relationship of 90°. The lower end of the second conductive rod 12 is welded with the second arm 132 by preferably welding with the second arm 132 at the position corresponding to the lower end of the second arm 132 of the third conductive rod 13, that is, the welding plane 1322 of the second arm 132, so that The second and third conductive rods 12 and 13 are integrated, and the lower end of the first arm 131 of the third conductive rod 13 is welded to the first bending portion 111, so that the first, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com