Aeroengine nozzle side fault-tolerant generator

A technology for aero-engines and generators, applied in electromechanical devices, electrical components, electric components, etc., can solve the problems of few patent applications and weak foundation of aero-generators, and achieve high back EMF, high motor power, and small internal resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention provides a five-phase permanent magnet motor for an extended-range electric vehicle. In order to make the technical solution and effect of the present invention clearer and clearer, the present invention is further described in detail with reference to the accompanying drawings and examples. It should be understood that the specific implementations described here are only used to explain the present invention, not to limit the present invention.

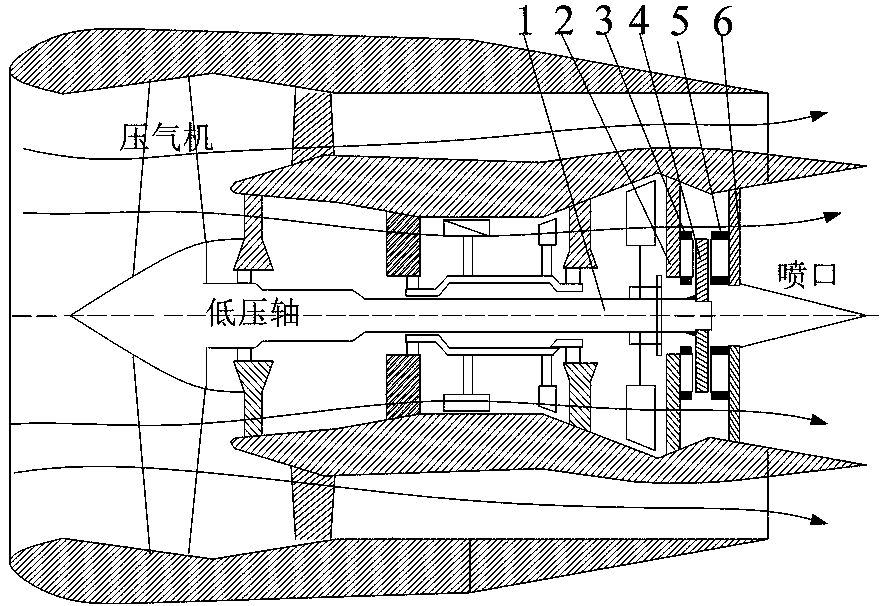

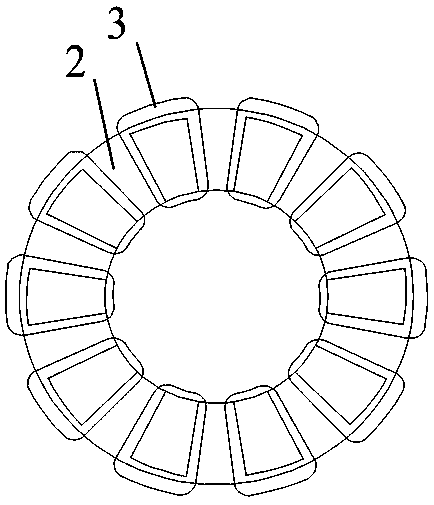

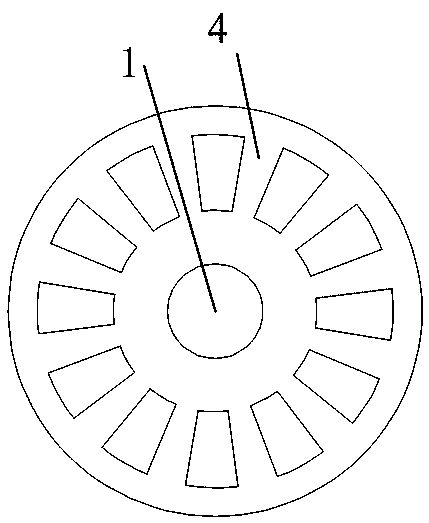

[0027] figure 1 It is a cross-sectional view of a fault-tolerant generator device on the nozzle side of an aero-engine, including an excitation winding, an excitation core, a rotor core, an armature winding and an armature core, and is characterized in that: the rotor core is fixed on the nozzle side of the low-pressure shaft of the aero-engine; The disc-shaped field core, rotor core and armature core are coaxially arranged sequentially, and the field core and armature core are fixed on the aircraft engin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com