Stator core, stator, permanent magnet synchronous motor, compressor and refrigeration equipment

A permanent magnet synchronous motor and stator core technology, applied in the field of compressors, can solve the problems of large vibration noise, silence and comfort, etc., and achieve the effect of improving vibration noise, improving hearing, and reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

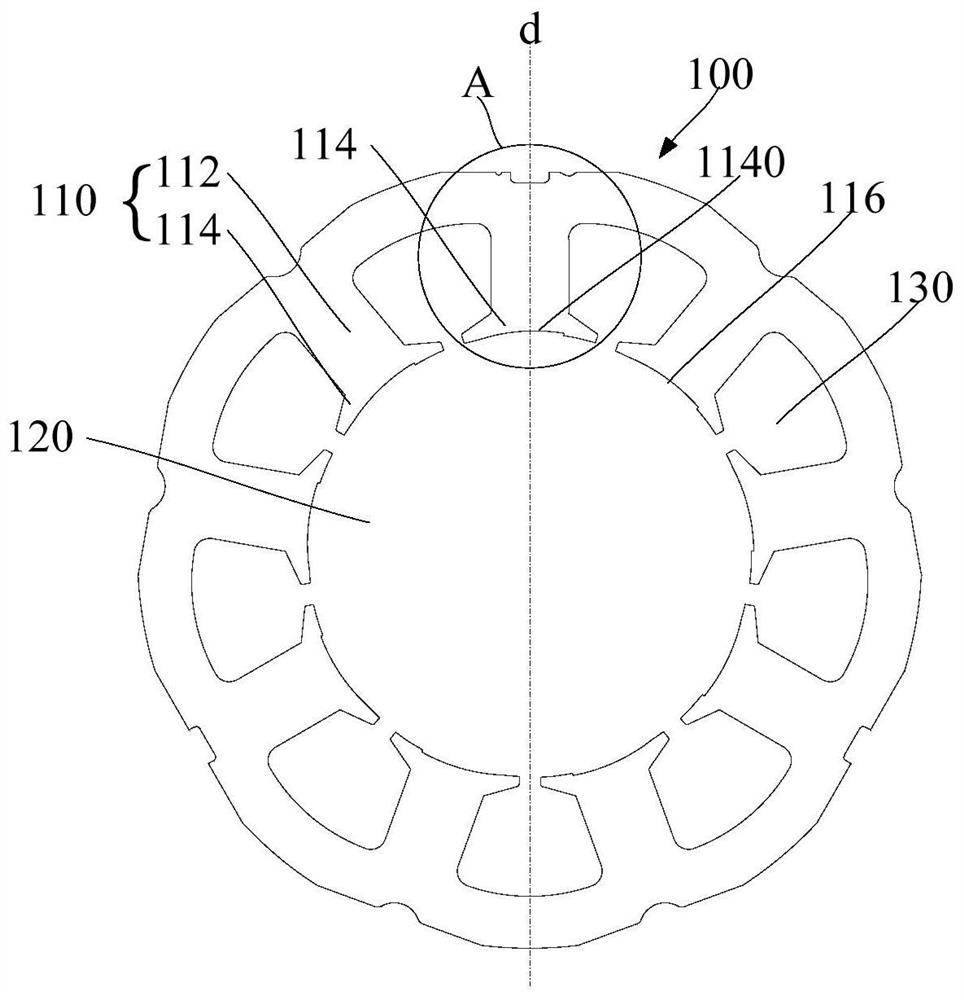

[0055] Such as figure 1 As shown, according to an embodiment of the present invention, a stator core is proposed, including: a plurality of stator punching pieces.

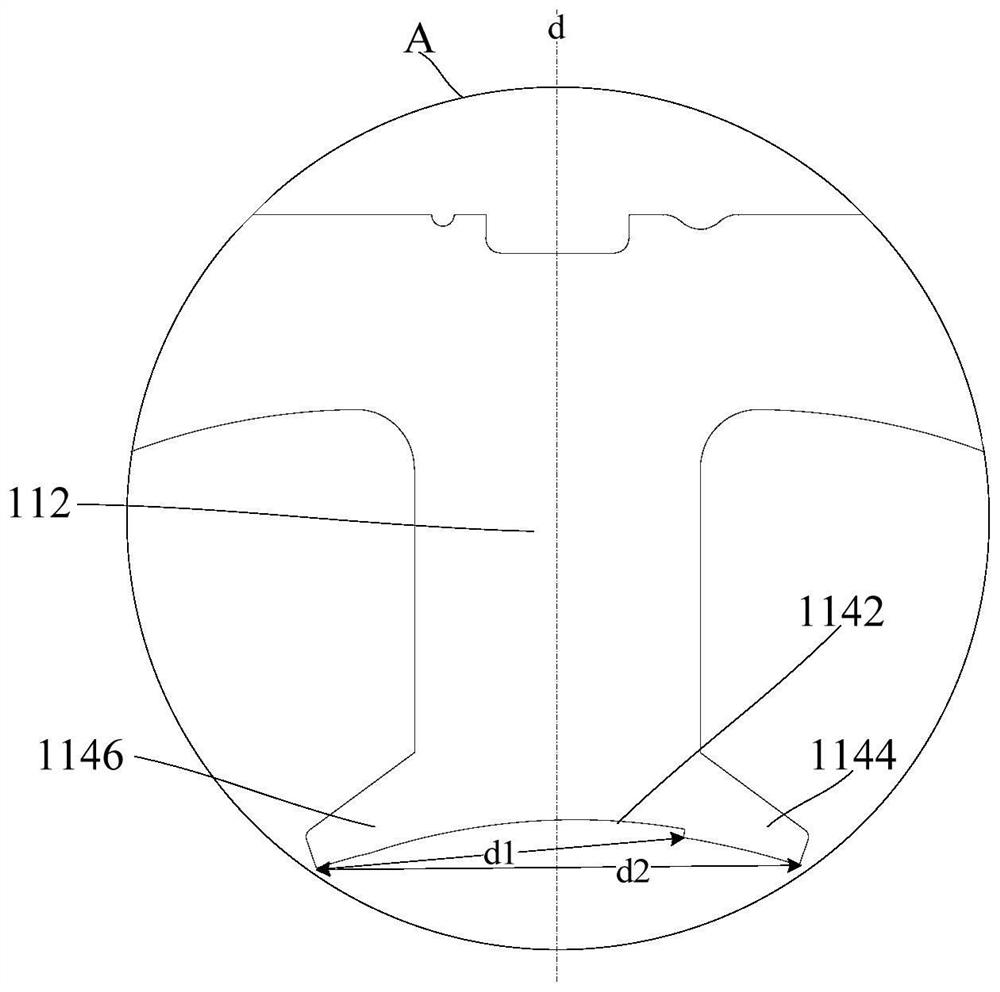

[0056] Specifically, each stator punching piece includes a plurality of stator teeth 110 distributed along the circumferential direction, and each stator tooth 110 includes: a tooth part 112 and a tooth shoe 114, and the tooth shoe 114 is arranged on the side of the tooth part 112 close to the inner hole 120 A plurality of tooth shoes 114 surround and form an inner hole 120 , and a plurality of stator stampings are stacked along the axial direction of the inner hole 120 . Wherein, the plurality of stator punching pieces include at least one first stator punching piece 100, the inner peripheral wall 116 of at least one tooth shoe 114 of the first stator punching piece 100 is provided with a recessed portion 1140, and the tooth shoe 114 includes a first tooth shoe portion 1144 , the part of the concave portion 1140...

Embodiment 2

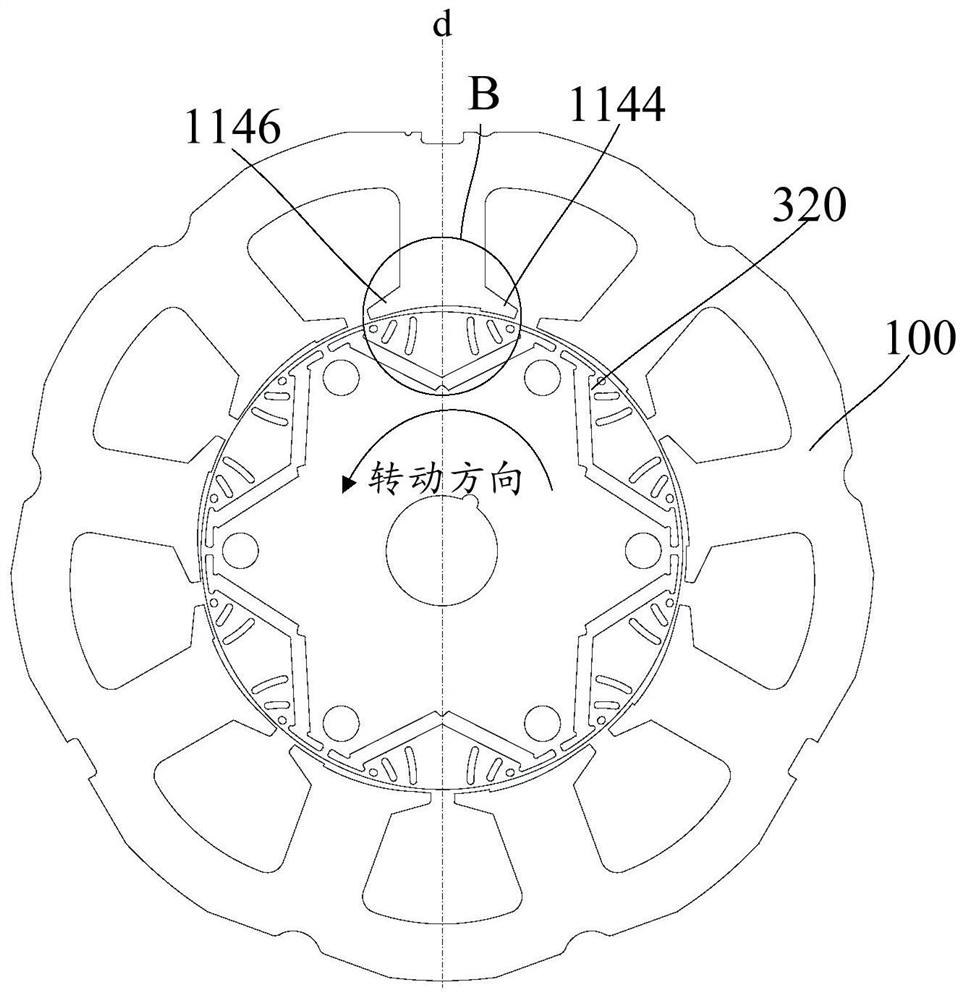

[0063] Such as Figure 1 to Figure 3 As shown, according to an embodiment of the present invention, it includes the features defined in any of the above-mentioned embodiments, and further: on a section perpendicular to the axis of the rotor 320 , along the rotation direction of the rotor 320 , the concave portion 112 faces the side of the rotor 320 The shortest distance from any point on the inner wall surface 1142 to the rotation center of the rotor 320 gradually decreases.

[0064] In this embodiment, the rotor 320 is installed in the inner hole 120 of the stator core. On a cross section perpendicular to the axis of the rotor 320 , along the rotation direction of the rotor 320 , the concave portion 112 faces any part of the inner wall surface 1142 of the rotor 320 . The shortest distance from one point to the rotation center of the rotor 320 gradually decreases. That is, the minimum distances between two adjacent points on the inner wall surface 1142 and the rotation center...

Embodiment 3

[0067] Such as Figure 1 to Figure 3 As shown, according to an embodiment of the present invention, it includes the features defined in any one of the above embodiments, and further: the tooth shoe 114 further includes: a second tooth shoe part 1146 .

[0068] In detail, along the rotation direction of the rotor 320, the second tooth shoe portion 1146 is arranged in the area where the symmetric center line d of the tooth portion 112 is away from the first tooth shoe portion 1144, and the second tooth shoe portion 1146 is provided with a concave portion 1140.

[0069] Wherein, the first tooth shoe part 1144 and the second tooth shoe part 1146 are respectively the parts of the tooth shoe 114 extending toward two adjacent stator slots.

[0070]In this embodiment, along the rotation direction of the rotor 320, a first tooth shoe portion 1144 and a second tooth shoe portion 1146 are respectively provided on both sides of the symmetric center line d of the tooth portion 112, that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com