Brushless electric machine rotor sheet of automobile brake system

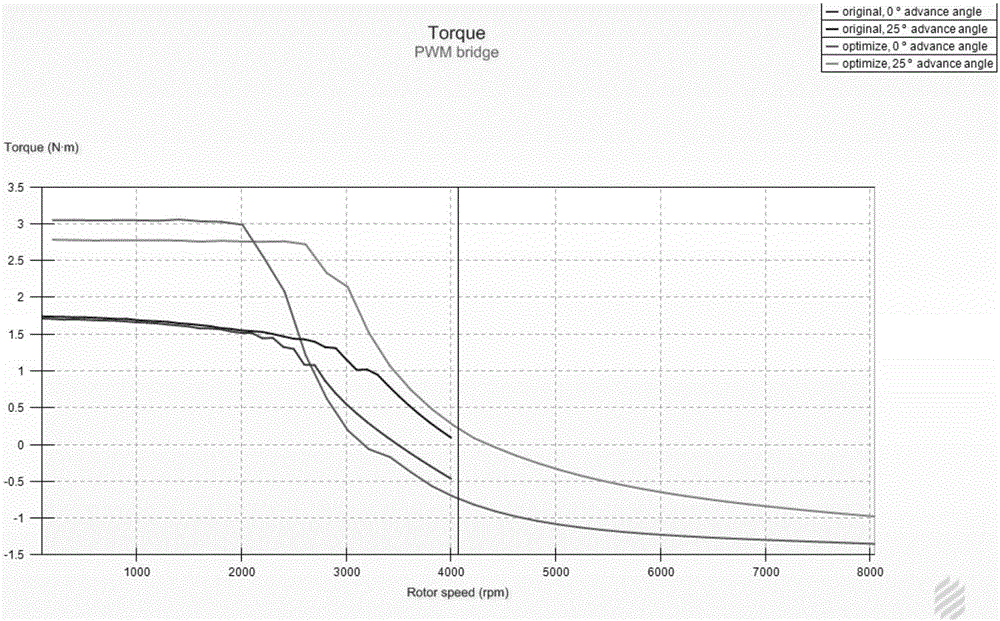

A technology of rotor punching and brushless motors, which is applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems that the main magnetic flux of the motor cannot be further improved, the speed of the weak magnetic field cannot be expanded, and the salient pole effect is not obvious. Achieve the effects of expanding the range of field-weakening speed regulation, reducing the quality, and reducing the harmonic content of the back EMF

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

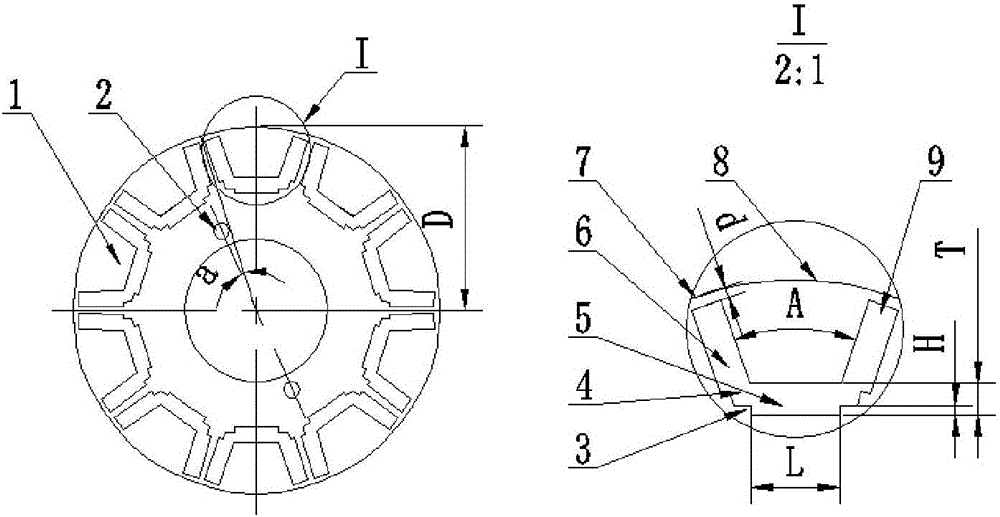

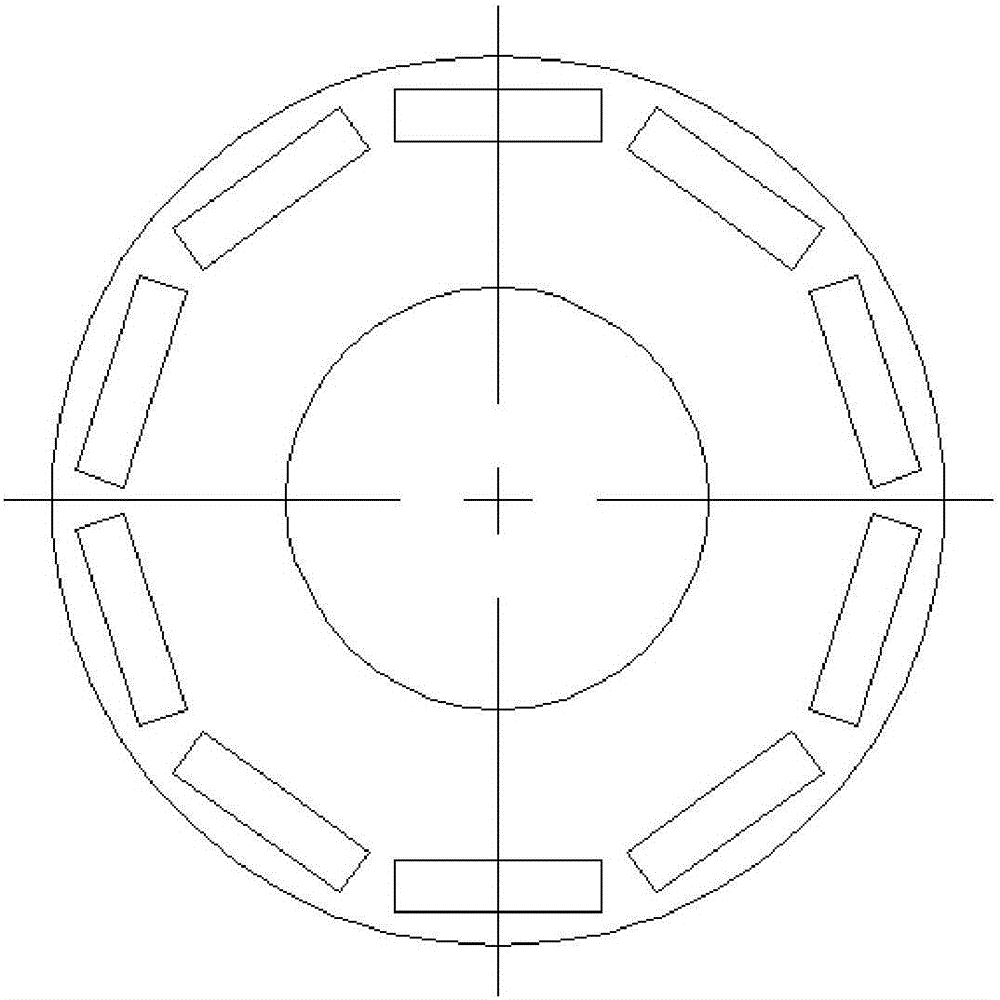

[0022] The punching structure of the present invention is as figure 1 shown.

[0023] The outer circumference of the rotor punch adopts a salient pole structure. The rotor punch has a U-shaped groove 1, and the connection of the U-shaped groove 1 is provided with a magnetic isolation bridge 4 and a positioning step 3. Positioning hole 2.

[0024] The outer circumference of the above-mentioned rotor punch adopts a straight line 7 and an arc 8 to form a salient pole structure. The straight line 7 corresponds to the top formed by two adjacent U-shaped grooves 1. The distance from the top to the straight line 7 is 0.6. When the distance is greater than 0.6, the back EMF harmonic The wave content will rise, and when the distance is less than 0.6, the separation force of the magnetic steel at high speed will damage the mechanical structure of the rotor. The highest point of the arc 8 on the outer circumference of the salient pole corresponds to the center of the U-shaped slot 1. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com