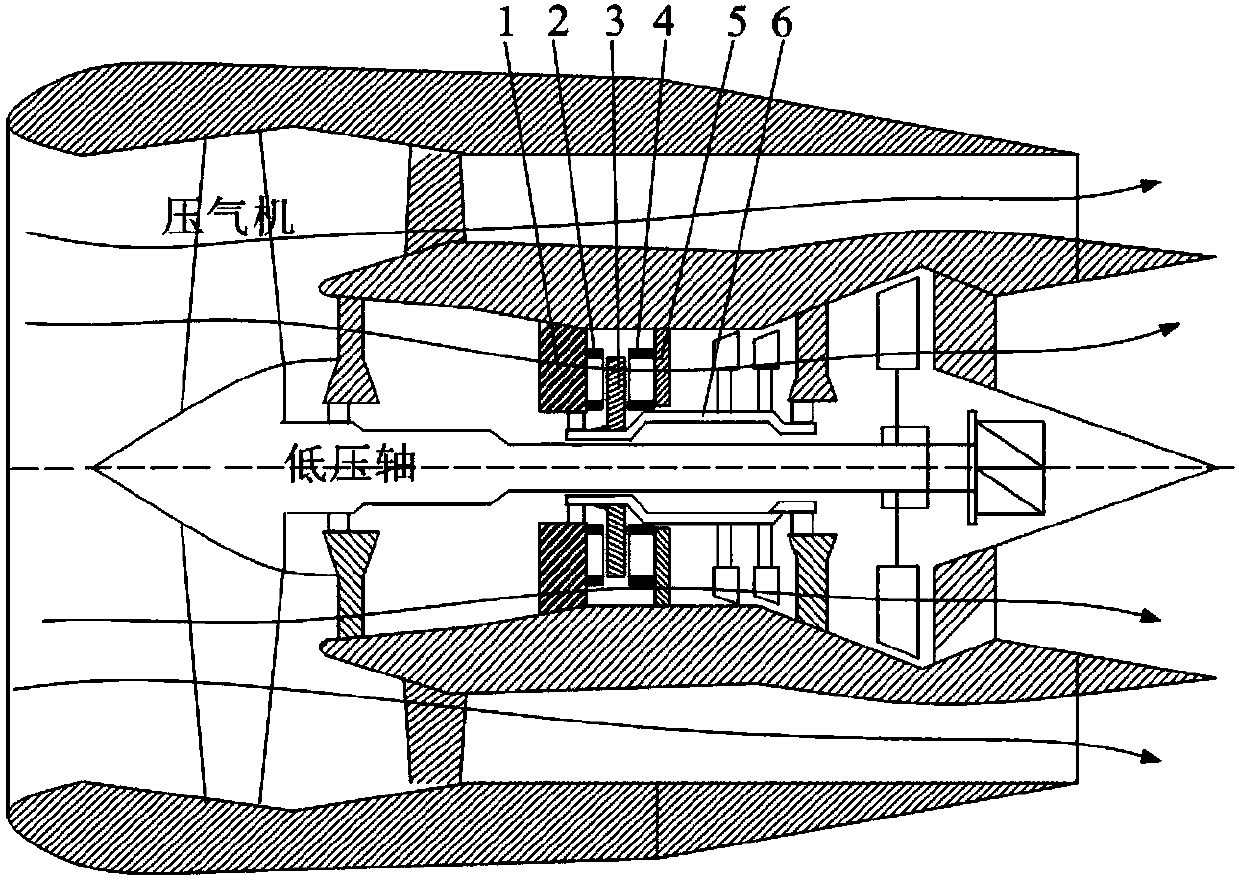

Disc-type built-in aero starter generator

A technology for starter generators and aero-engines, applied in the field of aeronautical engineering, can solve the problem of unretrieved patent documents, etc., and achieve the effects of light weight, fast response, and large magnetic flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

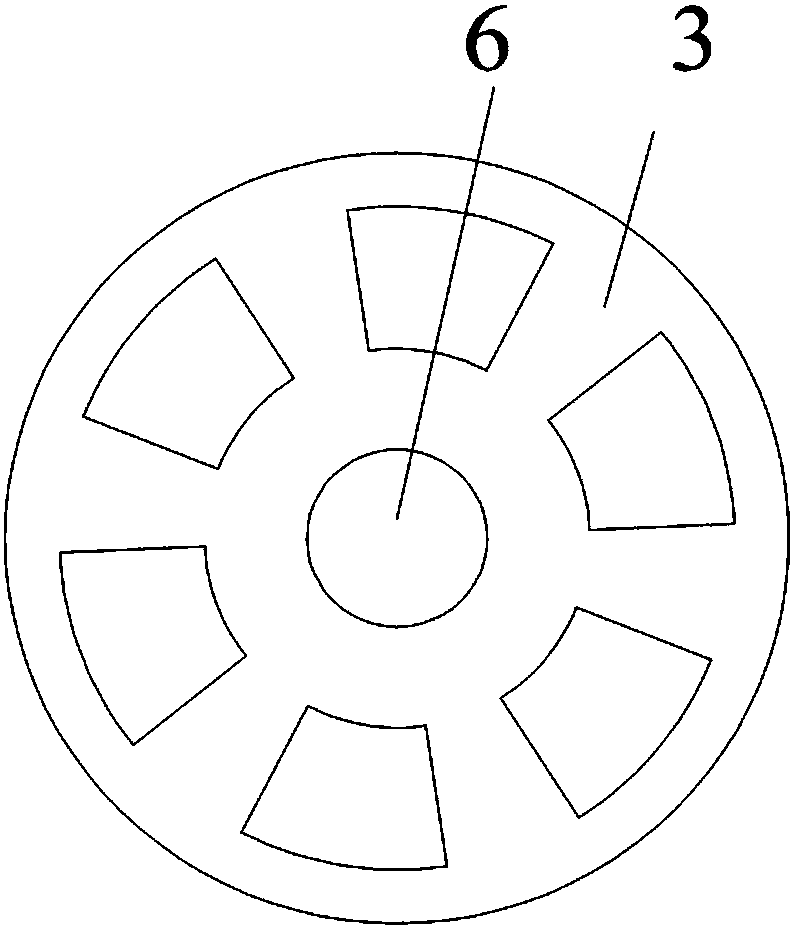

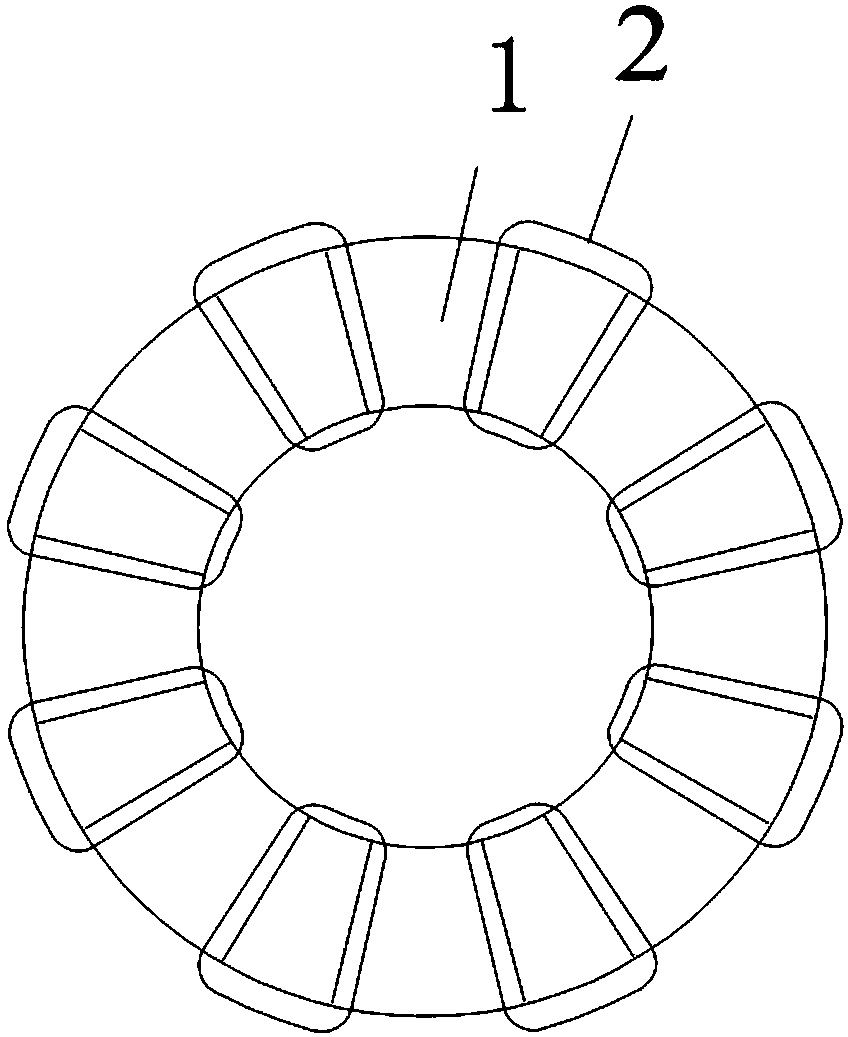

[0054] The working principle of Embodiment 1: Since the first armature core and the second armature core of the present invention are axially aligned, when the magnetically conductive part of the rotor core is aligned with the armature poles, the armature pole turn chain The reluctance of the armature turns is the smallest, and the flux linkage of the armature winding is the largest; when the fan-shaped through hole of the rotor core is aligned with the armature pole, the reluctance of the armature pole turn chain is the largest, and the flux linkage of the armature winding is the smallest.

[0055] When the magnetically conductive part of the rotor core gradually approaches the armature poles, the mutual inductance between the first armature winding and the second armature winding increases. When the magnetically conductive part of the rotor core separates from the armature poles, the self-inductance of the first armature winding and the second armature winding decreases.

[...

Embodiment 2

[0058] The working principle of embodiment two is:

[0059] Since the electric excitation magnetic poles and armature poles of the present invention are axially aligned, when the magnetically conductive part of the rotor core is aligned with the armature poles, the magnetic resistance of the armature pole turn chain is the smallest and the armature winding flux linkage is the largest ; When the fan-shaped through hole of the rotor core is aligned with the armature pole, the magnetic resistance of the armature pole turn chain is the largest, and the armature winding flux linkage is the smallest.

[0060] When the excitation winding of the motor of the present invention is energized, a magnetic field will be established inside the motor, and the generated magnetic flux will pass through the stator yoke, stator teeth, air gap, rotor teeth, and rotor yoke of each phase to form a closed loop.

[0061] In this application, the mutual inductance of the armature winding and the field ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com