Patents

Literature

47results about How to "Large magnetic area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

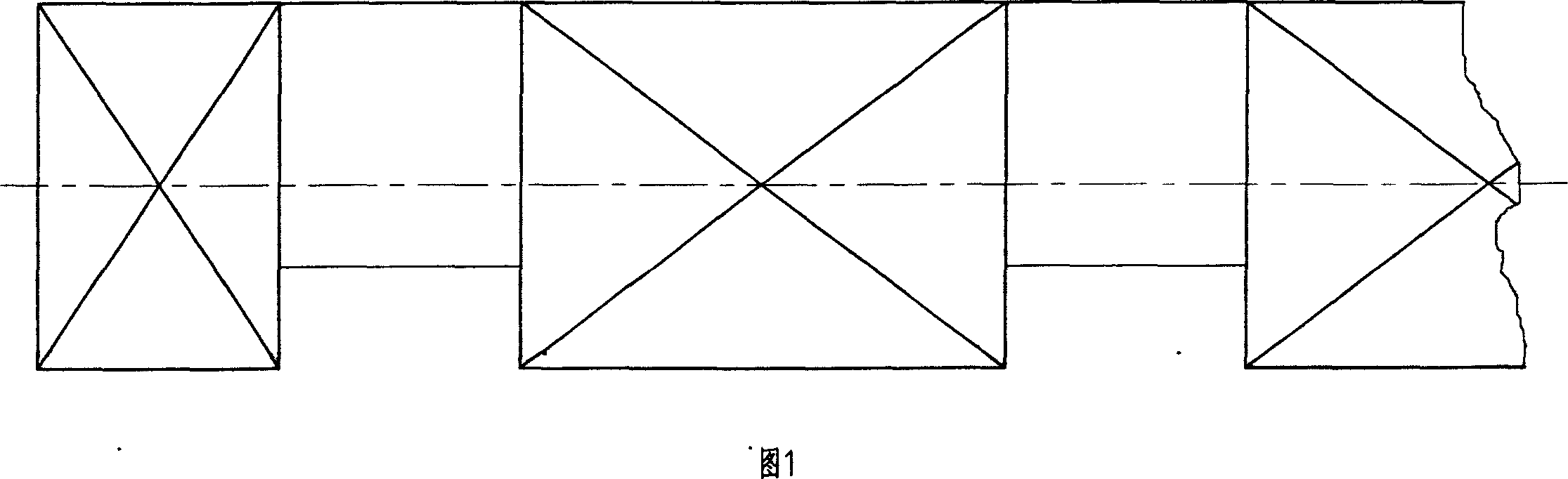

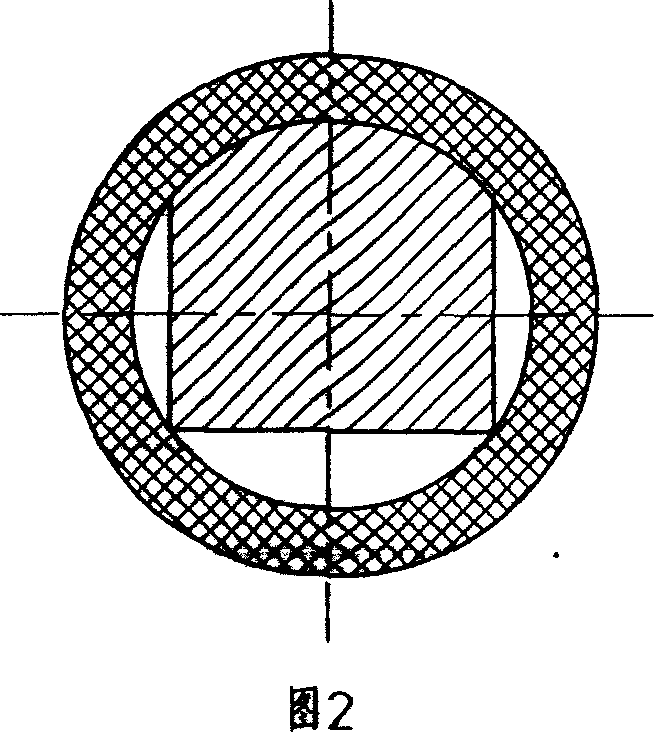

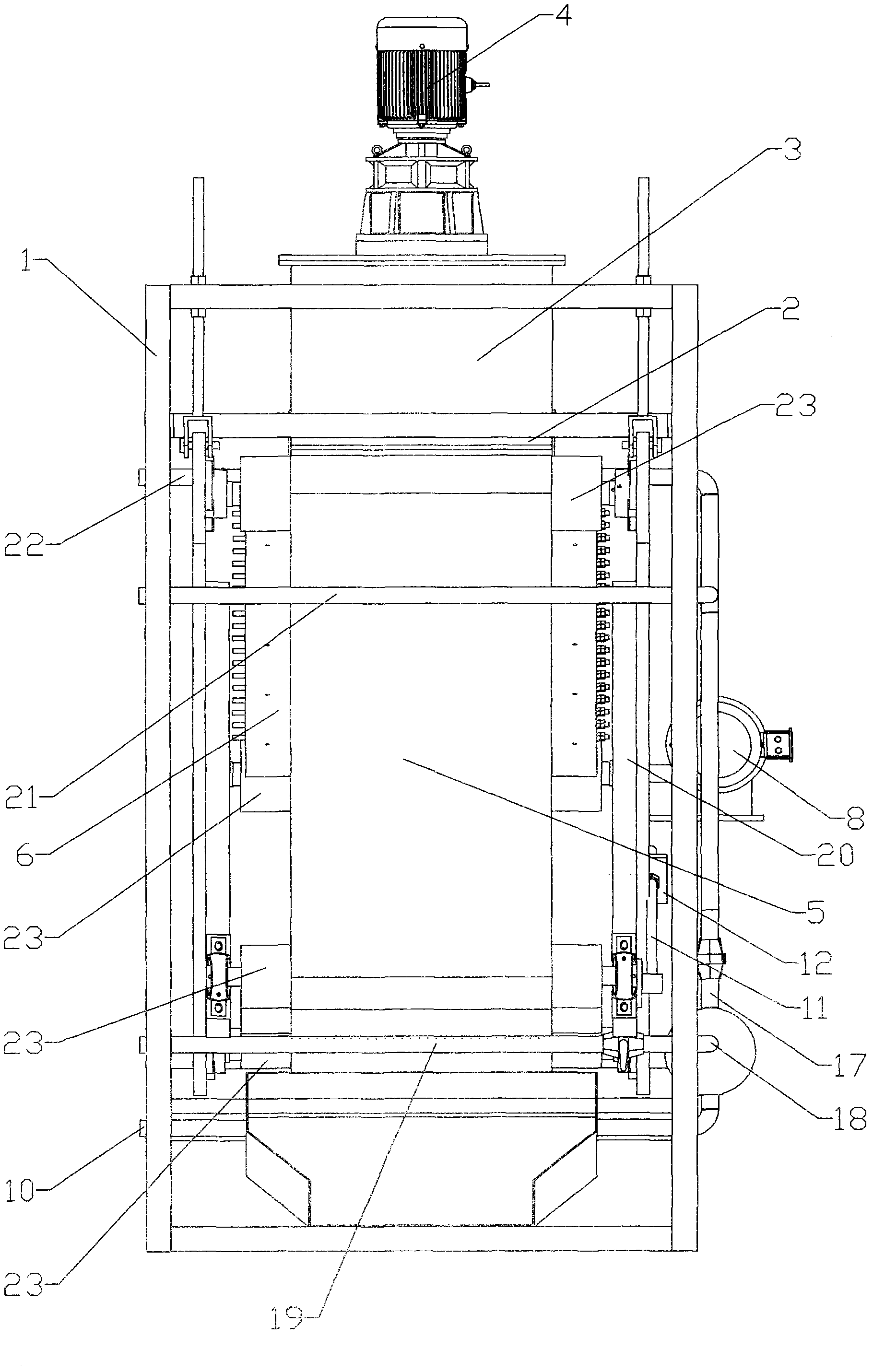

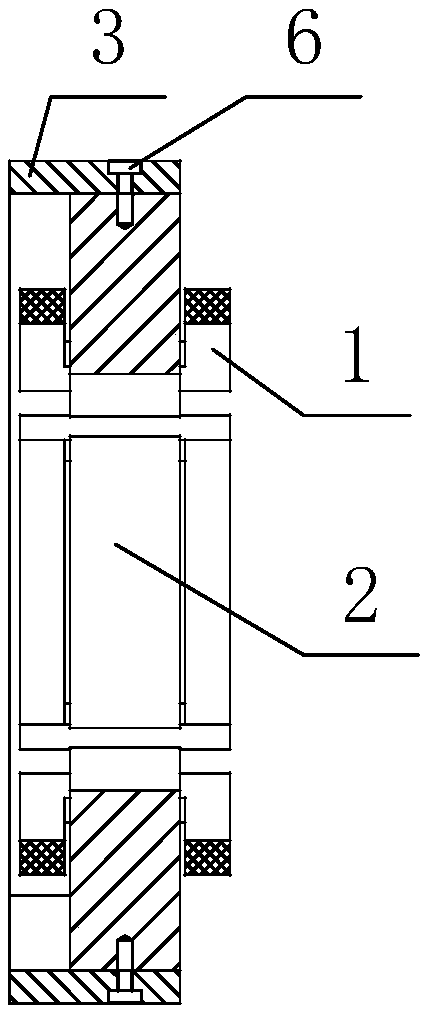

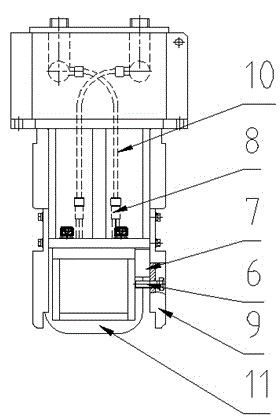

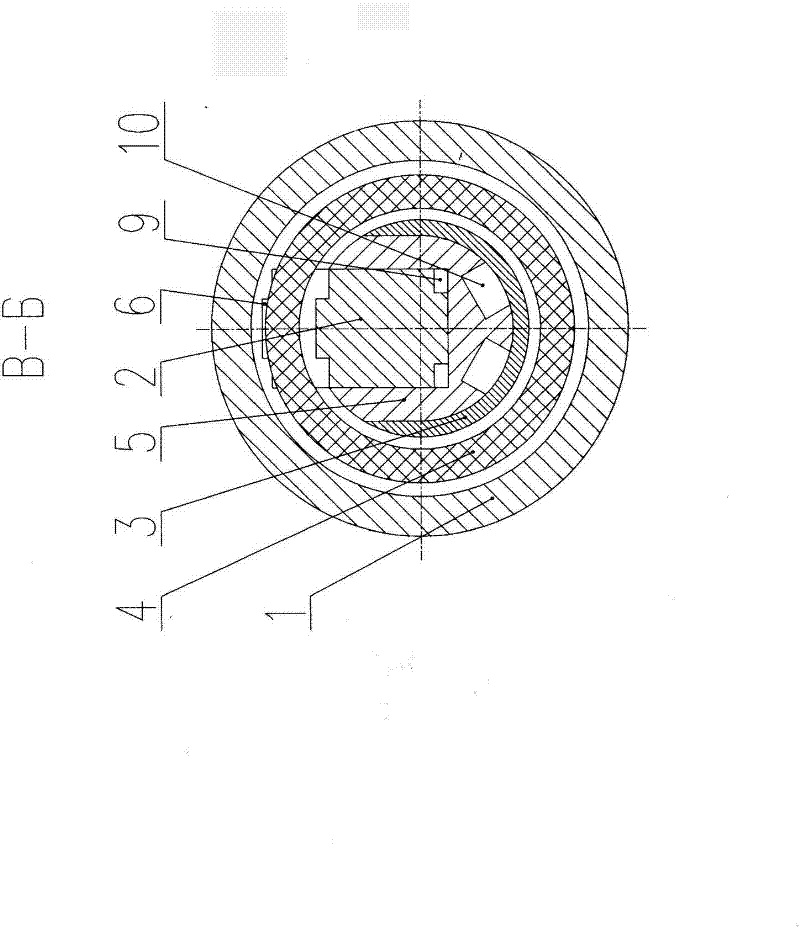

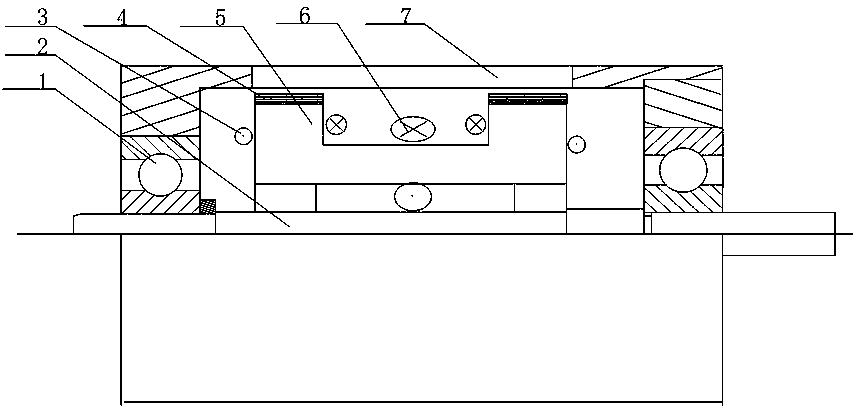

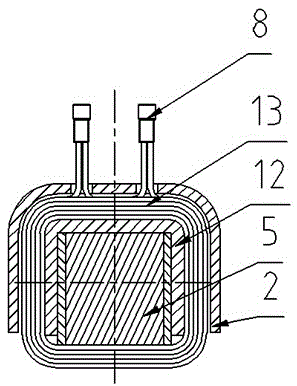

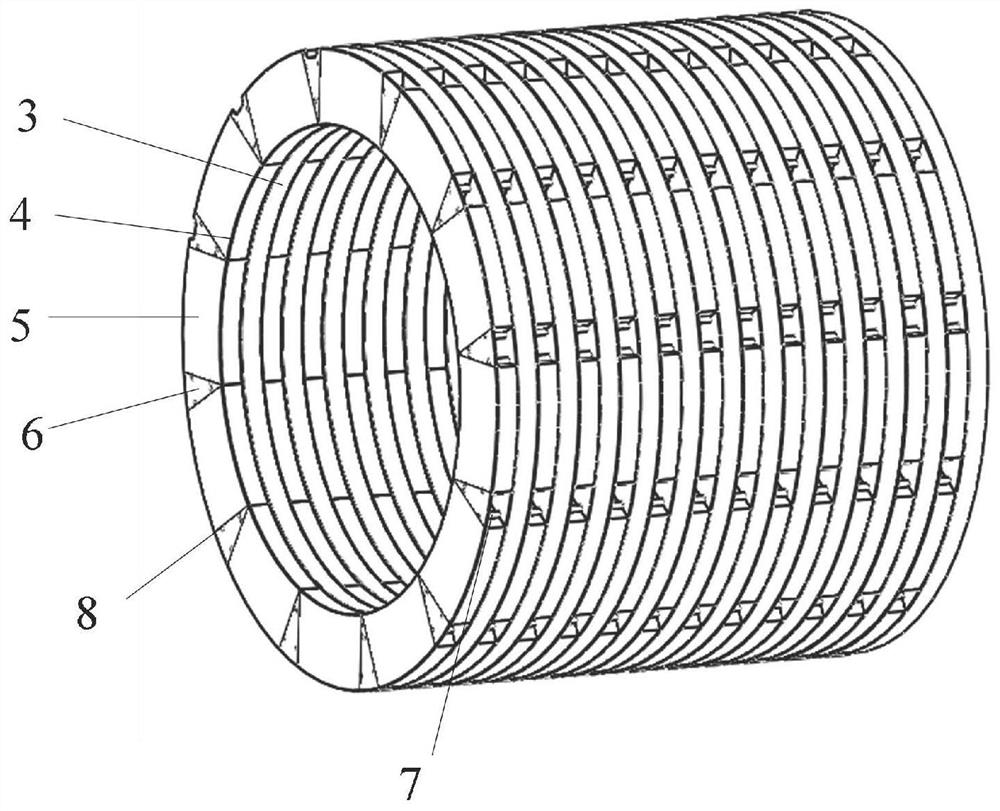

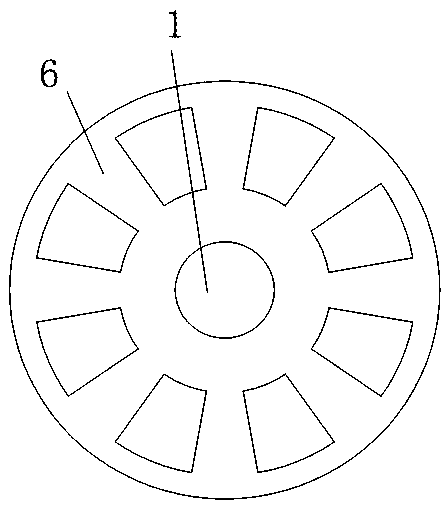

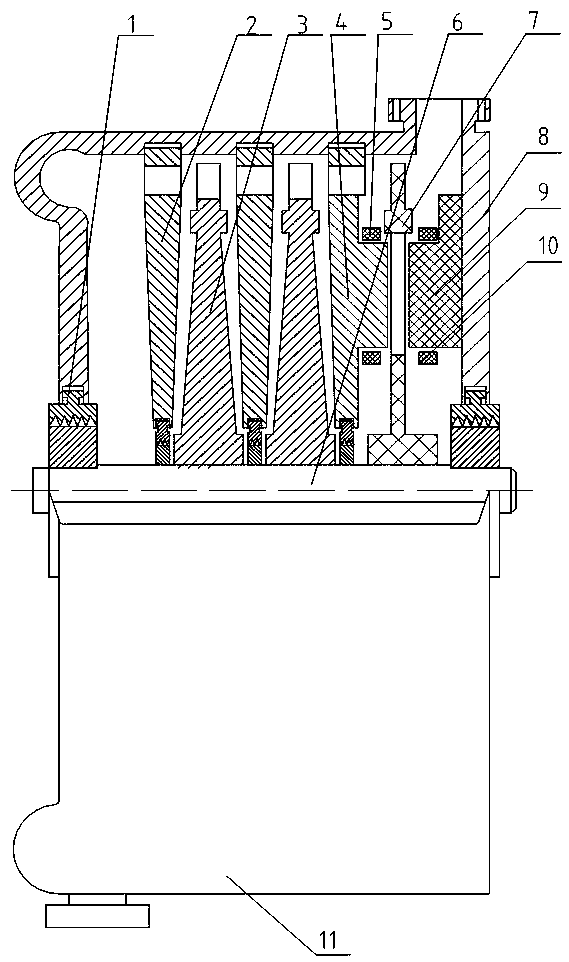

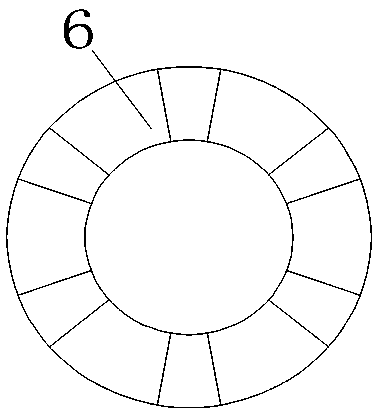

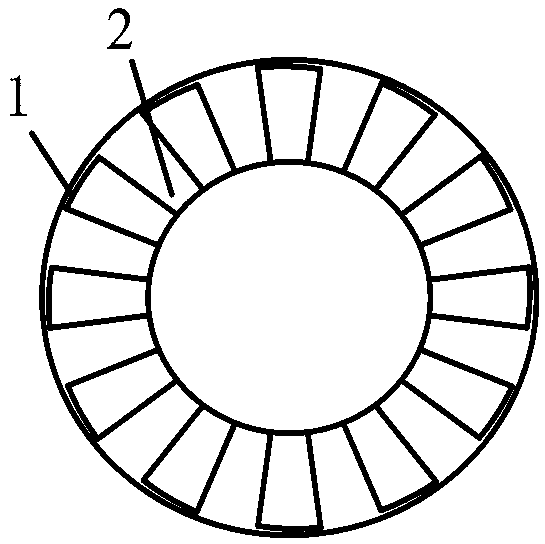

Electromagnetic mixing roller of two cool areas of highfield unburnt earthenware

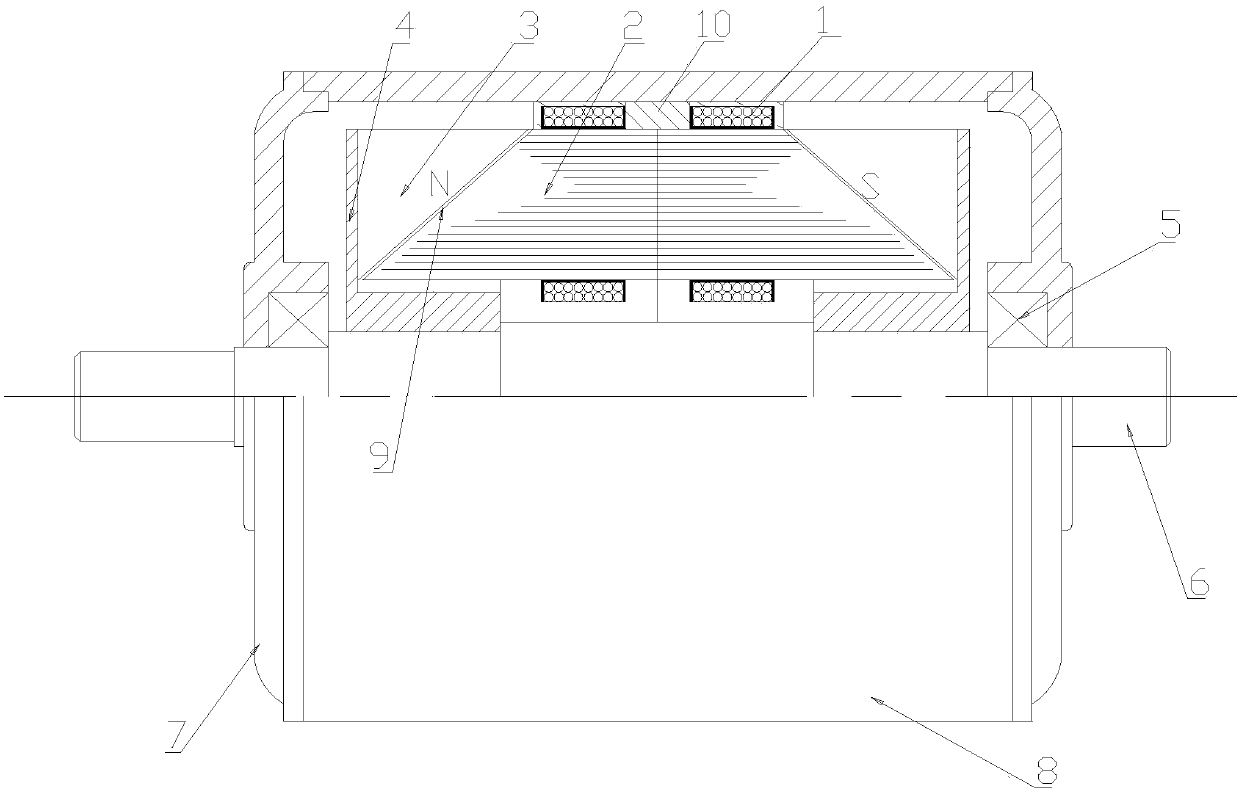

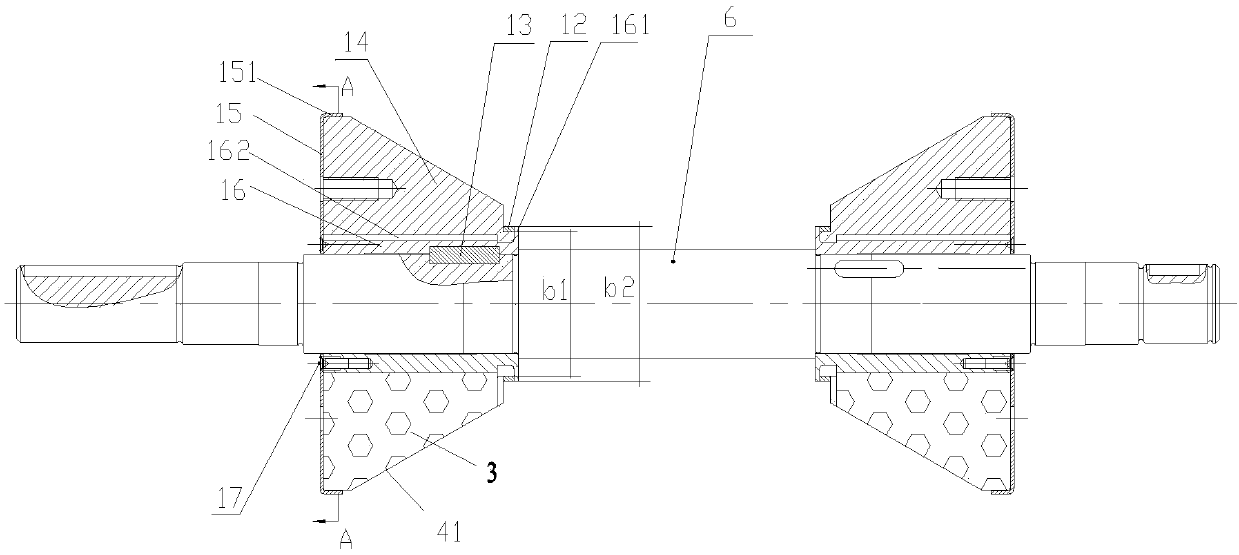

The present invention relates to electromagnetic stirring roller for continuous metal casting, and is especially one kind of high magnetic field two cold plate blank electromagnetic stirring roller. The electromagnetic stirring roller includes a winding and a cylindrical iron core, and has shielding rings to mask the non-working surface. Adopting cylindrical iron core without teeth and slots results in high space utilization rate of the winding, increased magnetic conducting area of the iron core, raised magnetic field strength and enhanced electromagnetic stirring force. Shielding the non-working surface with shielding rings can minimize the magnetic leakage, increase the magnetic field strength in the working surface and enhance the electromagnetic stirring force.

Owner:HUNAN ZHONGKE ELECTRIC

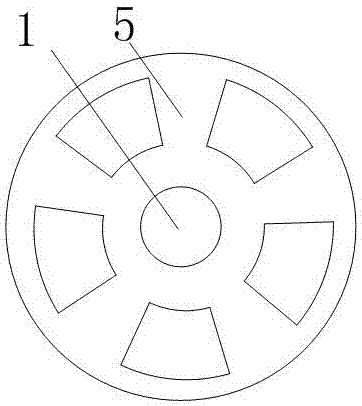

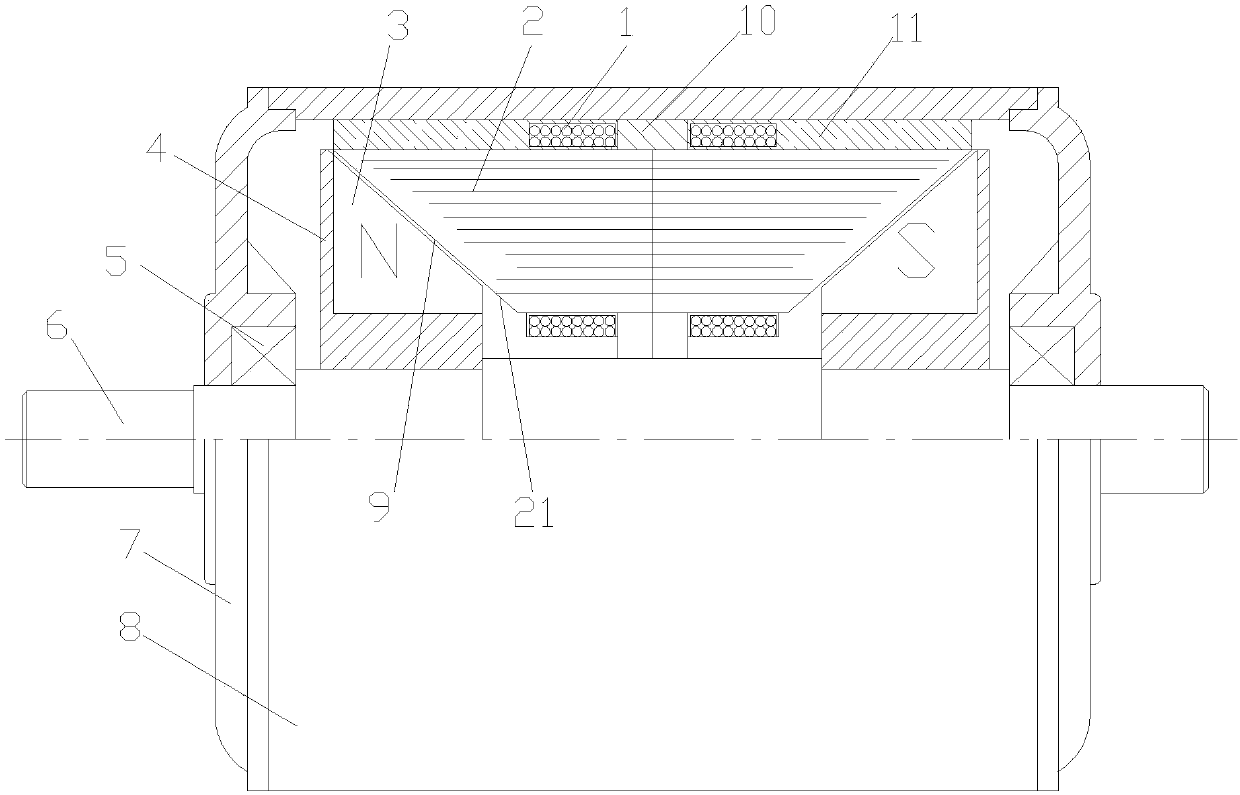

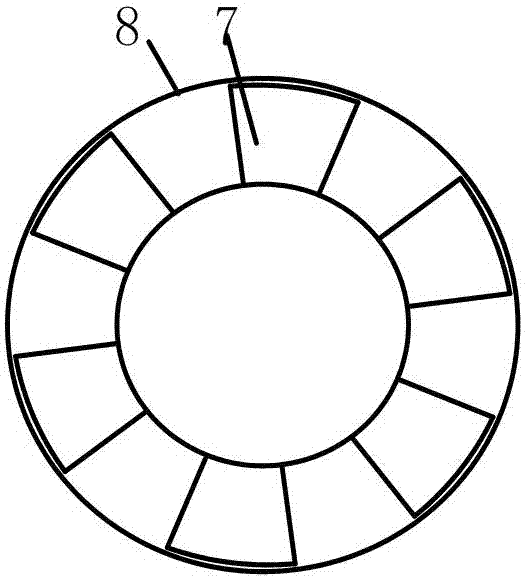

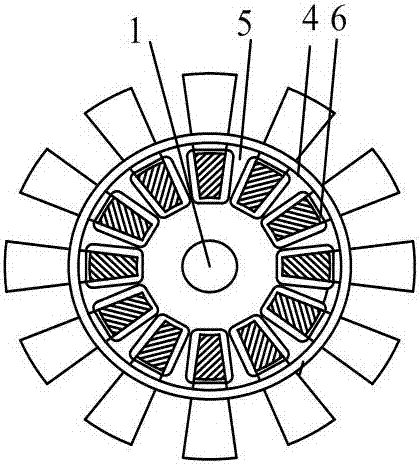

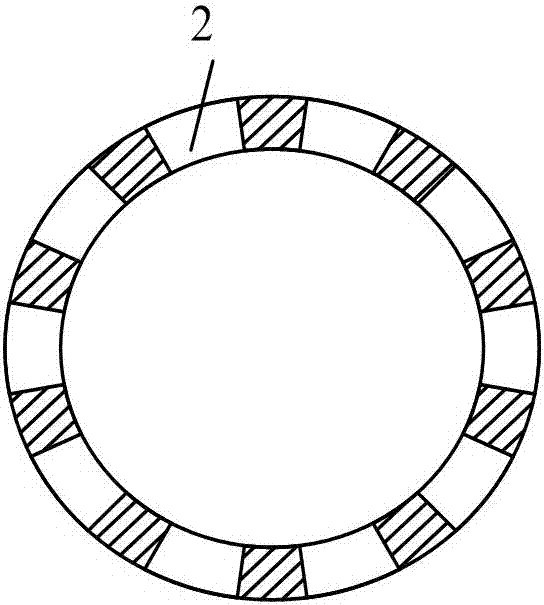

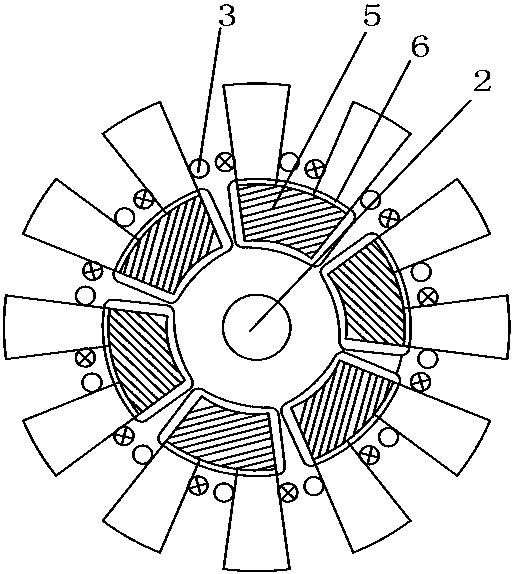

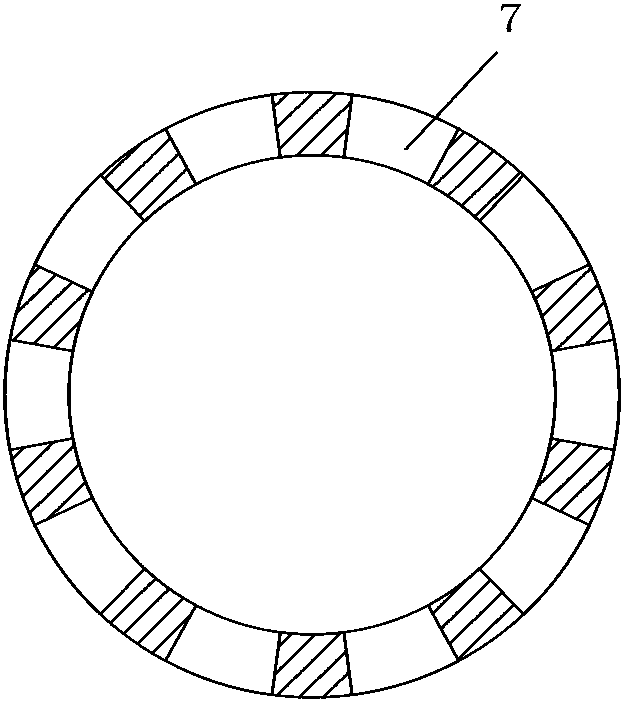

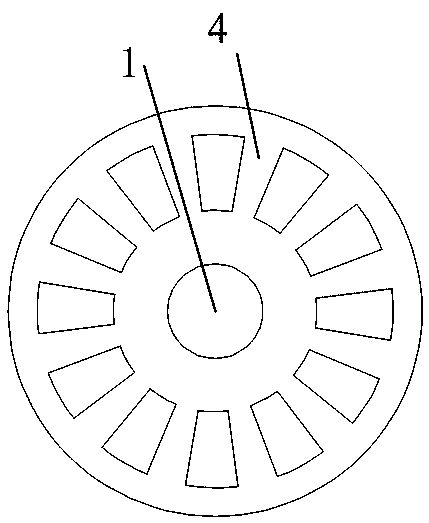

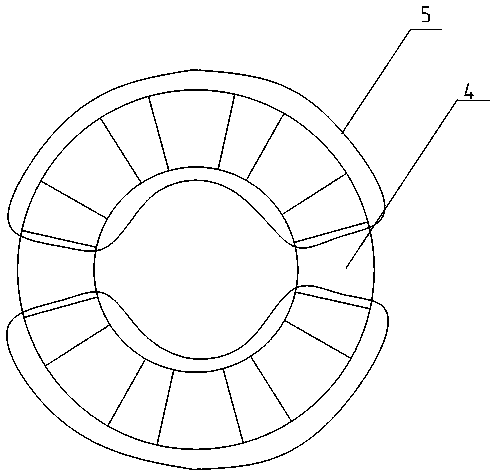

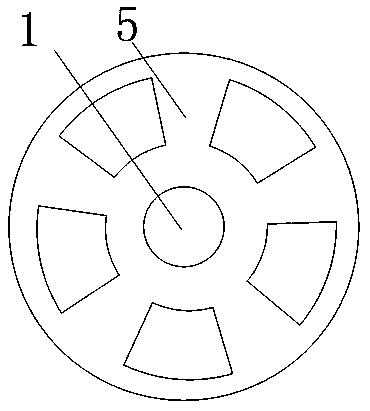

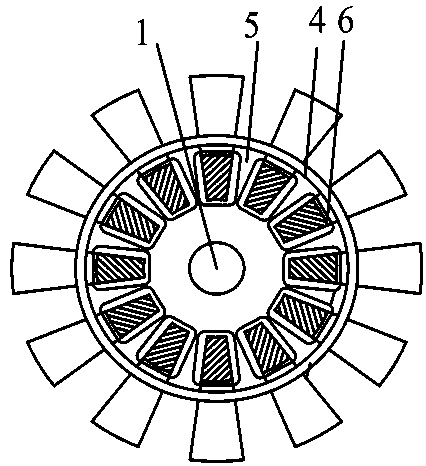

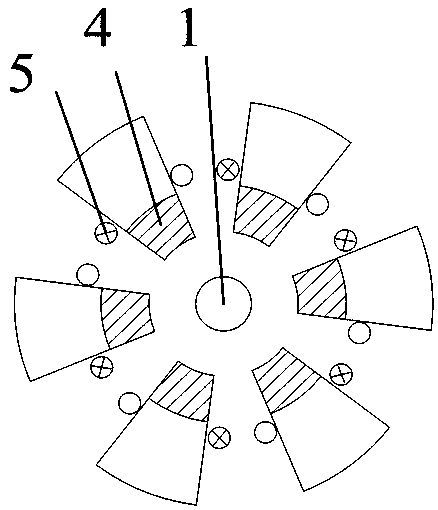

Electric vehicle magnetic grid type permanent magnetism doubly salient motor

ActiveCN107508444ALarge magnetic areaIncrease powerMagnetic circuit rotating partsSynchronous machine detailsDoubly salientElectric vehicle

An electric vehicle magnetic grid type permanent magnetism doubly salient motor belongs to the electric vehicle motor technology field, comprises a shaft, a front armature iron core, a front armature winding, a front rotor iron core, a front permanent magnet, a permanent magnet iron core, a back permanent magnet, a back rotor iron core, a back armature winding, a back armature iron core and a shell, and is characterized in that the disc-shaped front rotor iron core and back rotor iron core are fixed on the shaft at intervals, the permanent magnet iron core fixed on the shell is between the front rotor iron core and the back rotor iron core, and the permanent magnets are fixed on the two surfaces of the permanent magnet iron core towards the rotor iron cores respectively and uniformly; the front armature iron core and the back armature iron core which are fixed on the shell are at the two sides of the front rotor iron core and the back rotor iron core respectively, armature poles are arranged on the armature iron cores, and the armature windings are wound on the armature poles. The rotor iron cores of the technical scheme of the present invention are magnetic grid-shaped, and are large in contact area and specific power, so that the electric vehicle magnetic grid type permanent magnetism doubly salient motor is very suitable for being used as an electric vehicle motor having higher requirements for the power density.

Owner:江苏惠博机电科技股份有限公司

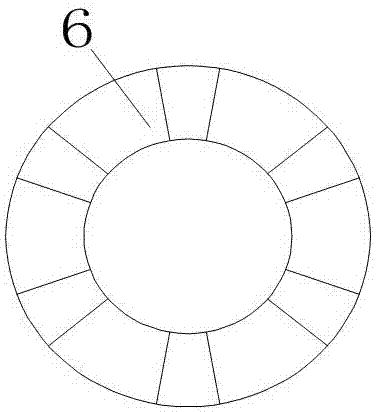

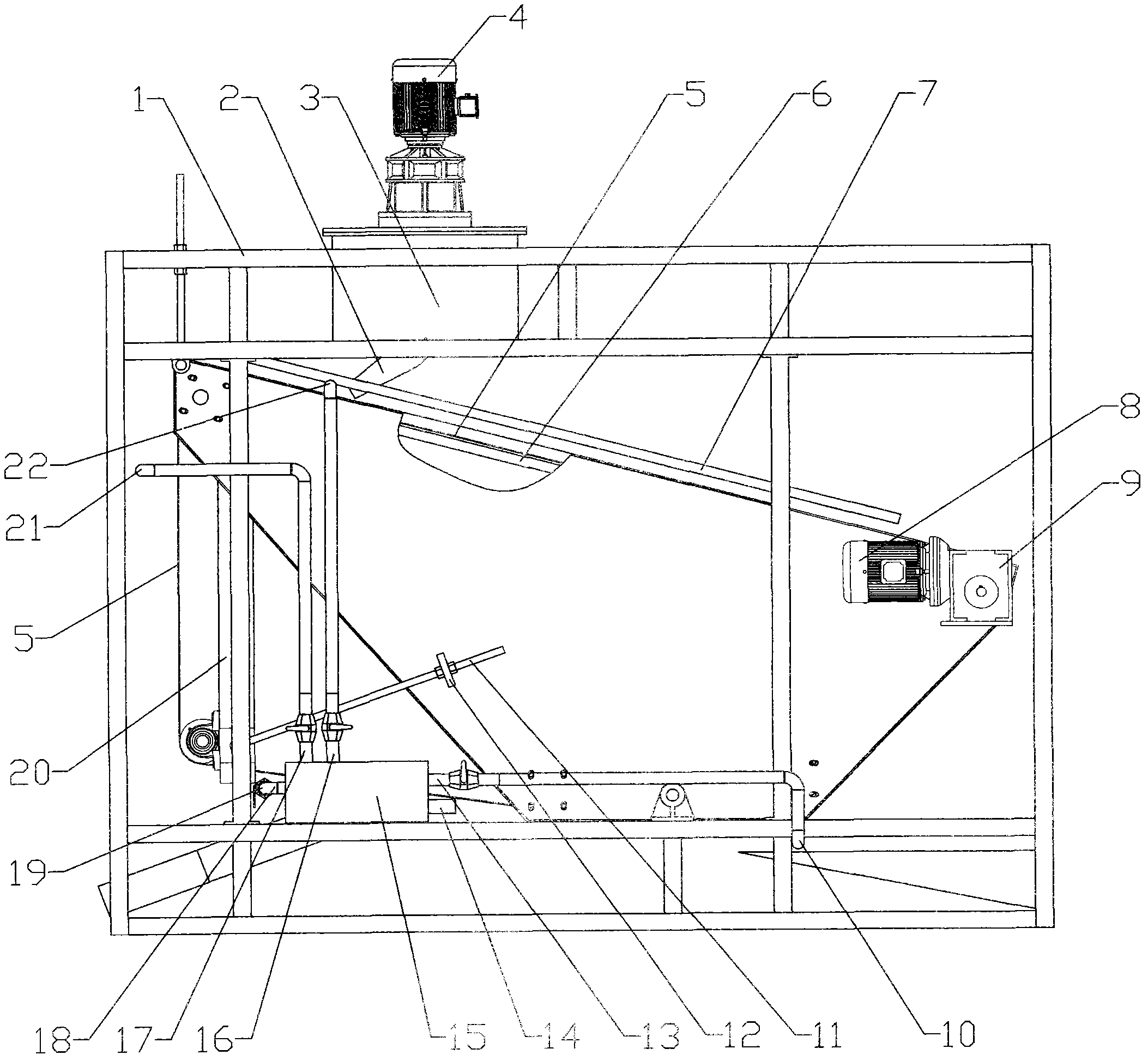

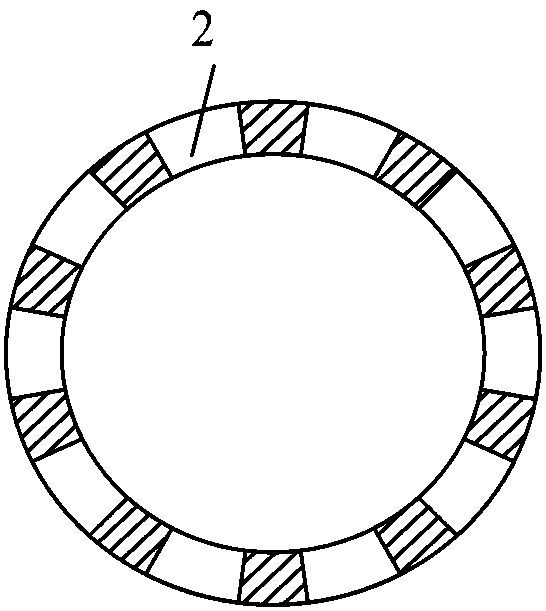

Belt-type magnetic separator

ActiveCN103316765ALarge magnetic areaGood magnetic selection effectMagnetic separationMagnetic separatorEngineering

The invention relates to a belt-type magnetic separator which comprises a rack, wherein the rack is provided with a conveying belt; the upper part of the conveying belt is provided with a feeding device; the lower part of the conveying belt is provided with a first magnet system; the rack is provided with a water spraying device matched with the conveying belt. The magnetic separator is simple in structure, low in manufacture cost, large in magnetic area, has a good magnetic separation effect, and is high in magnetic separation efficiency.

Owner:潍坊恒基磁电机械有限公司

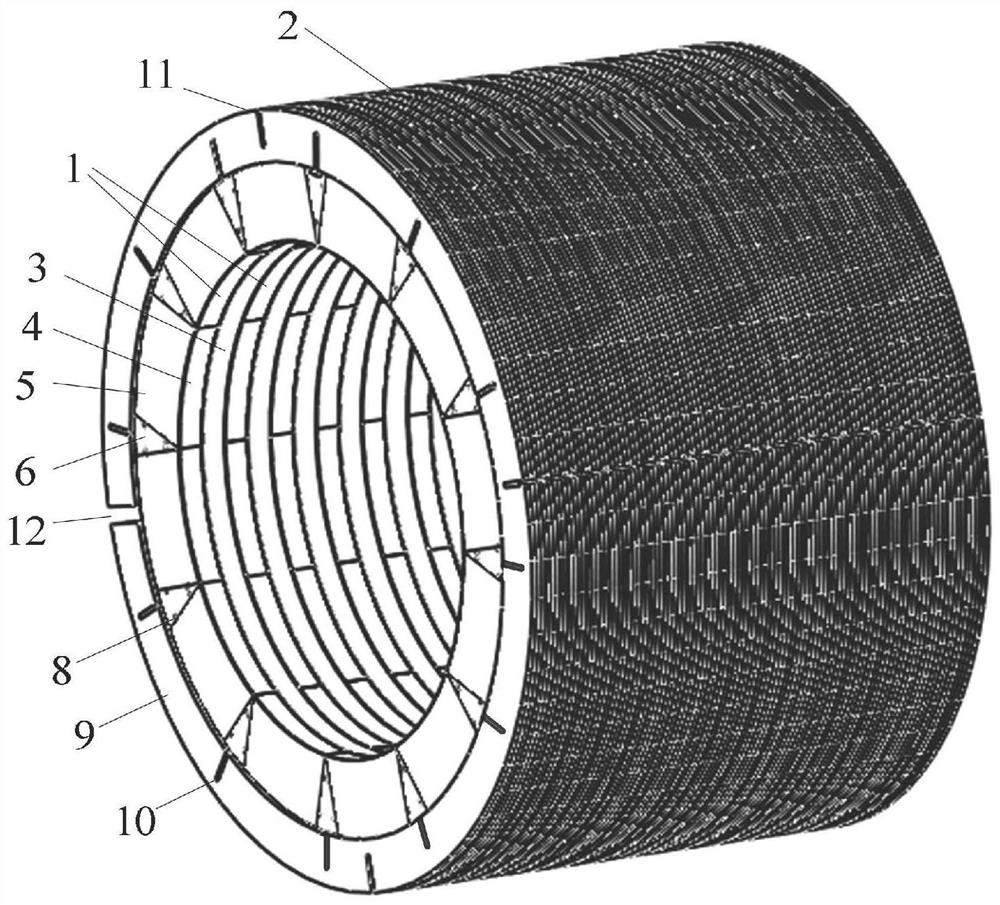

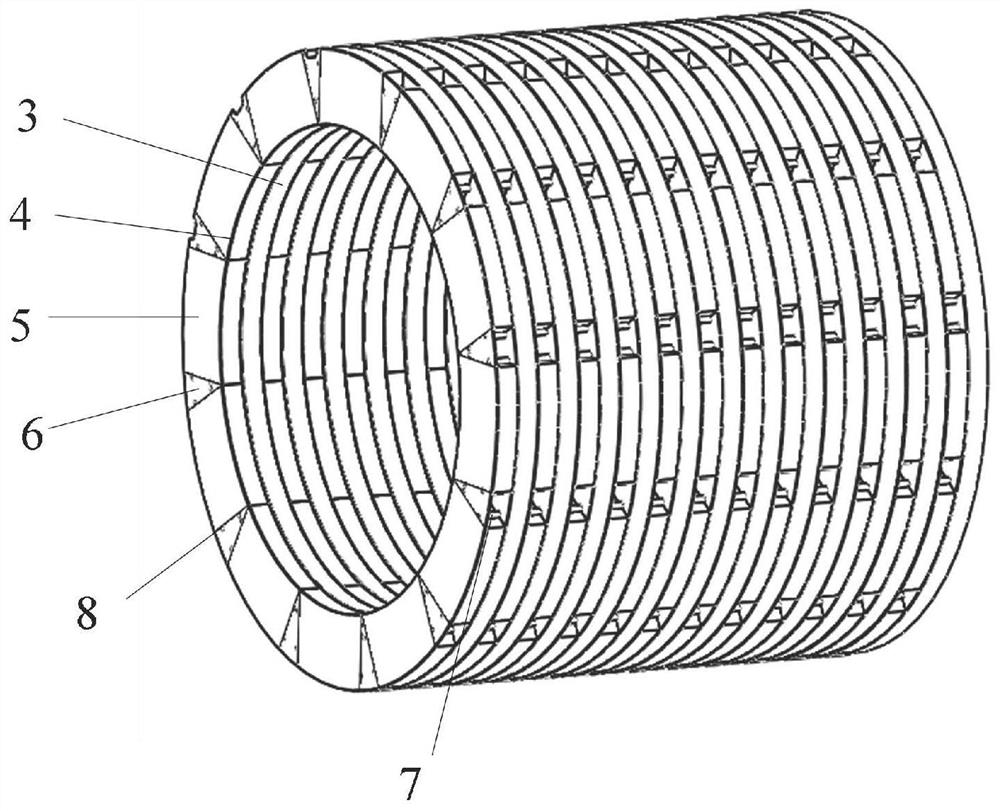

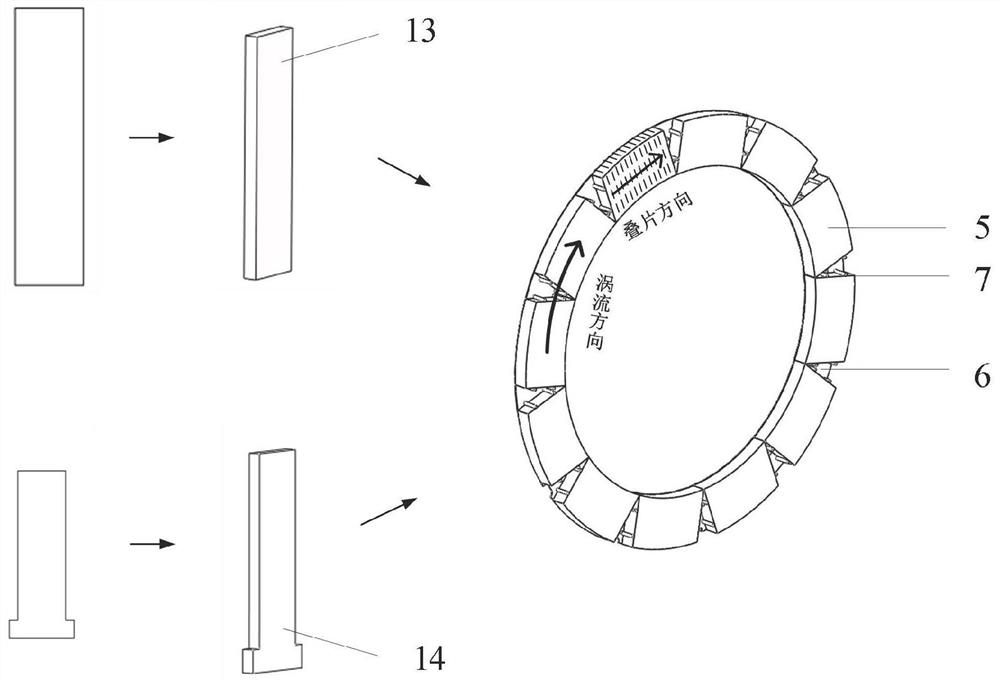

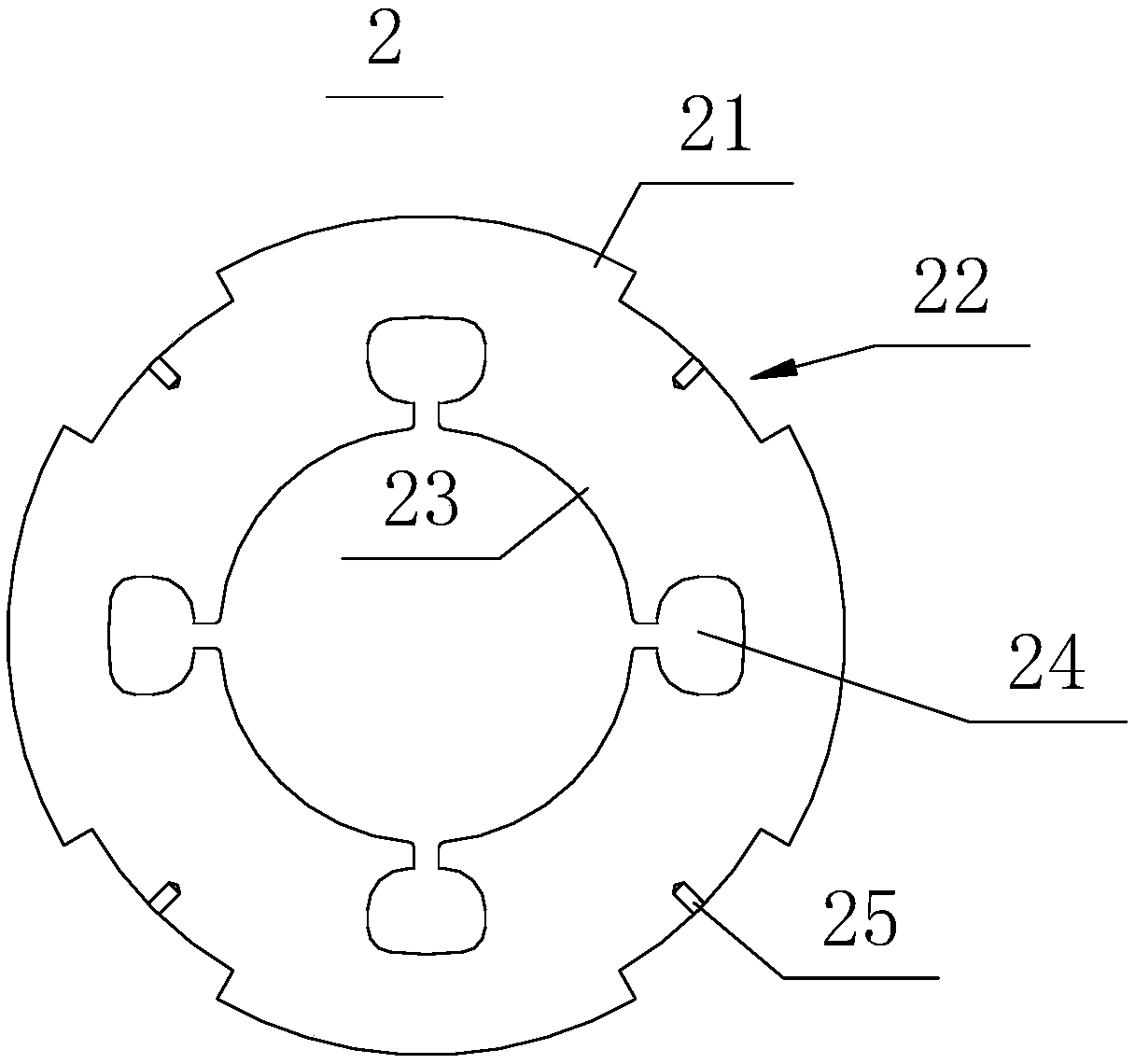

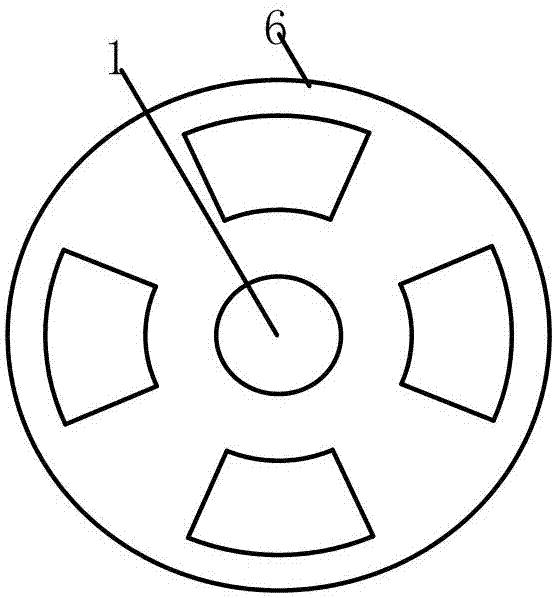

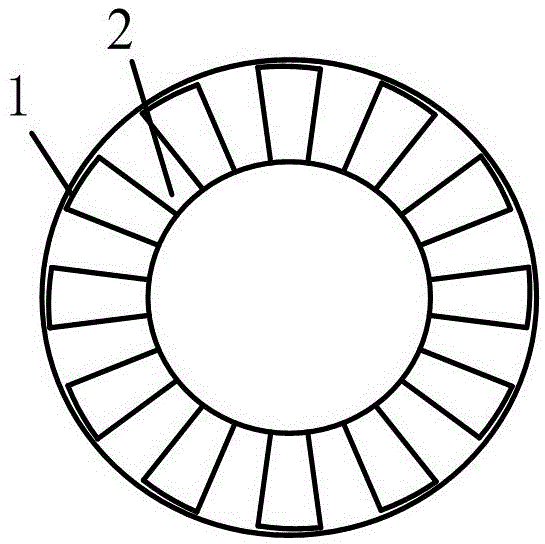

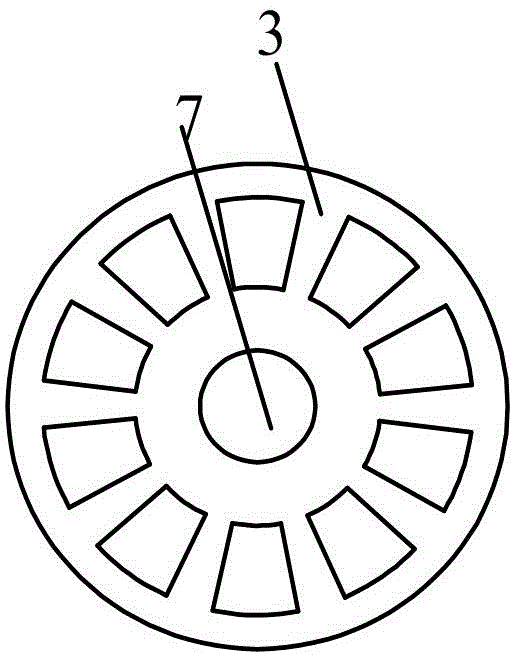

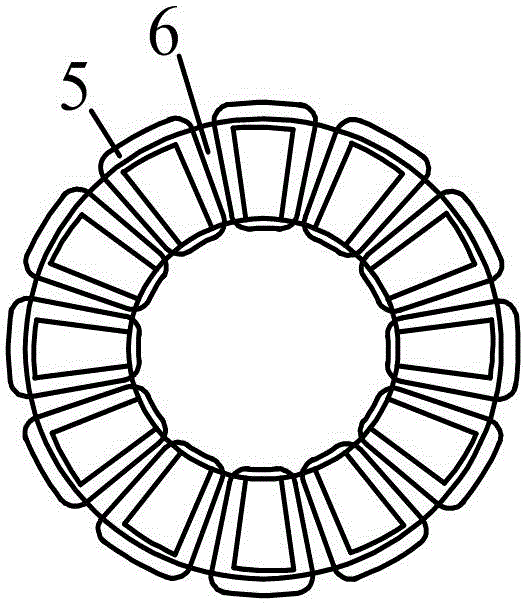

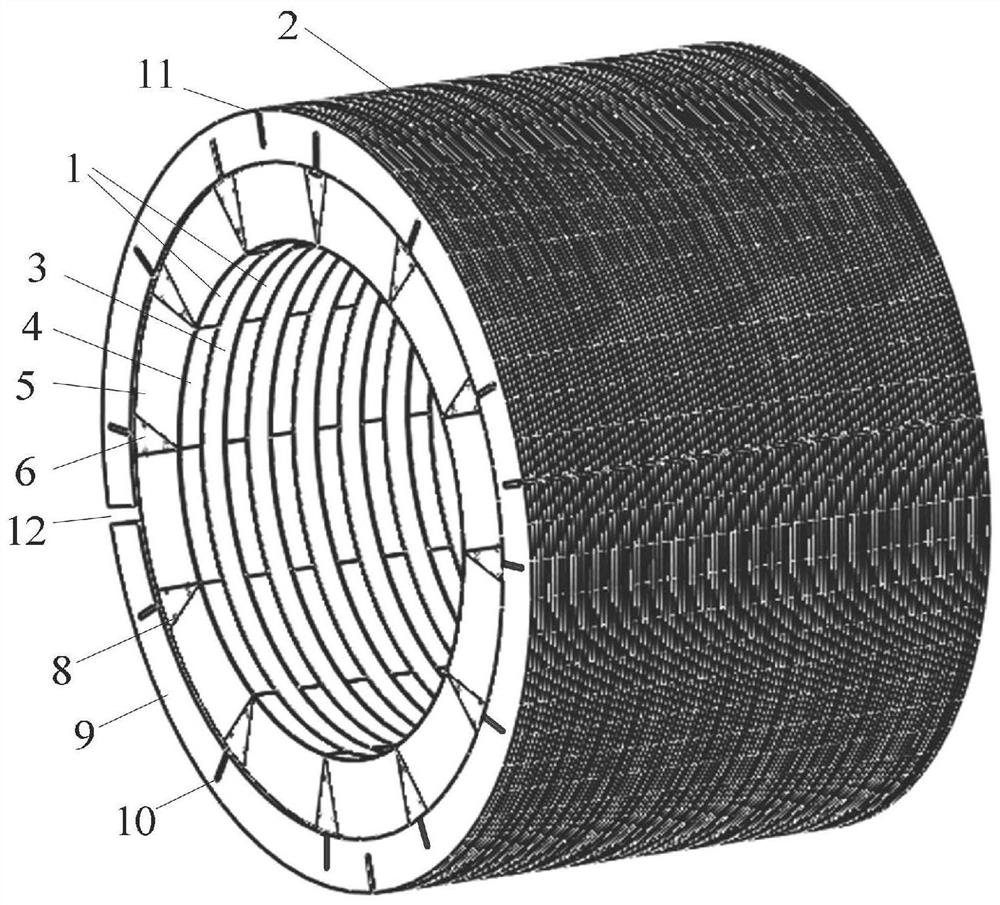

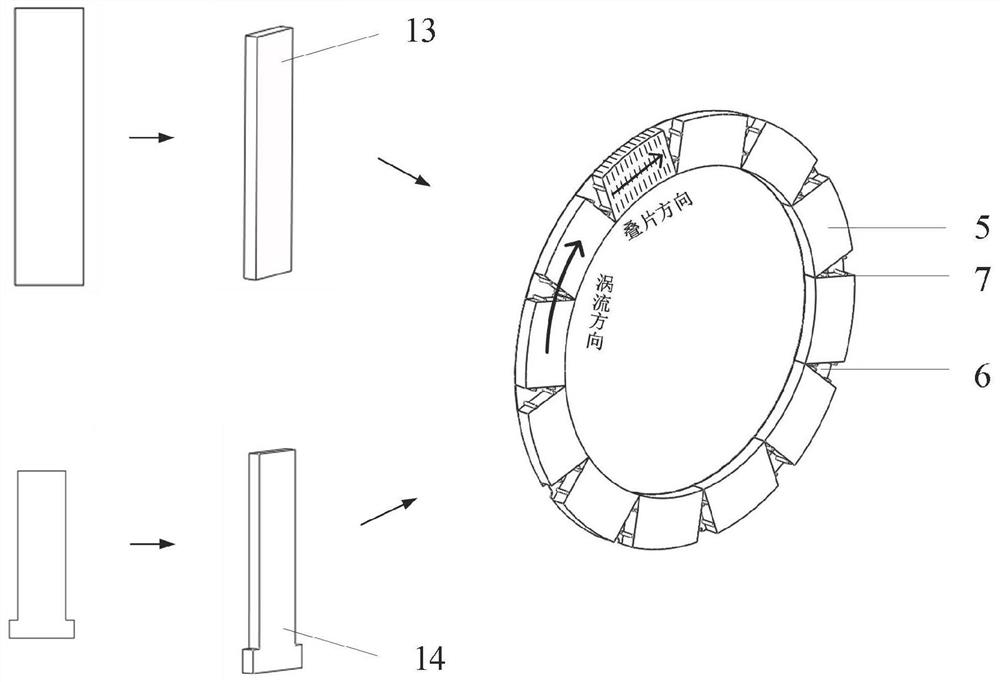

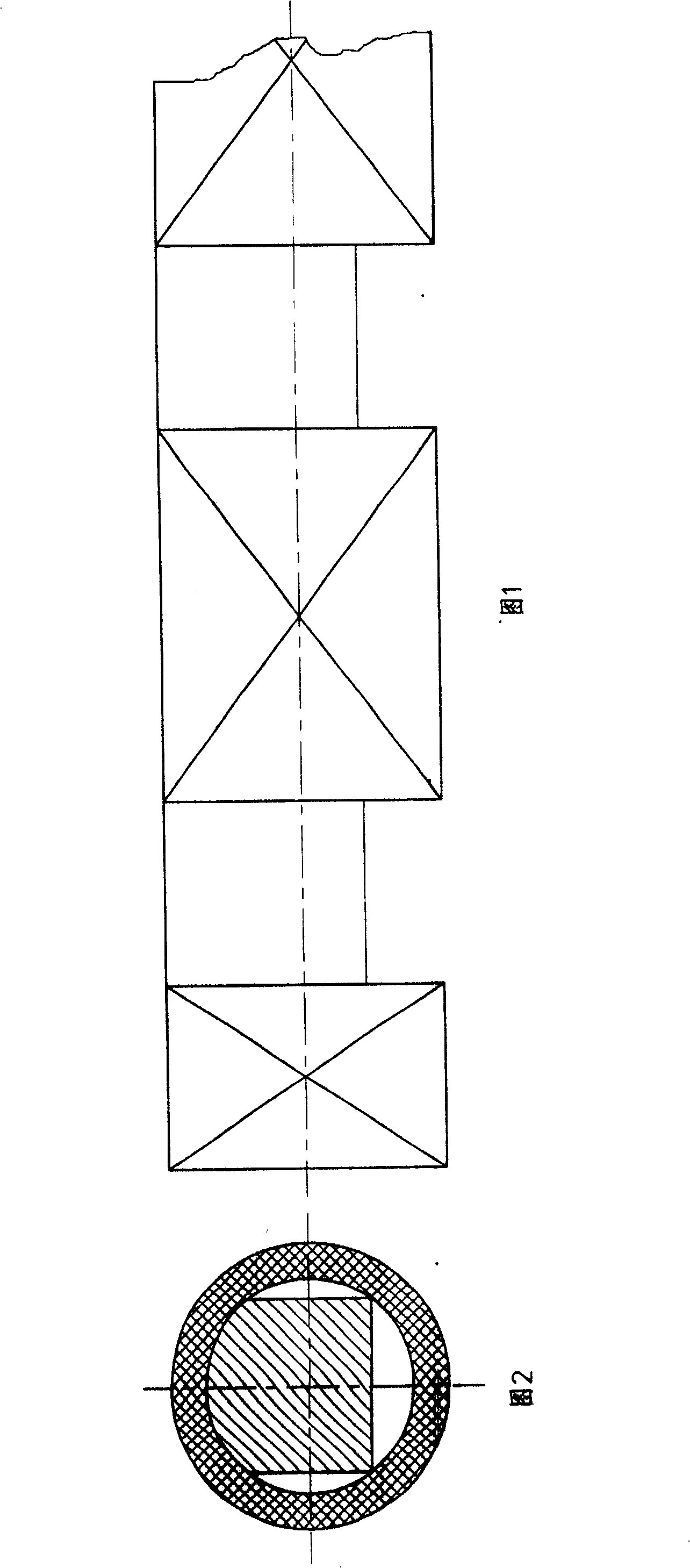

Low-eddy-current-loss primary structure of tooth groove type cylindrical linear motor

The invention discloses a low-eddy-current-loss primary structure of a tooth groove type cylindrical linear motor. The low-eddy-current-loss primary structure comprises primary teeth, a primary yoke and a plurality of ring windings; the primary teeth and the primary yoke are separated components and are tightly sleeved together to form a primary iron core; one or more circular ring windings are embedded between every two primary tooth components; each annular primary tooth component is formed by arranging a plurality of tooth iron core blocks of the same specification in an array mode along the side length of an equilateral polygon, and each iron core block is formed by laminating silicon steel sheets in the circumferential direction; and the primary yoke component is formed by laminating silicon steel sheets along the motion direction of the motor, and each lamination is uniformly provided with a plurality of yoke shallow slots along the circumferential direction so as to block an eddy current path along the direction. According to the low-eddy-current-loss primary structure of the tooth groove type cylindrical linear motor of the invention, the primary iron core is combined by adopting a mode of tooth and yoke separation and lamination in different directions, so that the eddy current loss of the tooth groove type cylindrical linear motor can be effectively reduced, the efficiency of the motor is improved, and meanwhile, the motor can maintain relatively high thrust density.

Owner:HEFEI UNIV OF TECH

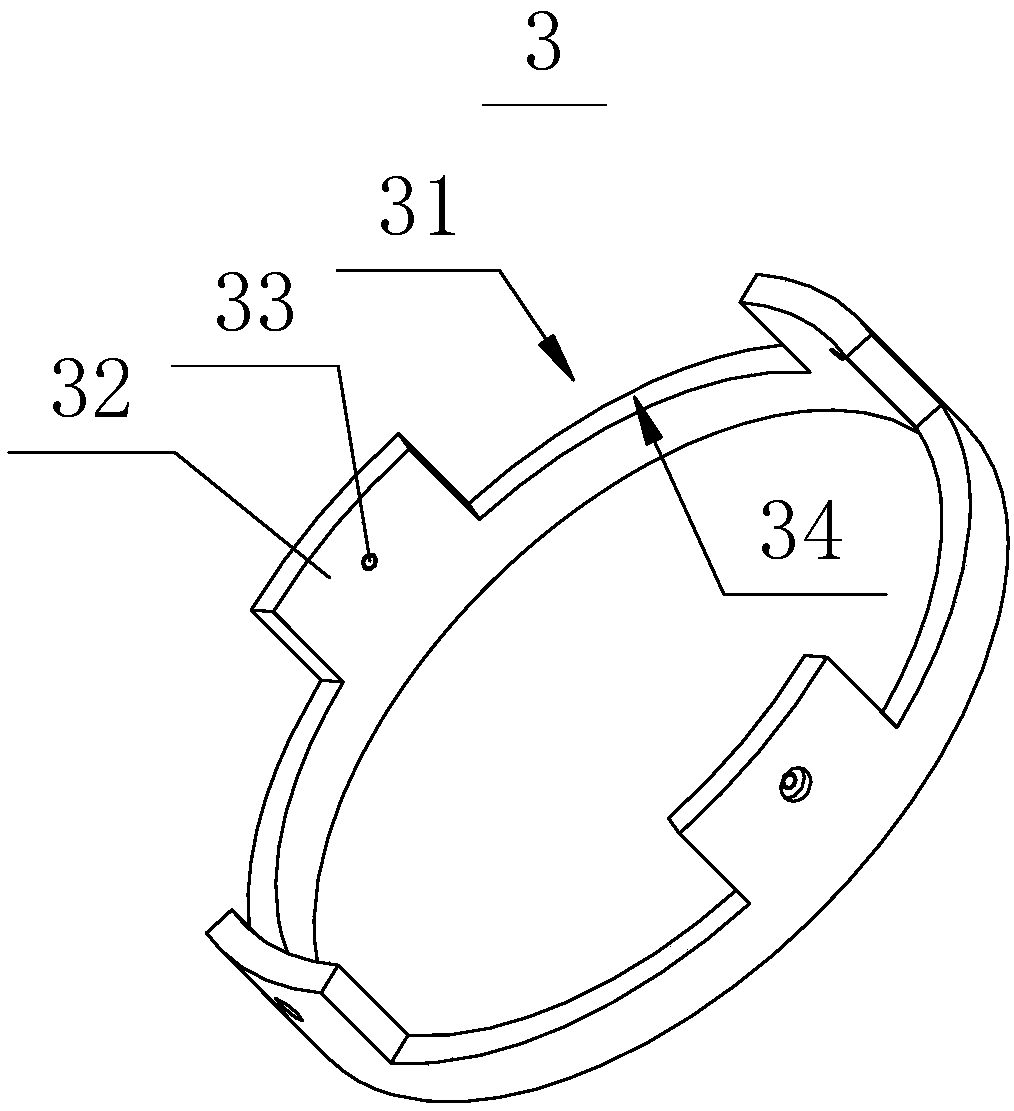

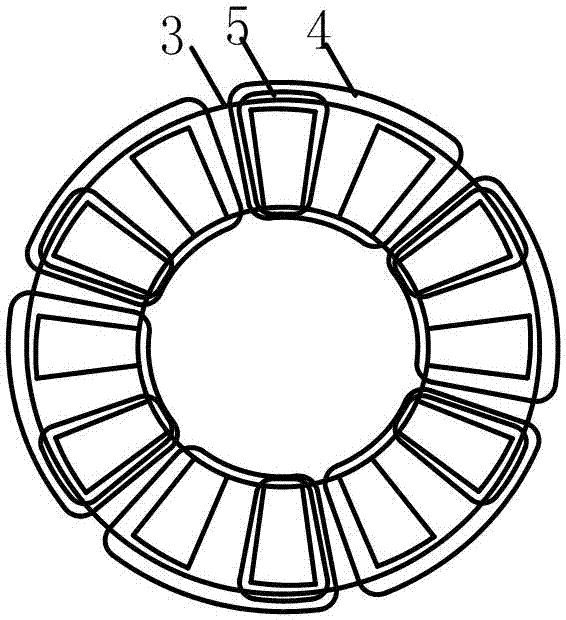

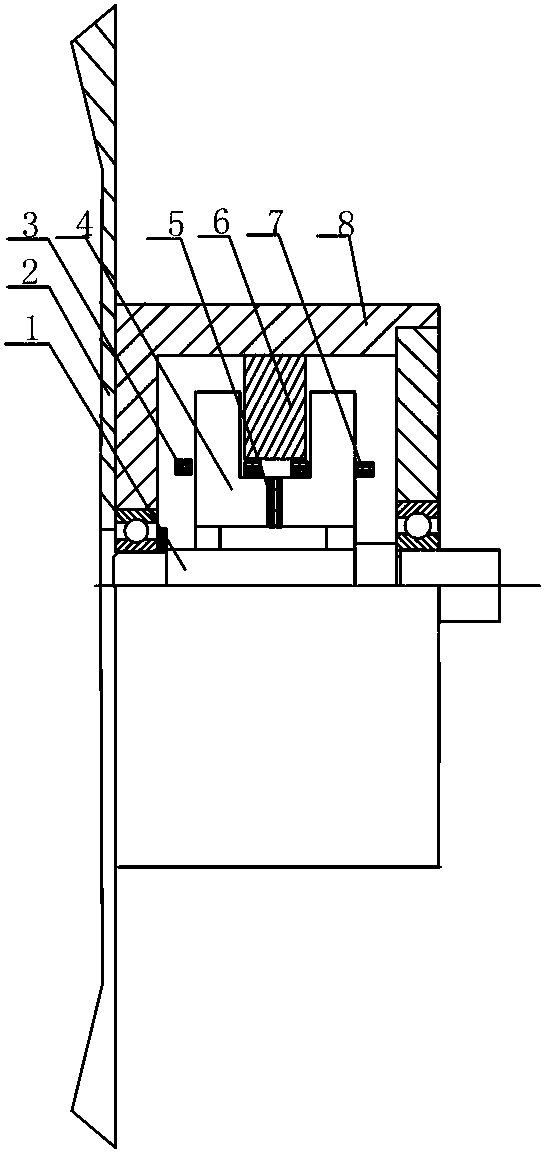

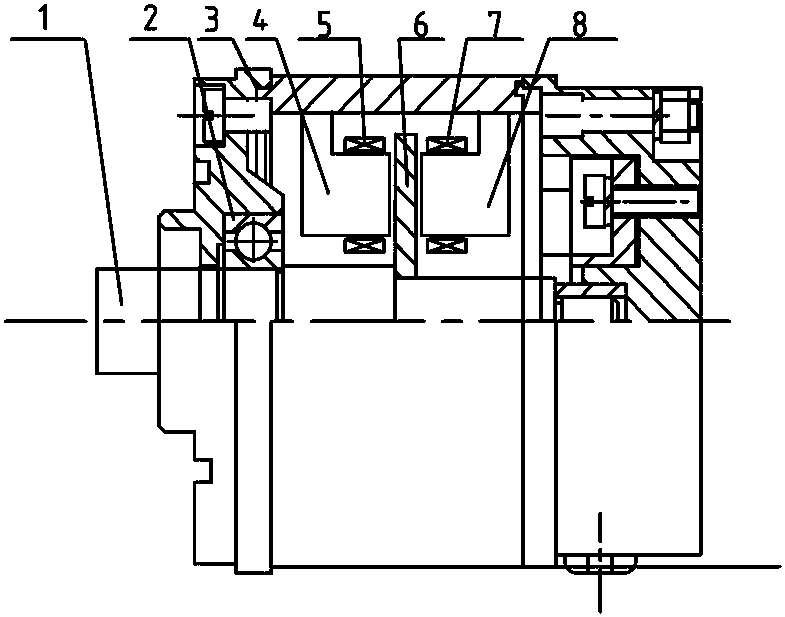

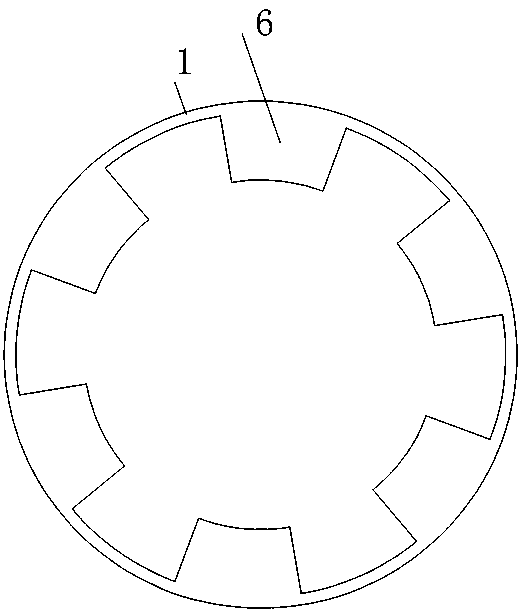

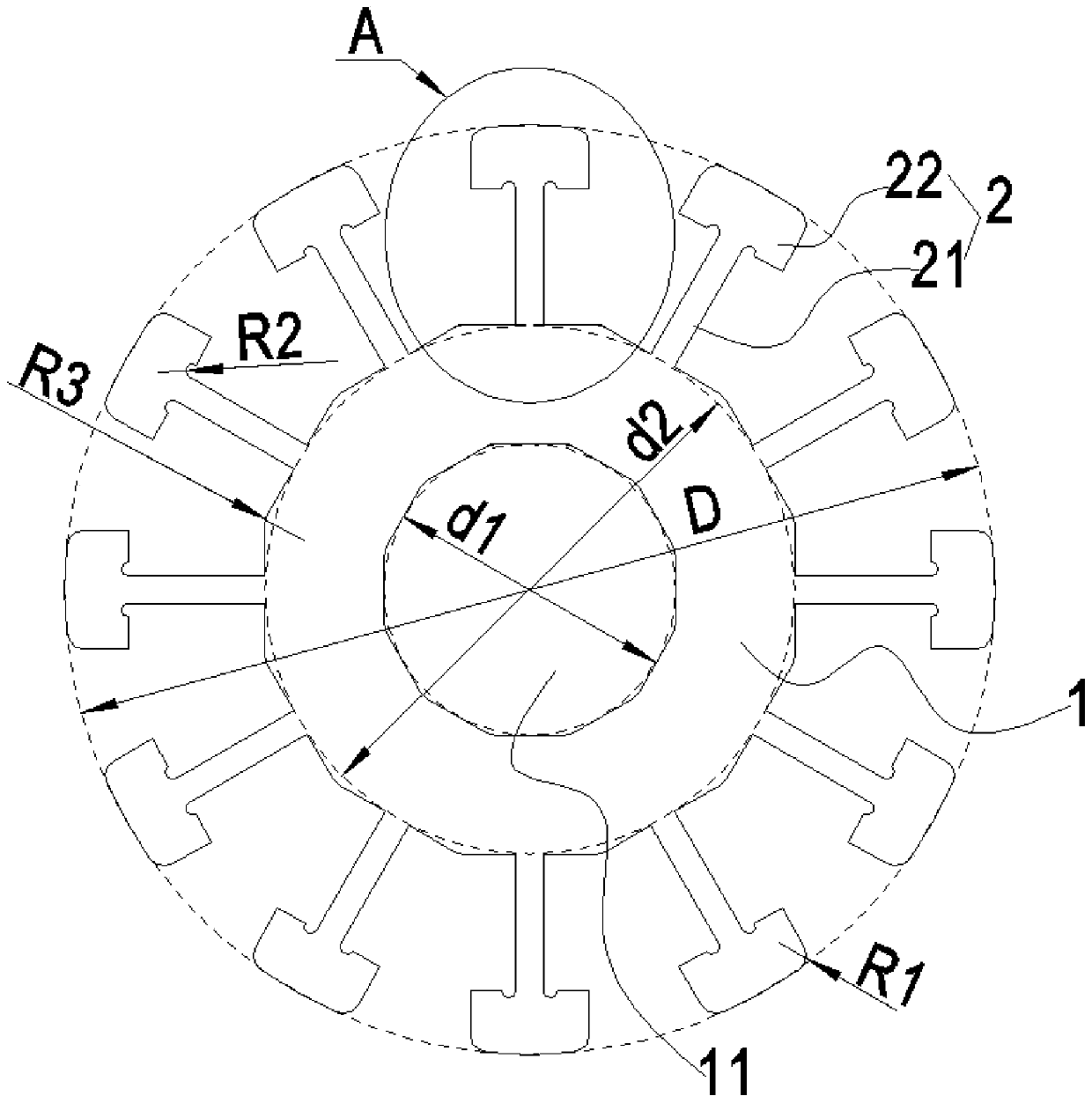

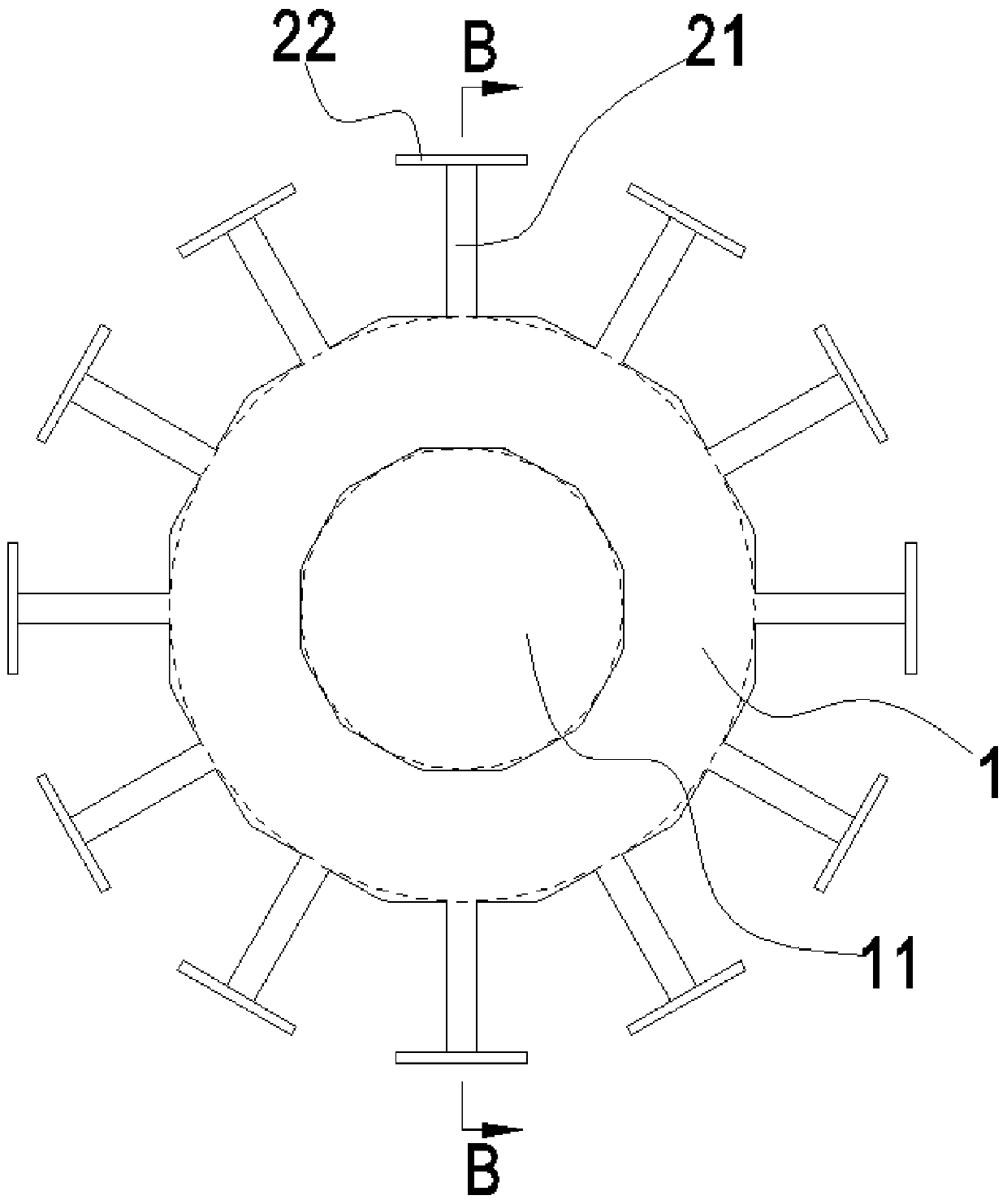

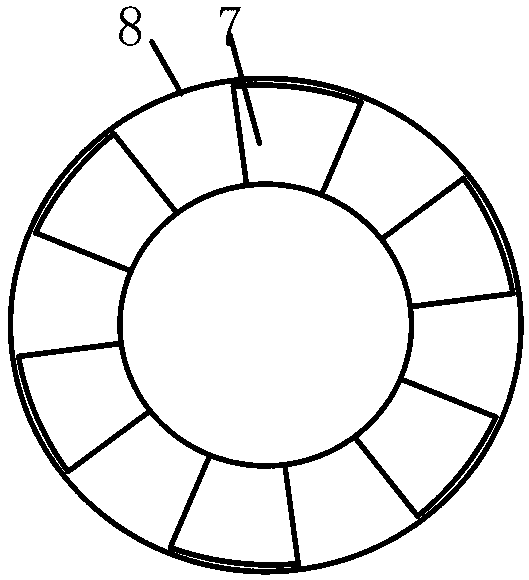

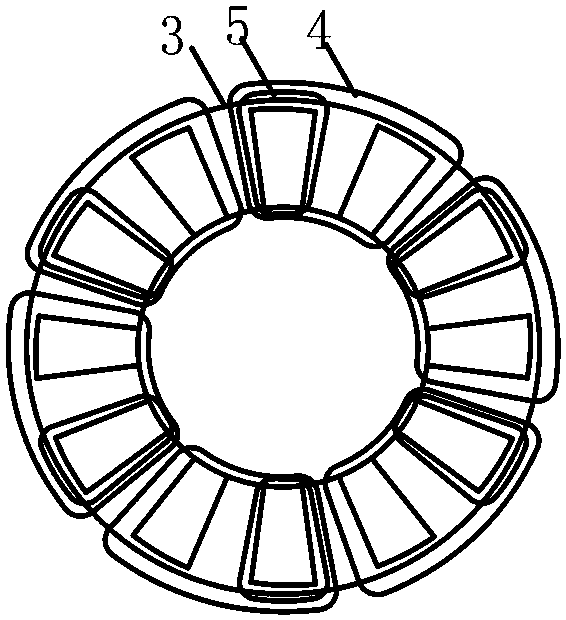

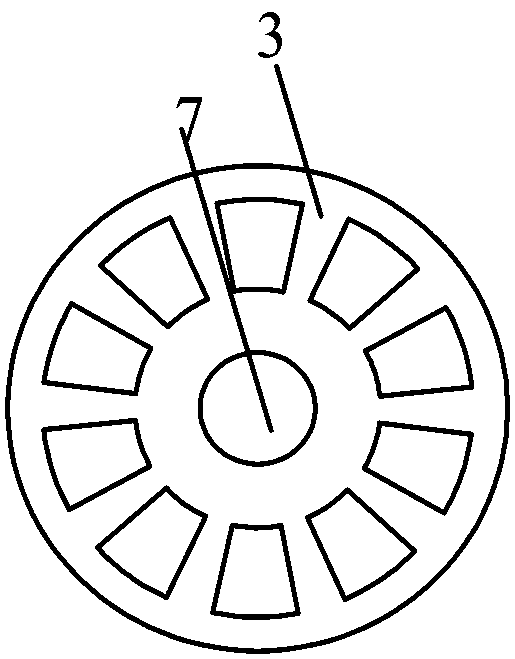

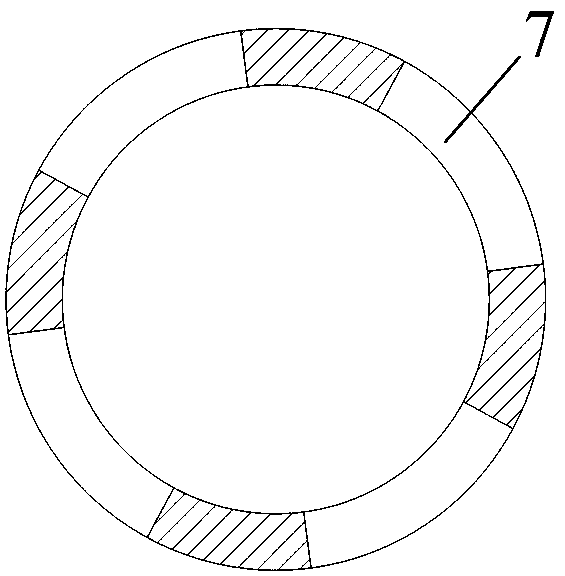

Radial stator core structure, bearing stator and hybrid radial magnetic bearing

The invention provides a radial stator core structure which comprises a radial stator core and a radial ring connected together, wherein the inner ring of the radial stator core is provided with a wire winding groove; a protruding part corresponding to the wire winding groove is arranged on the outer circumferential wall of the radial stator core; and a groove part in transition fit with the protruding part is arranged on the radial ring. The invention further provides a hybrid radial magnetic bearing which comprises a rotor and a bearing stator, wherein the rotor is coaxially arranged in thebearing stator. Compared with the prior art, the magnetic conductive area of the radial stator core is increased on the condition that the boundary dimension is not increased, and the problem in the prior art that magnetic saturation can be reached easily at the wire winding groove of the radial stator core is solved, so that the electromagnetism utilization ratio and the bearing capacity of the bearing are increased and improved. The radial stator core structure can further optimize the assembling technology to increase the assembling success rate and product percent of pass.

Owner:GREE ELECTRIC APPLIANCES INC

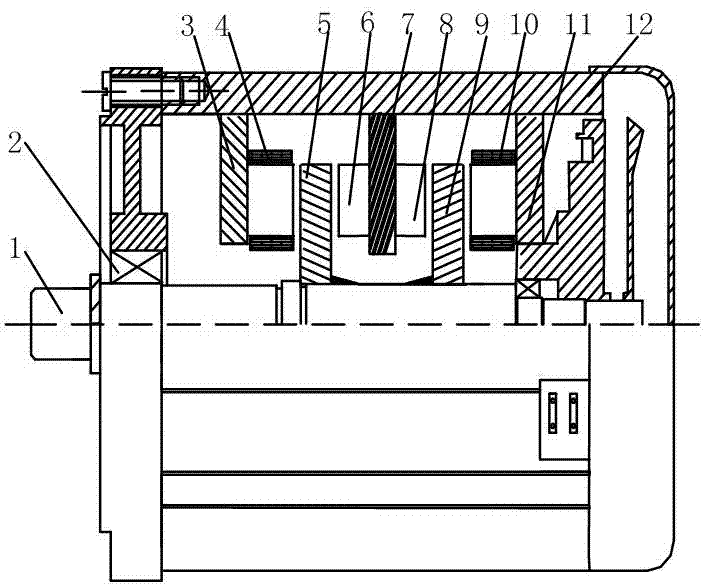

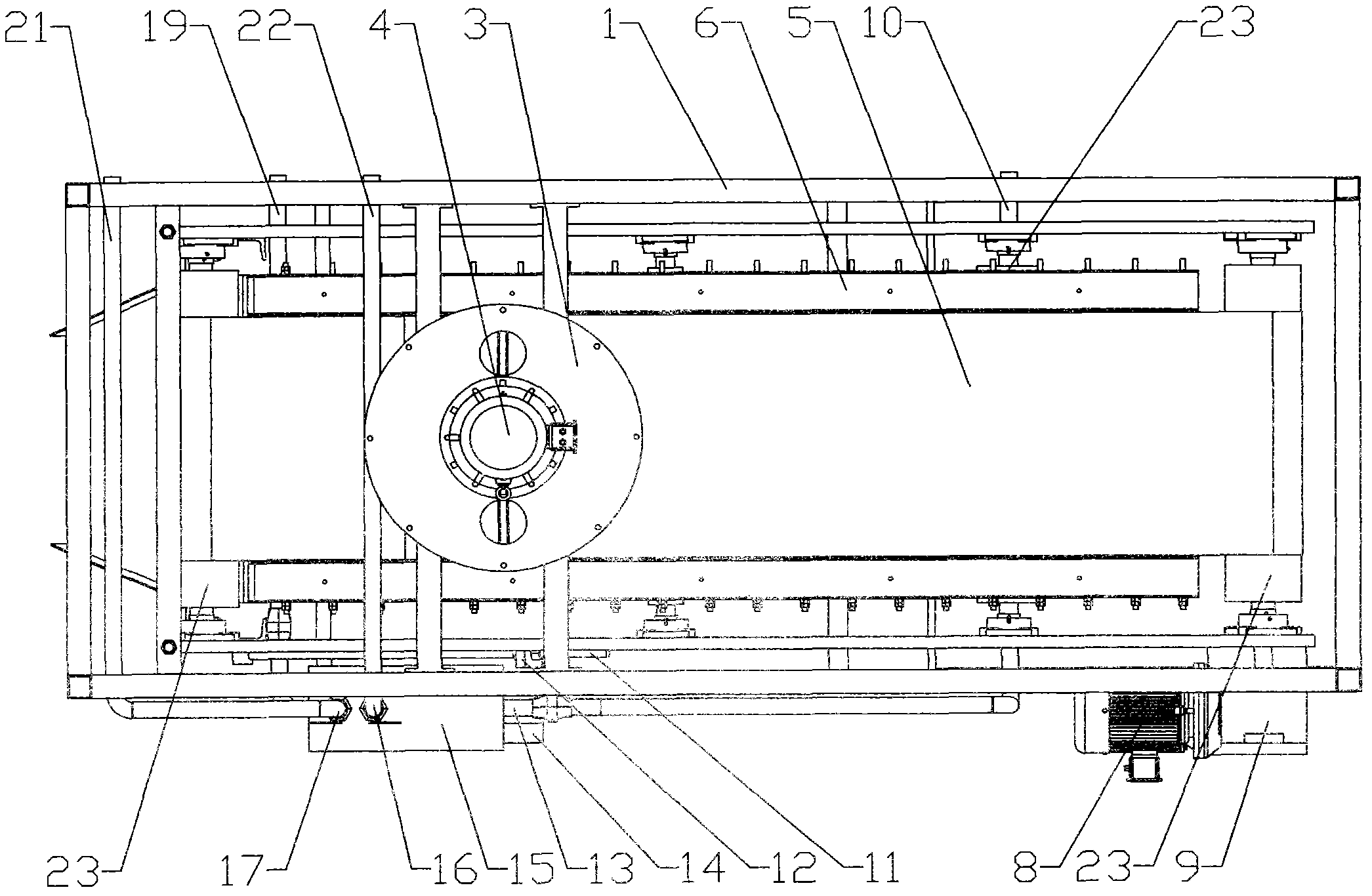

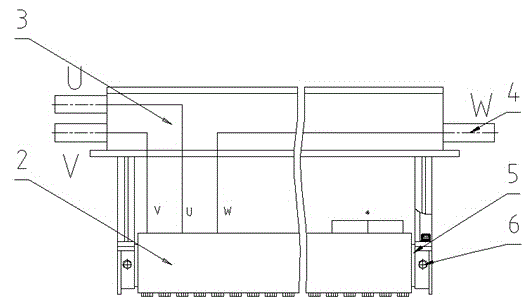

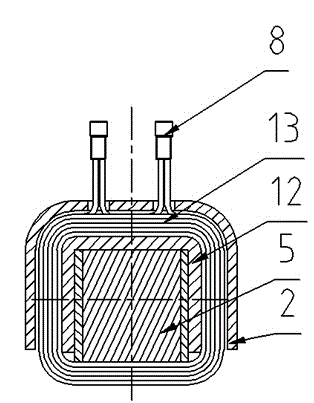

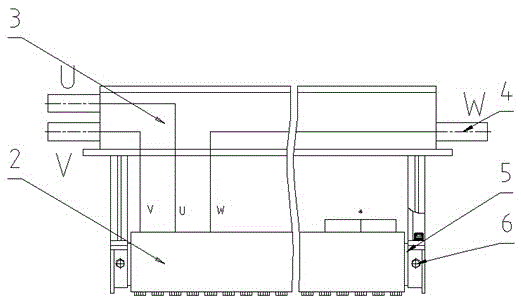

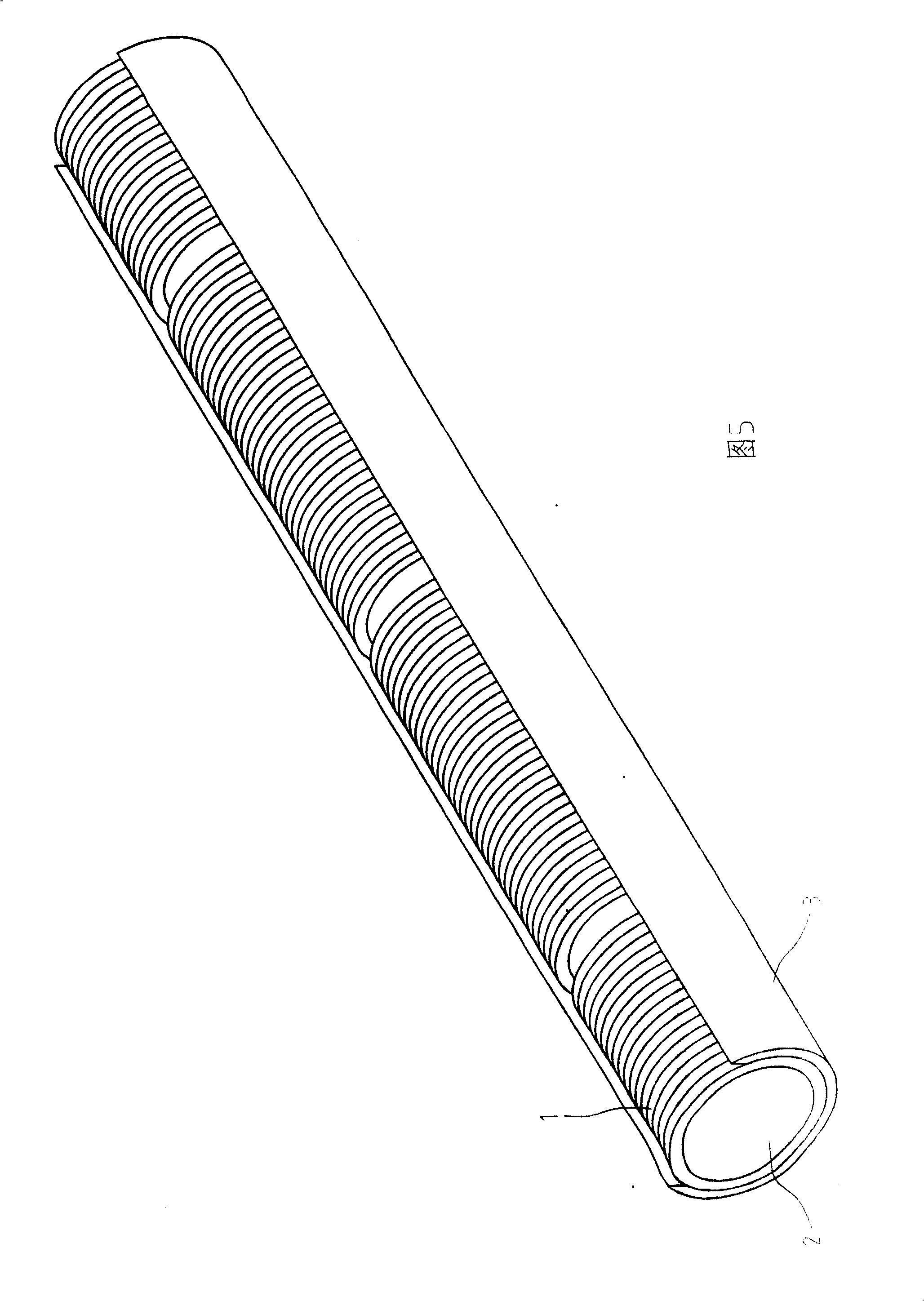

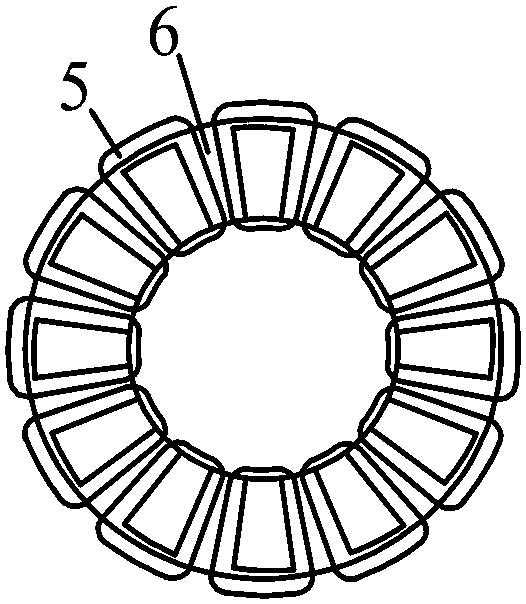

Full-winding electromagnetic stirring device for plate billet continuous casting crystallizer and plate billet continuous casting crystallizer

The invention discloses a full-winding electromagnetic stirring device for a plate billet continuous casting crystallizer and a plate billet continuous casting crystallizer. The electromagnetic stirring device comprises a columnar iron core of which the working surface is not provided with a tooth socket; the non-working surface of the columnar iron core is arranged in an inner water cooling sleeve; a plurality of coils are wound on the working surface of the columnar iron core and the inner water cooling sleeve; the coils on the inner water cooing sleeve are arranged in an outer water cooling sleeve; circulating pipes are arranged in both the inner water cooling sleeve and the outer water cooling sleeve; two ends of each circulating pipeline are respectively communicated with a water pipe connector. The space utilization of a coil winding is improved furthest, the magnetic conduction area of the columnar iron core is increased, and the magnetic field intensity is improved, so the electromagnetic force of the electromagnetic stirring device is increased by 10-20 percent, the production period is shortened by 1 / 3, and the universality is high.

Owner:HUNAN ZHONGKE ELECTRIC

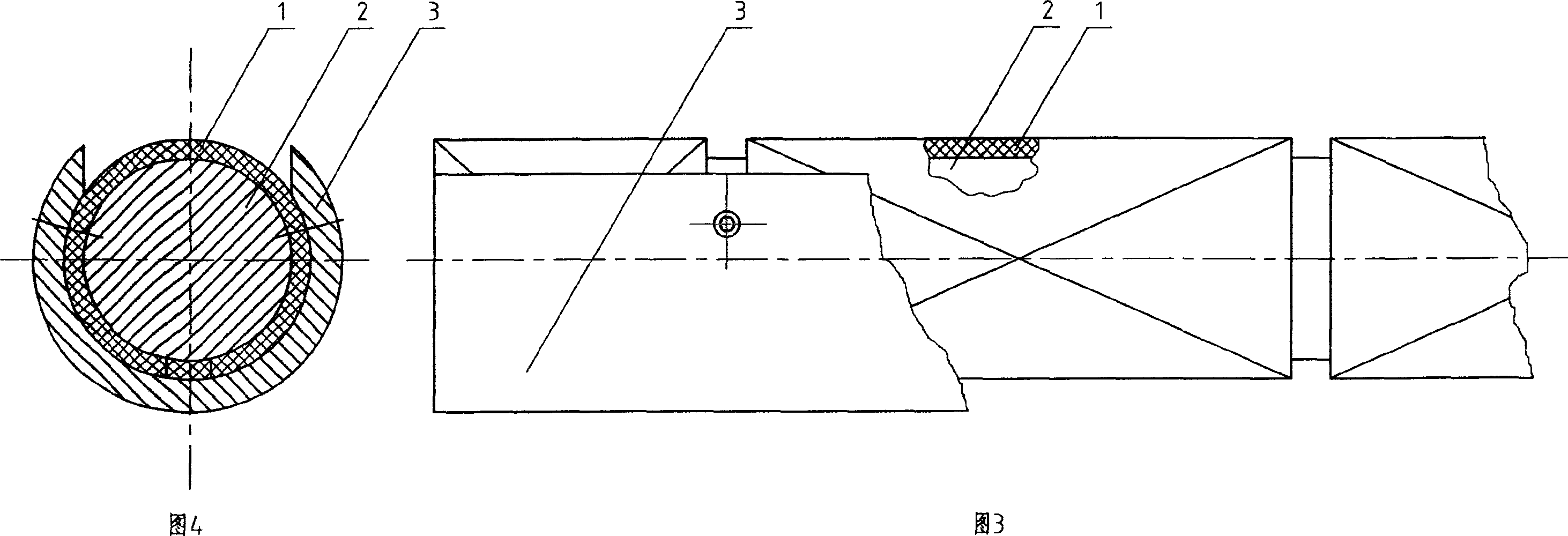

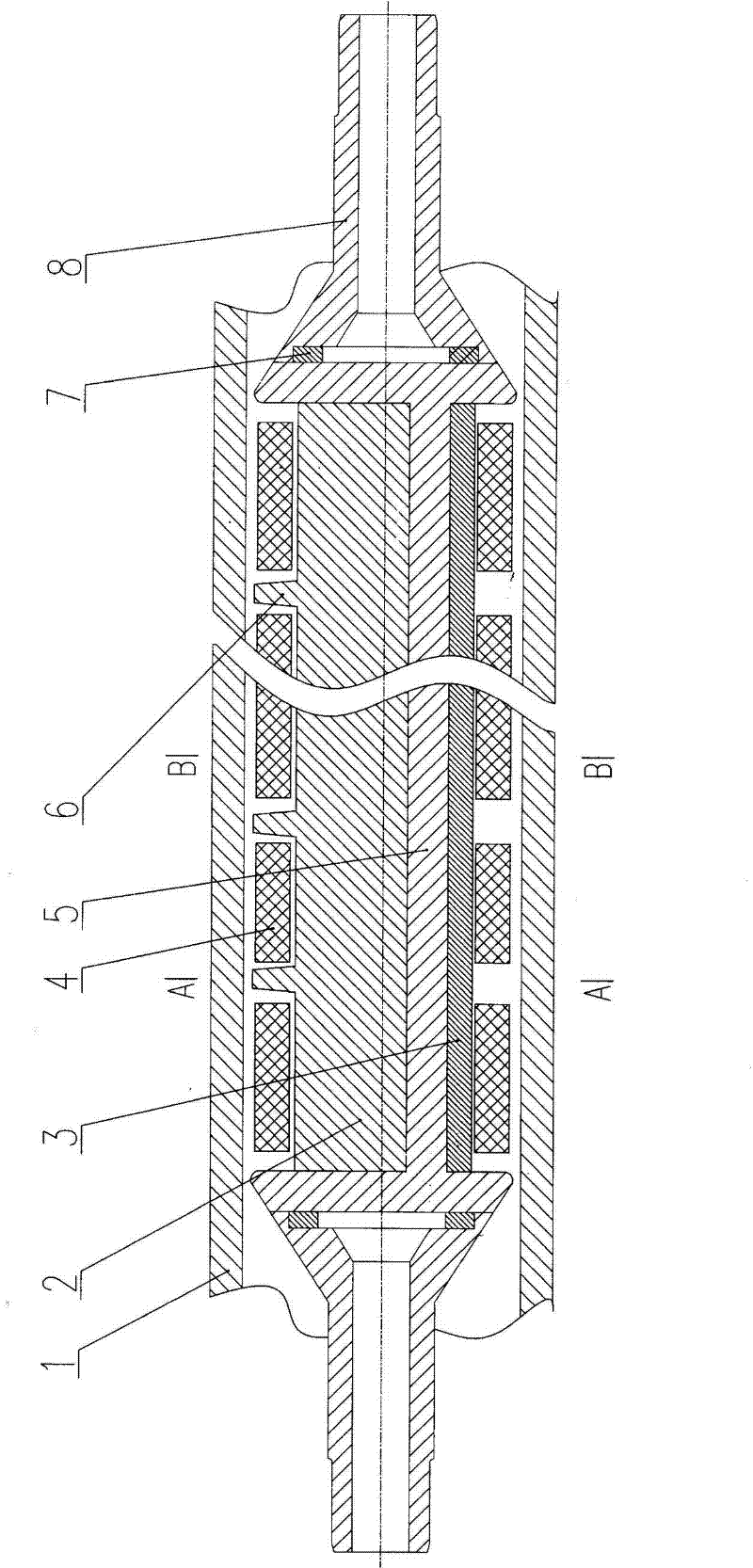

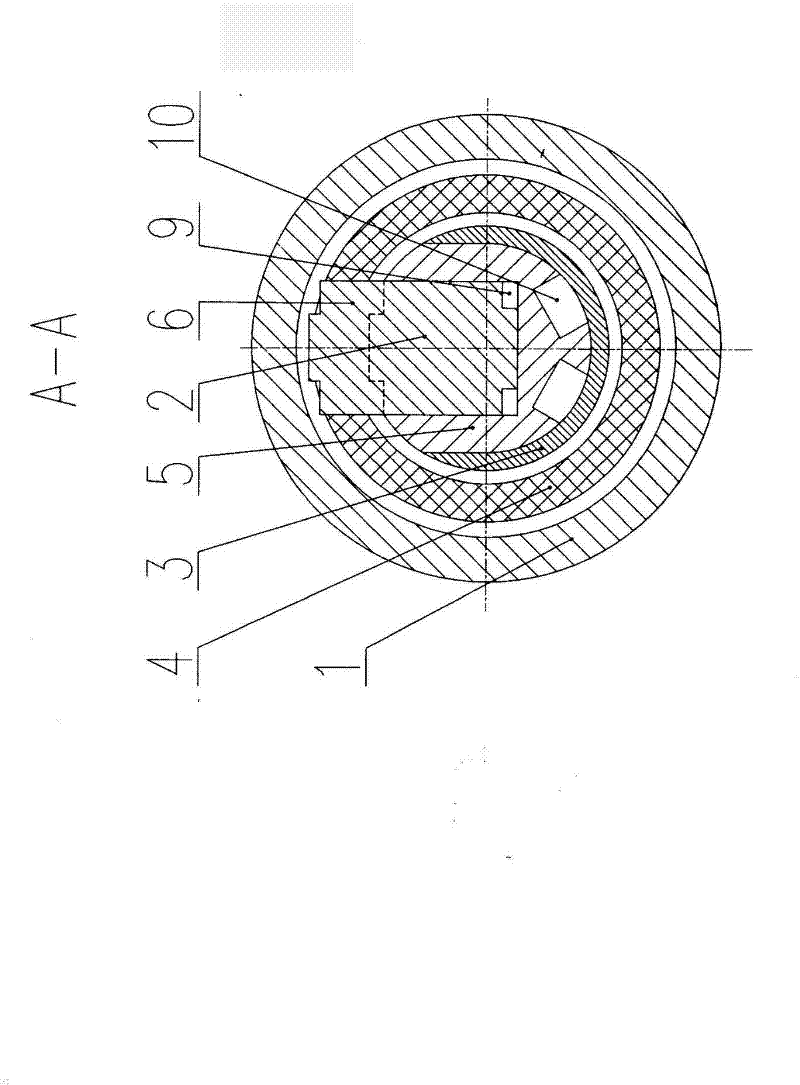

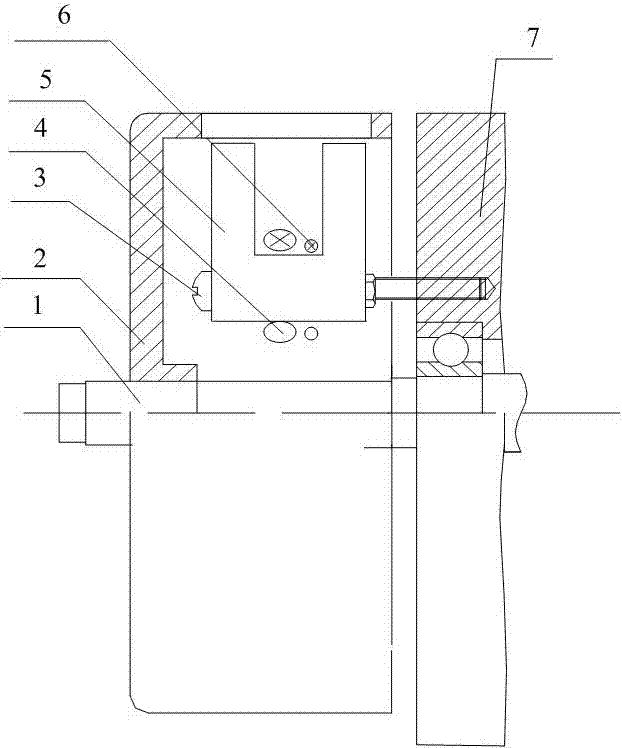

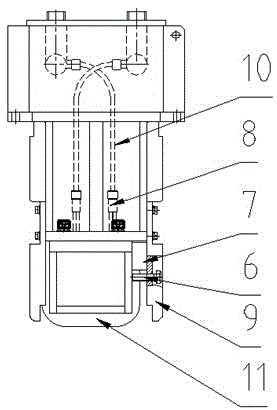

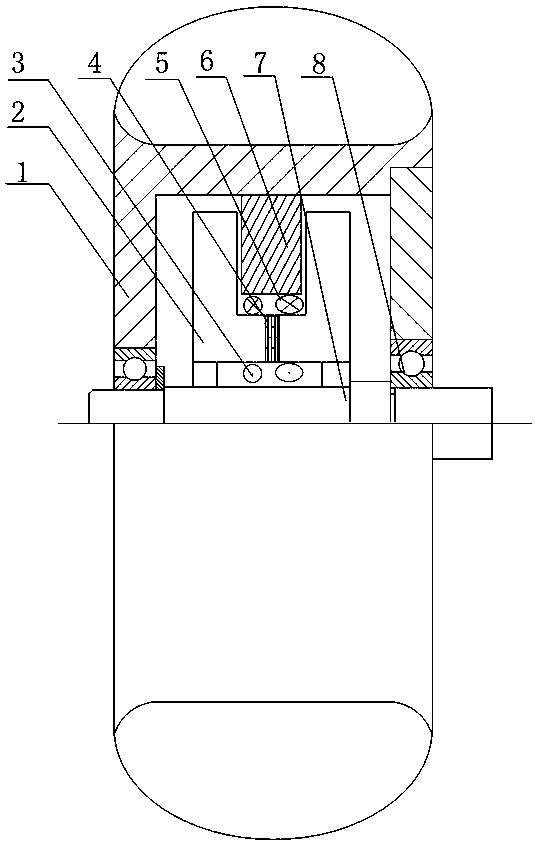

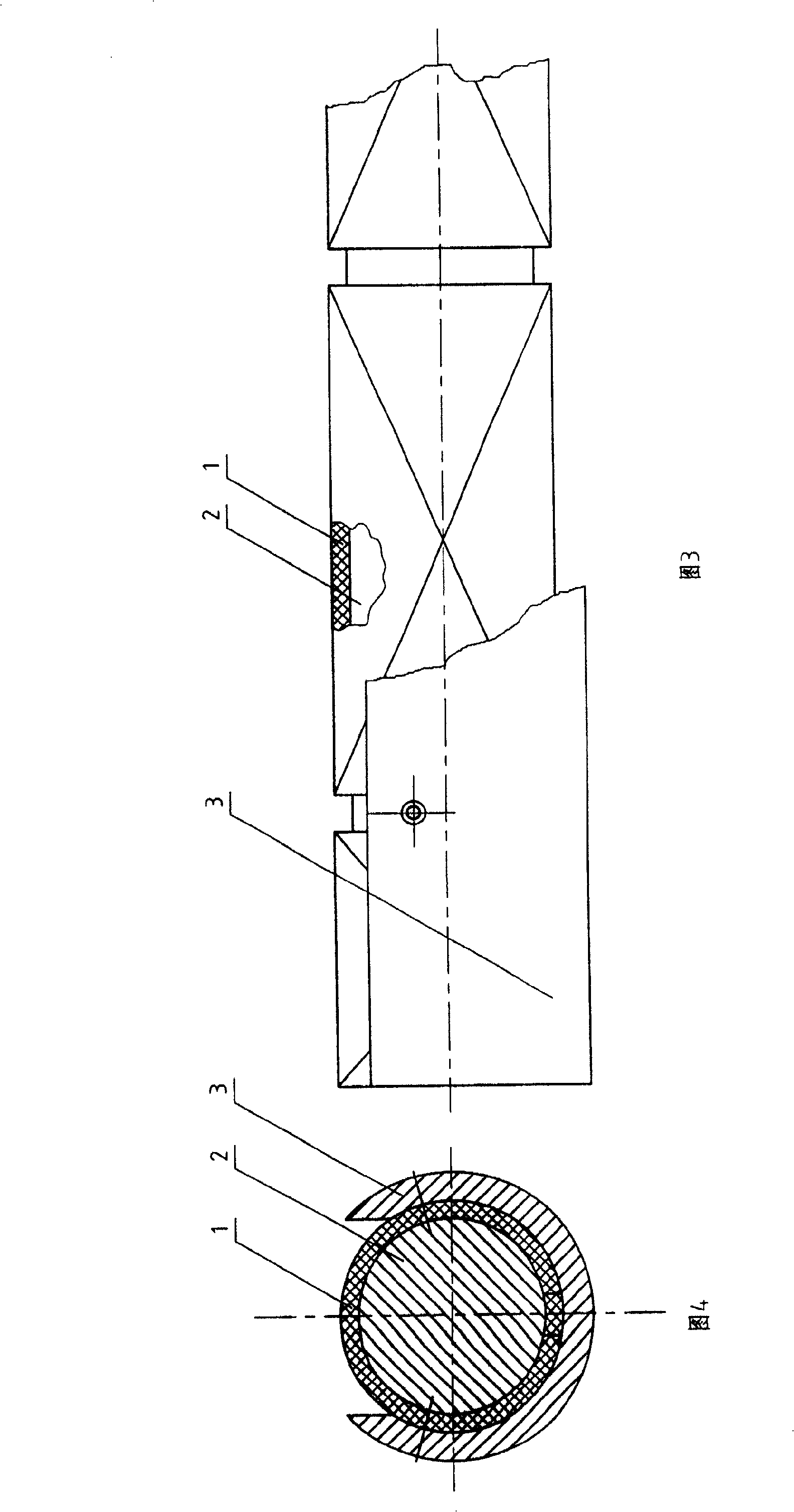

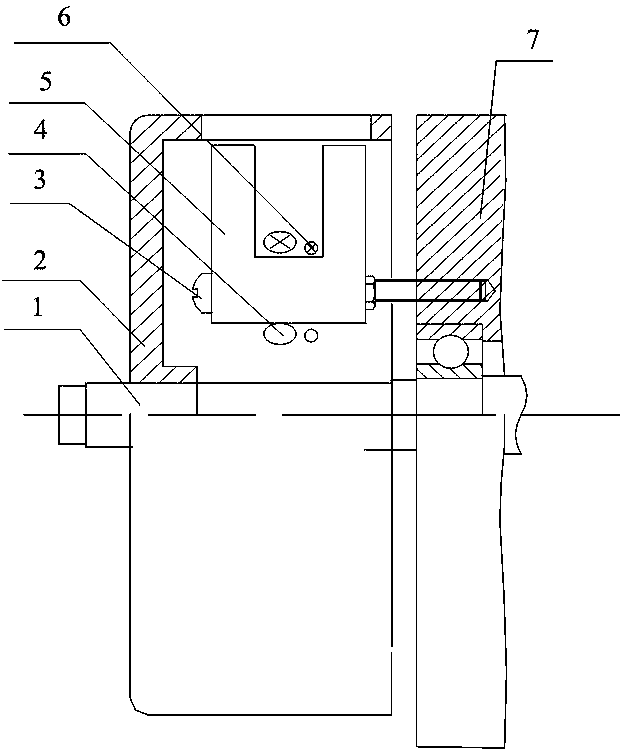

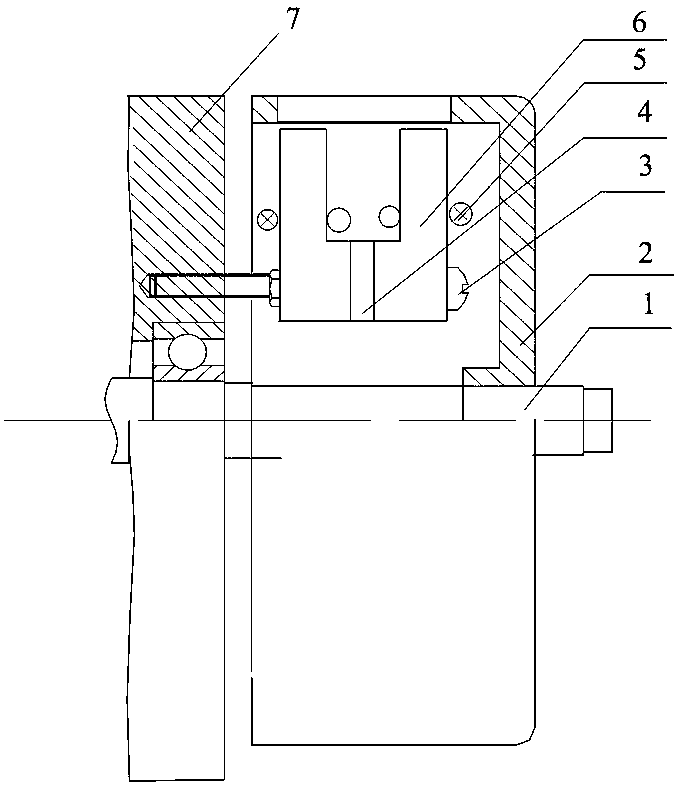

Iron-core shielding roller type electromagnetic stirring sensor

The invention relates to an iron-core shielding roller type electromagnetic stirring sensor, which comprises an iron core and coil windings, wherein the iron core is a combined iron core, the coil windings are wound around the outer circumference of the combined iron core in sections at intervals, the intervals between the combined iron core and the coil windings are arranged in a hollow roller, the combined iron core and the coil windings are fixed by iron core shaft ends at two ends, and the combined iron core, the coil windings and the hollow roller correspondingly rotate to move; the combined iron core comprises the iron core, U-shaped shielding rings and O-shaped shielding rings, the iron core consists a main iron core and a secondary iron core, the U-shaped shielding rings annularlycover the outer side of the secondary iron core and the inner side of each coil winding, and the O-shaped shielding rings are arranged at two ends of the iron core and the coil windings, wherein magnetic poles are arranged among all coil winding groups wound on the main iron core. The invention has the advantages of improving the effect of a roller type electromagnetic stirring device and increasing the magnetic conduction area of the iron core, the strength of a magnetic field and the electromagnetic stirring force, and also solves the problems that the stirring force is not enough, the effect is low, the efficiency is low, the electromagnetic stirring force is small, the magnetic leakage of a nonworking area is large.

Owner:HUNAN KEMEIDA ELECTRIC

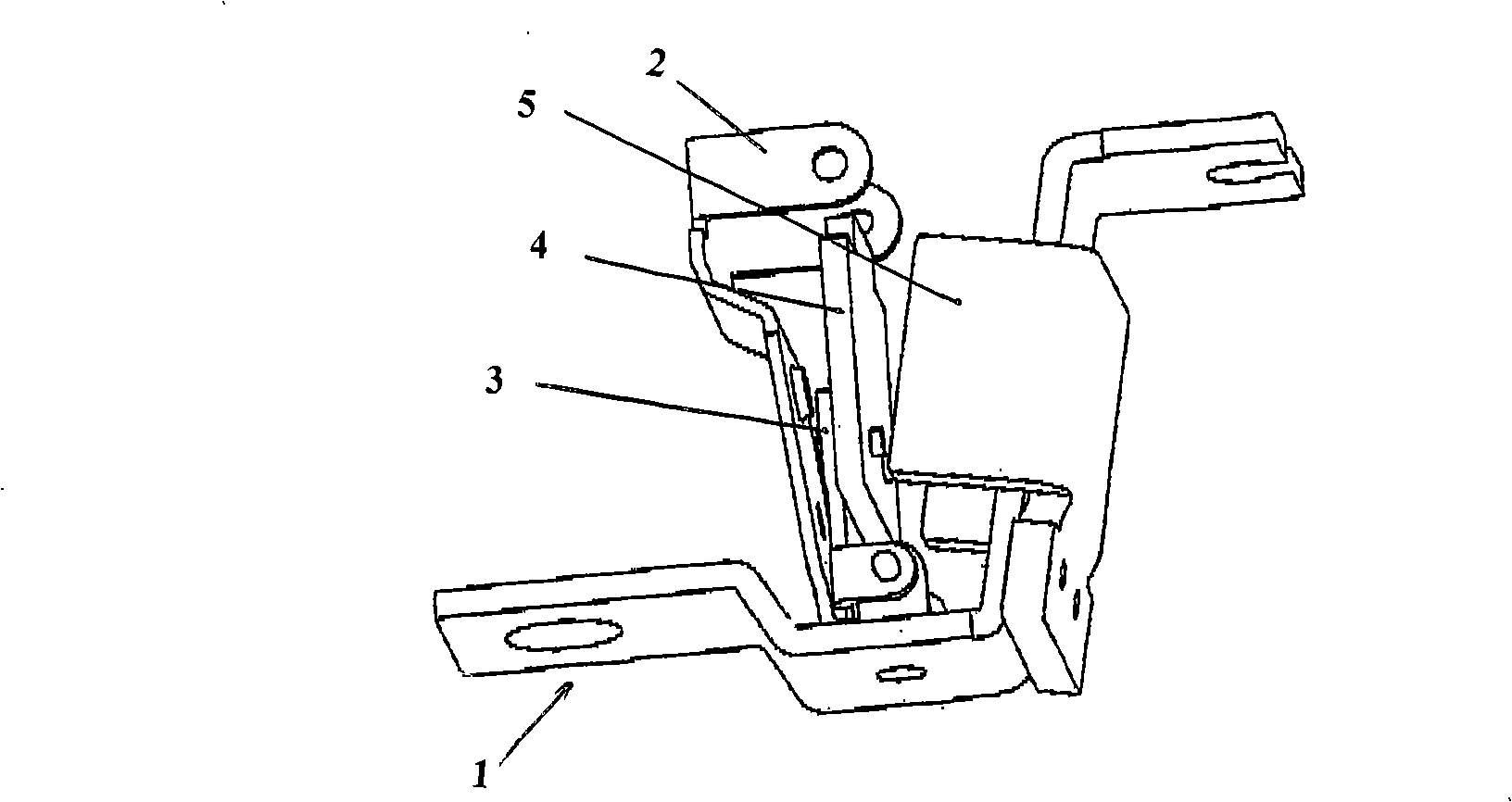

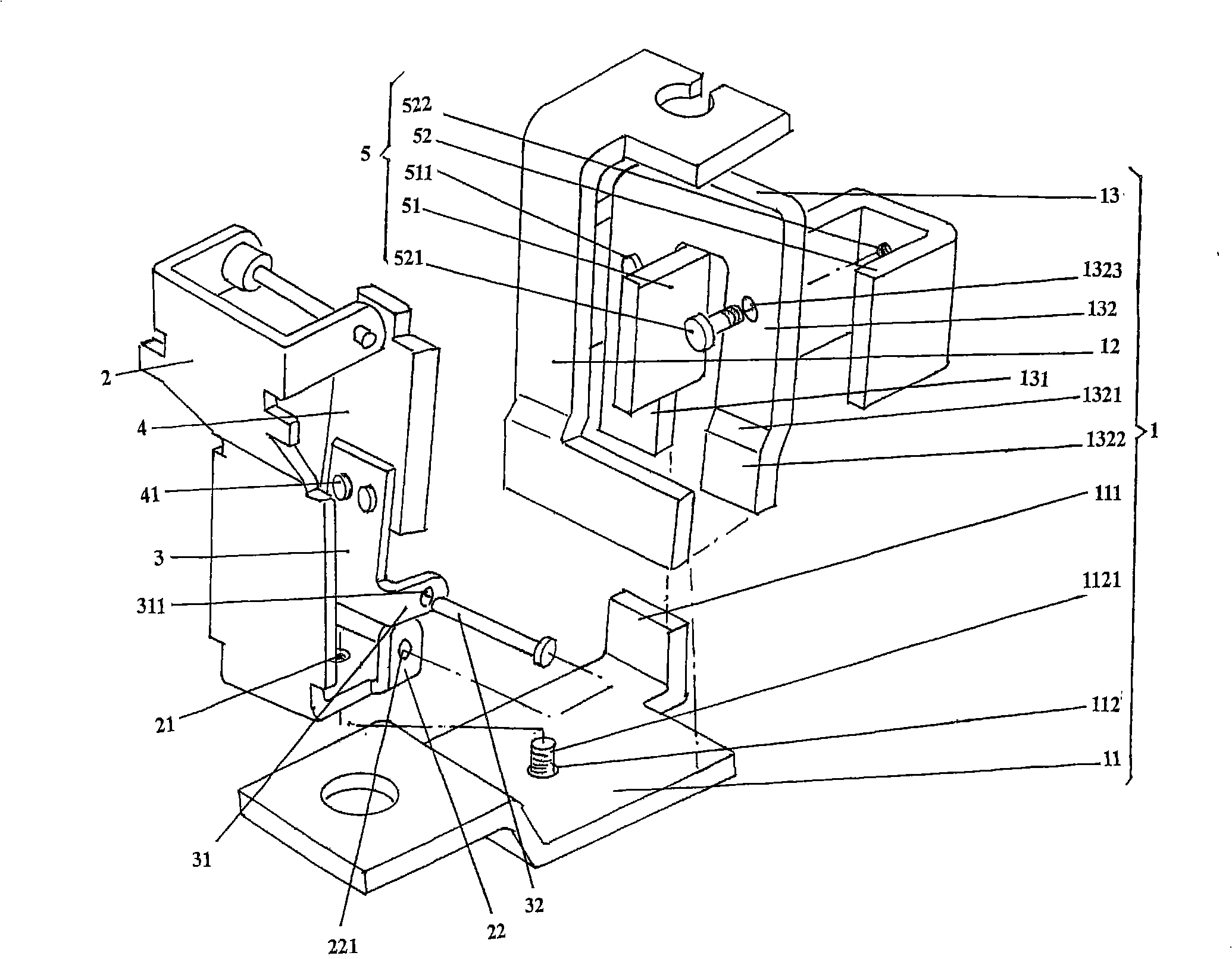

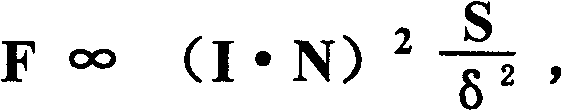

Clapping tunable electromagnetic release

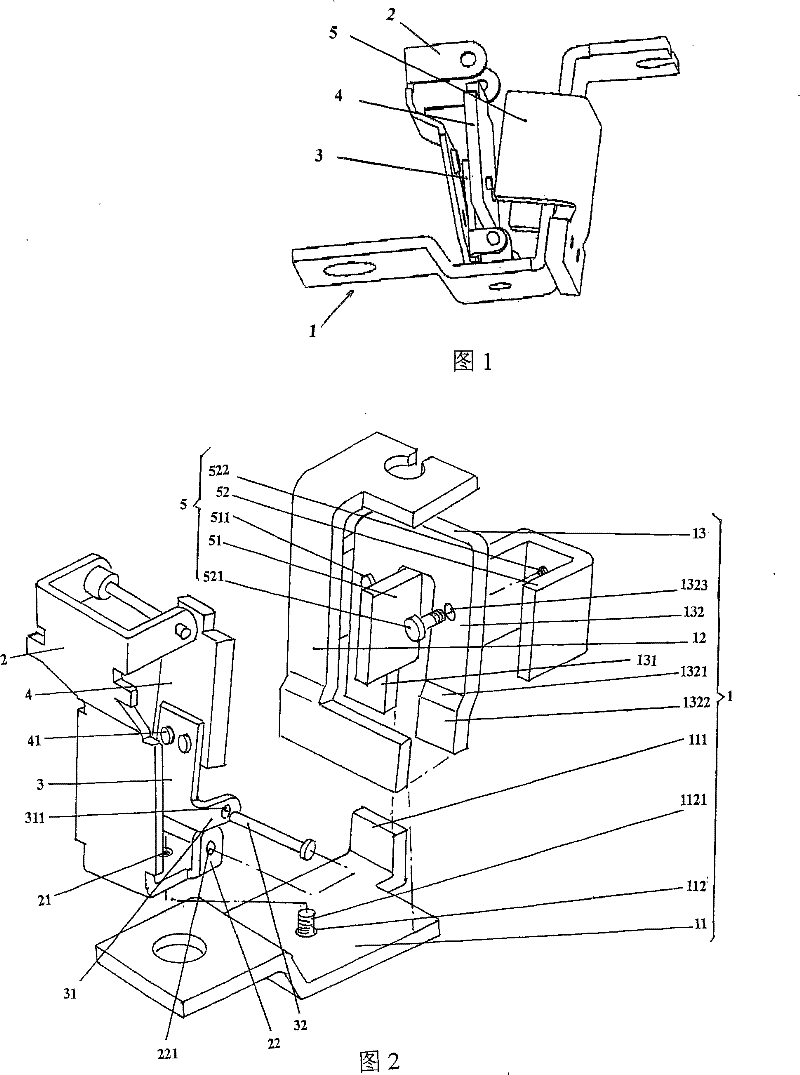

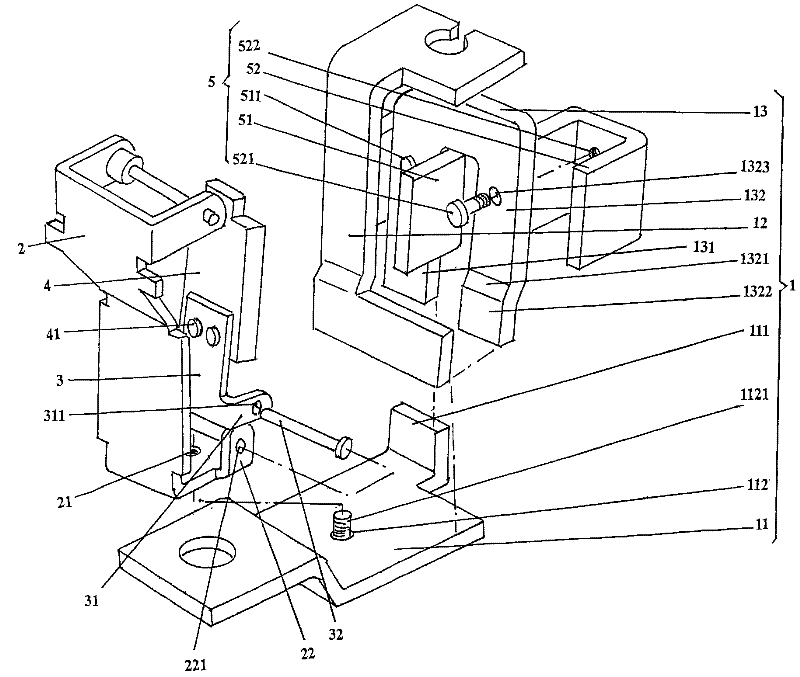

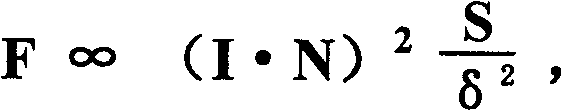

ActiveCN101308743ALarge magnetic areaGreat suctionProtective switch operating/release mechanismsEngineeringAmpere-turn

Disclosed is an adjustable clapper electromagnetic release, belonging to the breaker technical field. The adjustable clapper electromagnetic release comprises a current-carrying wire, a first bracket fixed on the current-carrying wire, a second bracket which is hinged on the first bracket, an armature iron fixed on the second bracket and an iron core which is fixed on the current-carrying wire and corresponds with the armature iron. The iron core comprises a first U-shaped core body and a second U-shaped core body, which are fixed with the current-carrying wire. The adjustable clapper electromagnetic release has the advantages that the adjustable clapper electromagnetic release adopts the first U-shaped core body and the second U-shaped core body which develop into two separate magnetic loops with the armature iron; in this way, the first U-shaped core body and the second U-shaped core body develop four magnetic air gaps Delta with the armature iron, thus enlarging the magnetic area S; meanwhile, the number of the ampere-turns that running through the first U-shaped core body is larger, so even when small current runs through the current-carrying wire, large magnetic force will be generated, thus ensuring sensitive and reliable release; the current adjustment range can be enlarged from 200-250A in the prior art to 125-250A.

Owner:CHANGSHU SWITCHGEAR MFG CO LTD (FORMER CHANGSHU SWITCHGEAR PLANT)

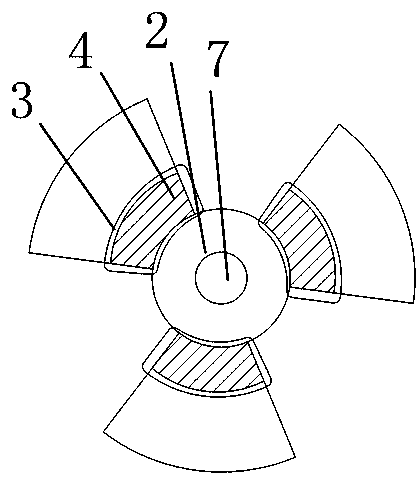

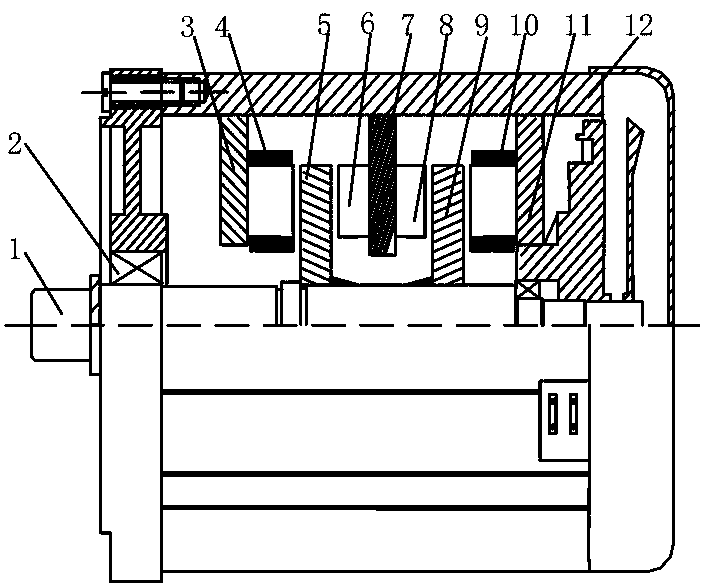

Disc-type built-in aero starter generator

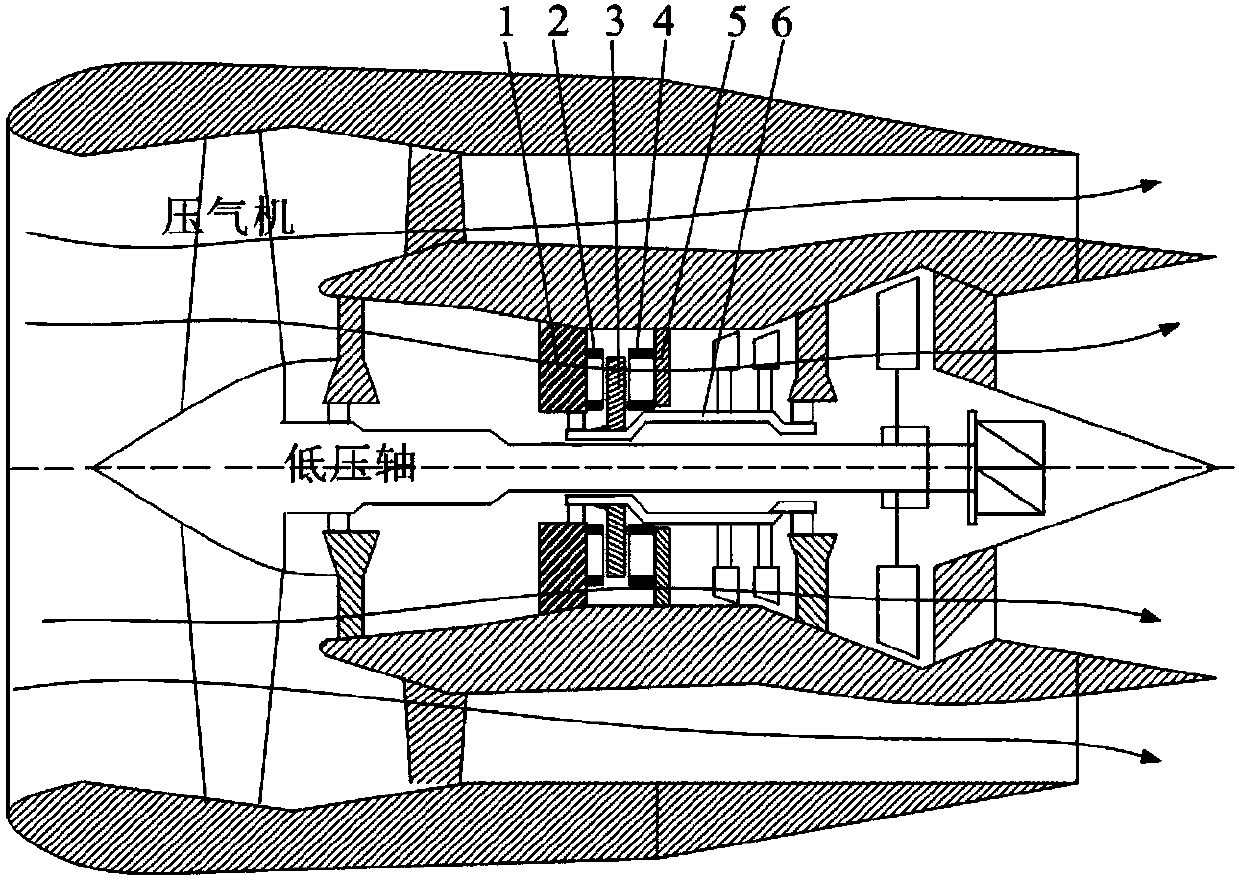

InactiveCN107846124AVery fewLight in massMagnetic circuit rotating partsMagnetic circuit stationary partsStarter generatorMoment of inertia

The invention discloses a disc-type built-in aero starter generator, which belongs to the field of aero engineering. The disc-type built-in aero starter generator comprises a high-voltage shaft, a first stator iron core, a rotor iron core, first armature coils and a second stator iron core, and is characterized in that the rotor iron core is fixed on the high-voltage shaft of the aero engine; thefirst stator iron core and the second stator iron core with the same structures are symmetrically located at two axial sides of the rotor iron core and are fixed on the shell of the aero engine; 3k fan-shaped through holes are distributed uniformly on the circumference of the rotor iron core, and k is a positive integer larger than 1; and one side, facing the rotor iron core, of each of the firststator iron core and the second stator iron core is provided with 4k uniformly-distributed fan-shaped convex armature poles, and the armature poles of the first stator iron core are wound with integrated armature coils. The rotor iron core in the invention has small moment of inertia, and high-speed rotation can be achieved; and the rotor iron core is located on the high-voltage shaft of the engine, the rotation speed is high, the power is larger, and the disc-type built-in aero starter generator is extremely suitable for serving as an aero built-in generator.

Owner:猫头鹰安防科技有限公司

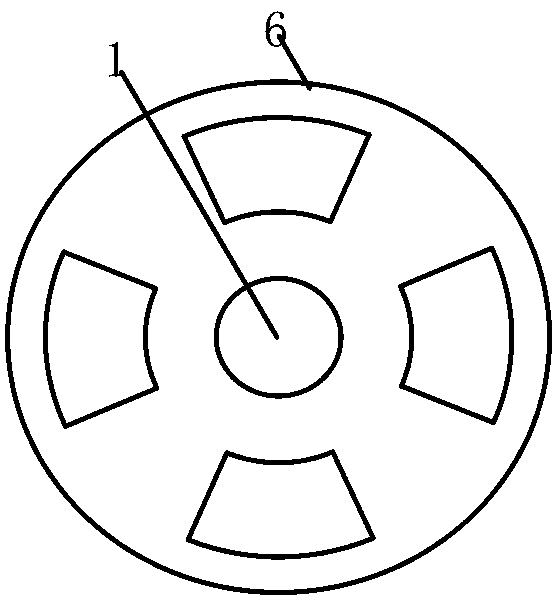

Conical air-gap and axial dual-loop type magnetic-field permanent-magnet synchronous motor

ActiveCN107612165AFree up spaceLarge magnetic areaMagnetic circuit rotating partsMagnetic circuit stationary partsSynchronous motorPermanent magnet synchronous motor

The present invention relates to the technical field of motors, and particularly relates to a conical air-gap and axial dual-loop magnetic-field permanent-magnet synchronous motor, which comprises a shell, two groups of stator iron cores and a rotor. The stator iron cores and the rotor are arranged in the shell. The two ends of the shell are respectively connected with one end cover. A rotating shaft is rotatably supported by a bearing on the end covers. The motor is characterized in that two groups of stator iron cores are arranged. Each group of stator iron cores comprises a stator yoke partlocated at a first end and a stator tooth part located at a second end. The end surfaces of the stator yoke parts of two groups of stator iron cores are attached to each other. A positioning ring isarranged on the circumferential surface of each stator yoke part. The two groups of stator iron cores are arranged in the shell by means of positioning rings. The end surface of the stator tooth partof each group of stator iron cores forms a stator conical surface. Each group of stator iron cores is matched and provided with one rotor. According to the invention, by means of the motor, the efficiency of motor production and assembly is effectively improved. Meanwhile, the use efficiency of the motor can be improved.

Owner:JIANGSU ZJA NEW MATERIAL

Snap-in adjustable electromagnetic release

ActiveCN101308743BLarge magnetic areaGreat suctionProtective switch operating/release mechanismsEngineeringCurrent regulation

Owner:CHANGSHU SWITCHGEAR MFG CO LTD (FORMER CHANGSHU SWITCHGEAR PLANT)

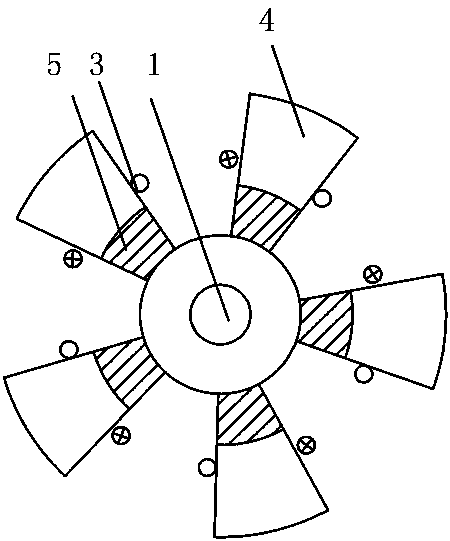

Permanent magnet wind-driven motor with low rotational inertia

ActiveCN107579640ALight in massSmall moment of inertiaSynchronous machine detailsWind energy generationWind drivenMoment of inertia

The invention discloses a permanent magnet wind-driven motor with low rotational inertia, and belongs to the technical field of special motors. The permanent magnet wind-driven motor comprises a shaft, an armature iron core, first armature windings, second armature windings, a rotor iron core, permanent magnets, a permanent magnet iron core and a shell, and is characterized in that 4k fan-shaped through holes are uniformly formed in a disc of the rotor iron core, and the k is a positive integer; the permanent magnet iron core and the armature iron core which are fixed onto the shell are arranged on two sides of the rotor iron core, the 6k fan-shaped permanent magnets are arranged on the surface, which faces the rotor iron core, of the permanent magnet iron core, 12k fan-shaped protruded armature poles are uniformly distributed on the side, which faces the rotor iron core, of the armature iron core, each first armature winding is wound on the two corresponding armature poles, and the second armature windings are wound on the odd-number armature poles along the clockwise direction. The permanent magnet wind-driven motor has the advantages that the rotor iron core is low in rotational inertia and can quickly respond, the second windings are capable of weakening demagnetization armature reaction and increasing the power density, and accordingly the permanent magnet wind-drivenmotor is quite suitable to be used as a wind-driven power generator started by breeze.

Owner:徐州普林惠新能源技术有限公司

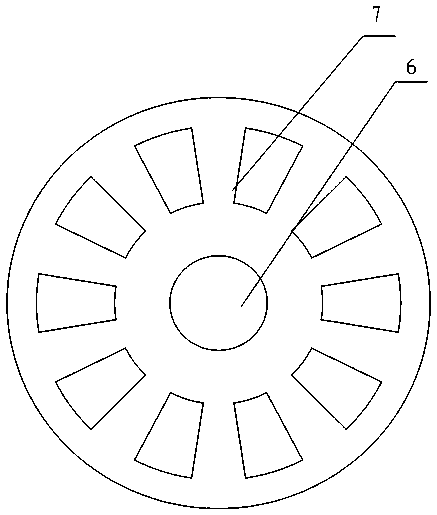

Grid-shaped rotor motor for range extender of electric automobile

ActiveCN107465322ALight in massSmall moment of inertiaMagnetic circuit rotating partsElectric machinesCopperHigh power density

The invention relates to a grid-shaped rotor motor for a range extender of an electric automobile and belongs to the technical field of electric automobiles. The grid-shaped rotor motor is composed of a crankshaft, a shell, a stator iron core, an exciting winding and an armature winding, wherein ten rectangular holes are uniformly formed in the circumferential surface of the shell, and a grid-shaped iron core capable of conducting magnetism is arranged between any two rectangular holes; the stator iron core fixedly arranged on a range extender shell is composed of 12 substator iron cores uniformly distributed in a left inverted 'n' shape, stator poles projecting along the radial direction are arranged at the two sides of each substator iron core, and the side surface of each stator pole is in a sectional shape; the distance between two stator poles on one substator iron core is less than the axial length of each rectangular hole in the shell; the exciting winding is formed by winding yokes of all the 12 substator iron cores. The grid-shaped rotor motor provided by the invention can fully play the advantage of high power density of a disc type motor, and the exciting winding is short in path and small in copper loss.

Owner:SHENZHEN POWER SUPPLY BUREAU +1

Electric roller permanent magnet motor

ActiveCN107846091AImprove cooling effectImprove reliabilityMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineDrive motor

The invention discloses an electric roller permanent magnet motor, which belongs to the technical field of electric rollers. The electric roller permanent magnet motor comprises a shaft, a roller, a stator core, armature windings, excitation windings, permanent magnets, rotor teeth and a bearing, wherein the circumferential surface of the roller is uniformly distributed with 5K rectangular holes;the stator core is formed by 3K uniformly-distributed [-shaped sub stator cores; two ends of each sub stator core are provided with two stator teeth respectively; all stator teeth face the outer sideof the circumference, and the distance between the stator teeth at two ends of the same sub stator core is smaller than the axial length of the rectangular hole of the roller; the surface of the stator tooth at one end of the sub stator core is provided with a permanent magnet; and each stator tooth is wound with an integrated armature winding. Thus, integrated design between the roller and a driving motor can be effectively realized, cooling is easy, advantages of integrated excitation can be made full use of, and high application value in the electric roller is realized.

Owner:TANGSHAN WEISEN NEW MATERIAL CO LTD

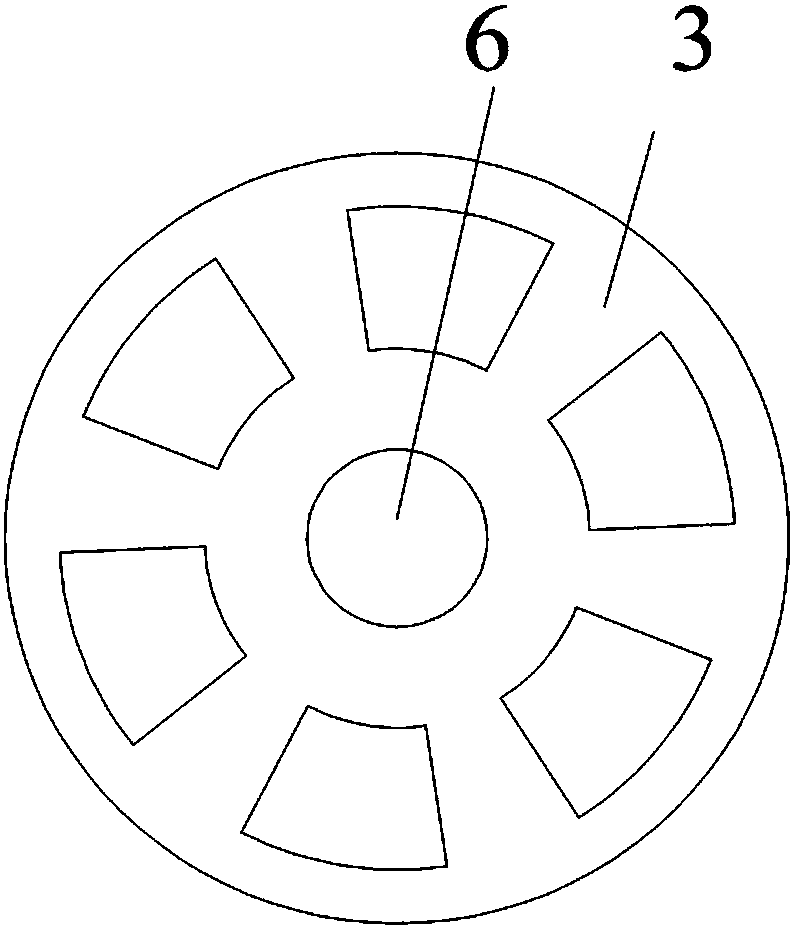

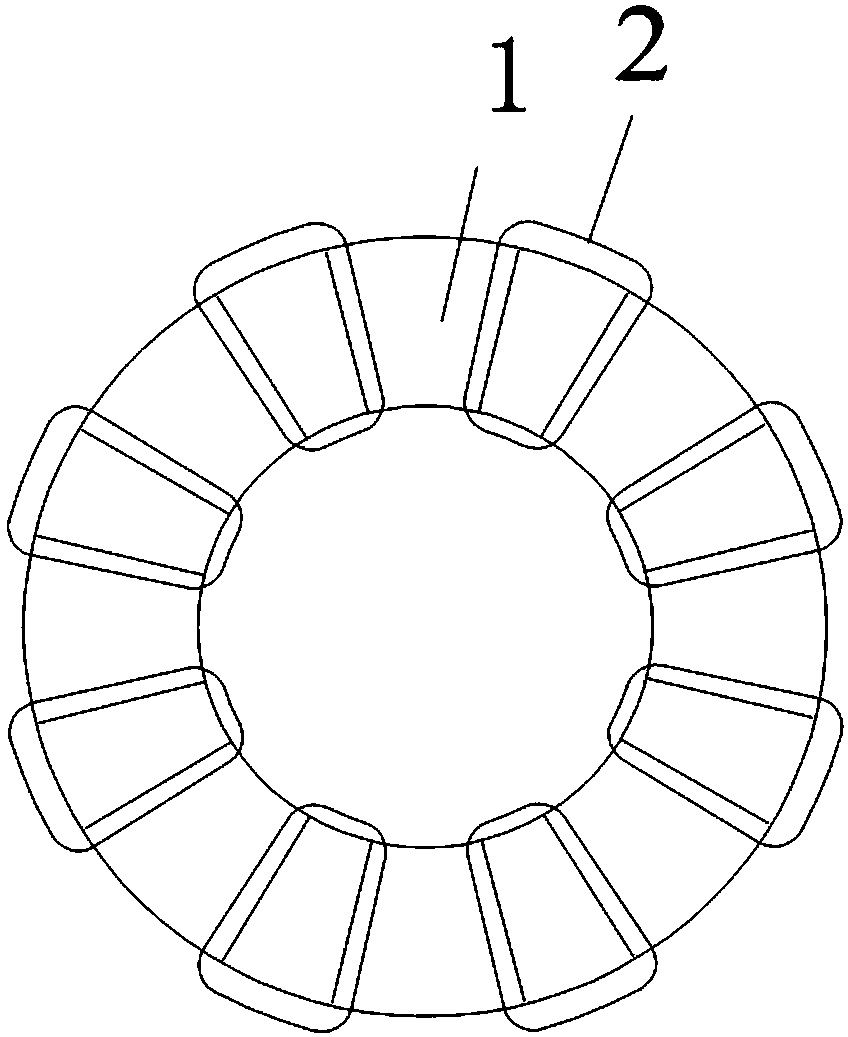

Aviation internal type permanent magnetism starting generator

ActiveCN107528442ALarge magnetic areaIncrease magnetic fluxSynchronous machine detailsPhysicsMoment of inertia

The invention discloses an aviation internal type permanent magnetism starting generator, which belongs to the field of electrical engineering, and comprises a permanent magnet, a permanent magnetism magnet yoke, a rotor iron core, an armature winding and an armature iron core. The aviation internal type permanent magnetism starting generator is characterized in that the rotor iron core is fixed to one side of an air inlet of the low pressure shaft of an aero-engine; the permanent magnetism magnet yoke and the armature iron core are respectively disposed at two axial sides of the rotor iron core; the circumference of the rotor iron core is uniformly provided with fan-shaped through holes in the number of 5k (k is a positive integer greater than 1); One side of the permanent magnetism magnet yoke orienting towards the rotor iron core is fixed with a fan-shaped permanent magnet; one side of the armature iron core orienting towards the rotor iron core is provided with fan-shaped protruding armature pole; the magnetizing direction of each adjacent three permanent magnets is of the same, and each armature pole is winded with a concentration type armature coil. The aviation internal type permanent magnetism starting generator is advantageous in that the temperature of the air inlet is quite low, which can adapt to the work of the permanent magnet; the moment of inertia of the rotor iron core is small, the pole number of the rotor is small, and high-speed rotation can be realized; the aviation internal type permanent magnetism starting generator can be operated both as a motor and a generator, and thereby it is very suitable for an aviation internal type starting generator.

Owner:山东飞奥航空发动机有限公司

An external rotor wind generator

ActiveCN107528441BLight in massSmall moment of inertiaSynchronous machine detailsMagnetic circuit rotating partsWind drivenNew energy

Provided is an external rotor wind driven generator, which belongs to the technical field of new energy generating, and comprises a shaft, a turbine fan blade, a first armature winding, a second armature winding, a rotor iron core, a permanent magnet, a stator iron core, and a housing. The external rotor wind driven generator is characterized in that the inner side of the rotor iron core is provided with protruding rotor teeth in the number of 6k (k is a positive integer); the stator iron core fixed to the shaft is composed of U-shaped sub-stator iron cores in the number of 5k, and the two sides of the sub-stator iron core are respectively provided with a stator tooth protruding along the radial direction; a yoke part at the middle of the sub-stator iron core is embedded with the permanent magnet magnetizing along the axial direction; the root part of the stator tooth at one side of the sub-stator iron core is winded with the concentration type first armature winding , and the root part of the stator tooth at the other side of the sub-stator iron core is winded with the concentration type second armature winding. The invention is advantageous in that the rotor structure is simple and reliable, and the positioning force and the moment of inertia is small, and response is rapid; the demagnetizing armature reaction can be weakened, and the power density excitation and coiling mode can be improved, and thereby the external rotor wind driven generator is very suitable for the wind driven generator of gentle breeze.

Owner:SHENZHEN POWER SUPPLY BUREAU +1

Full winding slab continuous casting mold electromagnetic stirring device and slab continuous casting mold

ActiveCN104646640BIncrease Electromagnetic ThrustLarge magnetic areaMetallurgyElectromagnetic interference

Owner:HUNAN ZHONGKE ELECTRIC

The Primary Structure of a Low Eddy-current Loss Cogged Cylindrical Linear Motor

The invention discloses a primary structure of a low eddy current loss cogging type cylindrical linear motor, which includes primary teeth, primary yokes and multiple circular ring groups; the primary teeth and primary yokes are separate components and are tightly fitted together , forming the primary iron core; one or more circular ring groups are embedded between each two primary tooth assemblies; the ring-shaped primary tooth assembly consists of multiple tooth core blocks of the same specification arranged in an array along the side length of an equilateral polygon Each core block is made of silicon steel sheets laminated along the circumferential direction; the primary yoke assembly is made of silicon steel sheets laminated along the motor moving direction, and each lamination is evenly opened with a number of shallow grooves in the yoke along the circumferential direction to prevent Break the eddy current path along this direction. The invention adopts the method of separating the teeth and yokes and laminating sheets in different directions to form the primary iron core, which can effectively reduce the eddy current loss of the cogged cylindrical linear motor, improve the efficiency of the motor, and at the same time maintain a high thrust density of the motor.

Owner:HEFEI UNIV OF TECH

A Low Moment of Inertia Servo Motor

ActiveCN107733118BLight in massSmall moment of inertiaMagnetic circuit rotating partsMagnetic circuit stationary partsMoment of inertiaConductor Coil

Owner:SHENZHEN POWER SUPPLY BUREAU +1

A brushless hybrid excitation motor for electric skateboard

ActiveCN107733107BImprove reliabilityLower internal resistanceMagnetic circuit stationary partsSynchronous machines with stationary armatures and rotating magnetsElectric machineElectric vehicle

The invention discloses a brushless hybrid excitation motor for an electric skateboard, which belongs to the technical field of electric vehicles. The brushless hybrid excitation motor for the electric skateboard is composed of a shaft, a hub, a stator iron core, armature windings, permanent magnets, a rotor iron core and a bearing, wherein the inner circumference of the hub is fixed with 4K rotorteeth, and K is a positive integer; the stator iron core is formed by 3K uniformly-distributed [-shaped sub stator iron cores, and two sides of each sub stator iron core are provided with stator teeth; all stator teeth face the outer side of the circumference, and the two stator teeth of the same sub stator iron core are arranged at two sides of the rotor tooth of the rotor iron core; the middleyoke part of each sub stator iron core is embedded with the permanent magnet; and the middle yoke part of each sub stator iron core is wound with a centralized armature winding. Centralized excitationcan be effectively realized, the magnetic path is short, and iron and copper consumption is little; the advantage of high power density of a disc motor can be thoroughly exerted, and high applicationvalue is realized in the micro electric vehicle such as the electric skateboard.

Owner:徐州宇飞电力科技有限公司

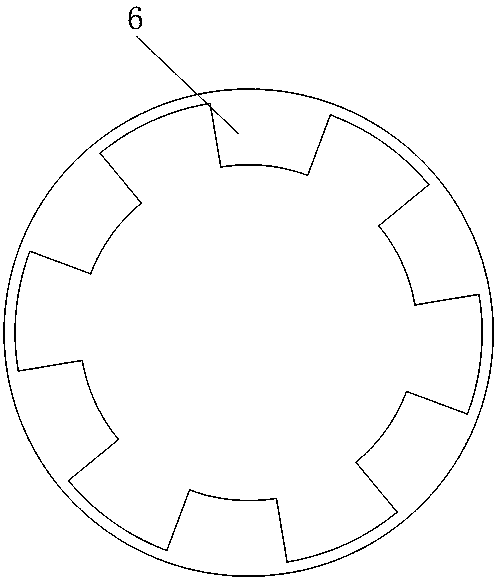

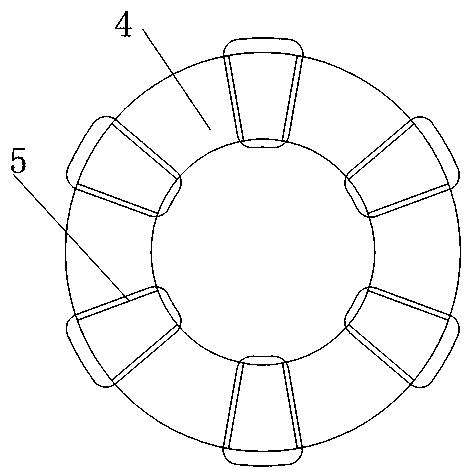

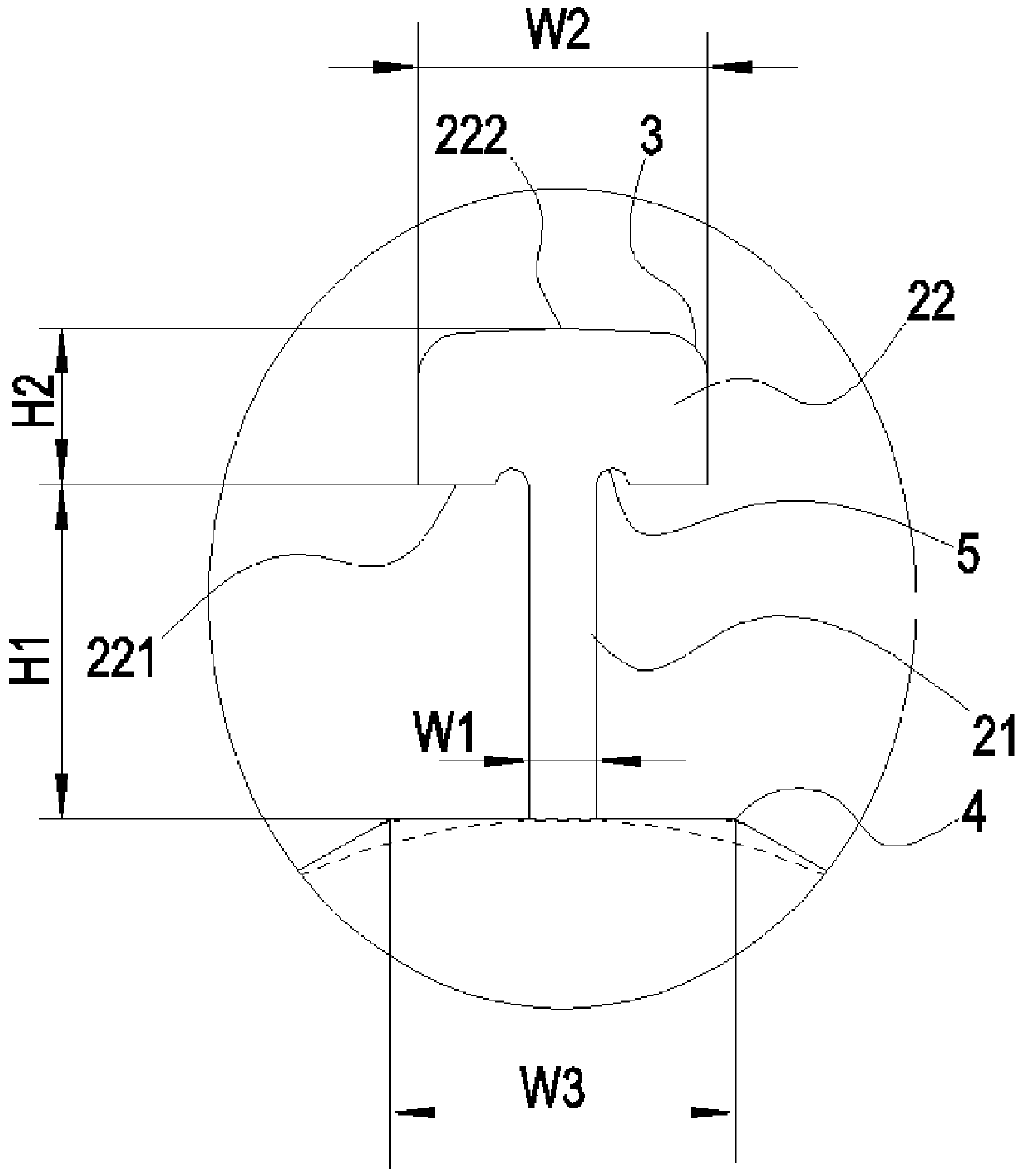

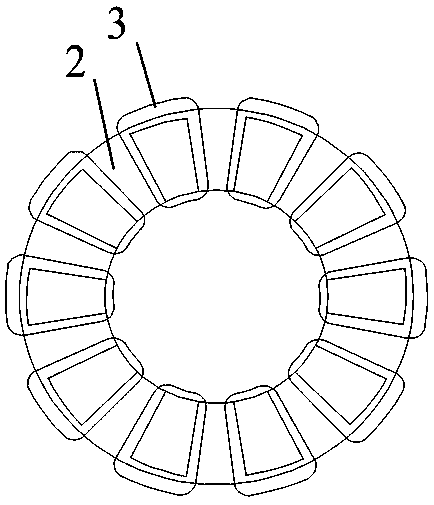

Punched sheet, iron core and motor

PendingCN110739781AImprove general performanceSimple structureMagnetic circuit shape/form/constructionElectric machineStructural engineering

The invention relates to a punched sheet, an iron core and a motor and belongs to the technical field of motors. The punched sheet comprises a punched sheet main body and a plurality of tooth yoke main bodies uniformly distributed on the punched sheet main body; the tooth yoke main body comprises a tooth body part and a tooth end part; the total width and total length of the tooth end part are W2and H2 respectively; the length and width of the tooth body part are respectively H1 and W1; W2 is larger than 4*W1; and H1 is larger than 2*H2. The punched sheet with the above structure is suitablefor the design of a multi-pole motor punched sheet with 4-18 teeth and has high universality. The iron core comprises first punched sheets and second punched sheets; the plate surface of the tooth endpart of the first punched sheet and the plate surface of the tooth body part of the first punched sheet are flush with each other; the plate surface of the tooth end part of the second punched sheetand the plate surface of the tooth body part of the second punched sheet are perpendicular to each other; the plurality of first punched sheets are laminated to form a combined part; and two second punched sheets are laminated at two ends of the combined part respectively with the tooth end parts of the second punched sheets facing one side far away from the combined part. The iron core with the above structure has the advantages of larger magnetic conduction area, stronger magnetic induction, more concentrated magnetic flux and lower loss. With the iron core adopted, the motor has the advantages of higher energy efficiency, lower temperature rise and lower cost.

Owner:CHONGQING KAIBANG MOTOR +1

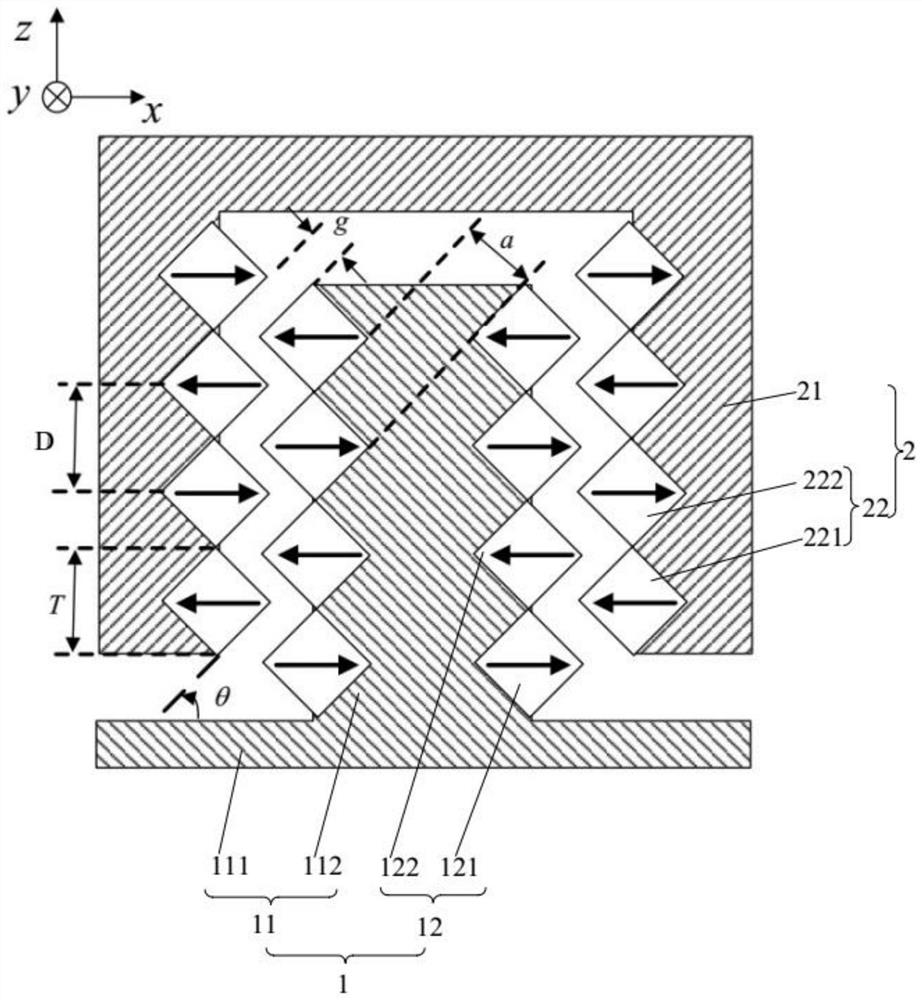

Gravity compensator and bearing device

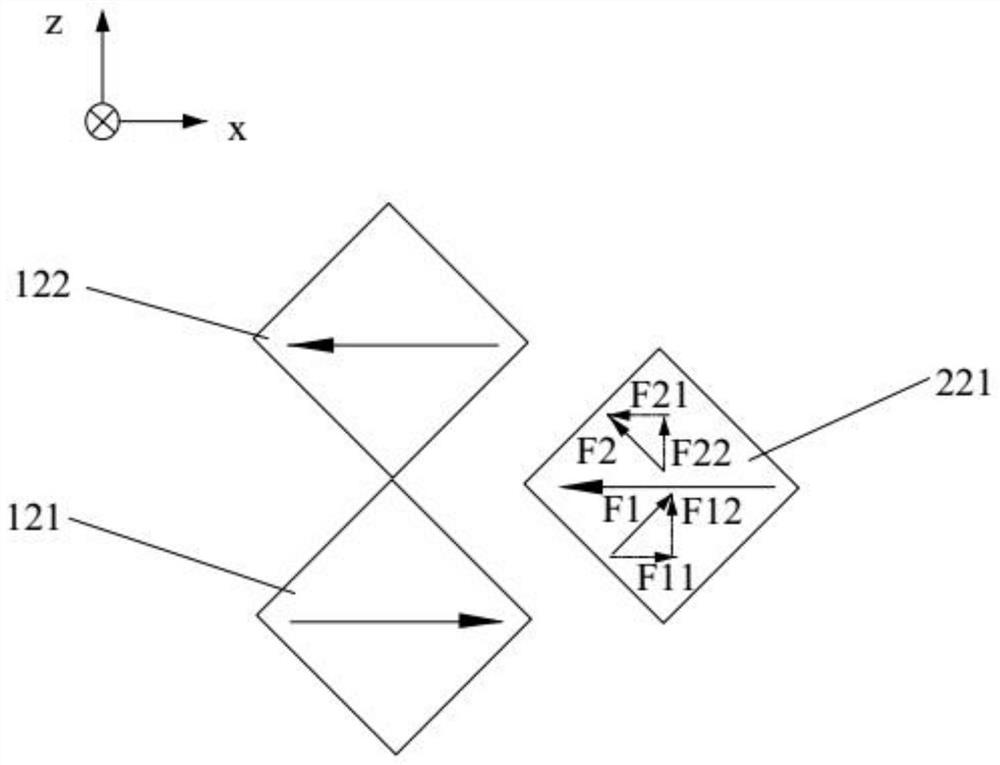

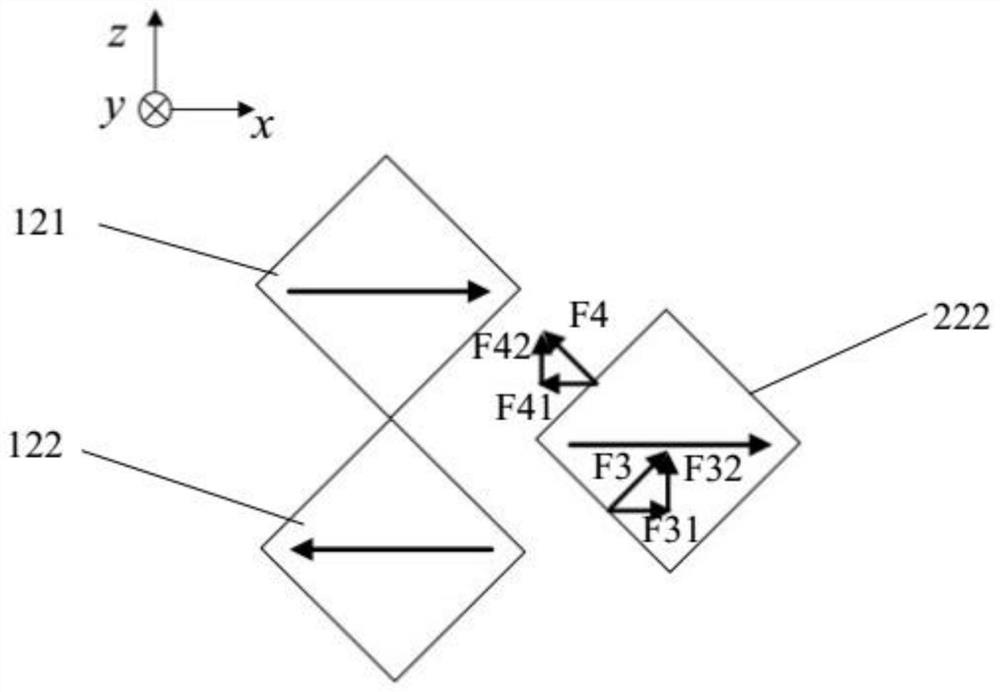

ActiveCN113048185AIncrease loadLarge gap areaVibration dampersNon-rotating vibration suppressionEngineeringMagnet

The invention belongs to the technical field of magnetic attraction, and discloses a gravity compensator and a bearing device. The gravity compensator comprises a first magnetic assembly and a second magnetic assembly, wherein the first magnetic assembly comprises a magnetic base and first magnet arrays arranged on the magnetic base, and the first magnet arrays extend in the Z-axis direction; and the second magnetic assembly comprises a magnetic frame and second magnet arrays arranged on the magnetic frame, each second magnet array corresponds to one first magnet array and is arranged opposite to the corresponding first magnet array, a gap is formed between each second magnet array and the corresponding first magnet array, the gaps are of a zigzag structure, and each first magnet array and the corresponding second magnet array are configured to apply magnetic acting force to each other, so that force in the Z-axis direction is generated between the first magnetic assembly and the second magnetic assembly for gravity compensation on the magnetic base or the magnetic frame used for bearing a load. According to the gravity compensator, the gaps are longer, the gap area is larger under the same height, and therefore large-stroke high-load performance is achieved.

Owner:FUDAN UNIV

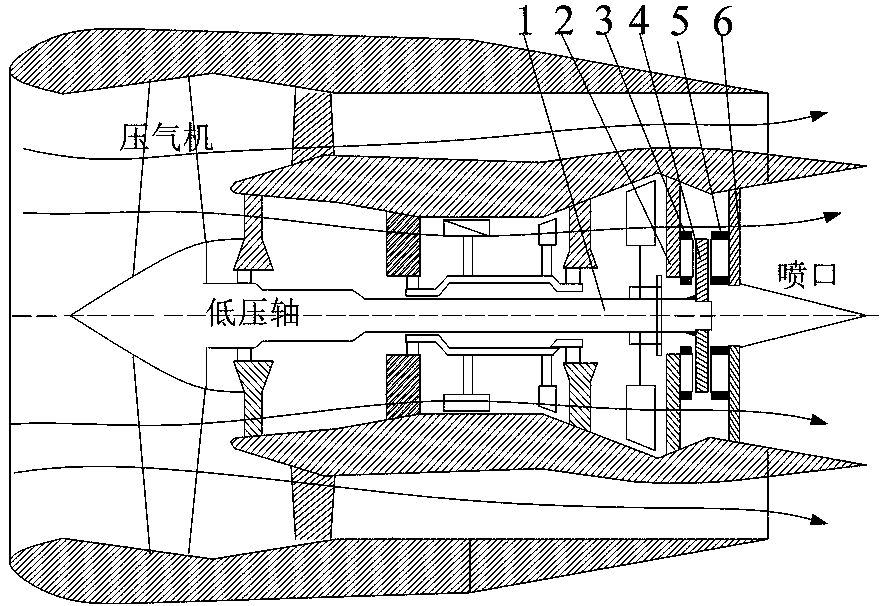

Aeroengine nozzle side fault-tolerant generator

ActiveCN107681794BImprove reliabilityEasy to useMagnetic circuit rotating partsMagnetic circuit stationary partsAviationFault tolerance

The invention relates to a fault tolerant generator at the nozzle side of an aerial engine, and belongs to the field of aircraft engineering. The fault tolerant generator comprises an excitation coil,an excitation iron core, a rotor iron core, an armature coil and an armature iron core; the rotor iron core is fixed at one side of the nozzle of the low-pressure shaft of the aerial engine; the excitation iron core and the armature iron core are separately positioned at two axial sides of the rotor iron core; 12 fan-shaped through holes are uniformly distributed on the circumference of the rotoriron core; 10 fan-shaped protruding excitation poles are at one side of the excitation iron core towards the rotor iron core; 10 fan-shaped protruding armature poles are at one side of the armature iron core towards the rotor iron core; a centralized excitation coil is wound on each excitation pole; and a centralized armature coil is wound on each armature pole. According to the fault tolerant generator disclosed by the invention, the rotational inertia of the rotor iron core is low; therefore, the rotor iron core can rotate at high speed; and thus, the rotor iron core is particularly suitable for the fault tolerant generator at the nozzle side of the aerial engine.

Owner:徐州博云航空科技有限公司

Electromagnetic mixing roller of two cool areas of highfield unburnt earthenware

The present invention relates to electromagnetic stirring roller for continuous metal casting, and is especially one kind of high magnetic field two cold plate blank electromagnetic stirring roller. The electromagnetic stirring roller includes a winding and a cylindrical iron core, and has shielding rings to mask the non-working surface. Adopting cylindrical iron core without teeth and slots results in high space utilization rate of the winding, increased magnetic conducting area of the iron core, raised magnetic field strength and enhanced electromagnetic stirring force. Shielding the non-working surface with shielding rings can minimize the magnetic leakage, increase the magnetic field strength in the working surface and enhance the electromagnetic stirring force.

Owner:HUNAN ZHONGKE ELECTRIC

A range-extended electric vehicle gas turbine generator

ActiveCN107612214BSimple structureImprove reliabilitySynchronous generatorsElectric machinesElectric machineMoment of inertia

The invention discloses an extended-range electric vehicle gas turbine generator and belongs to the field of electric engineering. The extended-range electric vehicle gas turbine generator comprises stationary blade grids, movable blade grids, an excitation iron core, an exciting winding, a shaft, a rotor core, an armature core, an armature winding and a motor housing. The extended-range electricvehicle gas turbine generator is characterized in that fuel gas flows through the stationary blade grids and then pushes the movable blade grids and the rotor core rotate around the shaft; the excitation iron core is arranged on one side of the rotor core, and the armature core is arranged on the other side of the rotor core; a plurality of uniformly distributed fan-shaped through holes are formedin the circumference of the rotor core; a plurality of exciting poles protruding towards one side of the rotor core are uniformly distributed in the circumferential direction of the excitation iron core, and a plurality of armature poles protruding towards one side of the rotor core are uniformly distributed in the circumferential direction of the armature core. The extended-range electric vehicle gas turbine generator can fully play the advantage that the power generation efficiency of the gas turbine generator is higher than that of a power generator driven by an internal combustion engine.The rotational inertia of the rotor core is small, and the rotor core can rotate at high speed and thus is very suitable for the extended-range electric vehicle gas turbine generator.

Owner:业达新能源有限公司

Magnetic grid permanent magnet double salient pole motor for electric vehicles

ActiveCN107508444BLight in massSmall moment of inertiaMagnetic circuit rotating partsSynchronous machine detailsElectric vehicleDoubly salient

An electric vehicle magnetic grid type permanent magnetism doubly salient motor belongs to the electric vehicle motor technology field, comprises a shaft, a front armature iron core, a front armature winding, a front rotor iron core, a front permanent magnet, a permanent magnet iron core, a back permanent magnet, a back rotor iron core, a back armature winding, a back armature iron core and a shell, and is characterized in that the disc-shaped front rotor iron core and back rotor iron core are fixed on the shaft at intervals, the permanent magnet iron core fixed on the shell is between the front rotor iron core and the back rotor iron core, and the permanent magnets are fixed on the two surfaces of the permanent magnet iron core towards the rotor iron cores respectively and uniformly; the front armature iron core and the back armature iron core which are fixed on the shell are at the two sides of the front rotor iron core and the back rotor iron core respectively, armature poles are arranged on the armature iron cores, and the armature windings are wound on the armature poles. The rotor iron cores of the technical scheme of the present invention are magnetic grid-shaped, and are large in contact area and specific power, so that the electric vehicle magnetic grid type permanent magnetism doubly salient motor is very suitable for being used as an electric vehicle motor having higher requirements for the power density.

Owner:江苏惠博机电科技股份有限公司

A Low Moment of Inertia Permanent Magnet Wind Motor

ActiveCN107579640BLight in massSmall moment of inertiaSynchronous machine detailsWind energy generationHigh power densityClockwise

The invention discloses a permanent magnet wind-driven motor with low rotational inertia, and belongs to the technical field of special motors. The permanent magnet wind-driven motor comprises a shaft, an armature iron core, first armature windings, second armature windings, a rotor iron core, permanent magnets, a permanent magnet iron core and a shell, and is characterized in that 4k fan-shaped through holes are uniformly formed in a disc of the rotor iron core, and the k is a positive integer; the permanent magnet iron core and the armature iron core which are fixed onto the shell are arranged on two sides of the rotor iron core, the 6k fan-shaped permanent magnets are arranged on the surface, which faces the rotor iron core, of the permanent magnet iron core, 12k fan-shaped protruded armature poles are uniformly distributed on the side, which faces the rotor iron core, of the armature iron core, each first armature winding is wound on the two corresponding armature poles, and the second armature windings are wound on the odd-number armature poles along the clockwise direction. The permanent magnet wind-driven motor has the advantages that the rotor iron core is low in rotational inertia and can quickly respond, the second windings are capable of weakening demagnetization armature reaction and increasing the power density, and accordingly the permanent magnet wind-drivenmotor is quite suitable to be used as a wind-driven power generator started by breeze.

Owner:徐州普林惠新能源技术有限公司

Electric vehicle range extender grid rotor motor

ActiveCN107465322BLight in massSmall moment of inertiaMagnetic circuit rotating partsElectric machinesElectric vehicleHigh power density

The invention relates to a grid-shaped rotor motor for a range extender of an electric automobile and belongs to the technical field of electric automobiles. The grid-shaped rotor motor is composed of a crankshaft, a shell, a stator iron core, an exciting winding and an armature winding, wherein ten rectangular holes are uniformly formed in the circumferential surface of the shell, and a grid-shaped iron core capable of conducting magnetism is arranged between any two rectangular holes; the stator iron core fixedly arranged on a range extender shell is composed of 12 substator iron cores uniformly distributed in a left inverted 'n' shape, stator poles projecting along the radial direction are arranged at the two sides of each substator iron core, and the side surface of each stator pole is in a sectional shape; the distance between two stator poles on one substator iron core is less than the axial length of each rectangular hole in the shell; the exciting winding is formed by winding yokes of all the 12 substator iron cores. The grid-shaped rotor motor provided by the invention can fully play the advantage of high power density of a disc type motor, and the exciting winding is short in path and small in copper loss.

Owner:SHENZHEN POWER SUPPLY BUREAU +1

Aviation built-in permanent magnet starter generator

ActiveCN107528442BLight in massSmall moment of inertiaSynchronous machine detailsStarter generatorAviation

The invention discloses an aviation internal type permanent magnetism starting generator, which belongs to the field of electrical engineering, and comprises a permanent magnet, a permanent magnetism magnet yoke, a rotor iron core, an armature winding and an armature iron core. The aviation internal type permanent magnetism starting generator is characterized in that the rotor iron core is fixed to one side of an air inlet of the low pressure shaft of an aero-engine; the permanent magnetism magnet yoke and the armature iron core are respectively disposed at two axial sides of the rotor iron core; the circumference of the rotor iron core is uniformly provided with fan-shaped through holes in the number of 5k (k is a positive integer greater than 1); One side of the permanent magnetism magnet yoke orienting towards the rotor iron core is fixed with a fan-shaped permanent magnet; one side of the armature iron core orienting towards the rotor iron core is provided with fan-shaped protruding armature pole; the magnetizing direction of each adjacent three permanent magnets is of the same, and each armature pole is winded with a concentration type armature coil. The aviation internal type permanent magnetism starting generator is advantageous in that the temperature of the air inlet is quite low, which can adapt to the work of the permanent magnet; the moment of inertia of the rotor iron core is small, the pole number of the rotor is small, and high-speed rotation can be realized; the aviation internal type permanent magnetism starting generator can be operated both as a motor and a generator, and thereby it is very suitable for an aviation internal type starting generator.

Owner:山东飞奥航空发动机有限公司

A car starter generator

ActiveCN107579641BImprove reliabilityLarge magnetic areaSynchronous machine detailsStarter generatorFully developed

Owner:江苏惠博机电科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com