A magnetism-concentrating stator permanent magnet vernier motor

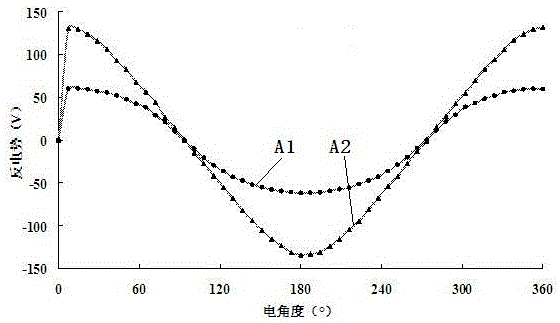

A vernier motor, permanent magnet type technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit static parts, etc., can solve the problems of small stator winding back EMF, large amount of permanent magnets, small magnetic density, etc., to achieve reverse The effect of increasing the potential, reducing the leakage flux of the teeth, and increasing the air gap flux density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

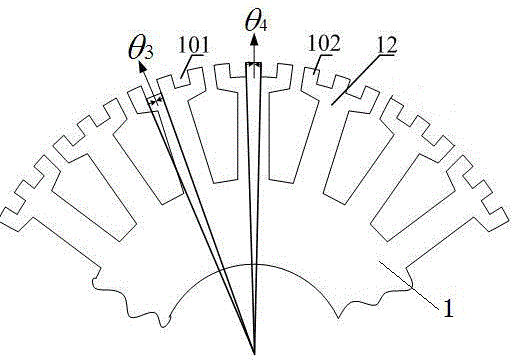

[0020] See figure 1 The present invention includes a coaxial stator 1 and a rotor 2, and the rotor 2 is located outside the stator 1. There is a slot 19 in the center of the stator 1 for placing the rotating shaft. There is an air gap between the rotor 2 and the stator 1, and the thickness of the air gap is selected according to the size and requirements of the motor. The stator 1 is composed of stator teeth 12 and stator slots 14, the stator slots 14 are used to place windings, and the tooth ends of the stator teeth 12 are embedded with permanent magnet units 300.

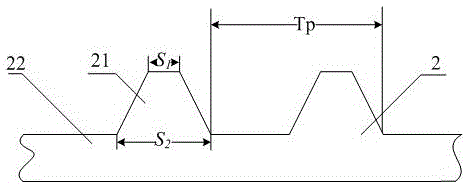

[0021] For the specific structure and proportional relationship of rotor 2, see figure 2 The rotor 2 is composed of rotor teeth 21 and a rotor yoke 22, and the tooth height of the rotor teeth 21 and the rotor yoke 22 can be optimized as required. The end of the rotor teeth 21 facing the air gap has a trapezoidal structure, and the tooth width of the rotor teeth 21 near the air gap S 1 Tooth pitch with rotor teeth 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com