Rotor, motor, compressor and refrigeration equipment

A rotor and rotor core technology, applied in the field of compressors, can solve problems affecting customers' use, etc., and achieve the effects of improving the air gap magnetic field waveform, increasing back EMF, and improving user experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

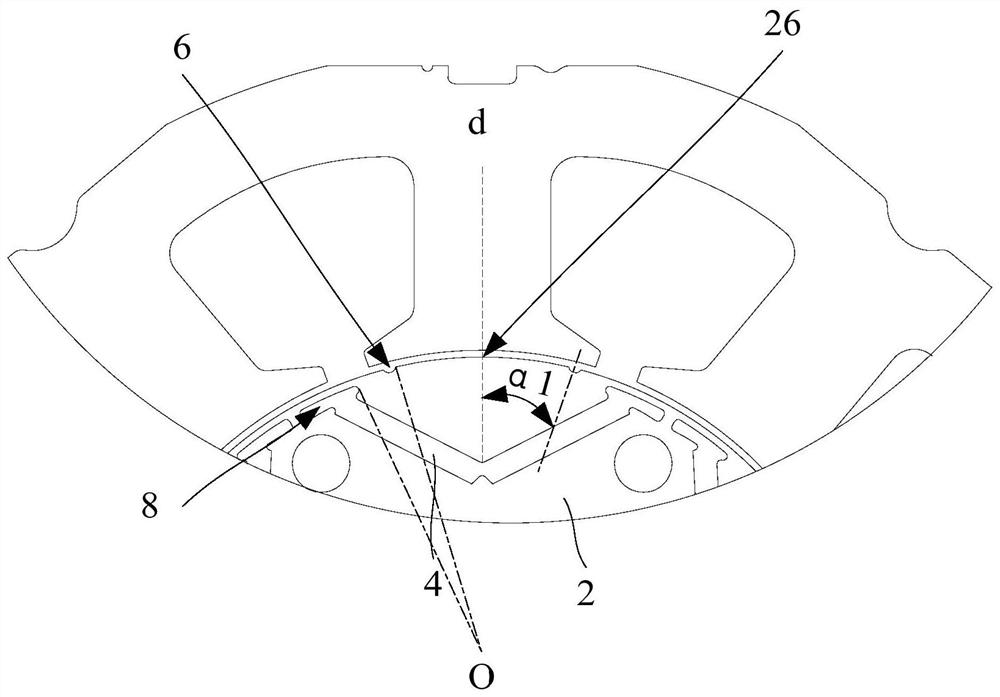

[0085] According to an embodiment of the present invention, in addition to the features defined in the above embodiments, preferably: on the section of the rotor core 2 perpendicular to the rotation axis of the rotor, the diameter of the circle where any point on the wall surface of the recessed part 6 is the same as that of the rotor The diameter ratio is less than 1 and greater than or equal to 0.985.

[0086] Further, on a section perpendicular to the rotation axis of the rotor, the diameter of the rotor is the line between any two points on the outer peripheral wall of the rotor core 2 passing through the line of the axis of the rotor, and any wall surface of the recessed portion 6 The circle where one point is located is a circle whose radius is the distance between any point on the wall surface of the recessed portion and the axis of the rotor, and the axis of the rotor is the center of the circle.

[0087] Preferably, the ratio of the diameter of the circle at the point...

Embodiment 2

[0097] Preferably, as Figure 13 As shown, the end of the gap groove away from the arched portion 22 extends from the end of the permanent magnet to the q-axis direction, wherein the extending direction 24 of two adjacent d-axes is defined as the q-axis.

[0098] Preferably, as Figure 12 As shown, the rotor is used in a motor, and the motor also includes a stator. The stator includes a stator core 20 and a tooth portion arranged on the inner wall of the stator core 20. The minimum distance between two arched portions 22 in the same magnetic pole is D1, along the circumferential direction of the rotor, the width of the side of the teeth facing the rotor is D2, and D1 is greater than D2.

[0099] In this embodiment, the end of the gap groove away from the arched portion 22 extends from the end of the permanent magnet to the q-axis direction, which can improve the magnetic isolation effect of the gap portion. The motor also includes a stator, and the rotor is rotatably connect...

Embodiment 3

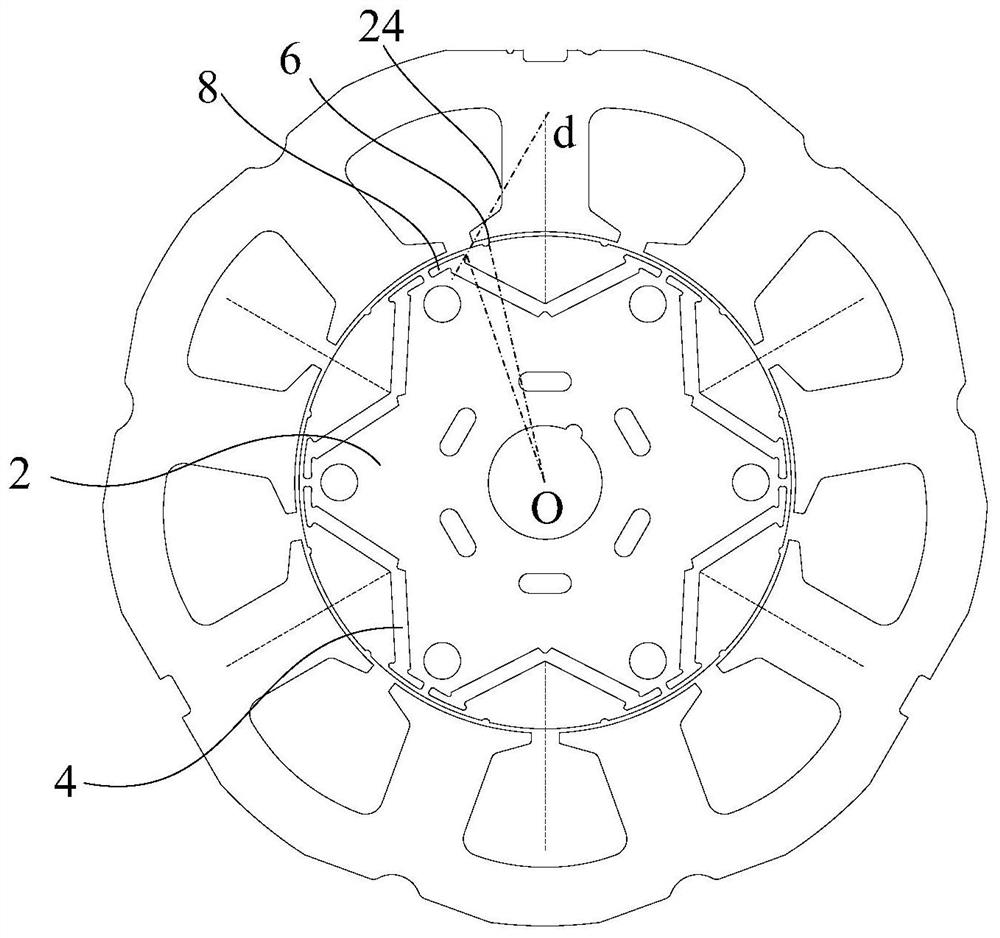

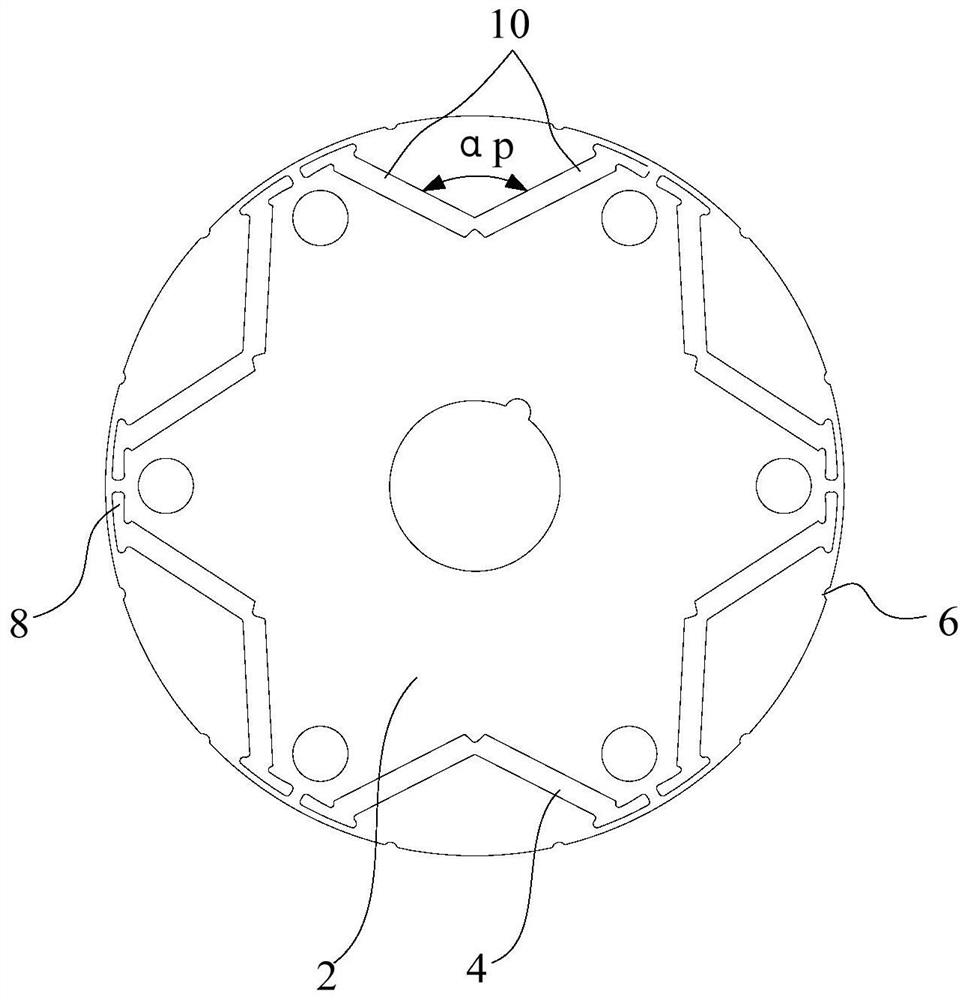

[0103] Such as Figure 5 to Figure 10 As shown, according to an embodiment of the present invention, in addition to the features defined in any of the above embodiments, preferably: there are multiple mounting slots 4, and the multiple mounting slots 4 are distributed along the circumferential direction of the rotor core 2; Along the circumferential direction of the rotor core 2 , the pole-to-pole width H between adjacent mounting slots 4 is greater than or equal to 0.6 mm and less than 1.2 mm.

[0104] In this example, if Figure 5 As shown, too small inter-pole width H between adjacent mounting slots 4 will reduce the mechanical strength, and too large inter-electrode width H between adjacent mounting slots 4 will reduce the back EMF and reduce the power density of the motor. Therefore, selecting the width H between poles to be greater than or equal to 0.6mm and less than 1.2mm can meet the structural strength of the motor while satisfying a certain amount of flux leakage. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com