Patents

Literature

43results about How to "High back EMF" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

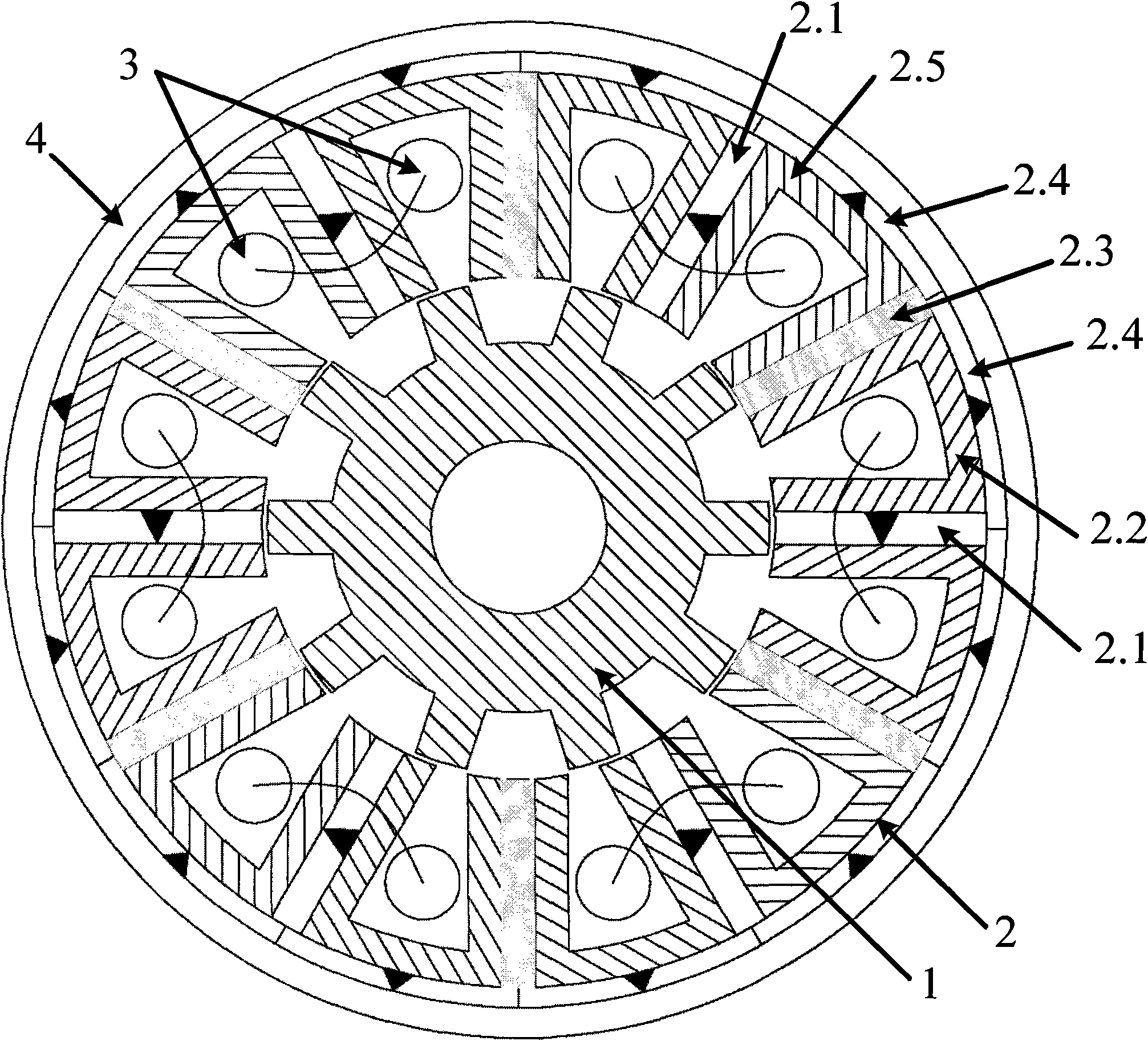

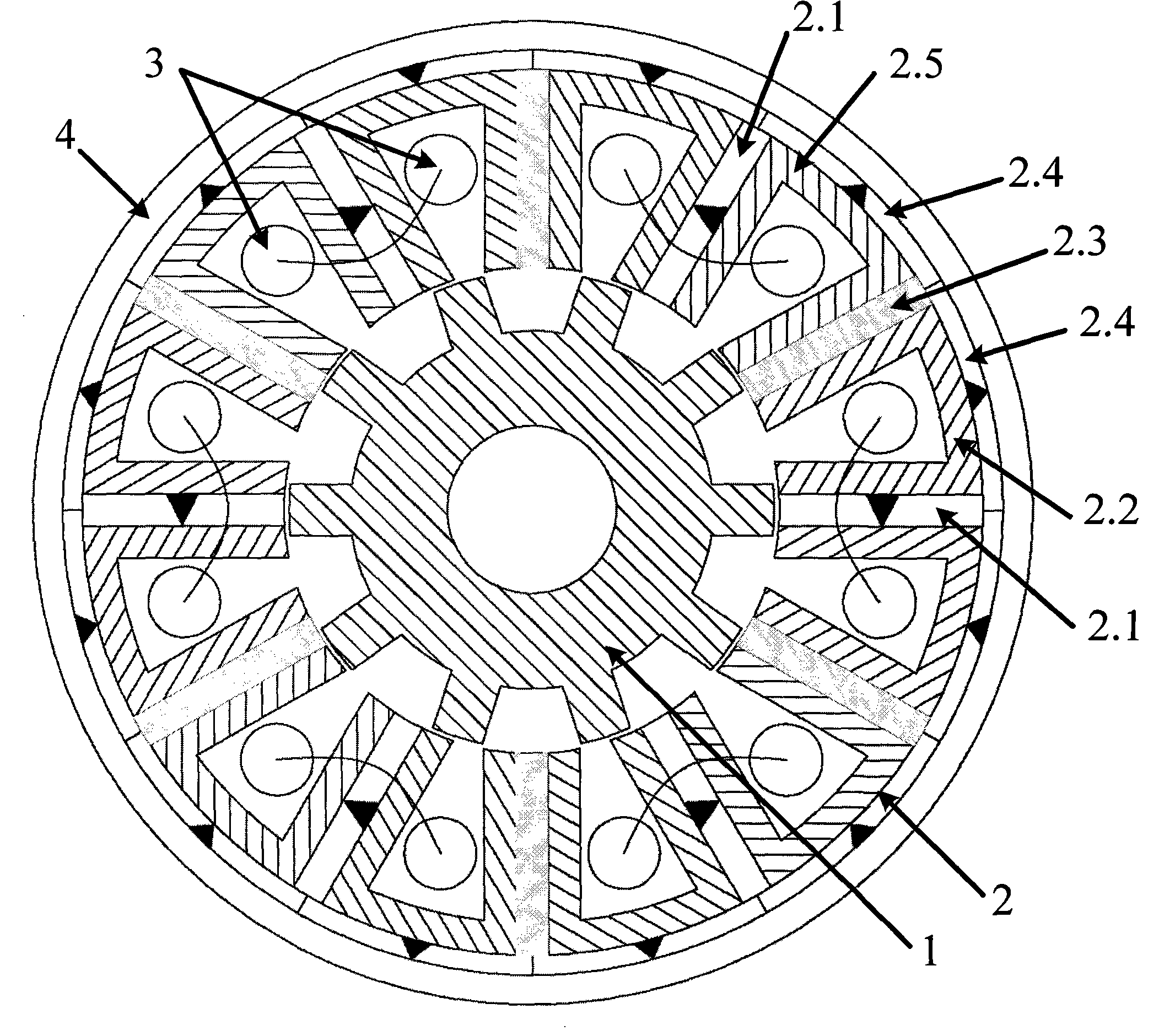

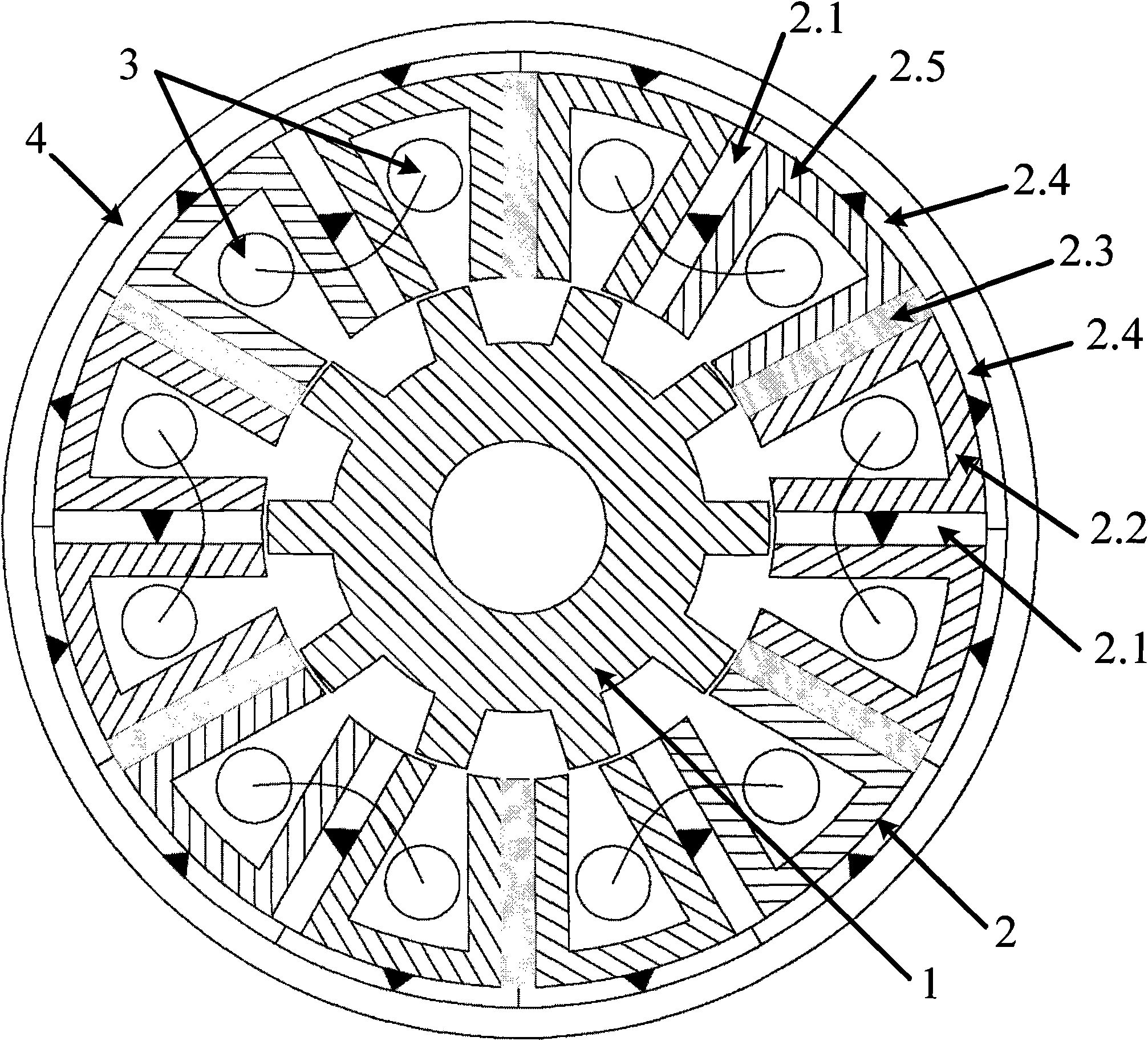

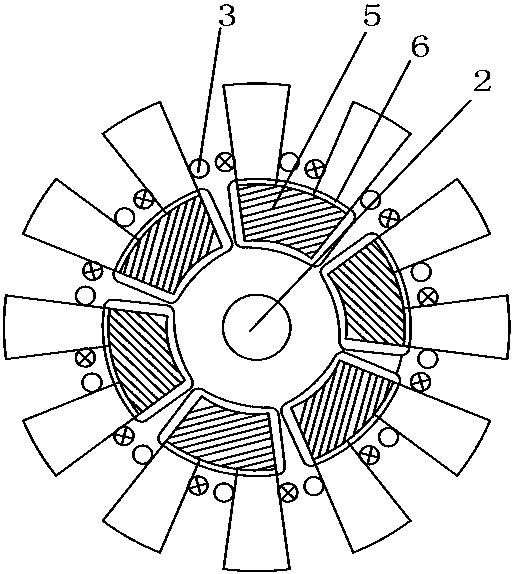

Magnetic-field-enhanced permanent-magnetic switching flux linkage motor with high fault tolerance

InactiveCN101562384AIncrease profitIncrease the amount of changeMagnetic circuit rotating partsMagnetic circuit stationary partsFault toleranceConductive materials

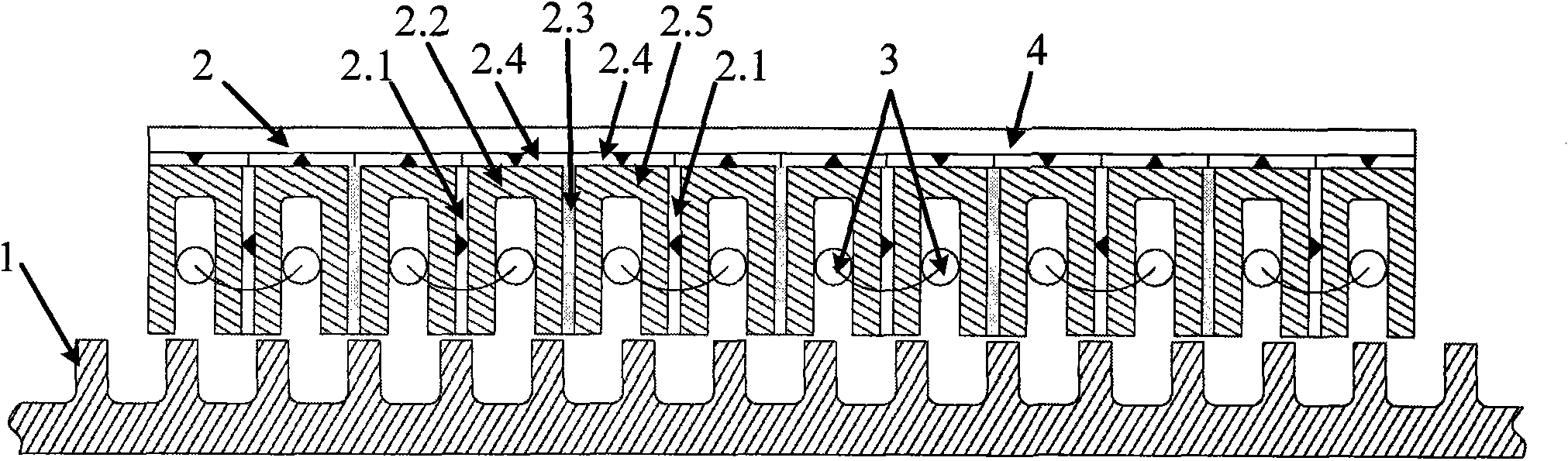

The invention discloses a magnetic-field-enhanced permanent-magnetic switching flux linkage motor with high fault tolerance. The motor comprises a rotor, a stator, three-phase armature windings and a casing, wherein the casing is made of magnetic conductive material; the rotor consists of toothspace-type core laminations; the stator fixed in the casing comprises first permanent magnets, a first U-shaped iron core, reluctance sheets and a second U-shaped iron core arranged one by one; N poles and S poles of the first permanent magnets are alternately arranged; armature teeth consist of the first permanent magnets and U-shaped iron core edges clinging to two sides of the first permanent magnets respectively; auxiliary teeth consist of the reluctance sheets and the U-shaped iron core edges clinging to two sides of the reluctance sheets respectively; the three-phase armature concentrated windings are wound round the armature teeth; second permanent magnets are arranged between the casing and the stator; and the first permanent magnets and the second permanent magnets in contact with the U-shaped iron cores have the same polarity on contact surface. The motor is simple in structure. Compared with the prior permanent-magnetic switching flux linkage motor, the motor has the advantages of improving anti-electromagnetic interference capability and electromagnetic compatibility and raising the rate of utilizing the permanent magnets, along with higher output power density and capability of avoiding magnetic leakage on the outer edge of the casing.

Owner:ZHEJIANG UNIV

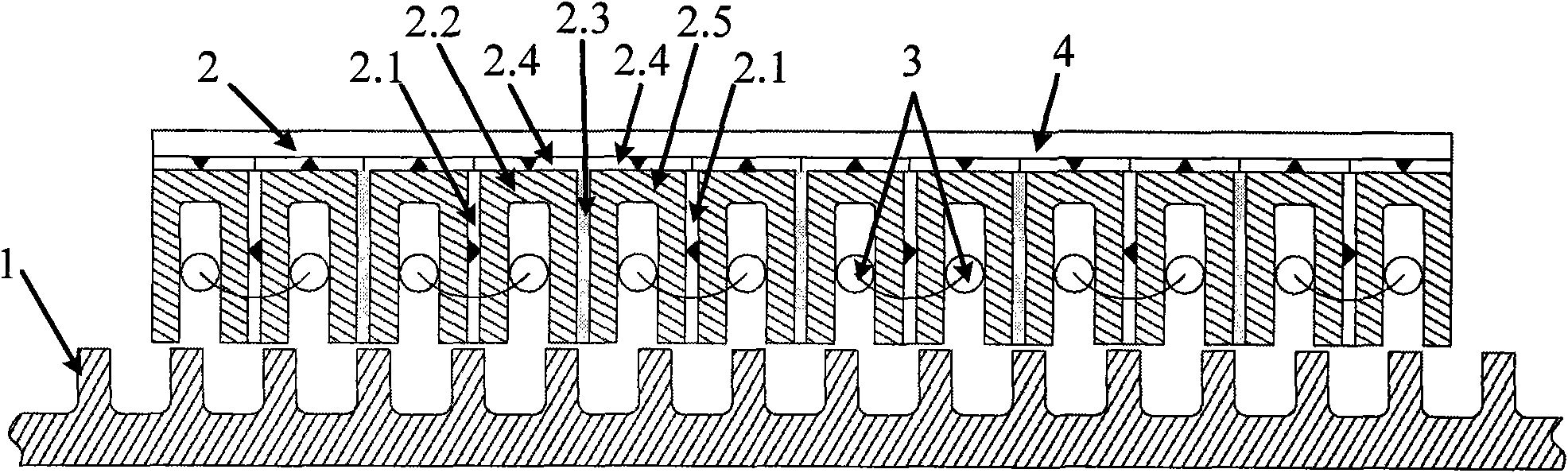

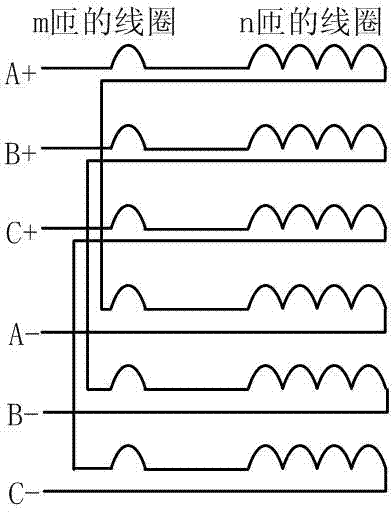

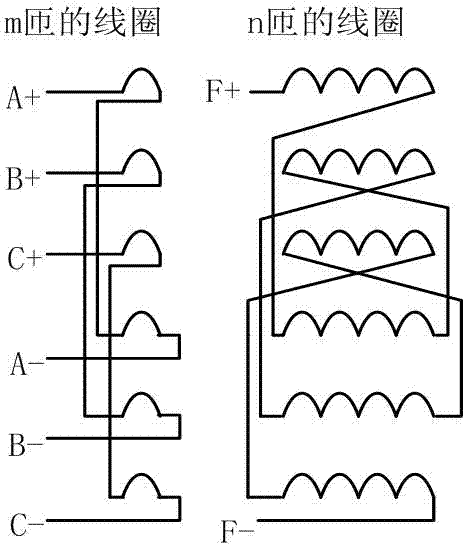

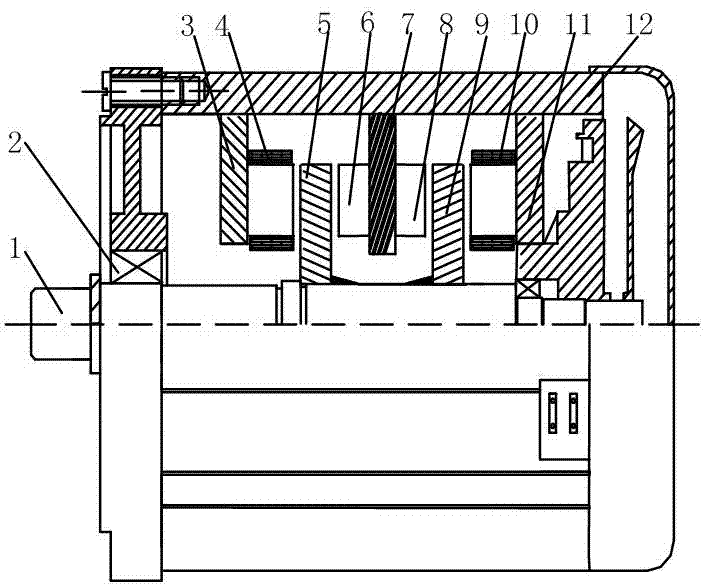

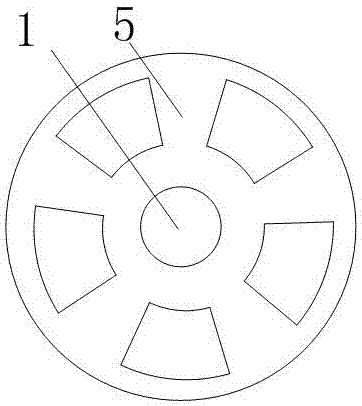

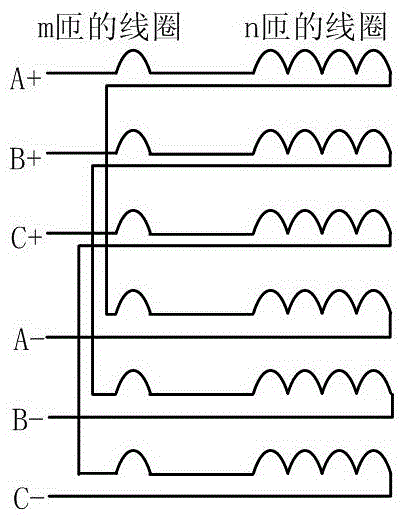

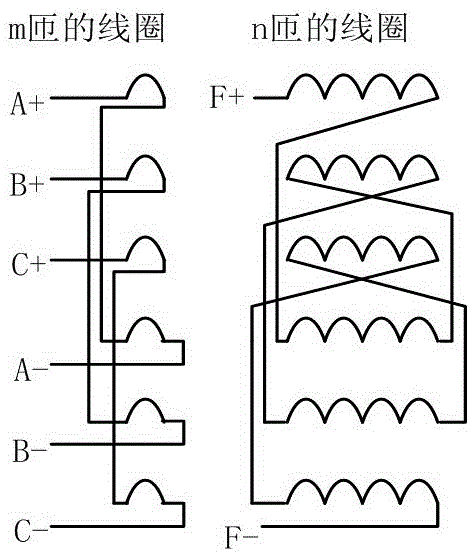

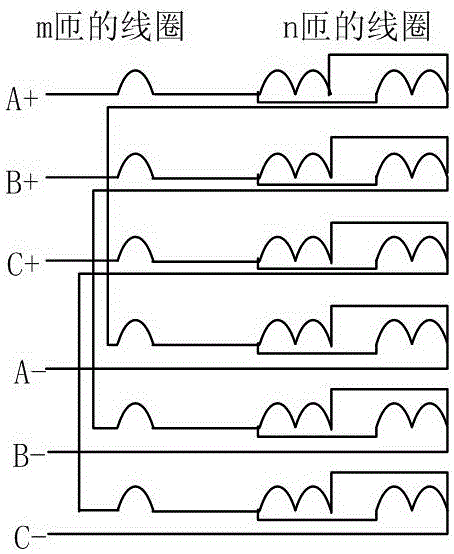

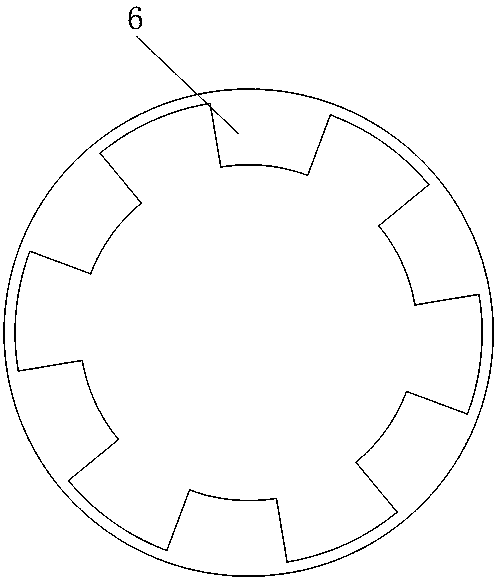

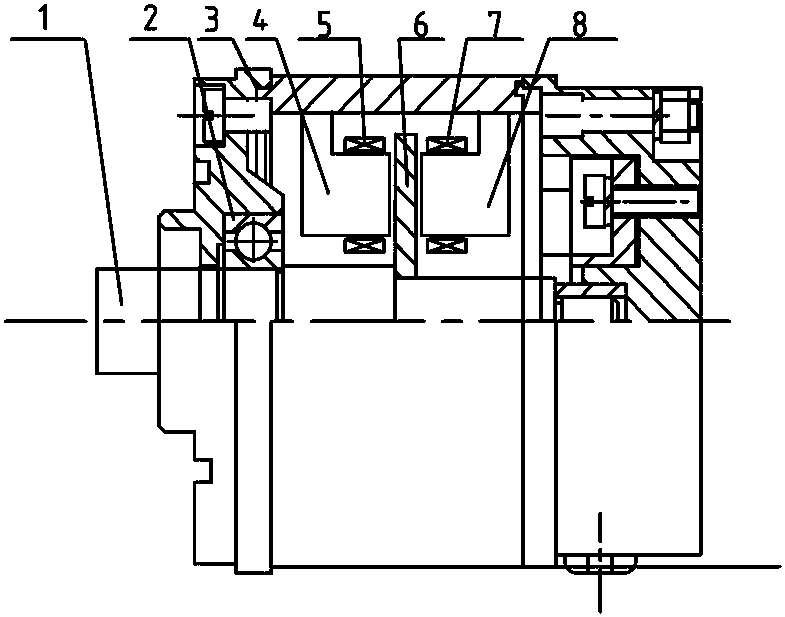

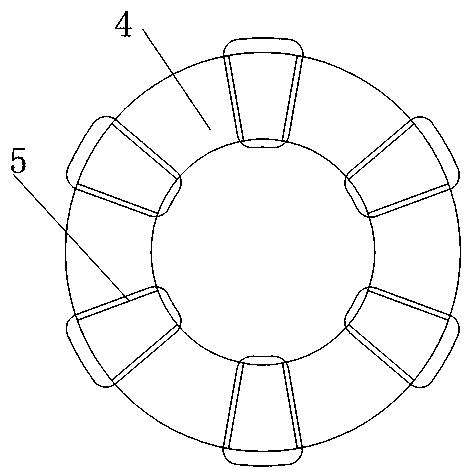

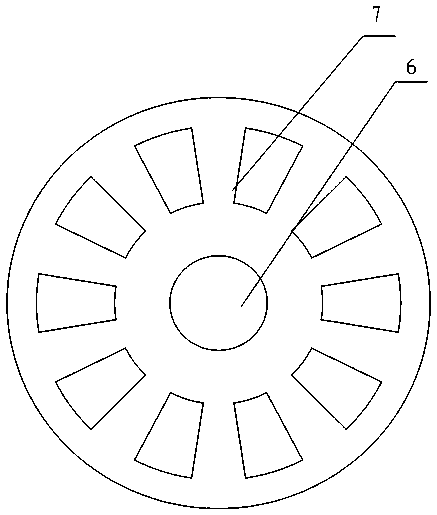

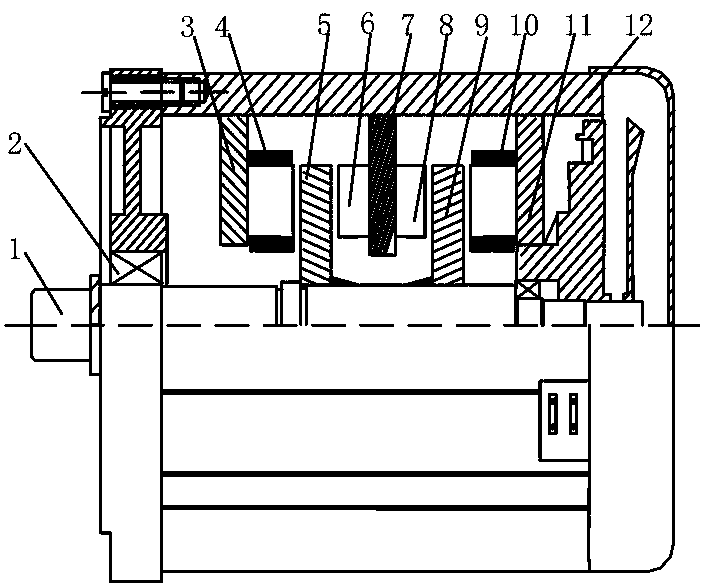

Variable winding starter generator for automobile

ActiveCN104242580AMany turnsHigh back EMFSynchronous generatorsSynchronous motorsStarter generatorEngineering

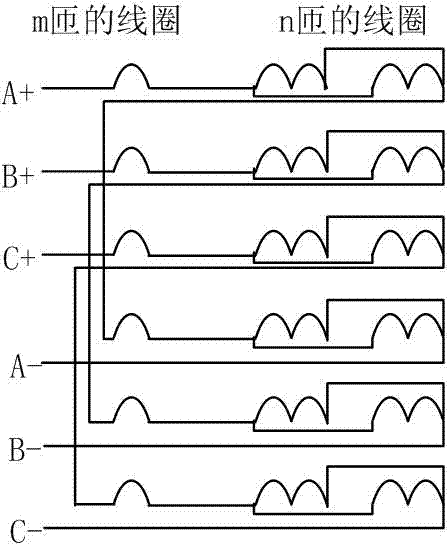

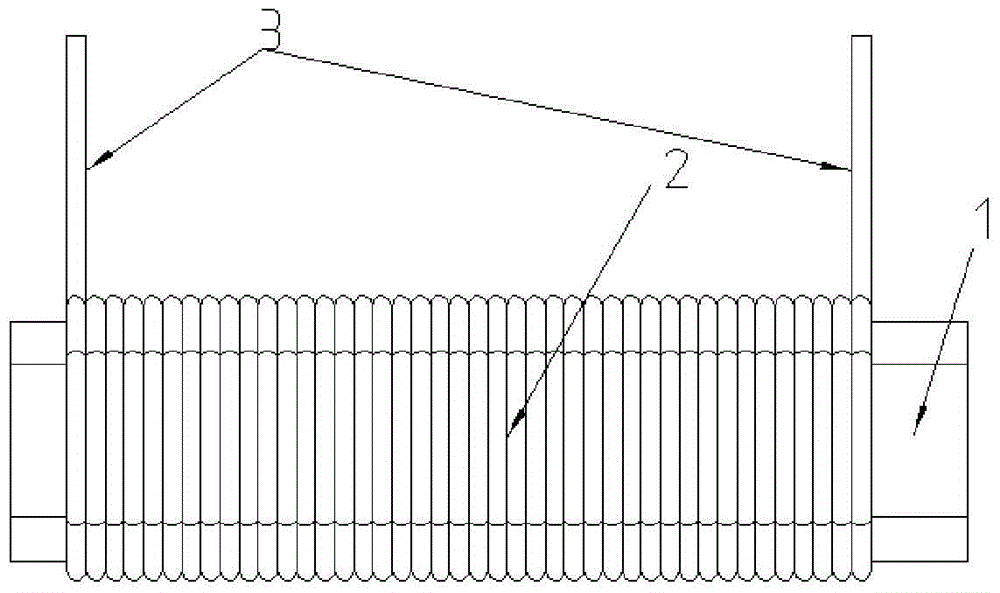

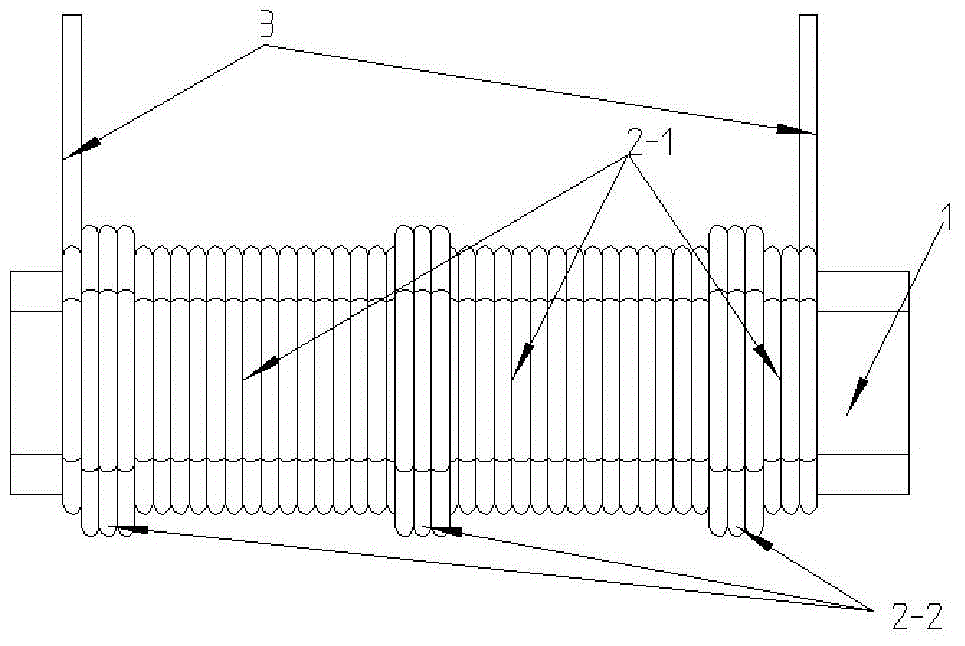

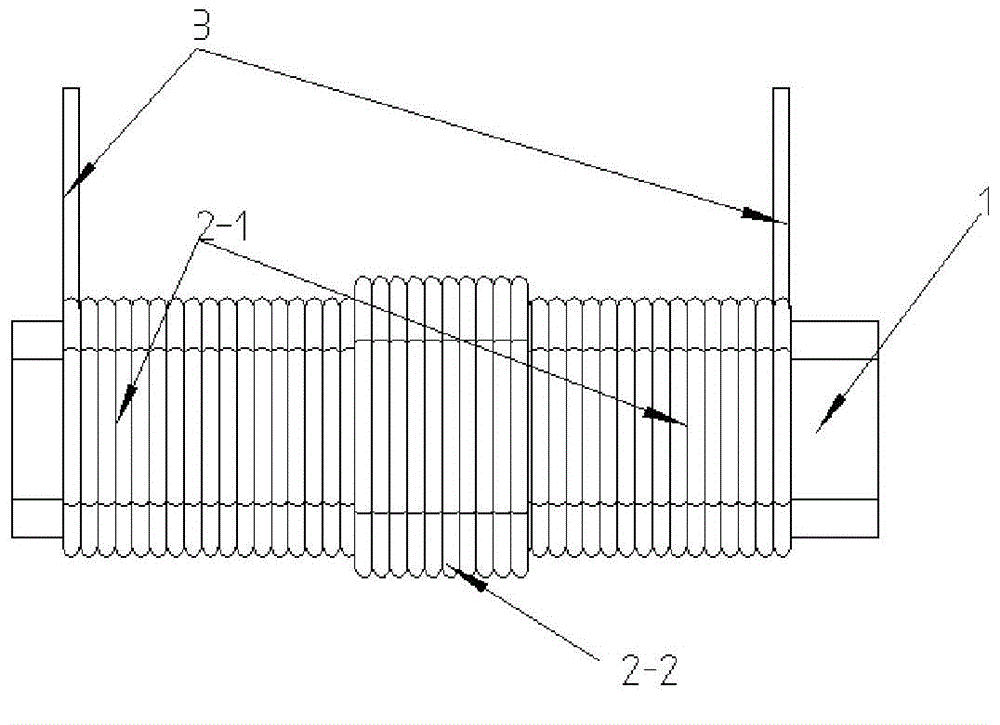

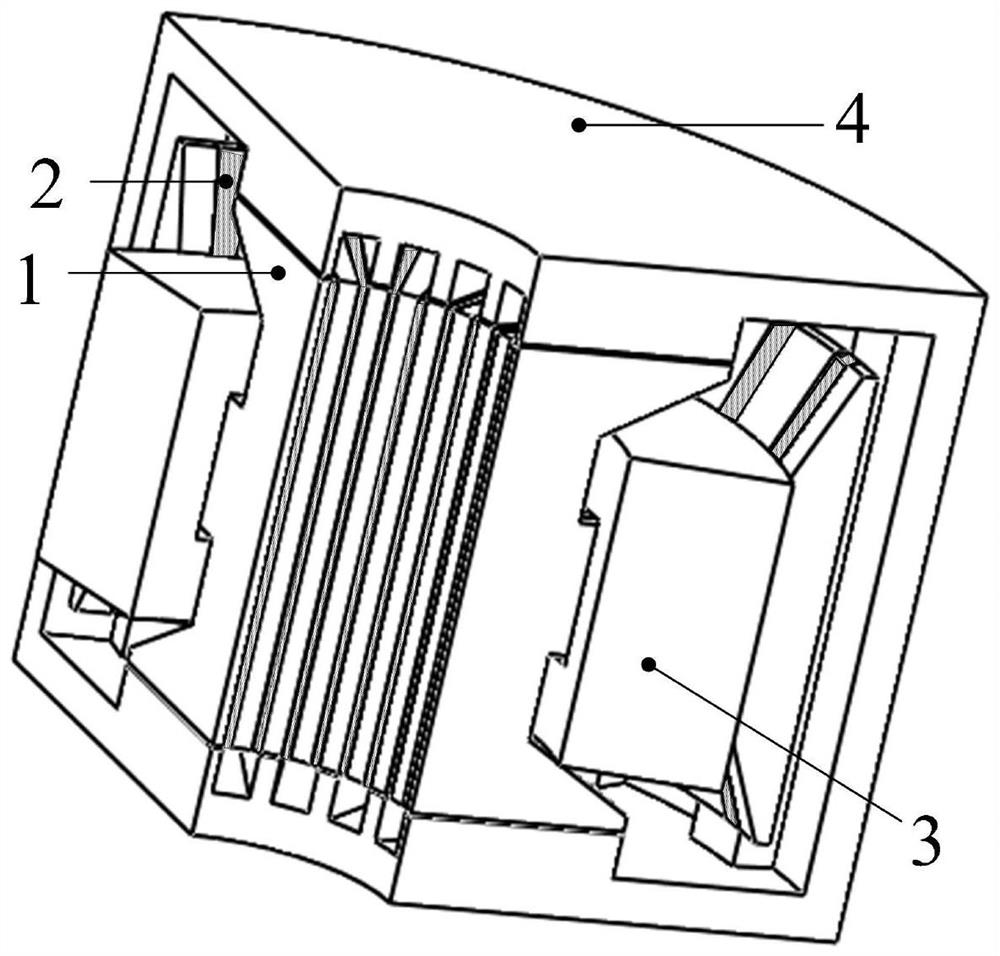

The invention provides a variable winding starter generator for an automobile. The variable winding starter generator for the automobile comprises a rotor core, a stator core, coils, a shaft, a shell and the like, and is characterized in that each stator electrode is provided with a centralized coil with (m) turns and a centralized coil with (n) turns; when the variable winding starter generator for the automobile serves as a starter, all the coils on the stator electrodes with the same phase are serially connected to one another by selector switches to form a phase armature winding; after each phase armature winding is connected with an asymmetrical half-bridge converter with diodes, the phase armature winding can electrically run in a switch reluctance machine mode; and when the variable winding starter generator for the automobile serves as a generator, the coils with the (n) turns on all the stator electrodes are serially connected to one another to form an exciting winding, the coils with the (m) turns on the stator electrodes with the same phase are serially connected to one another or connected to one another in parallel to form a phase armature winding, and the starter generator generates power and runs in an electro-magnetic doubly salient generator mode. By the variable winding starter generator, the advantage of high efficiency of a switch reluctance machine and the advantage of easiness in voltage adjustment and control of an electro-magnetic doubly salient generator can be effectively utilized.

Owner:SHANDONG UNIV OF TECH

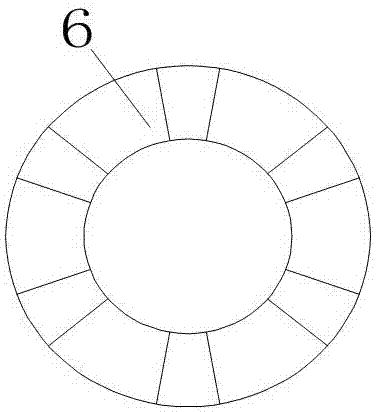

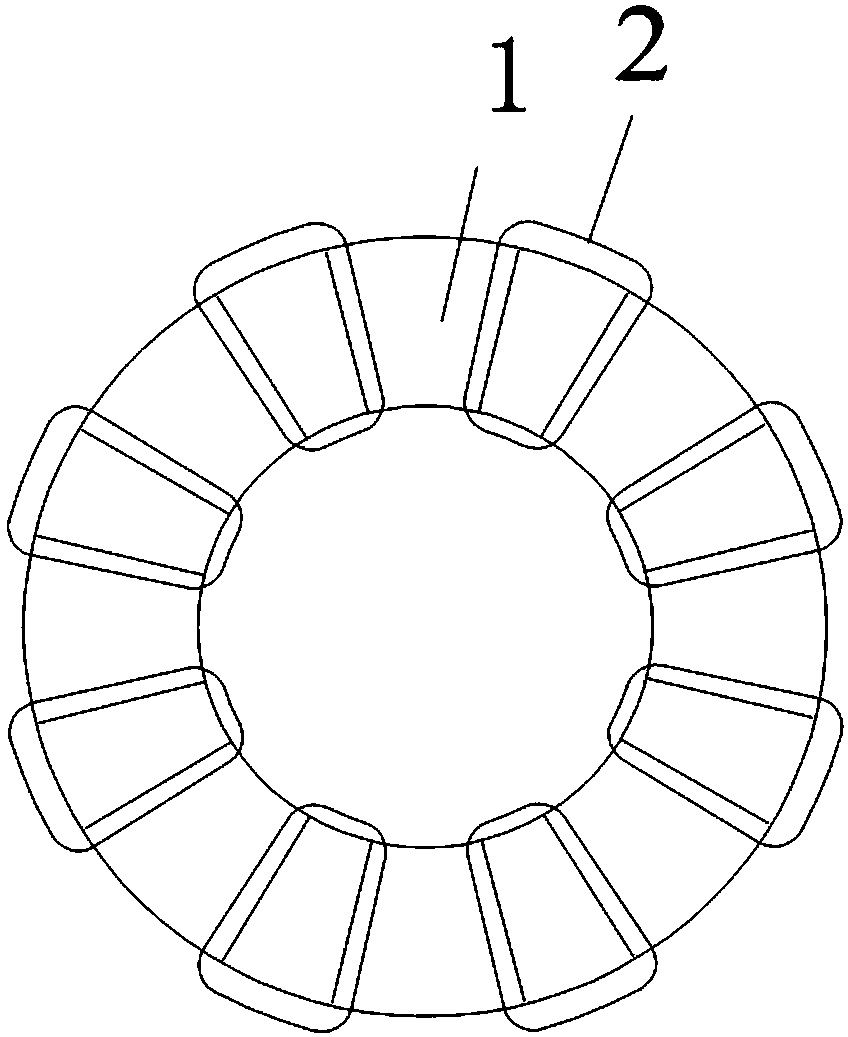

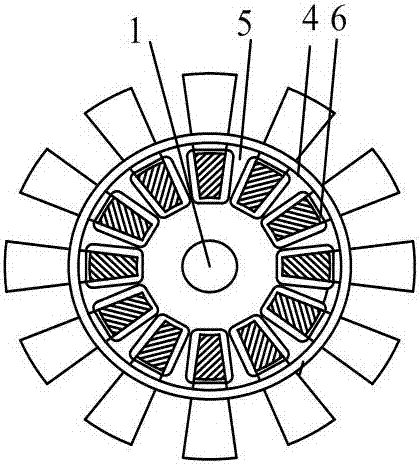

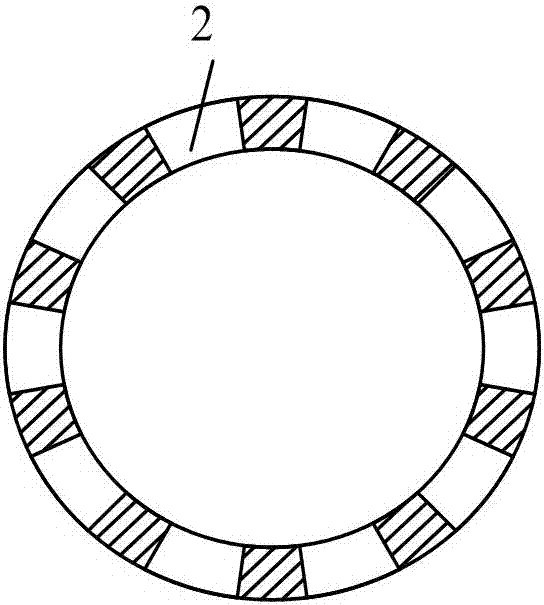

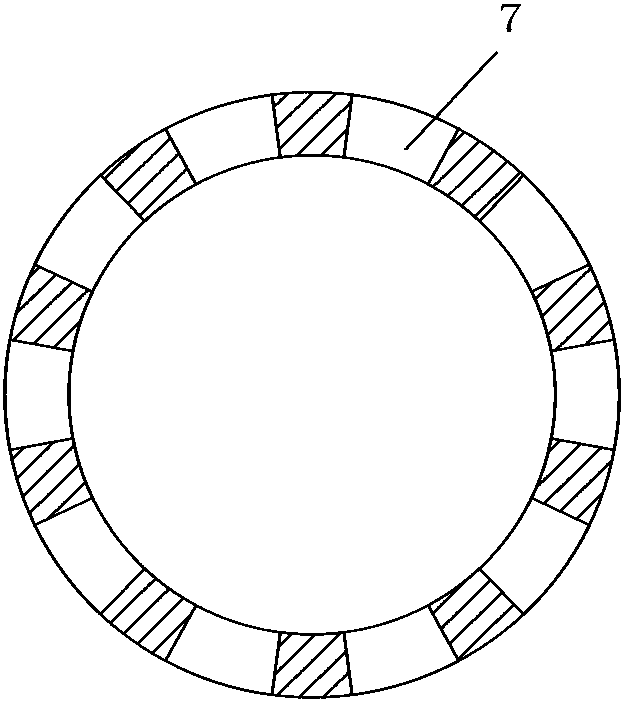

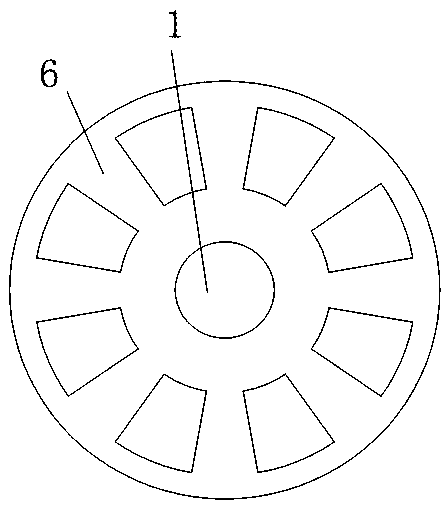

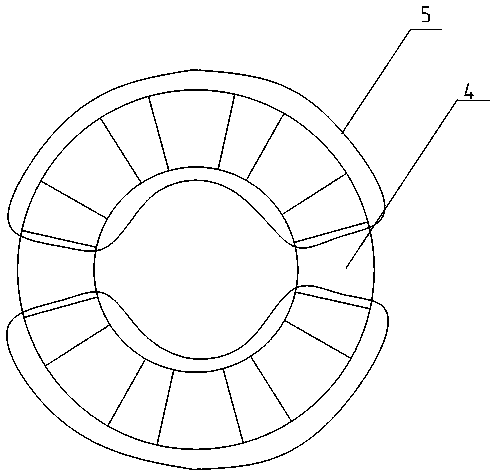

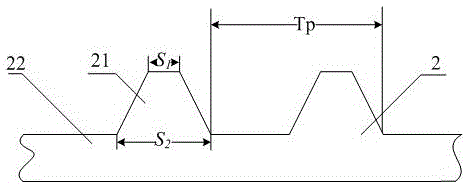

Stator permanent magnet vernier motor with modules evenly distributed at circumference

InactiveCN103490577AIncreased torque densityImprove power densitySynchronous machinesMagnetic circuit stationary partsConductor CoilPower density

The invention discloses a stator permanent magnet vernier motor with modules evenly distributed at the circumference. The stator permanent magnet vernier motor comprises an inner stator and an outer rotor. The multiple unit modules which are distributed along the circumference of an air gap are fixed to the outer ring of the inner stator. The side walls of every two adjacent unit modules are tightly attached together. Each unit module is composed of a permanent magnet and a magnetizer which are the same in size, wherein the side wall of the permanent magnet and the side wall of the magnetizer are tightly attached together. The permanent magnets are magnetized in a radial mode. The number P of pole-pairs of magnetic field distribution produced by the permanent magnets corresponds to the number of the unit modules and the number of rotor teeth. The magnetizer in each unit module can be replaced by another identical permanent magnet, and after replacement, the two permanent magnets in the same unit module are opposite in magnetizing direction. Due to the mutual cooperation of the unit modules, the limited notch space, near the stator, of the air gap is reasonably utilized, flux density in a magnetic circuit is increased effectively, counter potential in a winding is effectively improved, output torque and power density of the motor are improved, and the size is reduced correspondingly.

Owner:JIANGSU UNIV

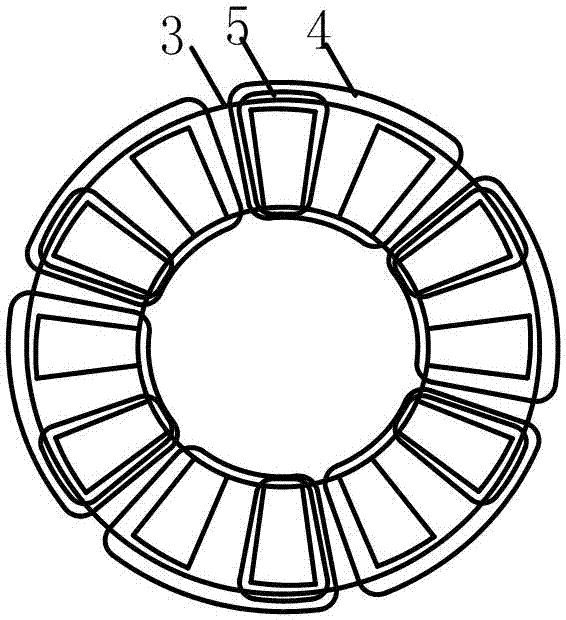

Centrally-distributed coreless winding

ActiveCN106340987AHigh back EMFImprove performanceCoilsWindings conductor shape/form/constructionElectrical conductorEngineering

Owner:SHANGHAI MOONS ELECTRICAL APPLIANCE

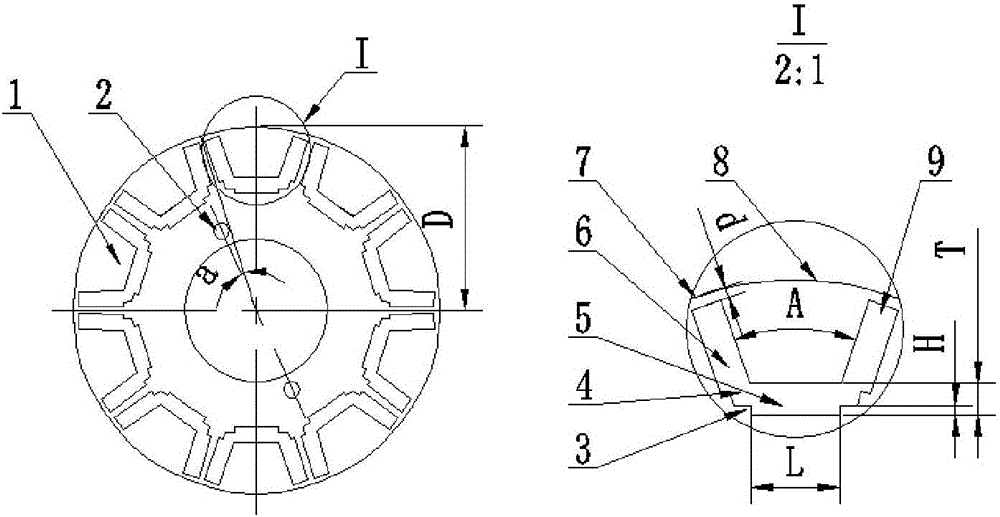

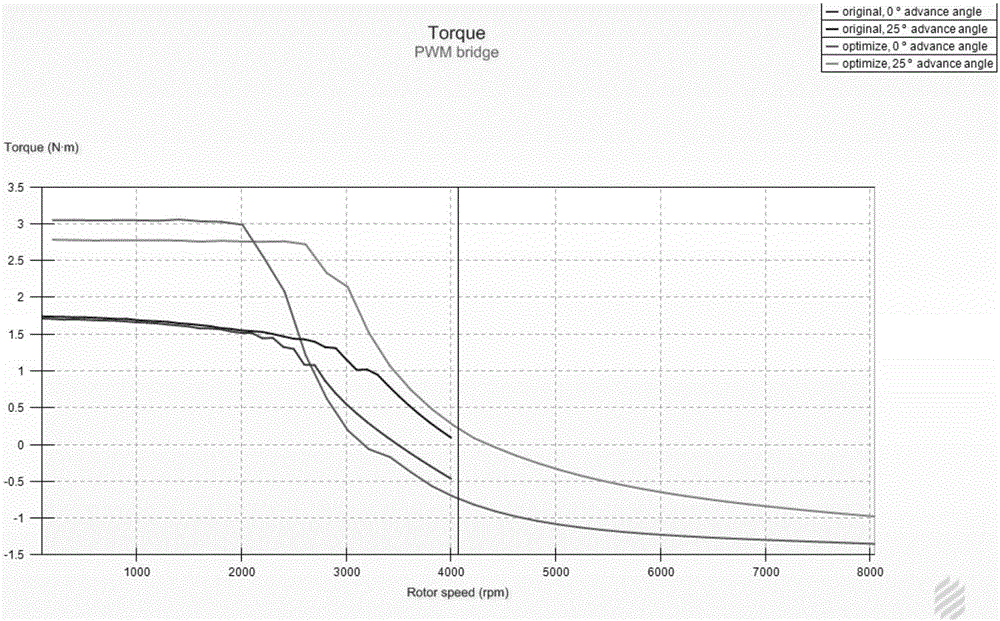

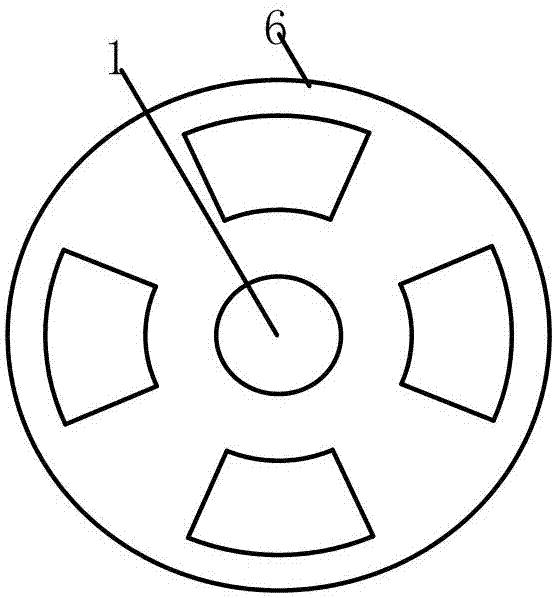

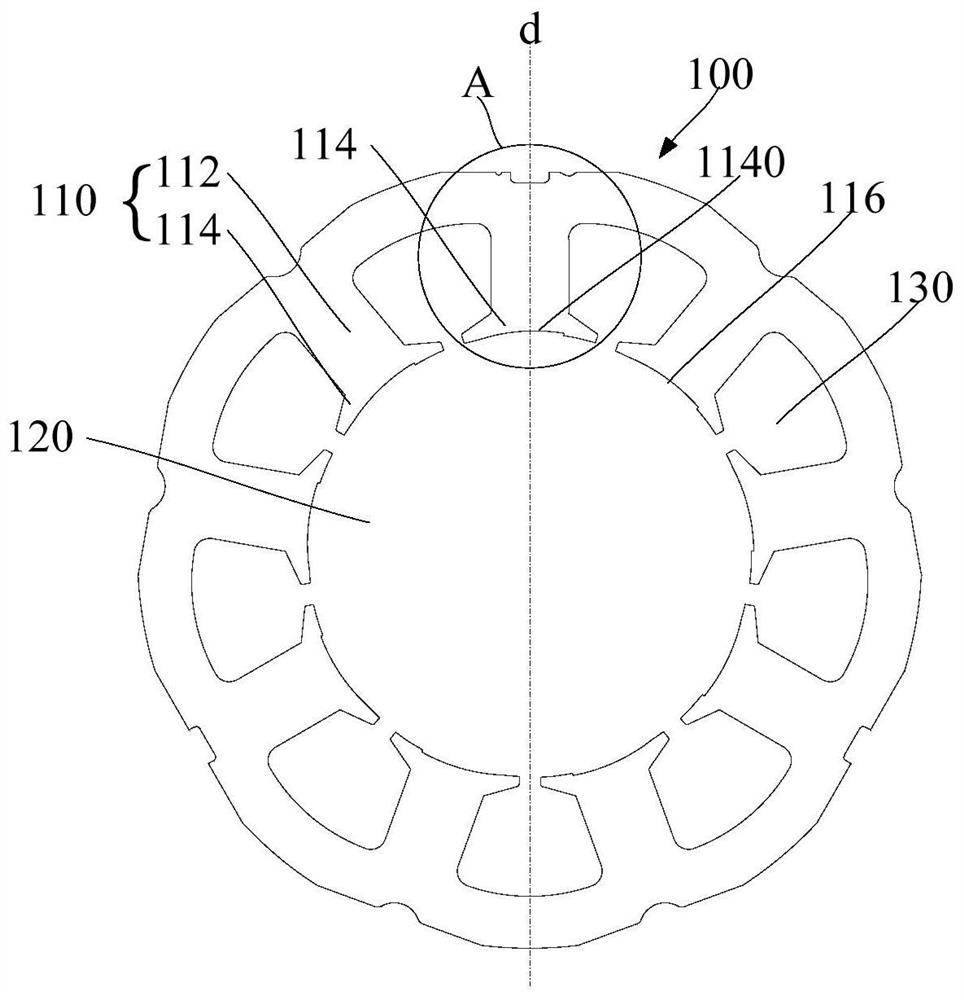

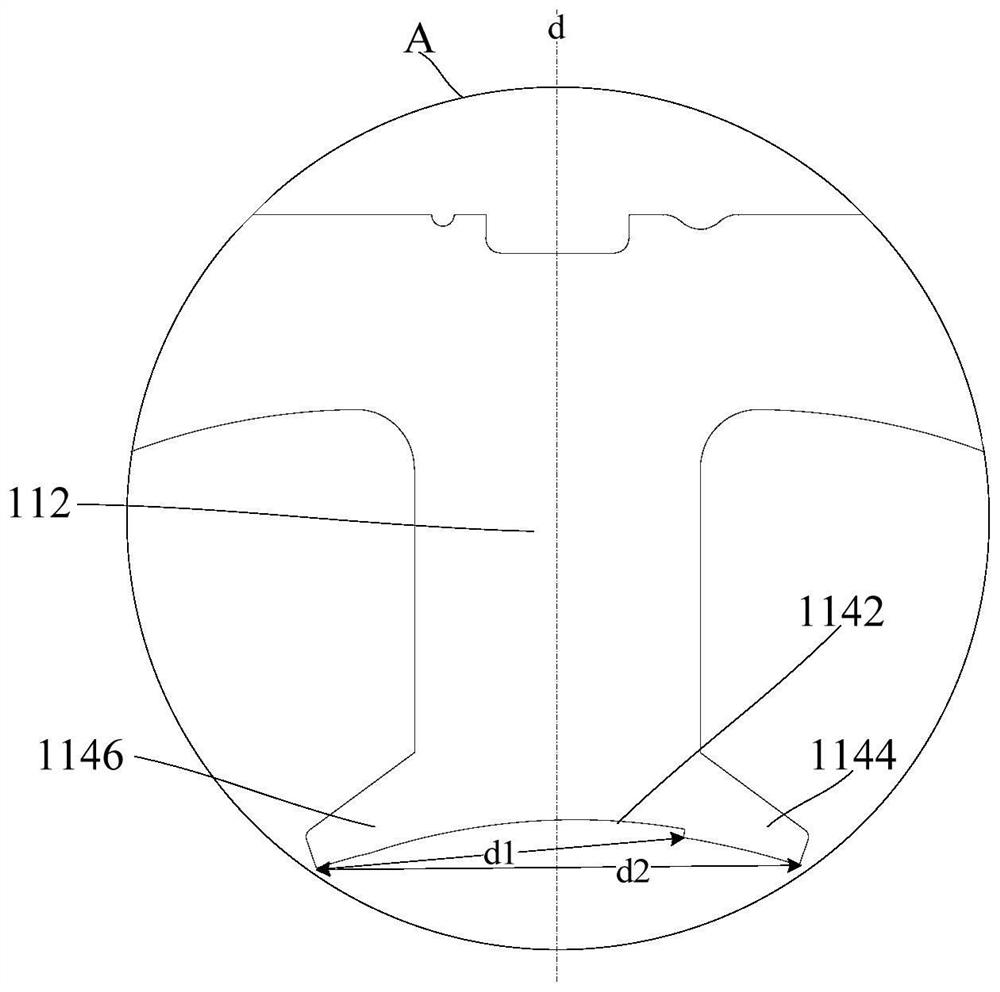

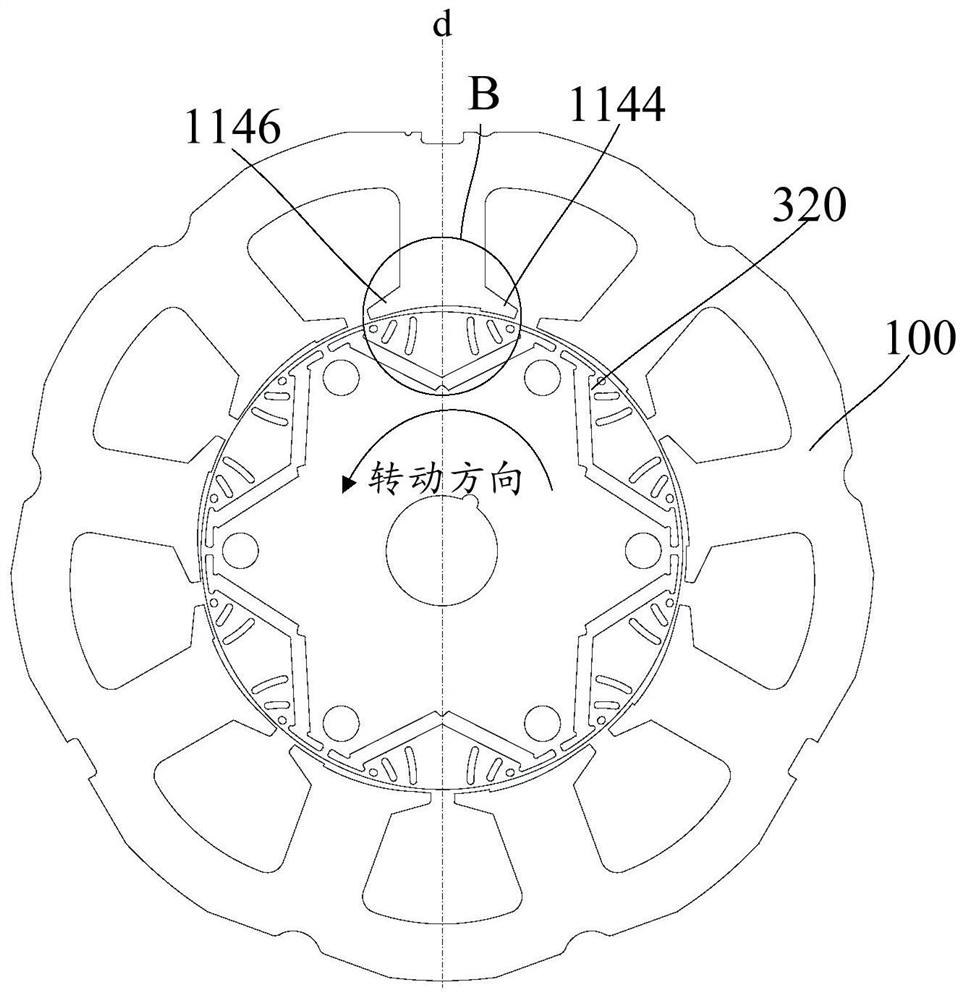

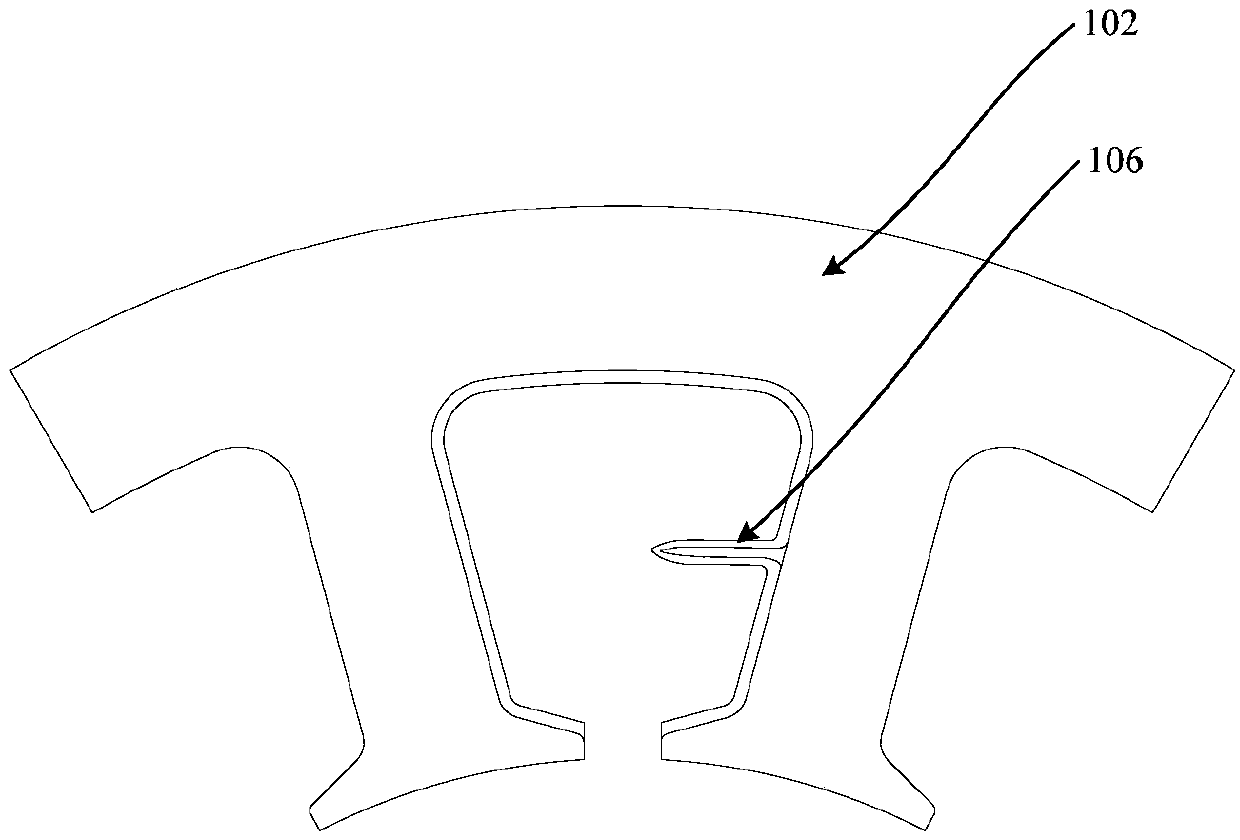

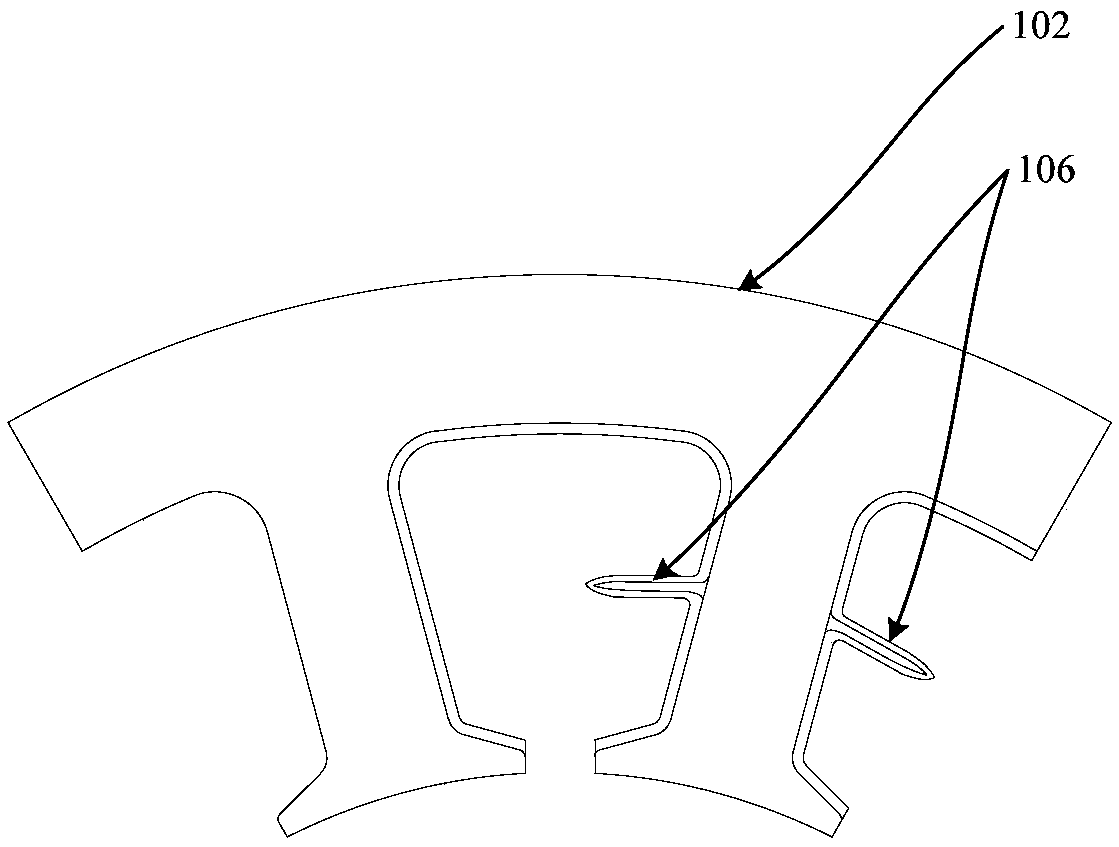

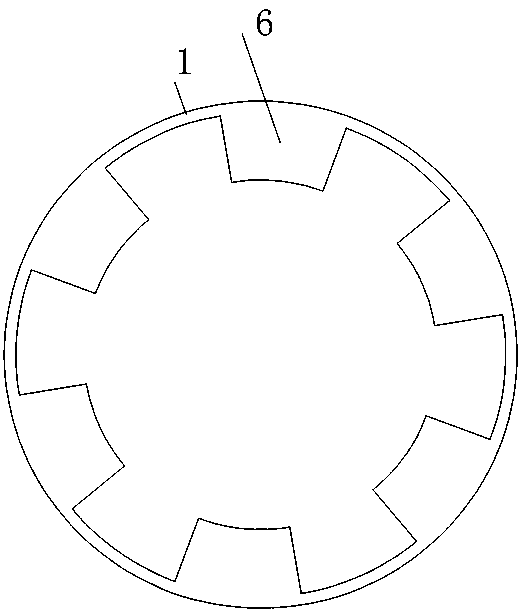

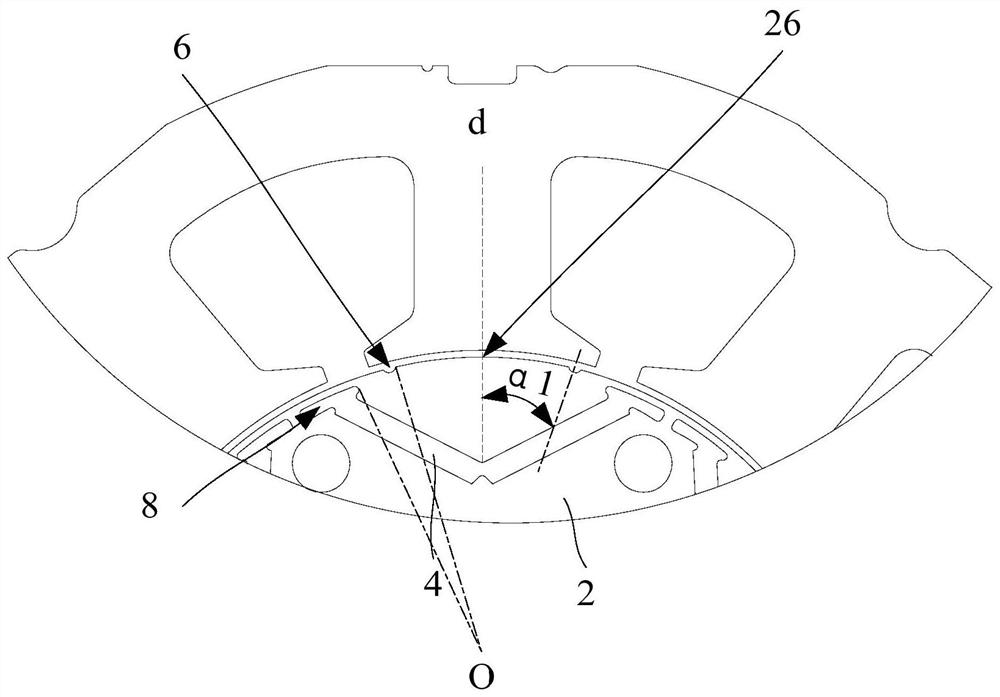

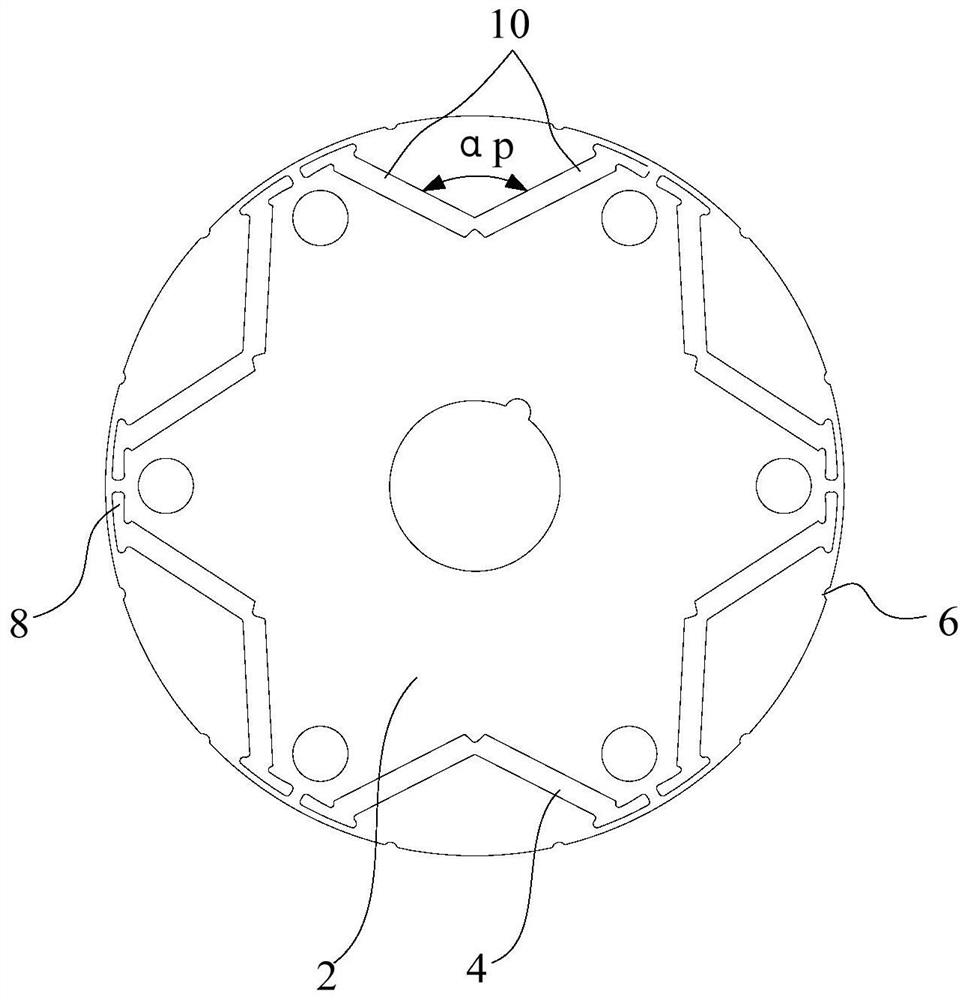

Brushless electric machine rotor sheet of automobile brake system

PendingCN106451988AExpand the range of field-weakening speed regulationHigh back EMFMagnetic circuit rotating partsHarmonicElectric machine

The invention discloses a brushless electric machine rotor sheet of automobile brake system, wherein a peripheral of a rotor sheet utilizes straight lines and arcs to form a salient pole structure. An U-shaped groove is disposed at the rotor sheet. The U-shaped groove is divided into three sections which have the same length. A flux-insulation bridge and a location step are disposed at a joint of the U-shaped groove. The rotor sheet is provided with a location hole for rotor-skewing. A peripheral of the salient pole of the rotor sheet utilizes a structure of straight line and arc, which reduces a content of a counter emf harmonic wave. Optimal designed shape and size of U-shaped magnetic steel groove and the peripheral of the salient pole can expand the range of field-weakening speed expansion of a motor. The motor can provide a certain torque in high speed running and meanwhile magnify the counter emf. A watt density of the motor is improved, and a quality of the motor is reduced. Three sections of the U-shaped groove have the same length, thus the motor only uses one size of magnetic steel, which decreases the cost of the motor. The flux-insulation bridge of the joint of the U-shaped groove also reduces the content of the counter emf harmonic wave. When the rotor is skewing, the skewing location pole is capable of providing a location without a rotor-skewing location frock. The brushless electric machine rotor sheet of automobile brake system is designed properly and is convenient and practical.

Owner:NIDEC KAIYU AUTO ELECTRIC JIANGSU

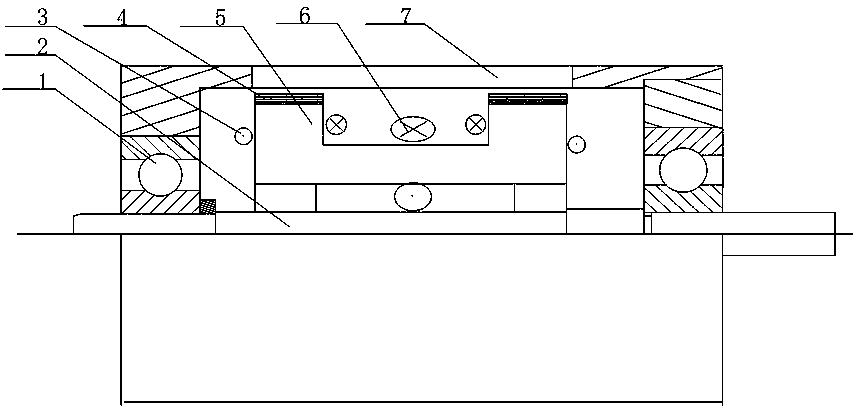

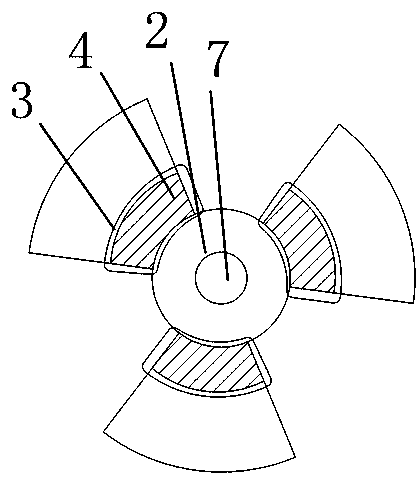

Electric vehicle magnetic grid type permanent magnetism doubly salient motor

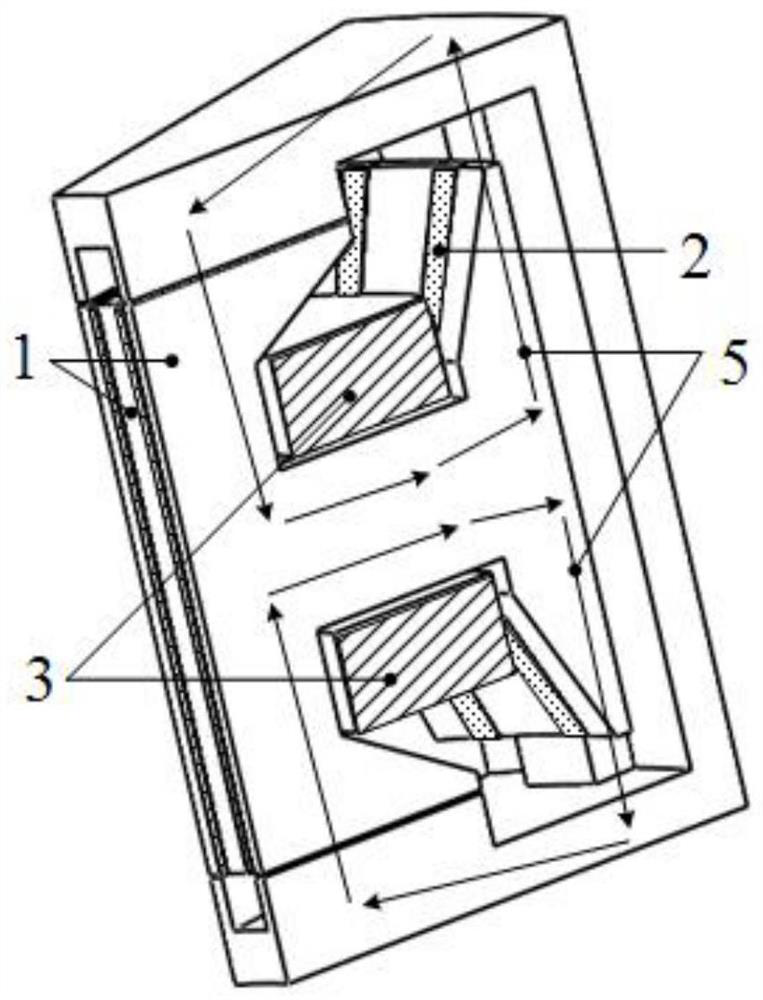

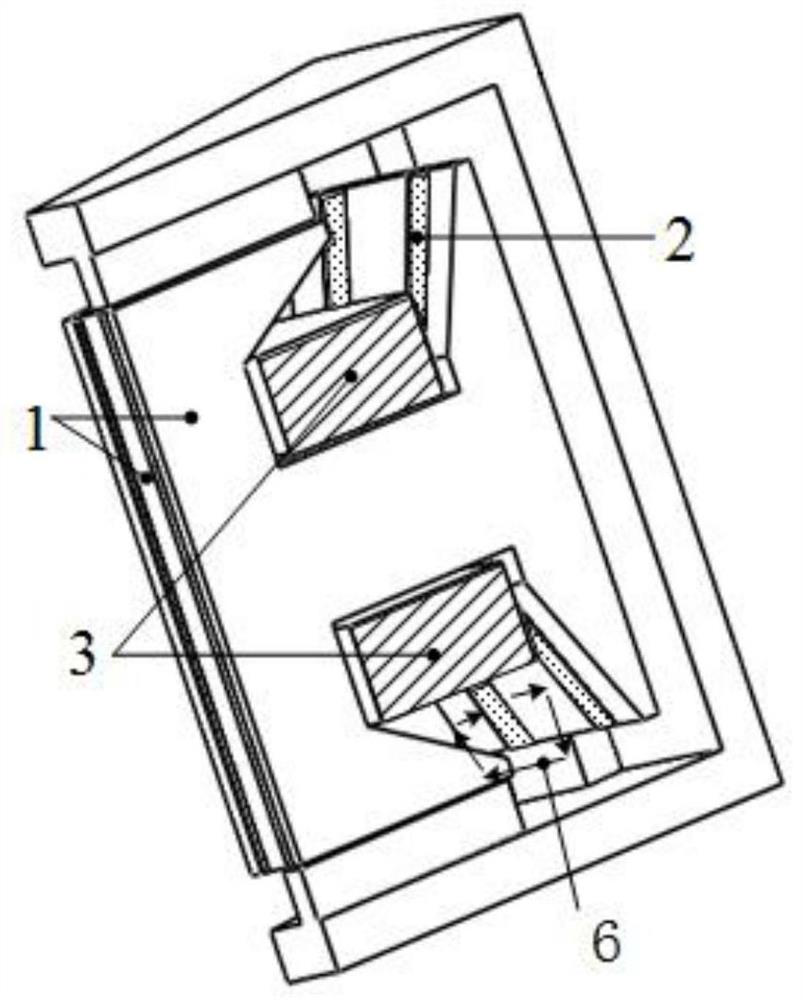

ActiveCN107508444ALarge magnetic areaIncrease powerMagnetic circuit rotating partsSynchronous machine detailsDoubly salientElectric vehicle

An electric vehicle magnetic grid type permanent magnetism doubly salient motor belongs to the electric vehicle motor technology field, comprises a shaft, a front armature iron core, a front armature winding, a front rotor iron core, a front permanent magnet, a permanent magnet iron core, a back permanent magnet, a back rotor iron core, a back armature winding, a back armature iron core and a shell, and is characterized in that the disc-shaped front rotor iron core and back rotor iron core are fixed on the shaft at intervals, the permanent magnet iron core fixed on the shell is between the front rotor iron core and the back rotor iron core, and the permanent magnets are fixed on the two surfaces of the permanent magnet iron core towards the rotor iron cores respectively and uniformly; the front armature iron core and the back armature iron core which are fixed on the shell are at the two sides of the front rotor iron core and the back rotor iron core respectively, armature poles are arranged on the armature iron cores, and the armature windings are wound on the armature poles. The rotor iron cores of the technical scheme of the present invention are magnetic grid-shaped, and are large in contact area and specific power, so that the electric vehicle magnetic grid type permanent magnetism doubly salient motor is very suitable for being used as an electric vehicle motor having higher requirements for the power density.

Owner:江苏惠博机电科技股份有限公司

Magnetic-field-enhanced permanent-magnetic switching flux linkage motor with high fault tolerance

InactiveCN101562384BIncrease profitIncrease the amount of changeMagnetic circuit rotating partsMagnetic circuit stationary partsFault toleranceConductive materials

The invention discloses a magnetic-field-enhanced permanent-magnetic switching flux linkage motor with high fault tolerance. The motor comprises a rotor, a stator, three-phase armature windings and a casing, wherein the casing is made of magnetic conductive material; the rotor consists of toothspace-type core laminations; the stator fixed in the casing comprises first permanent magnets, a first U-shaped iron core, reluctance sheets and a second U-shaped iron core arranged one by one; N poles and S poles of the first permanent magnets are alternately arranged; armature teeth consist of the first permanent magnets and U-shaped iron core edges clinging to two sides of the first permanent magnets respectively; auxiliary teeth consist of the reluctance sheets and the U-shaped iron core edges clinging to two sides of the reluctance sheets respectively; the three-phase armature concentrated windings are wound round the armature teeth; second permanent magnets are arranged between the casing and the stator; and the first permanent magnets and the second permanent magnets in contact with the U-shaped iron cores have the same polarity on contact surface. The motor is simple in structure. Compared with the prior permanent-magnetic switching flux linkage motor, the motor has the advantages of improving anti-electromagnetic interference capability and electromagnetic compatibility and raising the rate of utilizing the permanent magnets, along with higher output power density and capability of avoiding magnetic leakage on the outer edge of the casing.

Owner:ZHEJIANG UNIV

Radial-axial air gap type three-phase disc type transverse flux permanent magnet motor

ActiveCN111969823AIncrease magnetic fluxIncreased torque densityMagnetic circuit rotating partsSynchronous machinesTransverse fluxElectric machine

The invention discloses a radial-axial air gap type three-phase disc type transverse flux permanent magnet motor. Each phase of motor comprises a stator and a radial-axial rotor, wherein the stator iscomposed of a pole-shoe-shaped stator iron core and a pole-shoe-shaped permanent magnet. The permanent magnets are magnetized in the circumferential direction, the magnetization directions of every two adjacent permanent magnets are opposite, and the armature windings are wound in grooves formed after the stator core and the permanent magnets are arranged alternately. The radial-axial rotor comprises radial teeth, axial teeth and a right-angle yoke; the radial teeth and the axial teeth are connected through the right-angle yoke, the adjacent radial teeth are spaced by a 360 / n-degree mechanical angle, the adjacent axial teeth are spaced by a 360 / n-degree mechanical angle, the radial teeth and the axial teeth under the same pair of poles are spaced by a 180 / n-degree mechanical angle, and nis the number of pole pairs of the radial-axial air gap type three-phase disc type transverse flux permanent magnet motor. According to the invention, the pole-shoe-shaped stator core enables the relative area of the axial stator and rotor teeth to be increased, the groove cross section to be increased, and the number of turns of the windings to be increased, thereby increasing the flux linkage, and the radial-axial rotor structure enables the torque density of the motor to be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

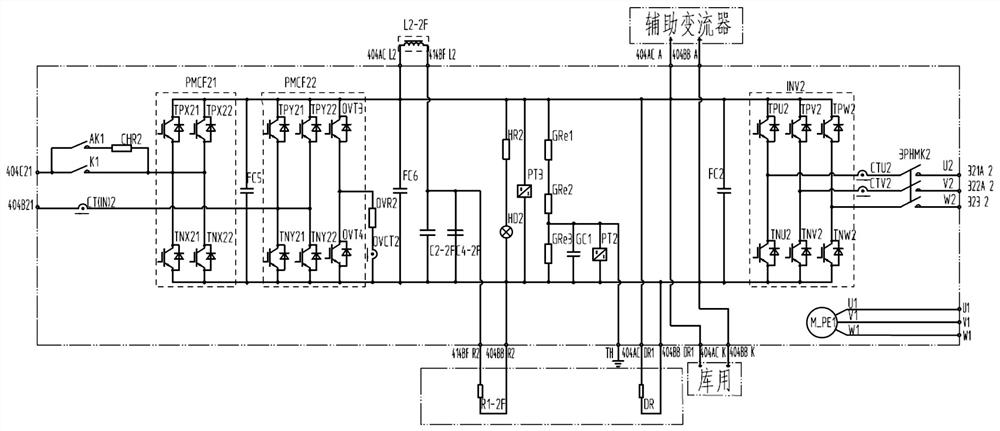

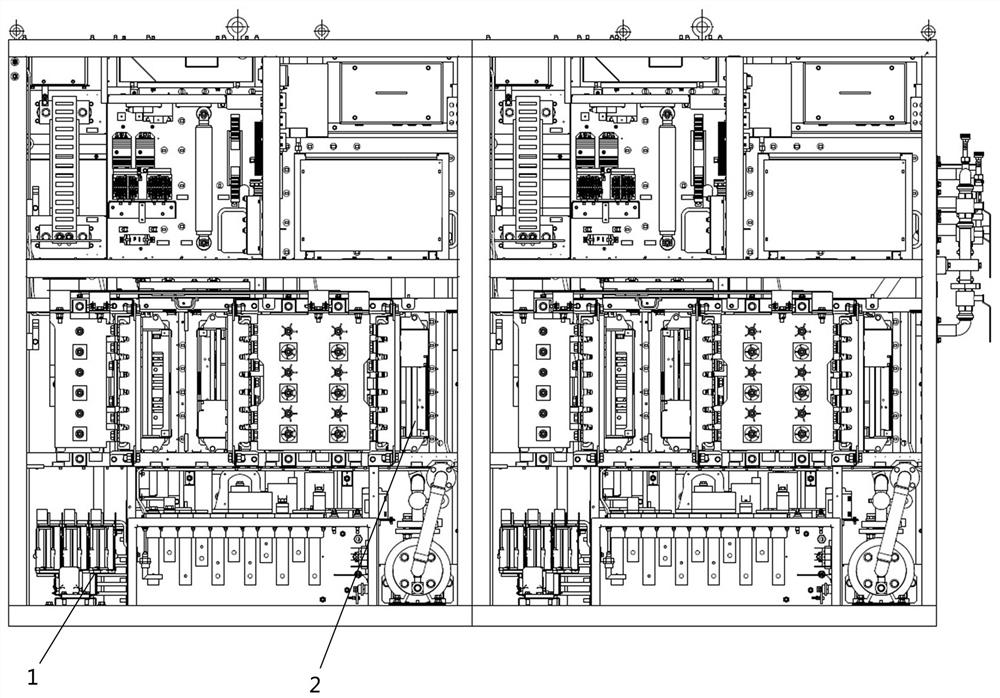

High-power permanent-magnet direct-drive freight locomotive traction converter

InactiveCN112737356ASolve the problem that the permanent magnet direct drive electric drive system cannot be directly appliedHigh back EMFElectric motor controlElectric motor propulsion transmissionConvertersPermanent magnet synchronous motor

The invention discloses a high-power permanent magnet direct-drive freight locomotive traction converter, and relates to the field of locomotive traction converters. The converter comprises two groups of independent traction main loops, wherein each group of traction main loops comprises a pre-charging loop, a four-quadrant power module, a four-quadrant chopping power module, an independent intermediate direct-current circuit, a traction inversion power module and a three-pole isolation contactor; the electrical principles and structures of the two traction main loops are completely the same. Each intermediate direct-current circuit comprises an energy storage circuit and a measurement and protection circuit; each energy storage circuit is used for stabilizing the voltage of an intermediate loop, each measurement and protection circuit is composed of a grounding measurement circuit, an intermediate voltage sensor and a voltage detection board, and a three-pole isolation contactor is arranged between the traction inversion power module and a permanent magnet synchronous motor. And each three-pole isolation contactor is connected with a three-phase traction inverter INV2 and a permanent magnet synchronous motor through copper bars. The problem that a traction converter of a high-power freight electric locomotive cannot be directly applied to a permanent magnet direct-drive electric transmission system is solved.

Owner:CRRC YONGJI ELECTRIC CO LTD

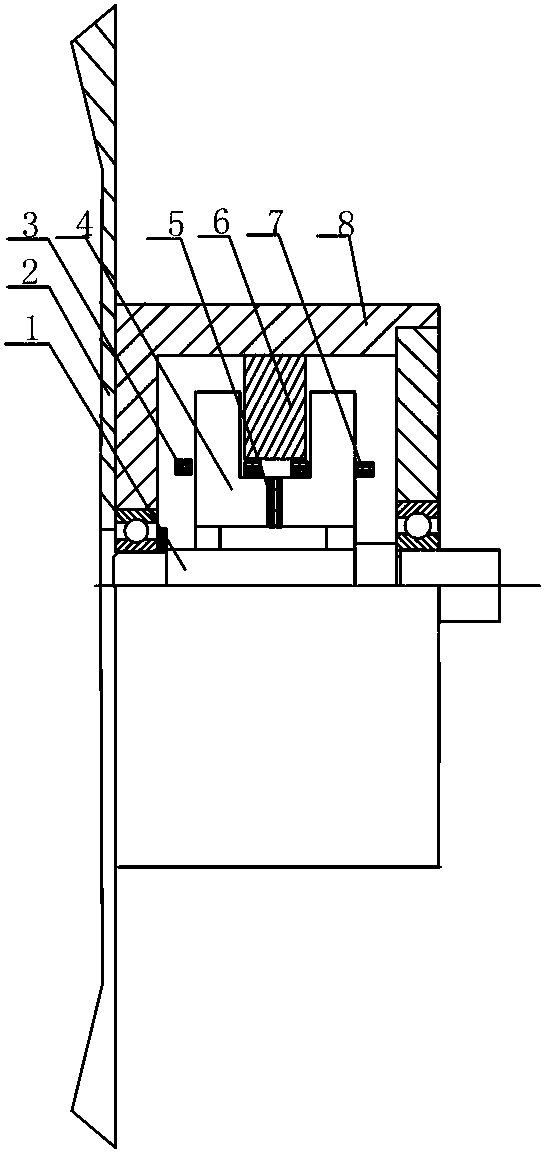

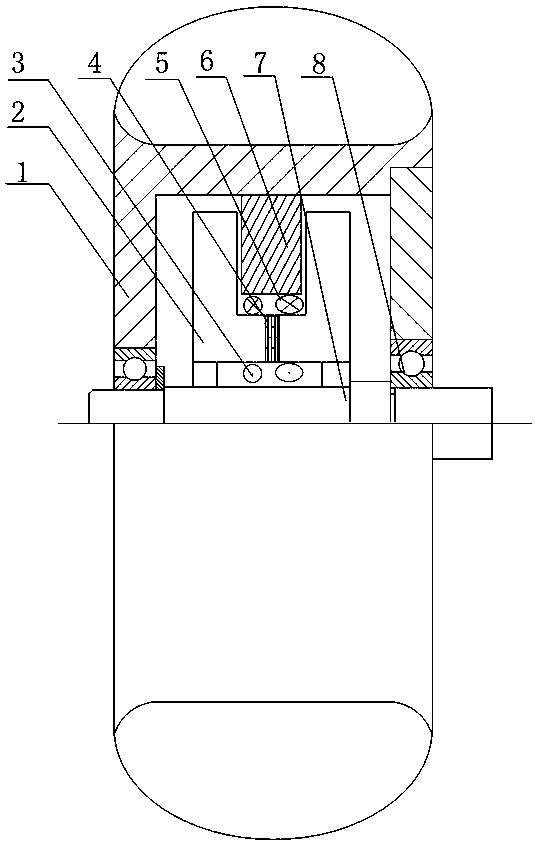

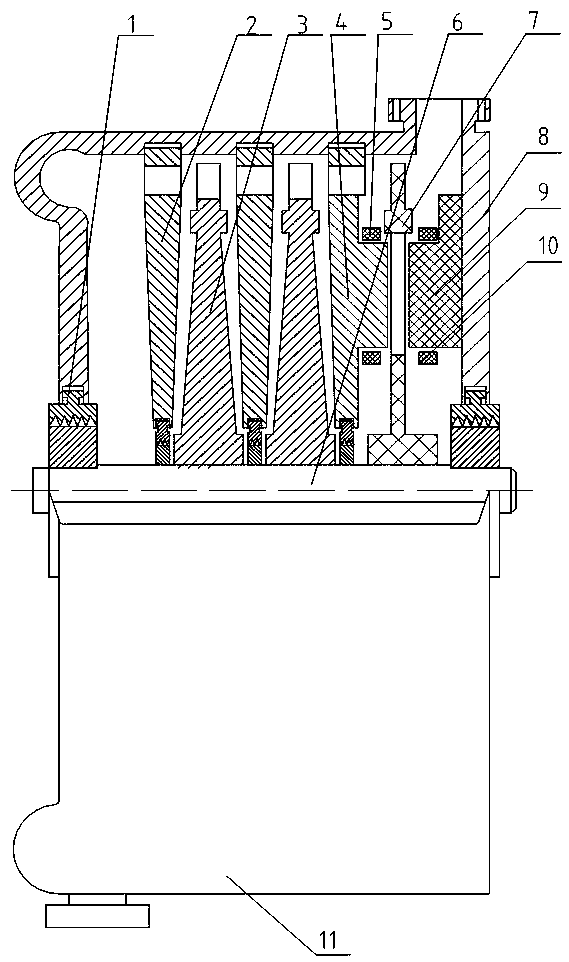

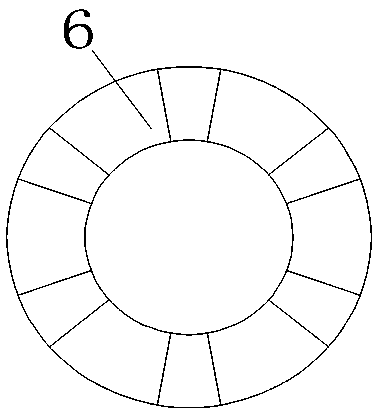

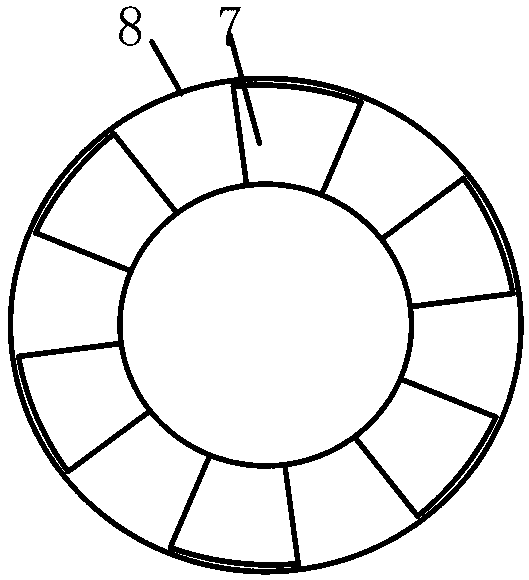

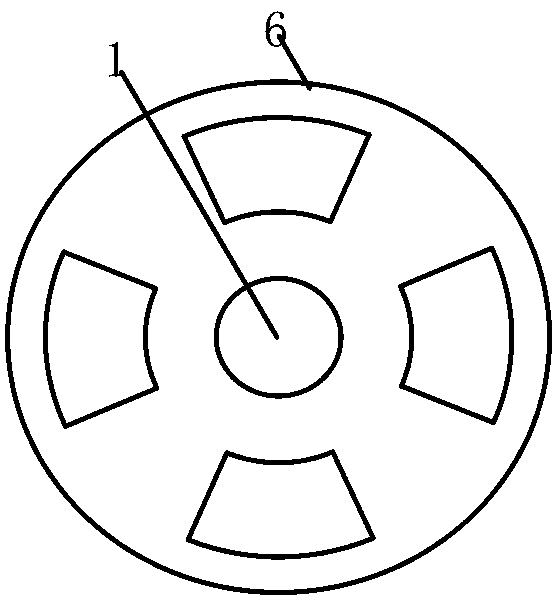

Disc-type built-in aero starter generator

InactiveCN107846124AVery fewLight in massMagnetic circuit rotating partsMagnetic circuit stationary partsStarter generatorMoment of inertia

The invention discloses a disc-type built-in aero starter generator, which belongs to the field of aero engineering. The disc-type built-in aero starter generator comprises a high-voltage shaft, a first stator iron core, a rotor iron core, first armature coils and a second stator iron core, and is characterized in that the rotor iron core is fixed on the high-voltage shaft of the aero engine; thefirst stator iron core and the second stator iron core with the same structures are symmetrically located at two axial sides of the rotor iron core and are fixed on the shell of the aero engine; 3k fan-shaped through holes are distributed uniformly on the circumference of the rotor iron core, and k is a positive integer larger than 1; and one side, facing the rotor iron core, of each of the firststator iron core and the second stator iron core is provided with 4k uniformly-distributed fan-shaped convex armature poles, and the armature poles of the first stator iron core are wound with integrated armature coils. The rotor iron core in the invention has small moment of inertia, and high-speed rotation can be achieved; and the rotor iron core is located on the high-voltage shaft of the engine, the rotation speed is high, the power is larger, and the disc-type built-in aero starter generator is extremely suitable for serving as an aero built-in generator.

Owner:猫头鹰安防科技有限公司

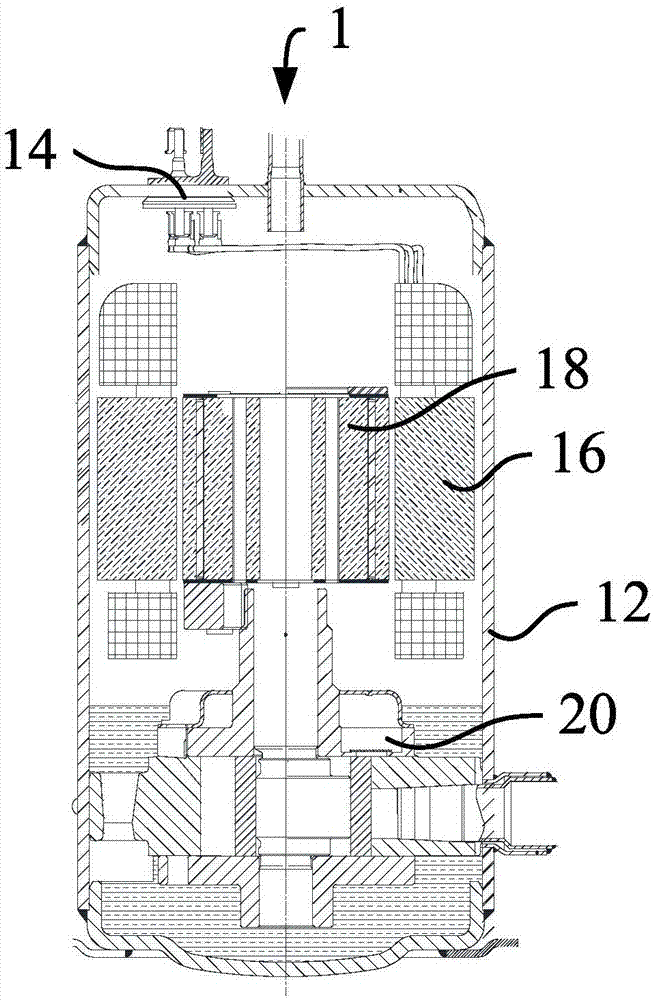

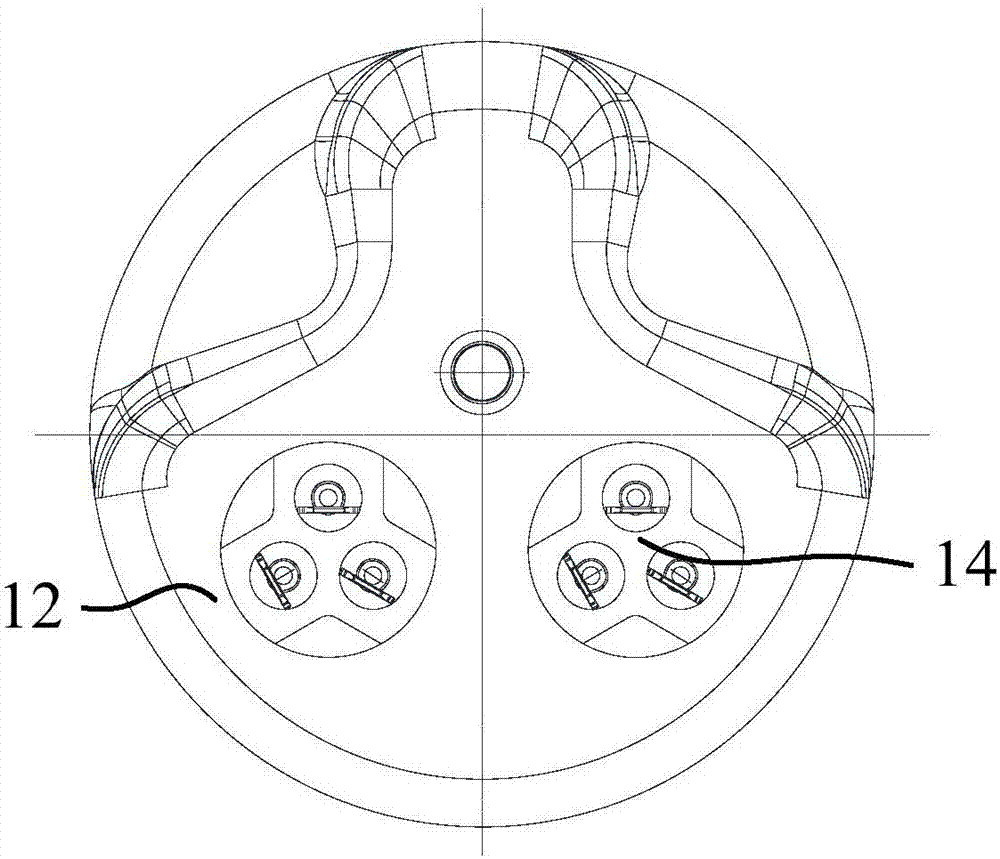

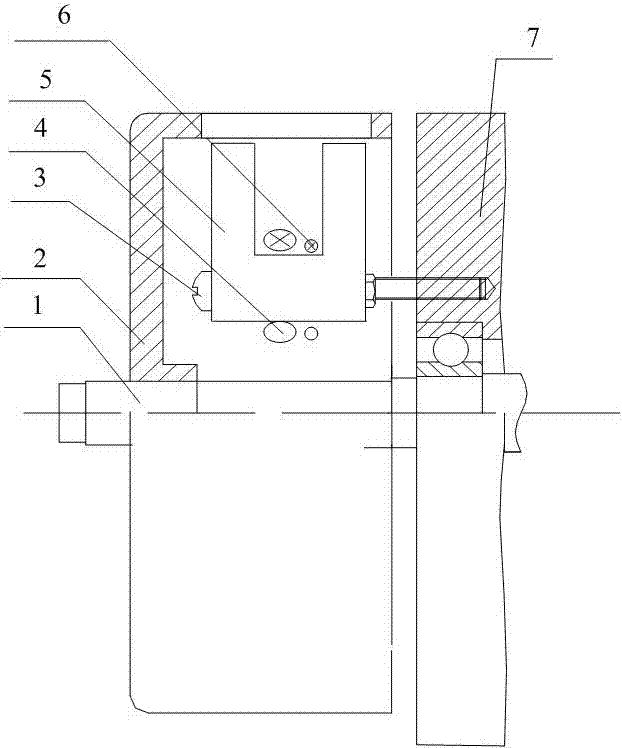

Compressor, air conditioner, and control method for power-on mode of compressor winding

ActiveCN107425683AImprove reliabilityImprove adaptabilitySynchronous motorsMicrocontrollerElectricity

The invention provides a compressor and an air conditioner. The compressor is used for the air conditioner; the compressor comprises a shell, a plurality of wiring terminals, a stator, a rotor, a pump body, a control circuit, and a microcontroller; the stator is provided with multiple phases of windings; one end of each winding is connected with one corresponding wiring terminal while the other end is connected with another corresponding wiring terminal; one end of the control circuit is connected with the power supply while the other end is connected with the wiring terminals for controlling the power-on condition of the windings; the microcontroller is used for detecting the bus voltage of the control circuit, the voltage drop generated after a current passes through the windings, the intra-line counter electromotive force of the windings and the turnover number of the pump body within unit time in real time, wherein when the compressor is in operation and when the turnover number within unit time is less than a preset turnover number, the microcontroller gives out a first signal to control the control circuit to enable one ends of each phase of the windings to be connected with the power supply and enable the other ends to be connected together so as to realize star-shaped connection of the windings. By virtue of the compressor disclosed in the invention, the operation reliability and adaptivity of the compressor are improved.

Owner:ANHUI MEIZHI PRECISION MFG

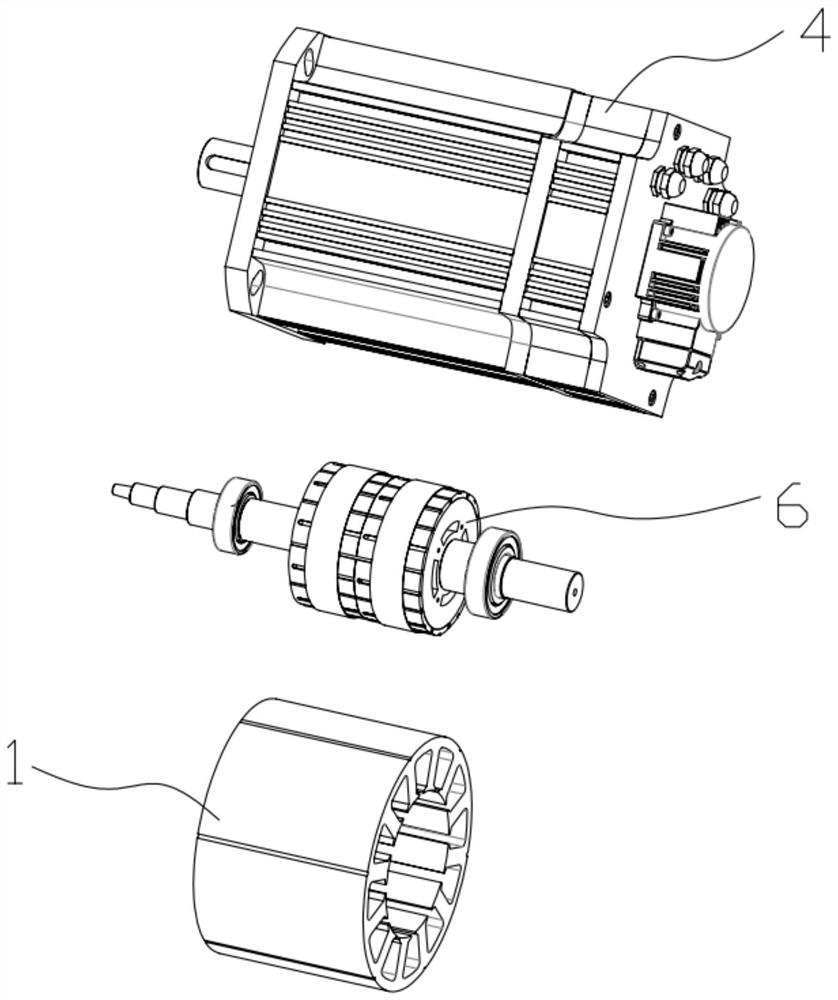

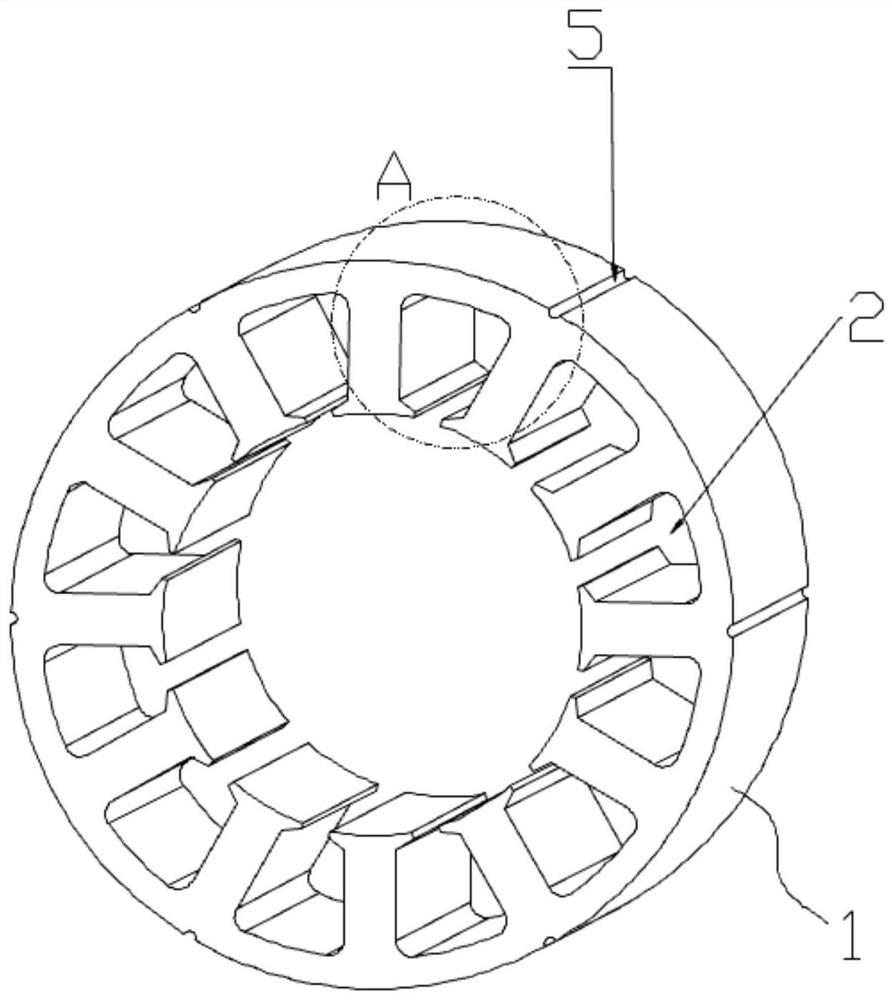

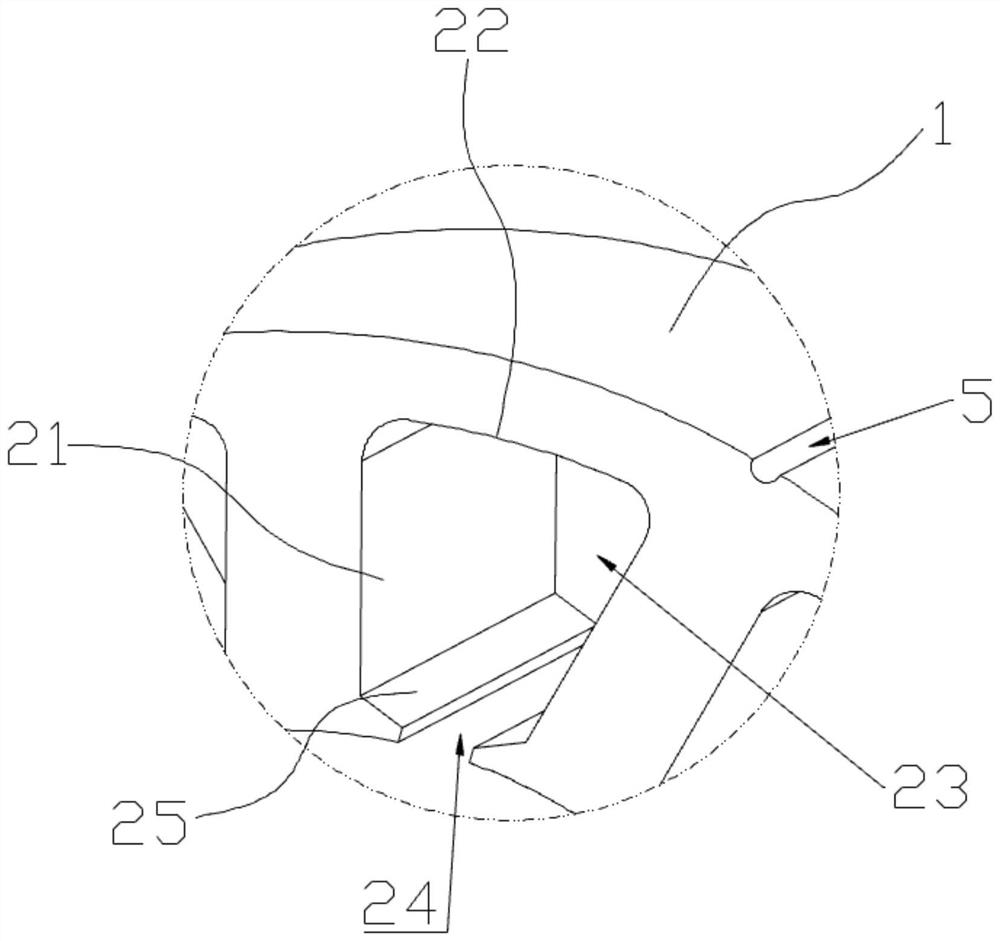

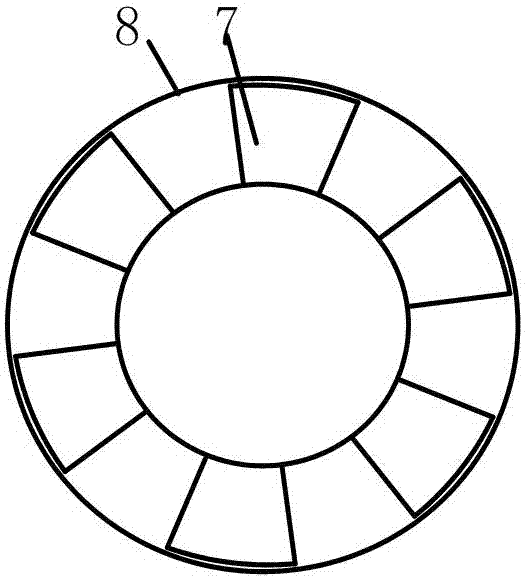

Large-current low-voltage servo motor

InactiveCN113644764ARealize double-layer stackingGuaranteed uptimeMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineElectrical polarity

The invention discloses a large-current low-voltage servo motor which comprises a machine shell, and an installation space is formed in the machine shell. A stator assembly is included and comprises a stator iron core arranged in the installation space, the inner circumferential surface of the stator iron core is provided with a stator groove for embedding a coil, a coil winding is embedded in the stator groove, and the coil winding is a three-phase coil winding; and a rotor assembly is included and comprises a rotor iron core, the stator iron core sleeves the outer peripheral surface of the rotor iron core, magnetic steel is adsorbed on the outer peripheral surface of the rotor iron core, the magnetic steel is arc-shaped, the magnetic steel is provided with an inner arc surface and an outer arc surface, the inner arc surface and the outer arc surface are eccentrically arranged, the number of the magnetic steel is multiple, and the multiple magnetic steel is distributed according to an N-S polarity alternating sequence. The invention provides a large-current low-voltage servo motor which solves the technical problem that an existing motor is poor in stability during low-speed operation.

Owner:JINAN KEYA ELECTRONICS SCI & TECH CO LTD

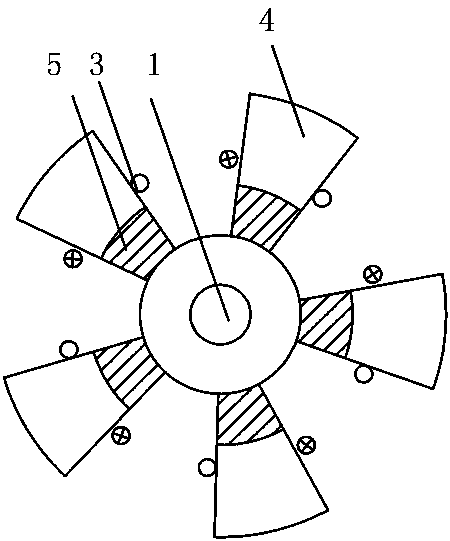

Permanent magnet wind-driven motor with low rotational inertia

ActiveCN107579640ALight in massSmall moment of inertiaSynchronous machine detailsWind energy generationWind drivenMoment of inertia

The invention discloses a permanent magnet wind-driven motor with low rotational inertia, and belongs to the technical field of special motors. The permanent magnet wind-driven motor comprises a shaft, an armature iron core, first armature windings, second armature windings, a rotor iron core, permanent magnets, a permanent magnet iron core and a shell, and is characterized in that 4k fan-shaped through holes are uniformly formed in a disc of the rotor iron core, and the k is a positive integer; the permanent magnet iron core and the armature iron core which are fixed onto the shell are arranged on two sides of the rotor iron core, the 6k fan-shaped permanent magnets are arranged on the surface, which faces the rotor iron core, of the permanent magnet iron core, 12k fan-shaped protruded armature poles are uniformly distributed on the side, which faces the rotor iron core, of the armature iron core, each first armature winding is wound on the two corresponding armature poles, and the second armature windings are wound on the odd-number armature poles along the clockwise direction. The permanent magnet wind-driven motor has the advantages that the rotor iron core is low in rotational inertia and can quickly respond, the second windings are capable of weakening demagnetization armature reaction and increasing the power density, and accordingly the permanent magnet wind-drivenmotor is quite suitable to be used as a wind-driven power generator started by breeze.

Owner:徐州普林惠新能源技术有限公司

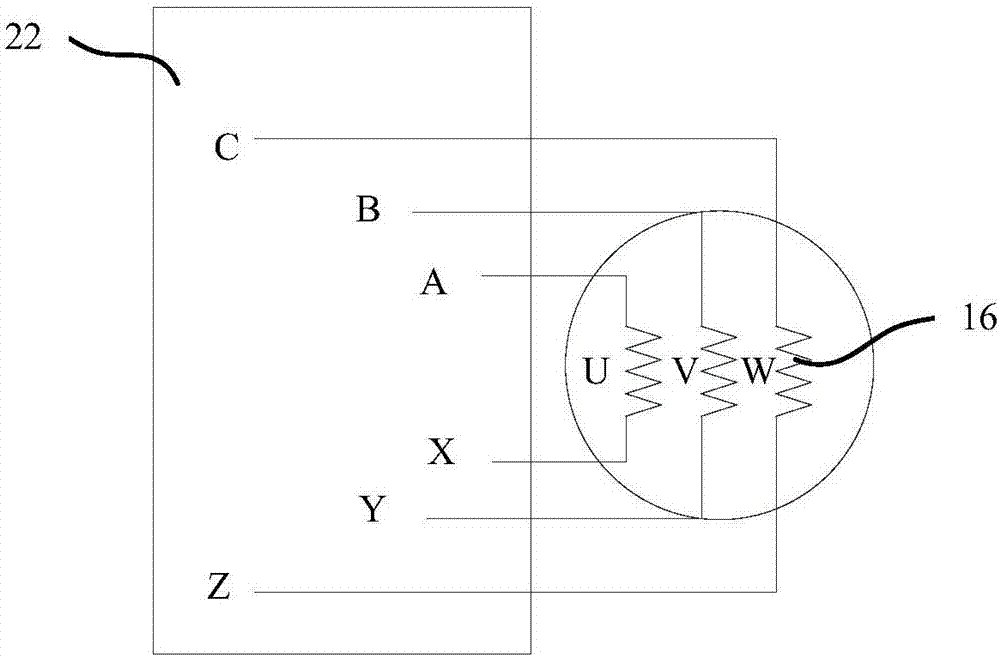

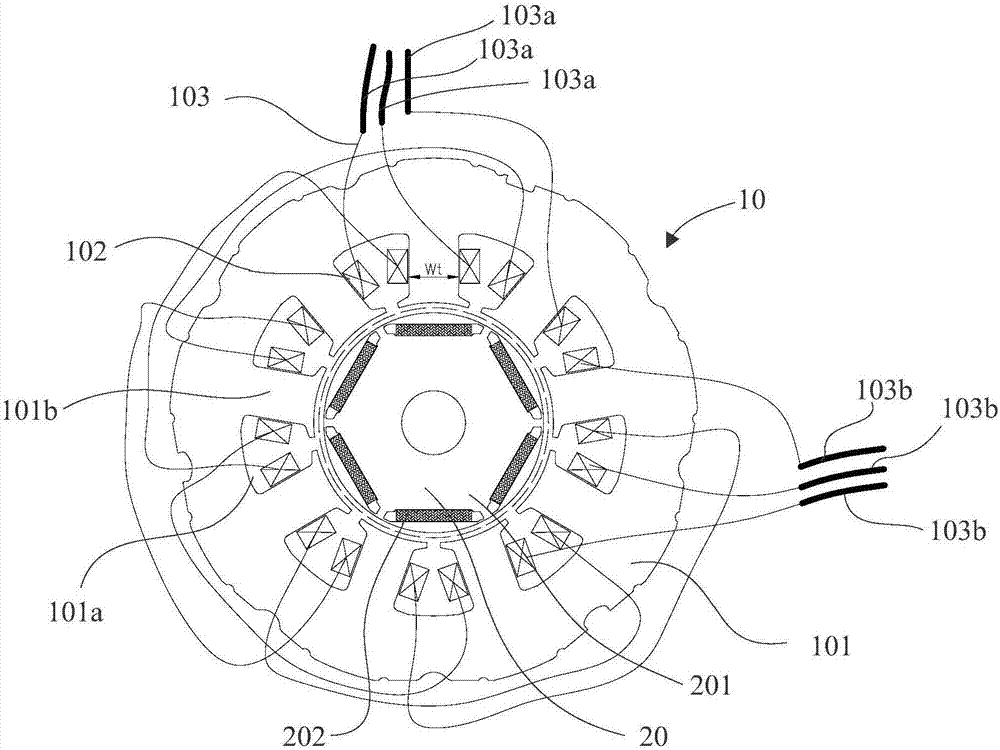

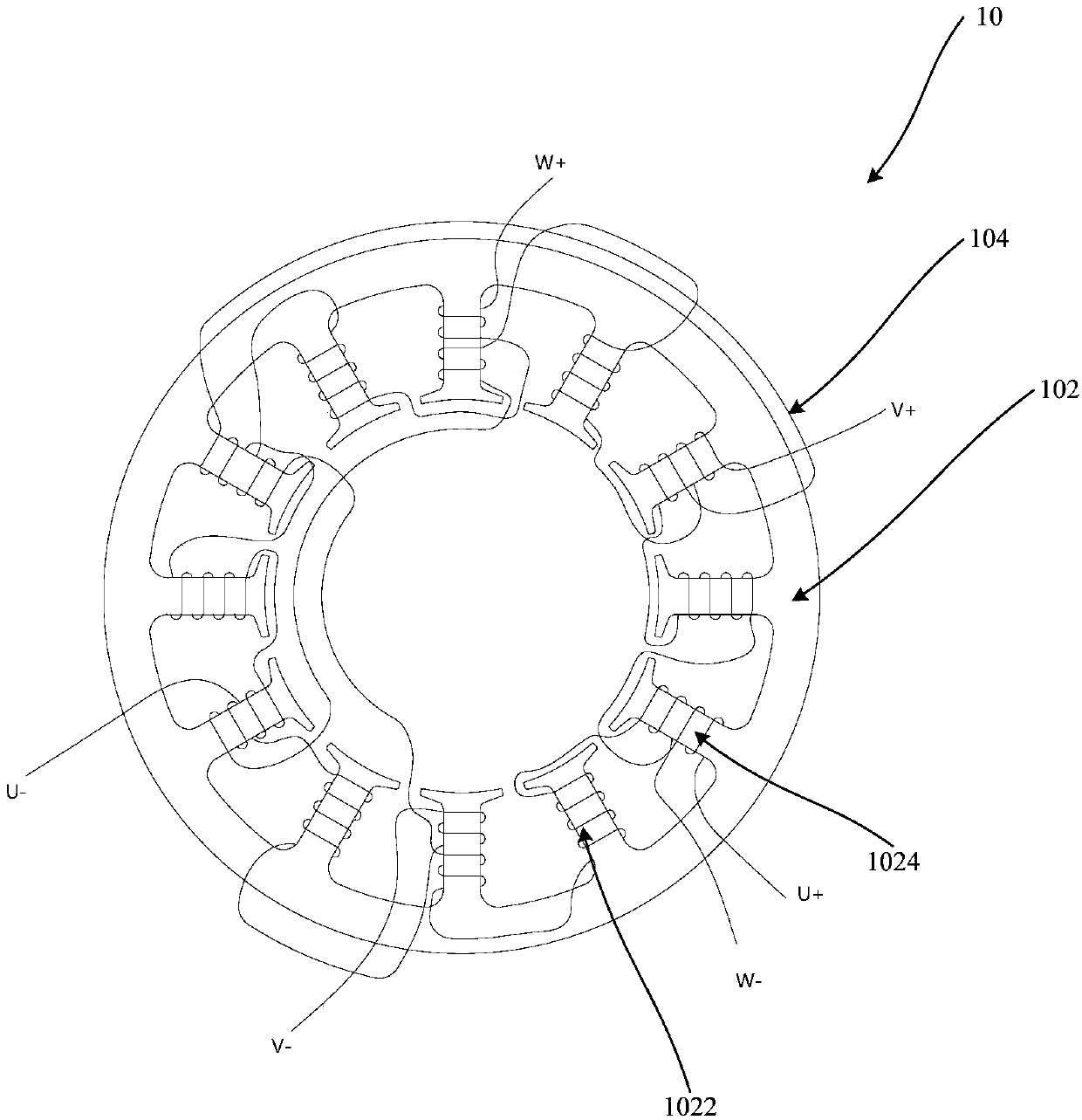

Motor stator, three-phase permanent magnet motor, and compressor

PendingCN107370256AHigh back EMFImprove performanceRotary/oscillating piston combinations for elastic fluidsMagnetic circuit stationary partsPhysicsMagnetic chain

The invention discloses a motor stator, a three-phase permanent magnet motor, and a compressor. The number n of parallel-connected branches of each phase of a stator winding is determined according to a parameter [psi], wherein [psi]=Bt x Wt x Z x L x N x k. When the [psi] is relatively high, phase magnetic chain can be reduced through setting a value of n, to make the phase magnetic chain in a certain range, so that a back electromotive force coefficient is also controlled in a certain range, and a permanent magnet motor has high back electromotive force under slow-speed of revolution and has low back electromotive force under high-speed of revolution. The motor is ensured to have excellent performance under slow-speed of revolution and high-speed of revolution.

Owner:GUANGDONG MEIZHI COMPRESSOR

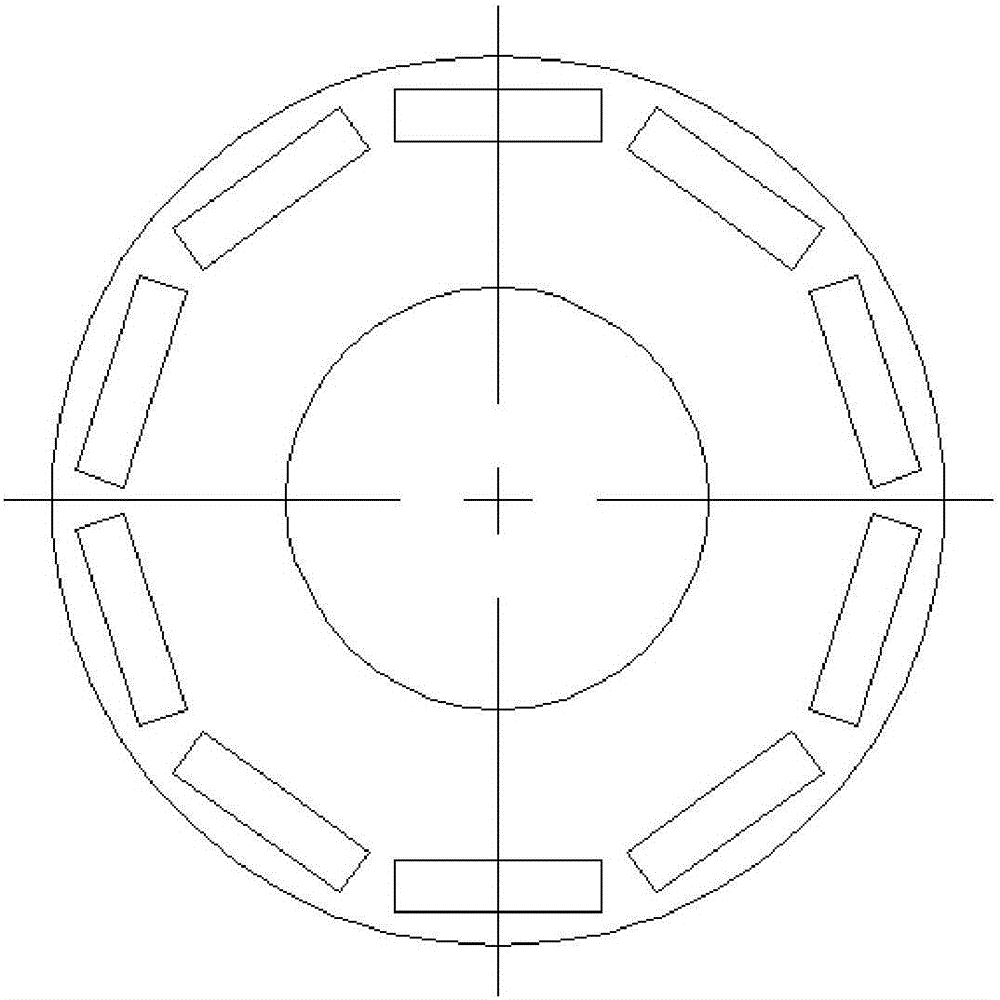

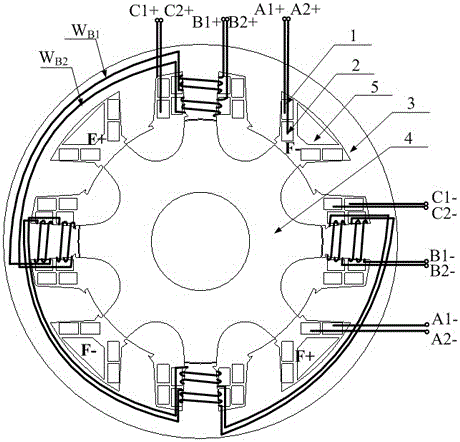

A variable winding starter generator for automobiles

ActiveCN104242580BMany turnsHigh back EMFSynchronous generatorsSynchronous motorsStarter generatorStator coil

The present invention proposes a variable winding starter generator, which includes rotor core, stator core, coil, shaft and casing, etc., and is characterized in that each stator pole has a centralized coil with one m-turn and one n-turn; when the When the variable-winding starter-generator used for automobiles is used as a starter, the switch connects all the coils on the stator poles with the same phase in series to form a phase armature winding, and each phase armature winding is connected to an asymmetrical half-bridge with a body diode After the converter, it can run electrically in the switched reluctance motor mode; when the automobile variable winding starter generator is used as a generator, the n-turn coils on all stator poles are connected in series to form an excitation winding, and the stator poles with the same phase The m-turn coils on the upper part are connected in series or in parallel to form a phase armature winding, and the starter generator operates in the mode of electric excitation double salient pole generator to generate electricity. The starter generator of the invention can effectively utilize the advantage of relatively high efficiency of the switched reluctance motor, and also effectively utilize the advantages of simple voltage regulation and control of the electrically excited double salient pole generator.

Owner:SHANDONG UNIV OF TECH

Stator core, stator, permanent magnet synchronous motor, compressor and refrigeration equipment

ActiveCN112583143AReduce deformationHarmonic suppressionMagnetic circuit stationary partsElectric machinePermanent magnet synchronous motor

The invention provides a stator core, a stator, a permanent magnet synchronous motor, a compressor and refrigeration equipment. The stator core comprises a plurality of stator punching sheets, the plurality of stator punching sheets are stacked in the axial direction of an inner hole, each stator punching sheet comprises a plurality of stator teeth distributed in the circumferential direction, each stator tooth comprises a tooth part and a tooth boot connected to the tooth part, and the plurality of tooth boots form the inner hole in an enclosing mode; the plurality of stator punching sheets comprise at least one first stator punching sheet, the inner circumferential wall of at least one tooth boot of the first stator punching sheet is provided with a concave part, the tooth boot comprisesa first tooth boot part, and a part of the concave part is located in an area, facing one side of the first tooth boot part, of the symmetric center line of the tooth part. Therefore, radial electromagnetic force waves generated by the interaction of armature magnetic field harmonics and rotor magnetic field harmonics are reduced, the deformation of the stator core is reduced, the vibration noiseof a motor key frequency band is remarkably improved, and the hearing feeling of the compressor is effectively improved.

Owner:ANHUI MEIZHI PRECISION MFG

Grid-shaped rotor motor for range extender of electric automobile

ActiveCN107465322ALight in massSmall moment of inertiaMagnetic circuit rotating partsElectric machinesCopperHigh power density

The invention relates to a grid-shaped rotor motor for a range extender of an electric automobile and belongs to the technical field of electric automobiles. The grid-shaped rotor motor is composed of a crankshaft, a shell, a stator iron core, an exciting winding and an armature winding, wherein ten rectangular holes are uniformly formed in the circumferential surface of the shell, and a grid-shaped iron core capable of conducting magnetism is arranged between any two rectangular holes; the stator iron core fixedly arranged on a range extender shell is composed of 12 substator iron cores uniformly distributed in a left inverted 'n' shape, stator poles projecting along the radial direction are arranged at the two sides of each substator iron core, and the side surface of each stator pole is in a sectional shape; the distance between two stator poles on one substator iron core is less than the axial length of each rectangular hole in the shell; the exciting winding is formed by winding yokes of all the 12 substator iron cores. The grid-shaped rotor motor provided by the invention can fully play the advantage of high power density of a disc type motor, and the exciting winding is short in path and small in copper loss.

Owner:SHENZHEN POWER SUPPLY BUREAU +1

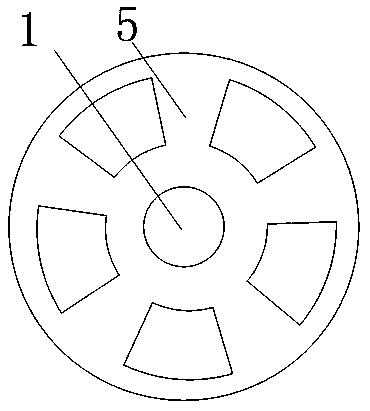

Electric roller permanent magnet motor

ActiveCN107846091AImprove cooling effectImprove reliabilityMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineDrive motor

The invention discloses an electric roller permanent magnet motor, which belongs to the technical field of electric rollers. The electric roller permanent magnet motor comprises a shaft, a roller, a stator core, armature windings, excitation windings, permanent magnets, rotor teeth and a bearing, wherein the circumferential surface of the roller is uniformly distributed with 5K rectangular holes;the stator core is formed by 3K uniformly-distributed [-shaped sub stator cores; two ends of each sub stator core are provided with two stator teeth respectively; all stator teeth face the outer sideof the circumference, and the distance between the stator teeth at two ends of the same sub stator core is smaller than the axial length of the rectangular hole of the roller; the surface of the stator tooth at one end of the sub stator core is provided with a permanent magnet; and each stator tooth is wound with an integrated armature winding. Thus, integrated design between the roller and a driving motor can be effectively realized, cooling is easy, advantages of integrated excitation can be made full use of, and high application value in the electric roller is realized.

Owner:TANGSHAN WEISEN NEW MATERIAL CO LTD

An external rotor wind generator

ActiveCN107528441BLight in massSmall moment of inertiaSynchronous machine detailsMagnetic circuit rotating partsWind drivenNew energy

Provided is an external rotor wind driven generator, which belongs to the technical field of new energy generating, and comprises a shaft, a turbine fan blade, a first armature winding, a second armature winding, a rotor iron core, a permanent magnet, a stator iron core, and a housing. The external rotor wind driven generator is characterized in that the inner side of the rotor iron core is provided with protruding rotor teeth in the number of 6k (k is a positive integer); the stator iron core fixed to the shaft is composed of U-shaped sub-stator iron cores in the number of 5k, and the two sides of the sub-stator iron core are respectively provided with a stator tooth protruding along the radial direction; a yoke part at the middle of the sub-stator iron core is embedded with the permanent magnet magnetizing along the axial direction; the root part of the stator tooth at one side of the sub-stator iron core is winded with the concentration type first armature winding , and the root part of the stator tooth at the other side of the sub-stator iron core is winded with the concentration type second armature winding. The invention is advantageous in that the rotor structure is simple and reliable, and the positioning force and the moment of inertia is small, and response is rapid; the demagnetizing armature reaction can be weakened, and the power density excitation and coiling mode can be improved, and thereby the external rotor wind driven generator is very suitable for the wind driven generator of gentle breeze.

Owner:SHENZHEN POWER SUPPLY BUREAU +1

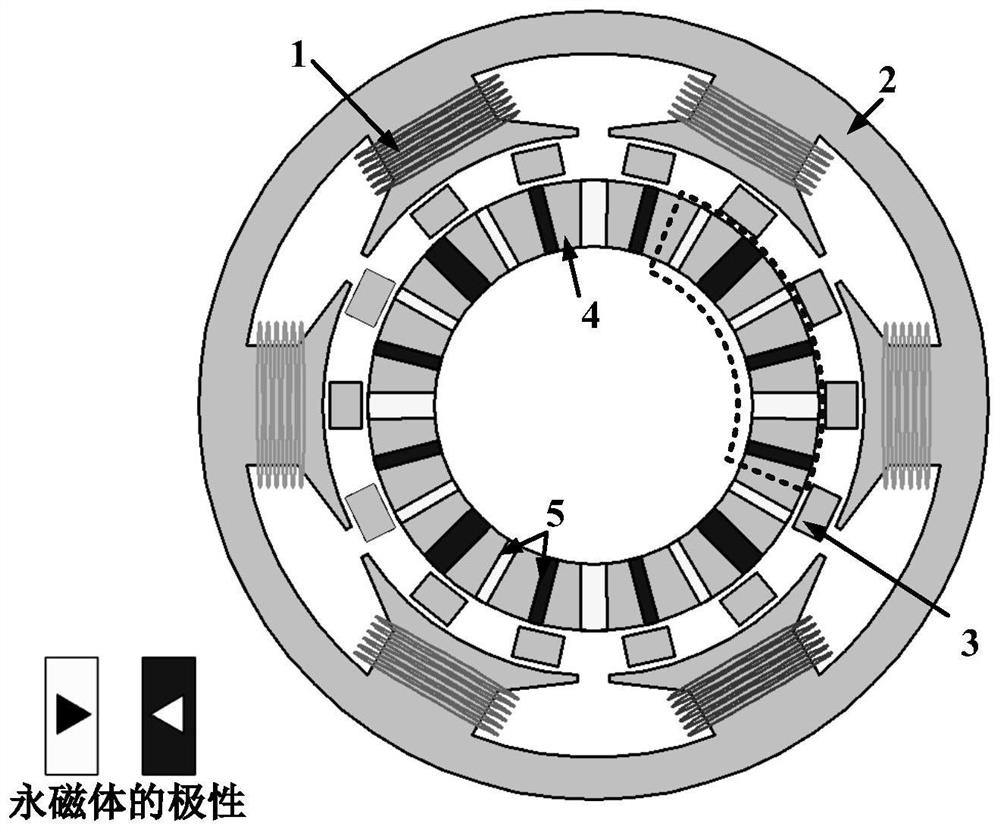

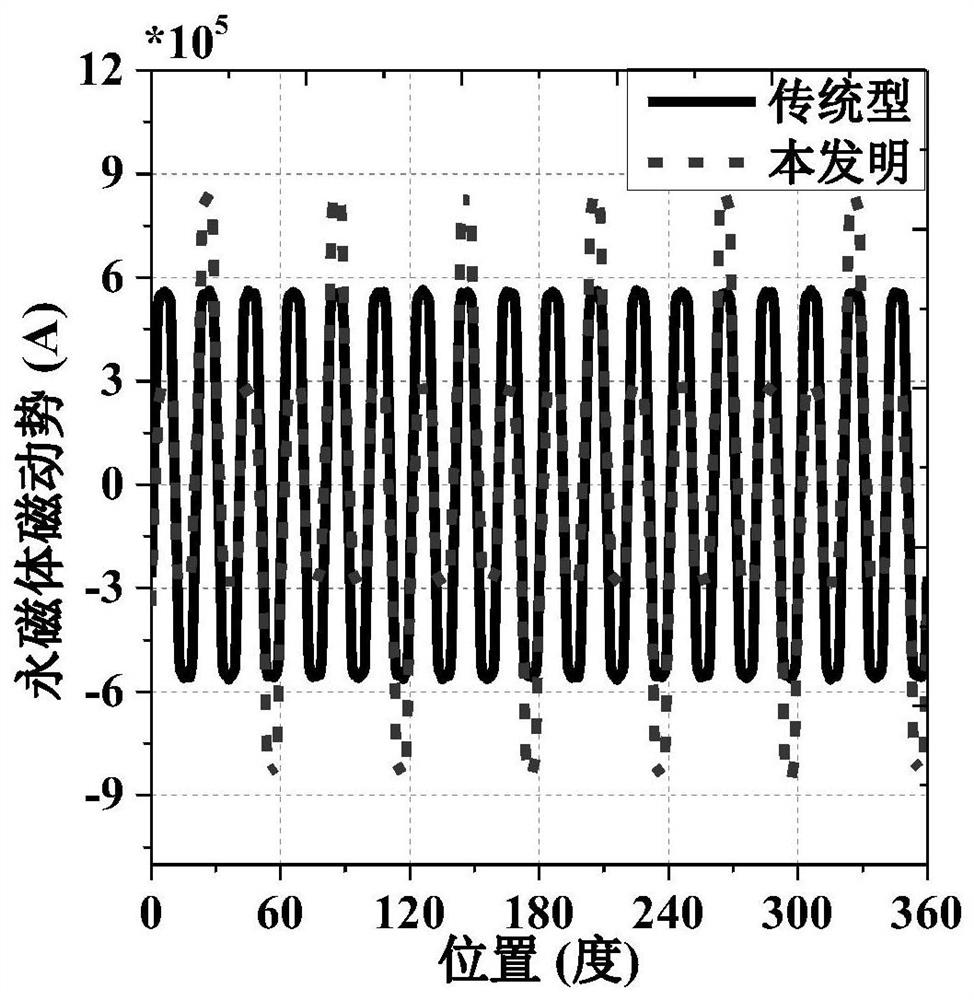

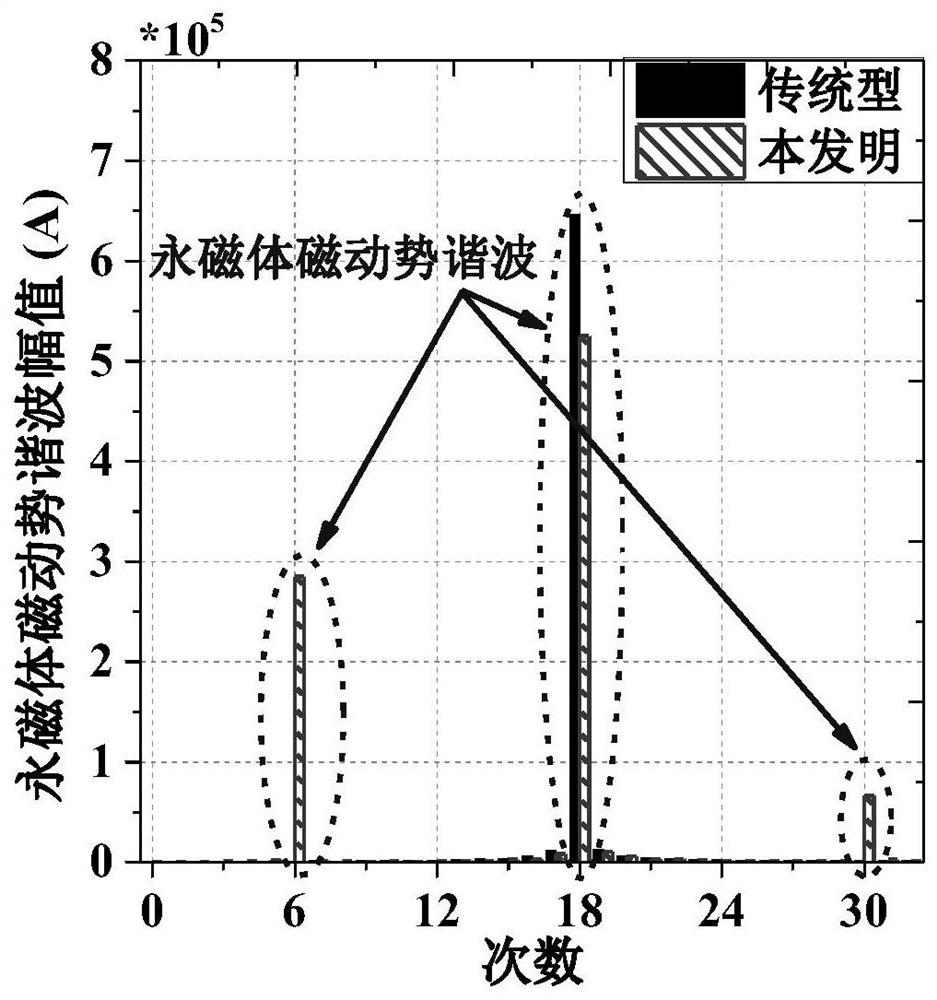

A Double Stator Tangentially Excited Magnetic Field Modulation Motor

ActiveCN111446830BIncreased torque densityReduce volumeMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineTorque density

The invention belongs to the technical field related to motors, and discloses a double-stator tangential excitation magnetic field modulation motor, the motor includes an outer stator, an inner stator and a rotor, and the outer stator, the inner stator and the rotor are coaxial , the rotor is located between the outer stator and the inner stator; the inner stator includes a cylindrical inner stator core, and a plurality of permanent magnet units are embedded on the inner stator core, each permanent magnet The unit includes six permanent magnets arranged at intervals along the circumference of the inner stator core, the permanent magnets at the second and fifth positions have the same width, and the permanent magnets at the first, third, fourth and sixth positions The widths of the permanent magnets are equal, and the width of the permanent magnets located in the second position is not equal to the width of the permanent magnets located in the first position. The invention improves back electromotive force, torque density, power factor and efficiency.

Owner:HUAZHONG UNIV OF SCI & TECH

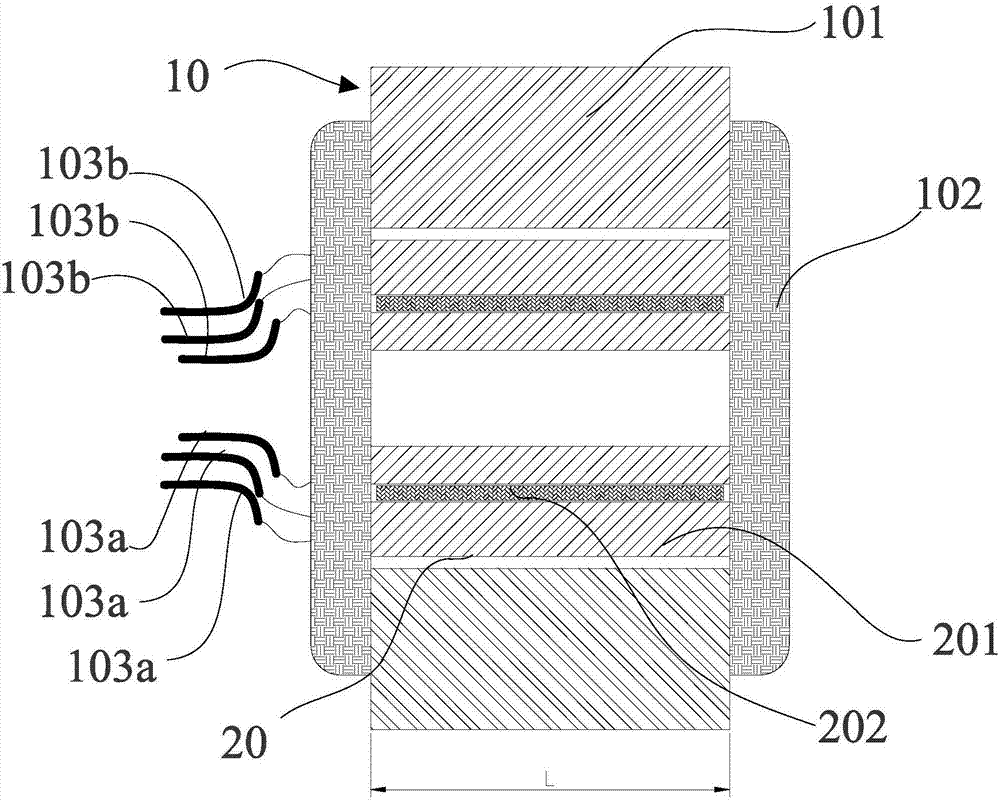

Permanent magnet synchronous motor and compressor

PendingCN110875646AHigh back EMFImprove performanceMagnetic circuit stationary partsWindings conductor shape/form/constructionElectric machinePermanent magnet synchronous motor

The invention provides a permanent magnet synchronous motor and a compressor. The permanent magnet synchronous motor comprises a motor stator and a motor rotor, wherein the motor stator comprises a stator core and a stator winding, the stator core comprises a plurality of stator teeth in the circumferential direction, a stator slot is defined between any two adjacent stator teeth, and the stator slots are used for accommodating the stator winding wound on the stator teeth; the motor rotor is sleeved and matched with the motor stator, the motor rotor comprises a rotor core and a plurality of permanent magnets, the end face of the rotor core is provided with a plurality of groups of slots in the circumferential direction of the rotor core, the plurality of permanent magnets are embedded in the plurality of groups of accommodating slots, the plurality of stator teeth can be divided into a plurality of tooth groups which are sequentially arranged according to the rotation direction of themotor rotor, each tooth group comprises a plurality of stator teeth which are adjacent in pairs, and at least one stator tooth in the plurality of stator teeth which are adjacent in pairs is wound with an out-phase winding. According to the technical scheme of the invention, the counter electromotive force of the stator winding can be improved when the motor is in operation, so that the copper loss of the winding is reduced, and the motor performance is improved.

Owner:GUANGDONG MEIZHI PRECISION MFG

A Low Moment of Inertia Servo Motor

ActiveCN107733118BLight in massSmall moment of inertiaMagnetic circuit rotating partsMagnetic circuit stationary partsMoment of inertiaConductor Coil

Owner:SHENZHEN POWER SUPPLY BUREAU +1

A brushless hybrid excitation motor for electric skateboard

ActiveCN107733107BImprove reliabilityLower internal resistanceMagnetic circuit stationary partsSynchronous machines with stationary armatures and rotating magnetsElectric machineElectric vehicle

The invention discloses a brushless hybrid excitation motor for an electric skateboard, which belongs to the technical field of electric vehicles. The brushless hybrid excitation motor for the electric skateboard is composed of a shaft, a hub, a stator iron core, armature windings, permanent magnets, a rotor iron core and a bearing, wherein the inner circumference of the hub is fixed with 4K rotorteeth, and K is a positive integer; the stator iron core is formed by 3K uniformly-distributed [-shaped sub stator iron cores, and two sides of each sub stator iron core are provided with stator teeth; all stator teeth face the outer side of the circumference, and the two stator teeth of the same sub stator iron core are arranged at two sides of the rotor tooth of the rotor iron core; the middleyoke part of each sub stator iron core is embedded with the permanent magnet; and the middle yoke part of each sub stator iron core is wound with a centralized armature winding. Centralized excitationcan be effectively realized, the magnetic path is short, and iron and copper consumption is little; the advantage of high power density of a disc motor can be thoroughly exerted, and high applicationvalue is realized in the micro electric vehicle such as the electric skateboard.

Owner:徐州宇飞电力科技有限公司

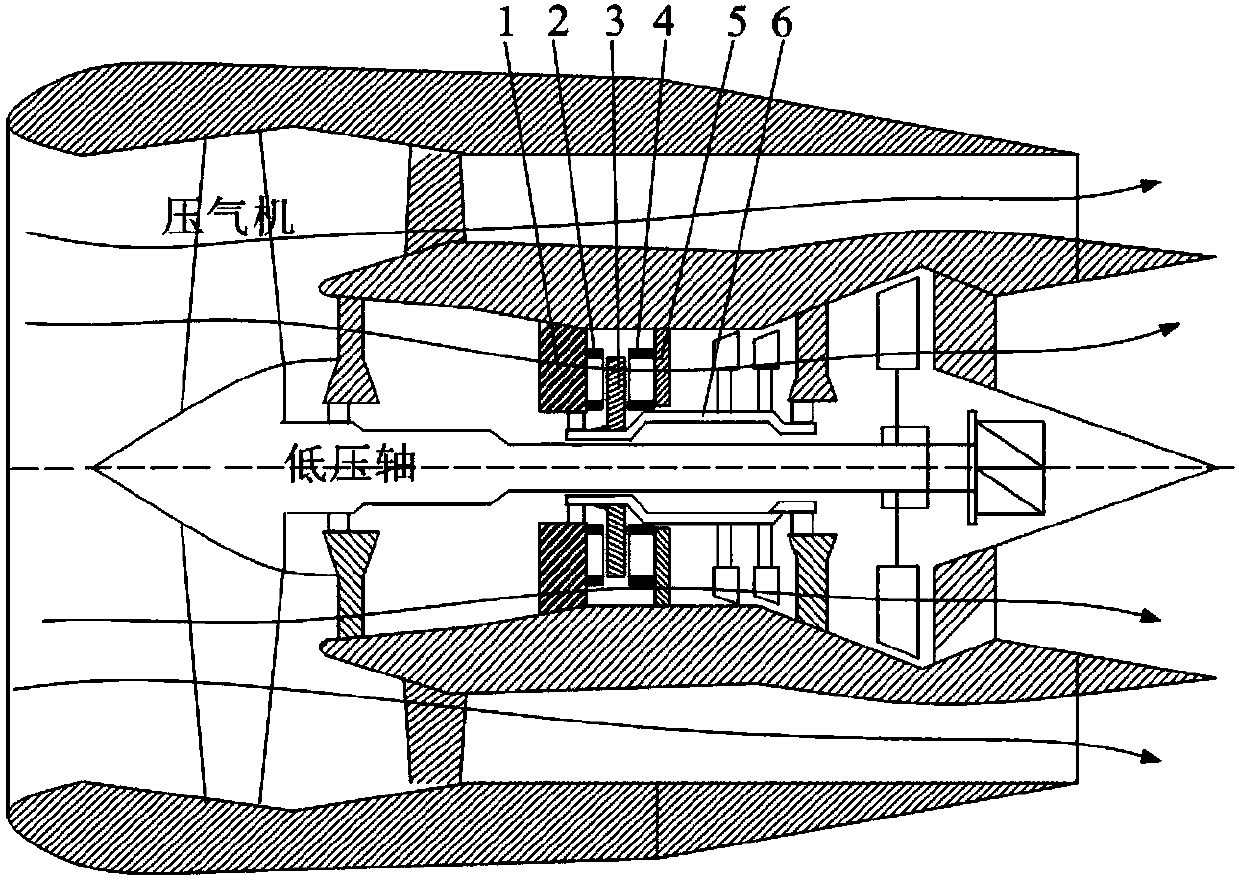

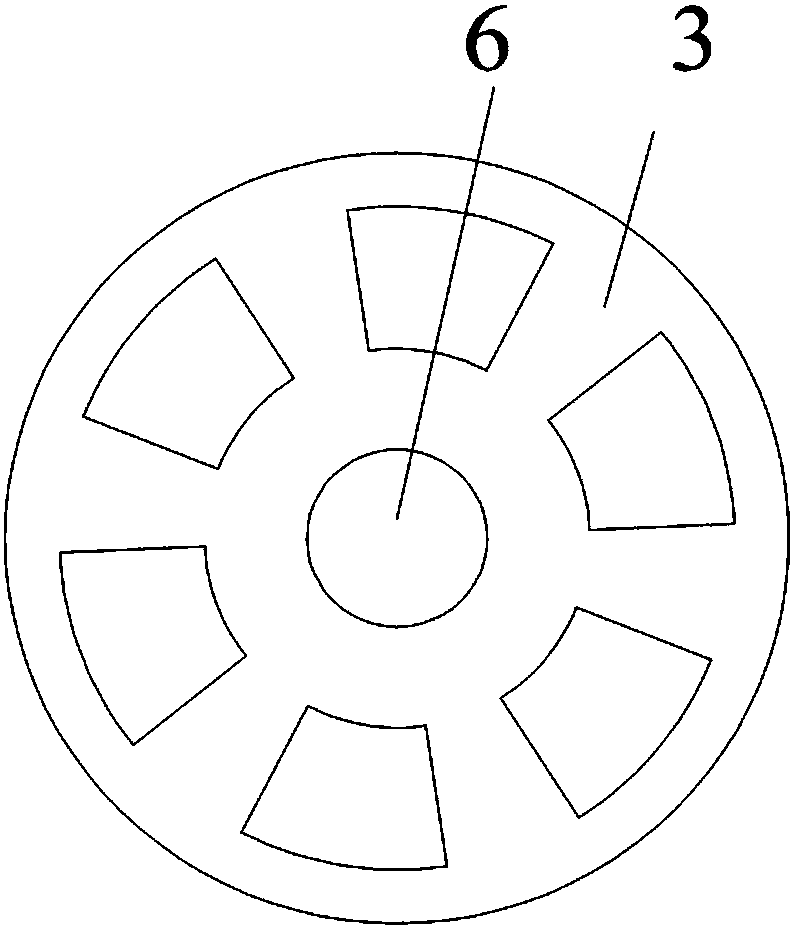

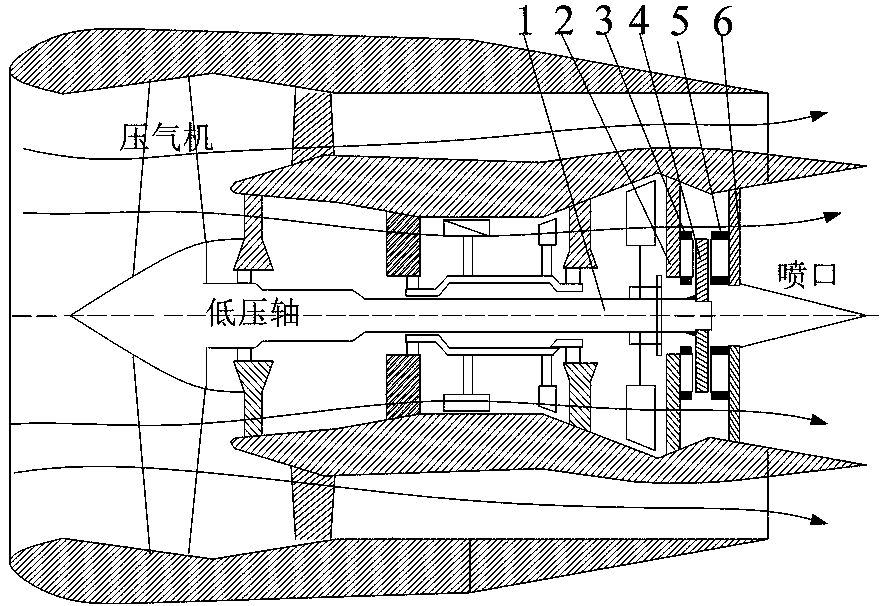

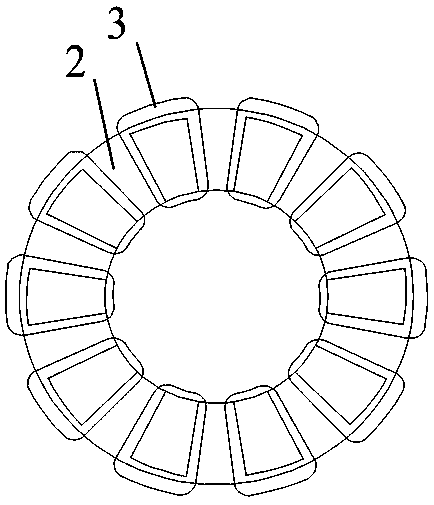

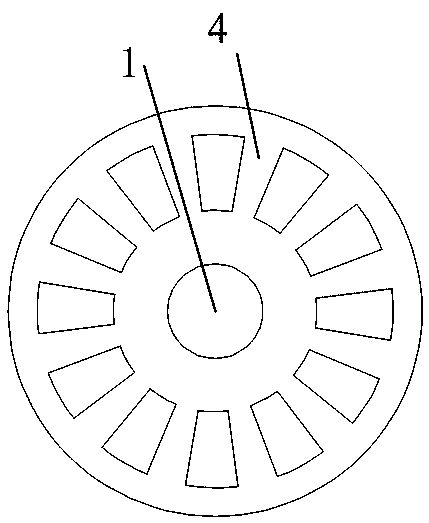

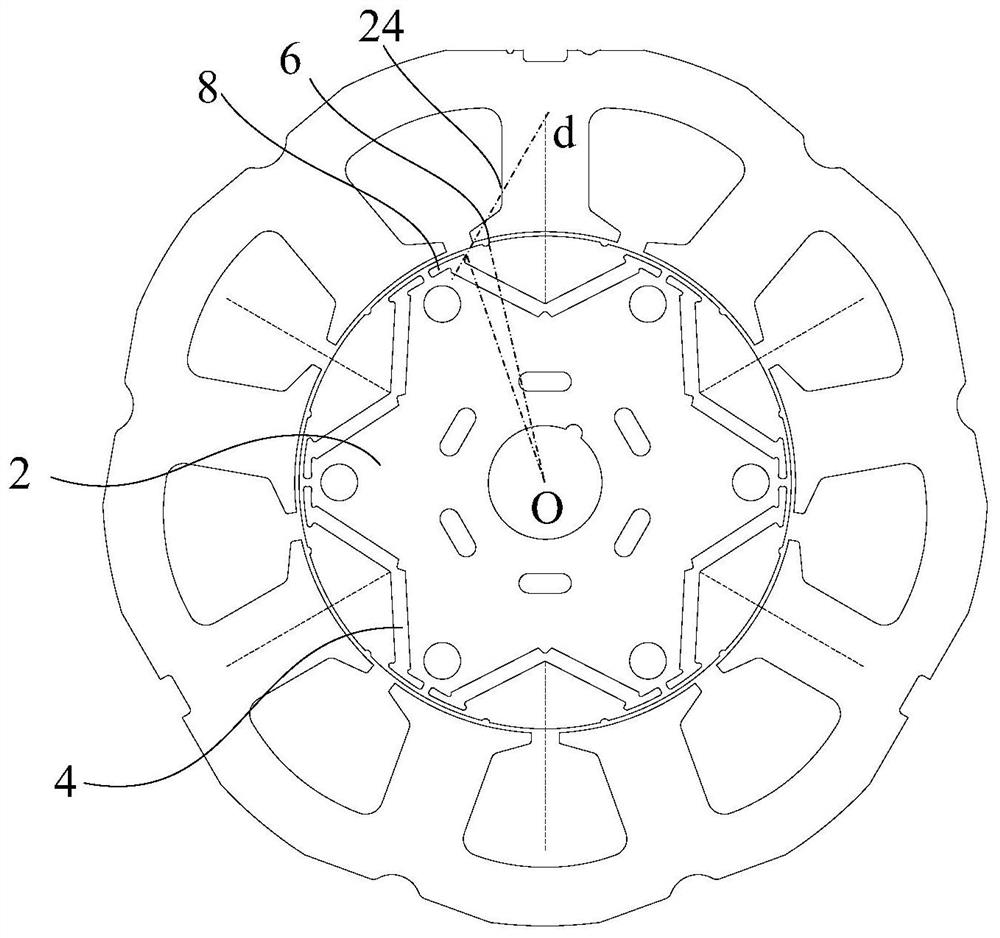

Aeroengine nozzle side fault-tolerant generator

ActiveCN107681794BImprove reliabilityEasy to useMagnetic circuit rotating partsMagnetic circuit stationary partsAviationFault tolerance

The invention relates to a fault tolerant generator at the nozzle side of an aerial engine, and belongs to the field of aircraft engineering. The fault tolerant generator comprises an excitation coil,an excitation iron core, a rotor iron core, an armature coil and an armature iron core; the rotor iron core is fixed at one side of the nozzle of the low-pressure shaft of the aerial engine; the excitation iron core and the armature iron core are separately positioned at two axial sides of the rotor iron core; 12 fan-shaped through holes are uniformly distributed on the circumference of the rotoriron core; 10 fan-shaped protruding excitation poles are at one side of the excitation iron core towards the rotor iron core; 10 fan-shaped protruding armature poles are at one side of the armature iron core towards the rotor iron core; a centralized excitation coil is wound on each excitation pole; and a centralized armature coil is wound on each armature pole. According to the fault tolerant generator disclosed by the invention, the rotational inertia of the rotor iron core is low; therefore, the rotor iron core can rotate at high speed; and thus, the rotor iron core is particularly suitable for the fault tolerant generator at the nozzle side of the aerial engine.

Owner:徐州博云航空科技有限公司

Rotor, motor, compressor and refrigeration equipment

ActiveCN112436629AReduce vibration and noiseGuaranteed energy efficiencySynchronous machine detailsMagnetic circuit rotating partsRotational axisElectric machinery

The invention provides a rotor, a motor, a compressor and refrigeration equipment. The rotor comprises: a rotor iron core, wherein the rotor iron core is provided with a plurality of mounting grooves,the peripheral wall of the rotor iron core is recessed towards the rotation axis direction of the rotor to form a recessed part, and the recessed part is located at one side, deviating from the rotation axis of the rotor, of each mounting groove; permanent magnets arranged in the mounting grooves to form a magnetic pole; and gap grooves which are formed in the rotor iron core, are positioned at the end parts of the mounting grooves, are communicated with the mounting grooves, and protrude towards the d-axis direction to form arching parts. The arching parts are located at one side, deviatingfrom the d axis, of a connecting line between the rotating axis of the rotor and any point on the wall surface of the concave part, the arching parts extend from the gap groove to the d axis direction, in any magnetic pole, a first intersection point is formed between the d axis and the peripheral wall of the rotor core, and the extending direction of the arching part is far away from the first intersection point. The rotor provided by the invention can improve the waveform of an air-gap magnetic field, can effectively reduce the vibration noise of the motor, and improves the noise hearing.

Owner:ANHUI MEIZHI PRECISION MFG

A range-extended electric vehicle gas turbine generator

ActiveCN107612214BSimple structureImprove reliabilitySynchronous generatorsElectric machinesElectric machineMoment of inertia

The invention discloses an extended-range electric vehicle gas turbine generator and belongs to the field of electric engineering. The extended-range electric vehicle gas turbine generator comprises stationary blade grids, movable blade grids, an excitation iron core, an exciting winding, a shaft, a rotor core, an armature core, an armature winding and a motor housing. The extended-range electricvehicle gas turbine generator is characterized in that fuel gas flows through the stationary blade grids and then pushes the movable blade grids and the rotor core rotate around the shaft; the excitation iron core is arranged on one side of the rotor core, and the armature core is arranged on the other side of the rotor core; a plurality of uniformly distributed fan-shaped through holes are formedin the circumference of the rotor core; a plurality of exciting poles protruding towards one side of the rotor core are uniformly distributed in the circumferential direction of the excitation iron core, and a plurality of armature poles protruding towards one side of the rotor core are uniformly distributed in the circumferential direction of the armature core. The extended-range electric vehicle gas turbine generator can fully play the advantage that the power generation efficiency of the gas turbine generator is higher than that of a power generator driven by an internal combustion engine.The rotational inertia of the rotor core is small, and the rotor core can rotate at high speed and thus is very suitable for the extended-range electric vehicle gas turbine generator.

Owner:业达新能源有限公司

Magnetic grid permanent magnet double salient pole motor for electric vehicles

ActiveCN107508444BLight in massSmall moment of inertiaMagnetic circuit rotating partsSynchronous machine detailsElectric vehicleDoubly salient

An electric vehicle magnetic grid type permanent magnetism doubly salient motor belongs to the electric vehicle motor technology field, comprises a shaft, a front armature iron core, a front armature winding, a front rotor iron core, a front permanent magnet, a permanent magnet iron core, a back permanent magnet, a back rotor iron core, a back armature winding, a back armature iron core and a shell, and is characterized in that the disc-shaped front rotor iron core and back rotor iron core are fixed on the shaft at intervals, the permanent magnet iron core fixed on the shell is between the front rotor iron core and the back rotor iron core, and the permanent magnets are fixed on the two surfaces of the permanent magnet iron core towards the rotor iron cores respectively and uniformly; the front armature iron core and the back armature iron core which are fixed on the shell are at the two sides of the front rotor iron core and the back rotor iron core respectively, armature poles are arranged on the armature iron cores, and the armature windings are wound on the armature poles. The rotor iron cores of the technical scheme of the present invention are magnetic grid-shaped, and are large in contact area and specific power, so that the electric vehicle magnetic grid type permanent magnetism doubly salient motor is very suitable for being used as an electric vehicle motor having higher requirements for the power density.

Owner:江苏惠博机电科技股份有限公司

A magnetism-concentrating stator permanent magnet vernier motor

ActiveCN103066719BReduce dosageReduce manufacturing costMagnetic circuit stationary partsElectrical polarityMagnetic flux

Owner:CHANGSHU HUASEN TEXTILE

A Low Moment of Inertia Permanent Magnet Wind Motor

ActiveCN107579640BLight in massSmall moment of inertiaSynchronous machine detailsWind energy generationHigh power densityClockwise

The invention discloses a permanent magnet wind-driven motor with low rotational inertia, and belongs to the technical field of special motors. The permanent magnet wind-driven motor comprises a shaft, an armature iron core, first armature windings, second armature windings, a rotor iron core, permanent magnets, a permanent magnet iron core and a shell, and is characterized in that 4k fan-shaped through holes are uniformly formed in a disc of the rotor iron core, and the k is a positive integer; the permanent magnet iron core and the armature iron core which are fixed onto the shell are arranged on two sides of the rotor iron core, the 6k fan-shaped permanent magnets are arranged on the surface, which faces the rotor iron core, of the permanent magnet iron core, 12k fan-shaped protruded armature poles are uniformly distributed on the side, which faces the rotor iron core, of the armature iron core, each first armature winding is wound on the two corresponding armature poles, and the second armature windings are wound on the odd-number armature poles along the clockwise direction. The permanent magnet wind-driven motor has the advantages that the rotor iron core is low in rotational inertia and can quickly respond, the second windings are capable of weakening demagnetization armature reaction and increasing the power density, and accordingly the permanent magnet wind-drivenmotor is quite suitable to be used as a wind-driven power generator started by breeze.

Owner:徐州普林惠新能源技术有限公司

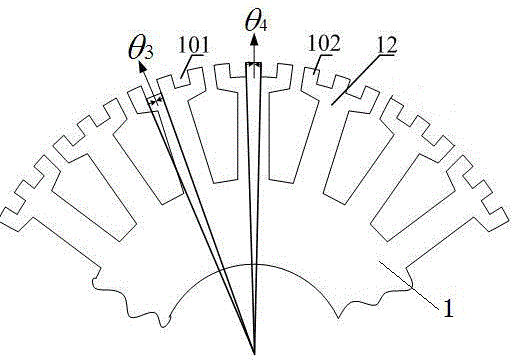

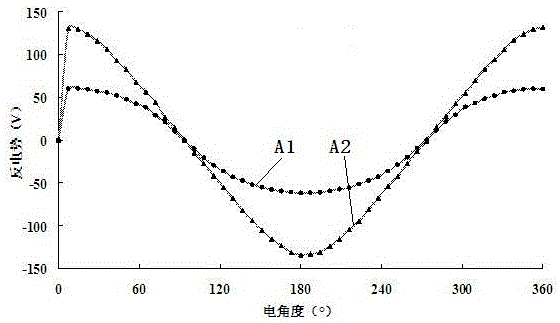

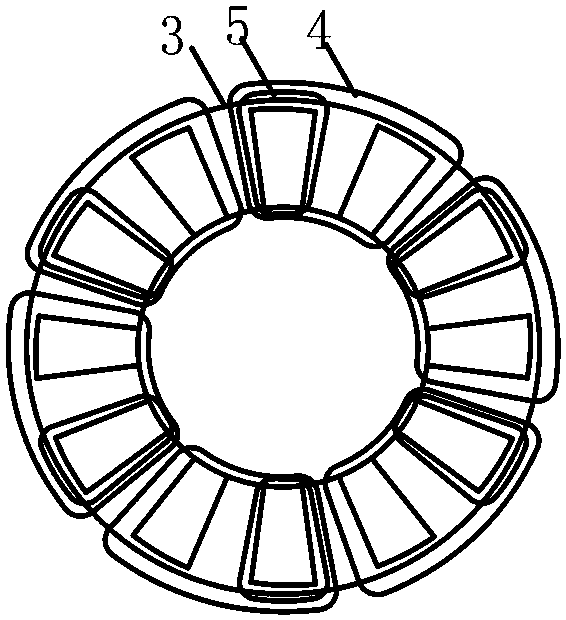

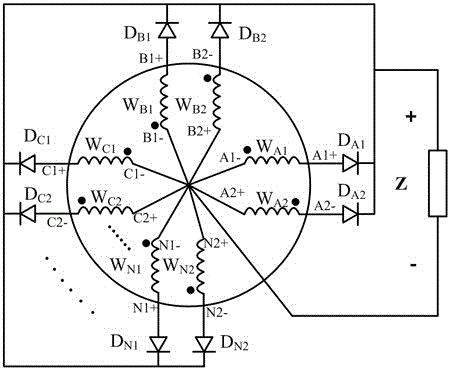

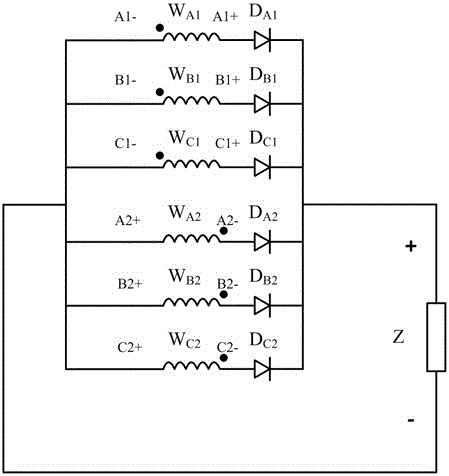

Double armature winding double salient pole motor power generation system

InactiveCN103840577BImprove power densityImprove fault toleranceMagnetic circuit stationary partsStructural associationDoubly salientConductor Coil

The invention discloses a double-armature-winding double-salient-pole motor power generation system. Two armature windings are arranged on each stator tooth of a double-salient-pole motor, the armature windings on the corresponding stator tooth are connected mutually in series to form a phase armature winding, the positive ends of one phase armature windings in the two phase armature windings formed by the two armature windings of the corresponding teeth are connected together, are led out through lead wires and serve as the negative electrodes of a double-salient-pole power generation system, and the negative ends of the one phase armature windings in the two phase armature windings formed by the two armature windings of the corresponding teeth are connected with anodes of rectifier tubes. The negative ends of the other phase armature windings are connected together, are lead out through lead wires, and serve as the negative electrodes of the double-salient-pole power generation system, the positive ends of the other phase armature windings are connected with the anodes of the rectifier tubes, cathodes of the rectifier tubes are connected to one point, are led out through lead wires and serve as the positive electrode of the double-salient-pole power generation system to be connected into a load, and thus the novel double-salient-pole motor power generation system is formed. The double-armature-winding double-salient-pole motor power generation system increases the power density of the double-salient-pole motor, and improves the fault-tolerant capability of the system.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com