High-power permanent-magnet direct-drive freight locomotive traction converter

A traction converter, permanent magnet direct drive technology, which is applied in the conversion of AC power input to AC power output, output power conversion device, motor control, etc., can solve the problem that the traction converter cannot directly apply permanent magnet direct drive power Transmission system and other problems, to achieve the effect of low life cost, high power density and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

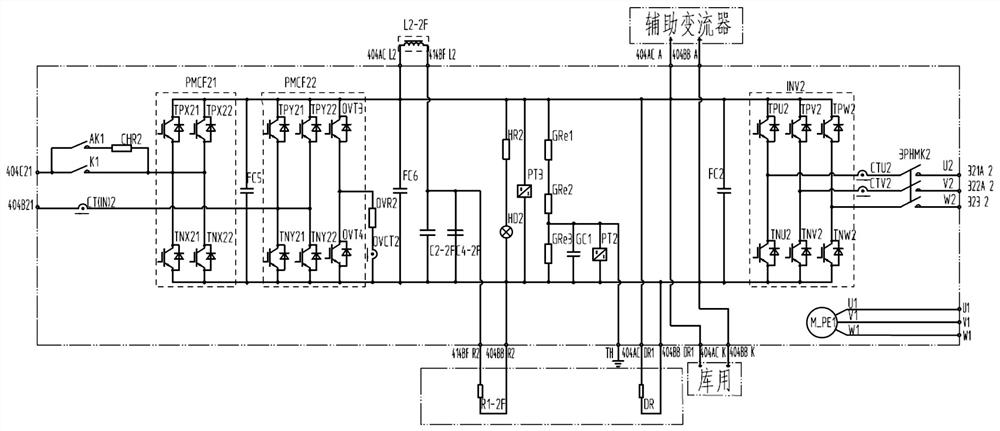

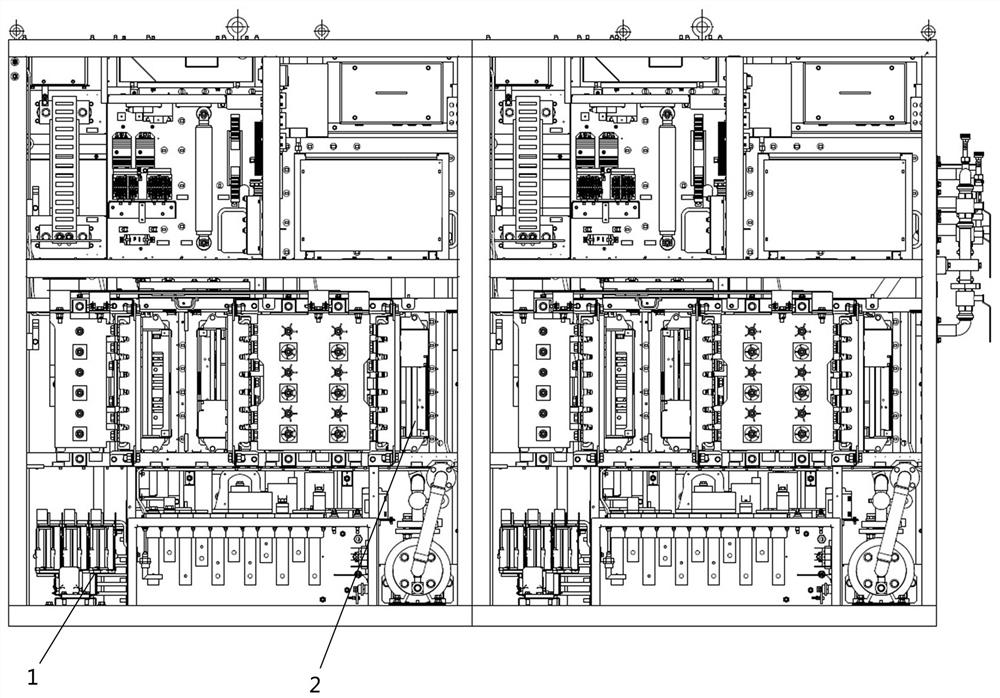

[0015] The present invention will be further described below in conjunction with specific examples. Such as figure 1 and figure 2 Shown:

[0016] A high-power permanent magnet direct drive freight locomotive traction converter, including two sets of independent traction main circuits, each group of traction main circuits includes a pre-charging circuit, a four-quadrant power module, a four-quadrant chopper power module, a Independent intermediate DC circuit, a traction inverter power module and a three-pole isolation contactor; the electrical principle and structure of the two sets of traction main circuits are identical, the four-quadrant power module, four-quadrant chopper module and traction inverter power The modules all use 3300V / 1500A IGBTs; the pre-charging circuit is: the pre-charging contactor AK1 is connected in series with the pre-charging resistor CHR and then connected in parallel with the main contactor K1; Bridge, TPX22 and TNX22 form another parallel half-b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com