Electric roller permanent magnet motor

A technology of permanent magnet motor and electric drum, applied in the direction of magnetic circuit rotating parts, magnetic circuit static parts, magnetic circuit shape/style/structure, etc. problems, to achieve the effect of small positioning force and rotational inertia, large magnetic conduction area, and light weight of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

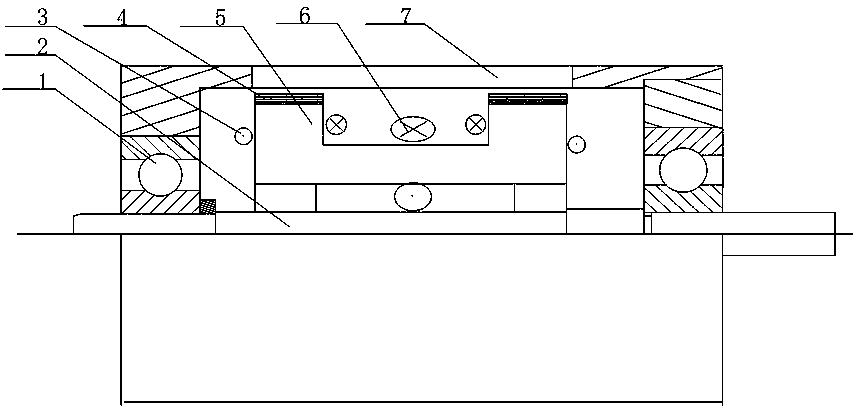

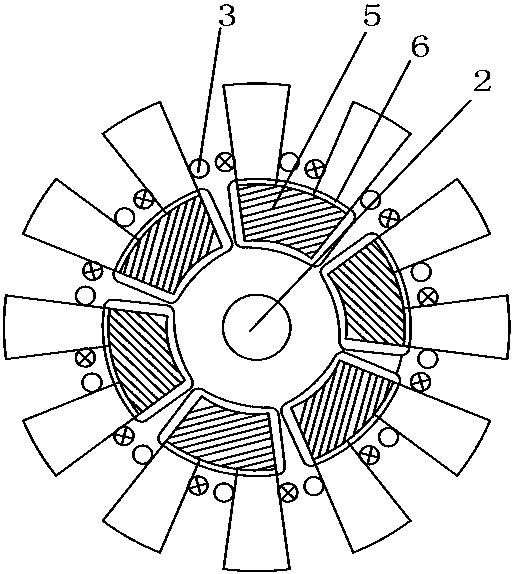

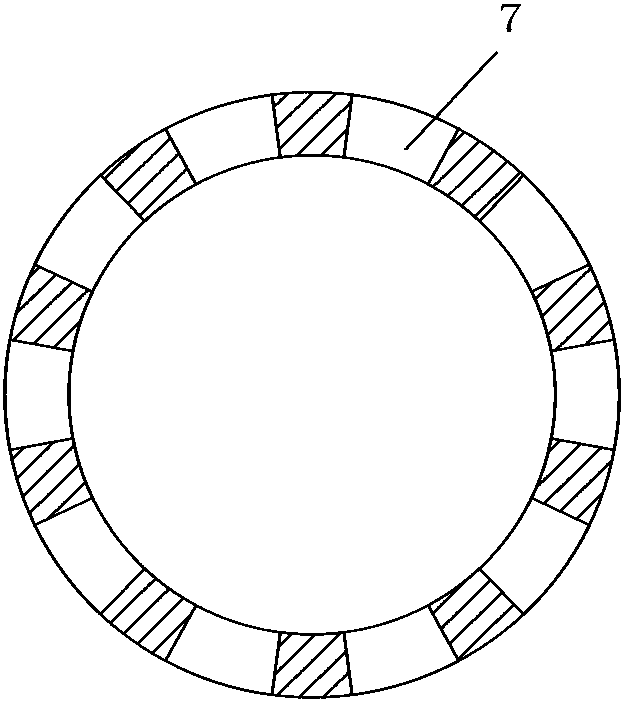

[0025] figure 1 It is a longitudinal cross-sectional view of a permanent magnet motor of the electric drum motor when the flux linkage is minimum. Among them, 1 bearing, 2 shafts, 3 armature windings, 4 permanent magnets, 5 stator cores, 6 field windings, and 7 rollers.

[0026] A permanent magnet motor for electric drum, which is characterized in that the drum is mounted on the shaft through a bearing and can rotate around the shaft, and 5K rectangular holes are evenly distributed on the circumferential surface of the drum. K is a positive integer, where k=2, rectangular when viewed from the side The holes are fan-shaped.

[0027] The stator core is fixed in the middle of the shaft. The stator core is composed of 3K evenly distributed "匚"-shaped sub-stator cores. The yoke in the middle of the sub-stator core is parallel to the axis; each sub-stator core has two stator teeth at each end. The sides of the stator teeth are sector-shaped; all the stator teeth face the outside of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com