A turbocharged generator

A power generation device and turbocharging technology, which is applied to combustion engines, machines/engines, internal combustion piston engines, etc., can solve the problems of high tank fill rate and difficult heat dissipation, and achieve reduced tank fill rate, fewer rotor poles, and durability The effect of high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

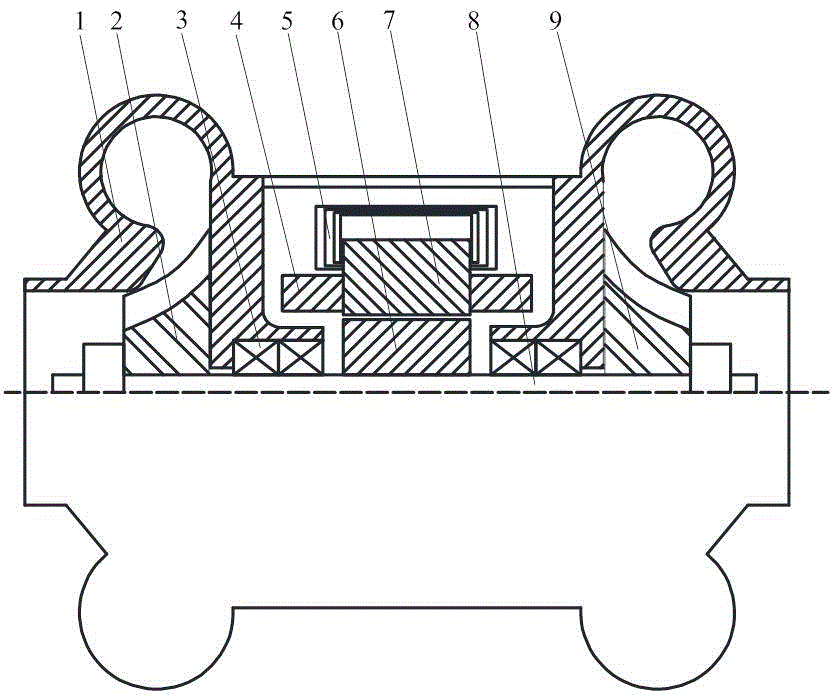

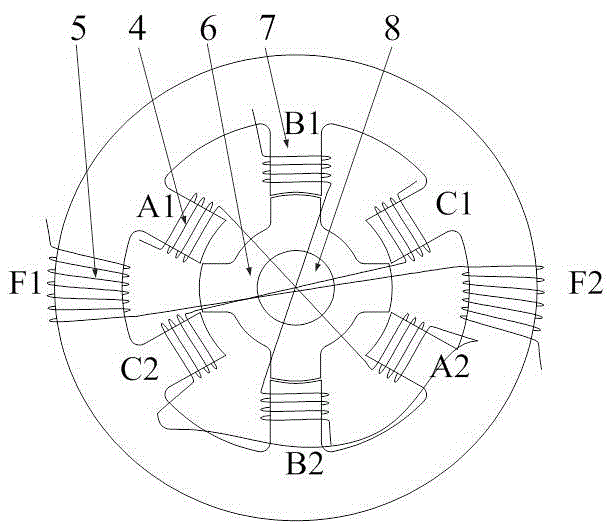

[0026] Such as figure 1 A turbocharged power generation device shown includes a casing, a bearing, a stator, a controller, and a rotor composed of an exhaust turbine, an intake turbine, a shaft, and a rotor core. The intake turbine, exhaust turbine, and rotor core are fixed on a shaft, and the shaft is fixed on the casing through bearings, and the bearings on both sides are combined sliding bearings lubricated by machine oil, which can not only realize radial support, but also Achieve axial support. This kind of bearing can use the pressure of engine oil to support the rotating parts, so that the shaft and the hole do not contact, realize non-contact rotation, and have large bearing capacity and high speed.

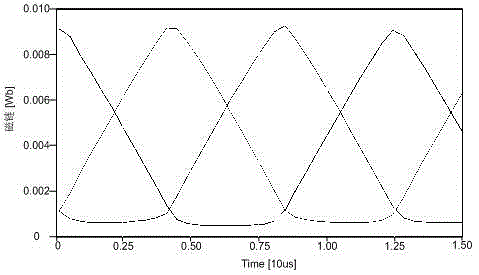

[0027] When the turbocharger generator is working normally, the exhaust turbine drives the rotor to rotate. When the engine is just started, the rotor speed is low, and the turbocharger generator can be used as an electric motor to rapidly increase the turbocharger turbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com