A Low Moment of Inertia Servo Motor

A technology of moment of inertia and servo motor, applied in the direction of magnetic circuit rotating parts, electromechanical devices, electrical components, etc., can solve the problems of motor electromechanical time constant becoming larger, affecting motor life, and motor use restrictions, etc., to achieve light weight and easy Effect of heat dissipation and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention provides a low moment of inertia servo motor, and the specific implementation described here is only used to explain the present invention, and is not intended to limit the present invention.

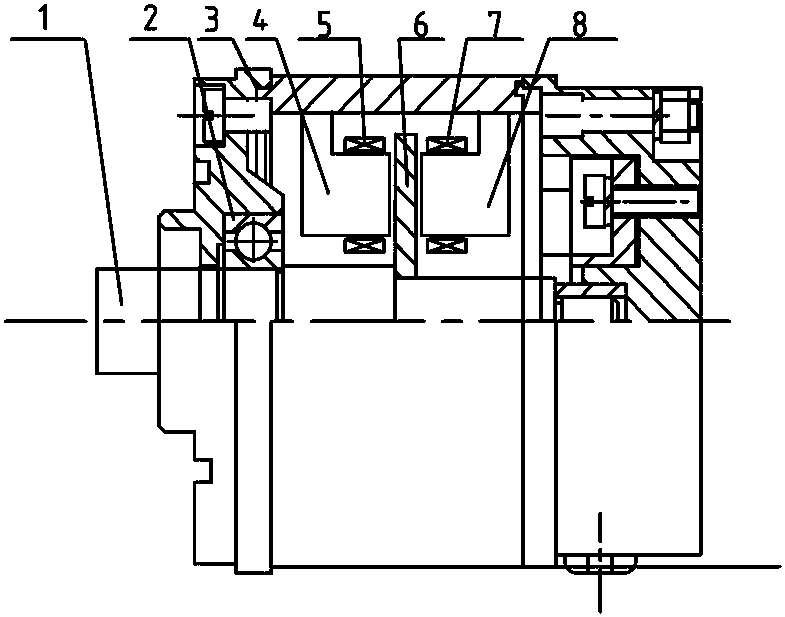

[0038] figure 1 It is a structural schematic diagram of a low moment of inertia servo motor of the present invention. As shown in the figure, the low moment of inertia servo motor belongs to the field of motor technology, including a motor casing, an excitation stator core, an armature stator core, a rotor core, an excitation winding, an armature winding and a shaft.

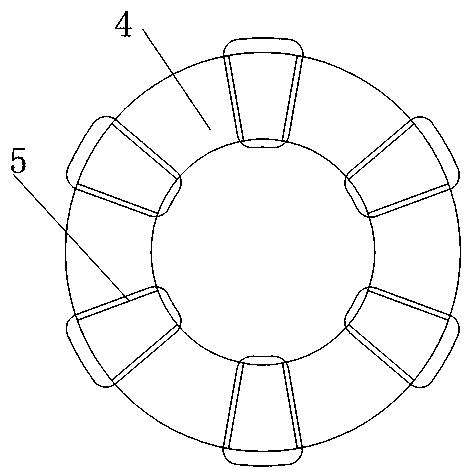

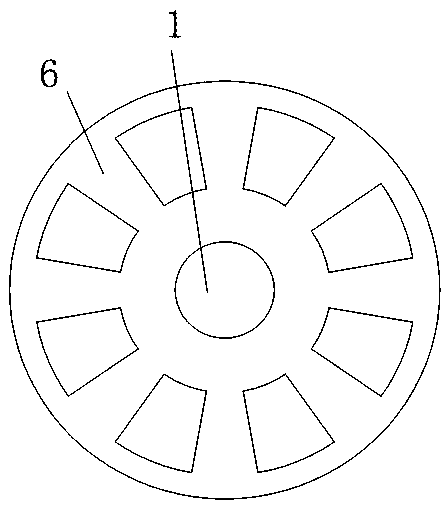

[0039] The low moment of inertia servo motor has an inner rotor structure, and a disc-shaped rotor core is fixed on the shaft. There are 4k evenly distributed fan-shaped through holes on the disc of the rotor core, and k is a positive integer. In this embodiment k=2.

[0040] The axial sides of the rotor core have an excitation stator core and an armature stator core respectively, both of wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com