Radial-axial air gap type three-phase disc type transverse flux permanent magnet motor

A technology of transverse magnetic flux and axial air gap, applied in the direction of magnetic circuits, synchronous machines, electromechanical devices, etc., can solve the problems of complex stator structure and low air gap flux density, increase the number of winding turns, and reduce eddy current loss , the effect of increasing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The drawings constituting a part of the present invention are used to provide a further understanding of the present invention, and the schematic embodiments and descriptions of the present invention are used to explain the present invention, and do not constitute an improper limitation of the present invention.

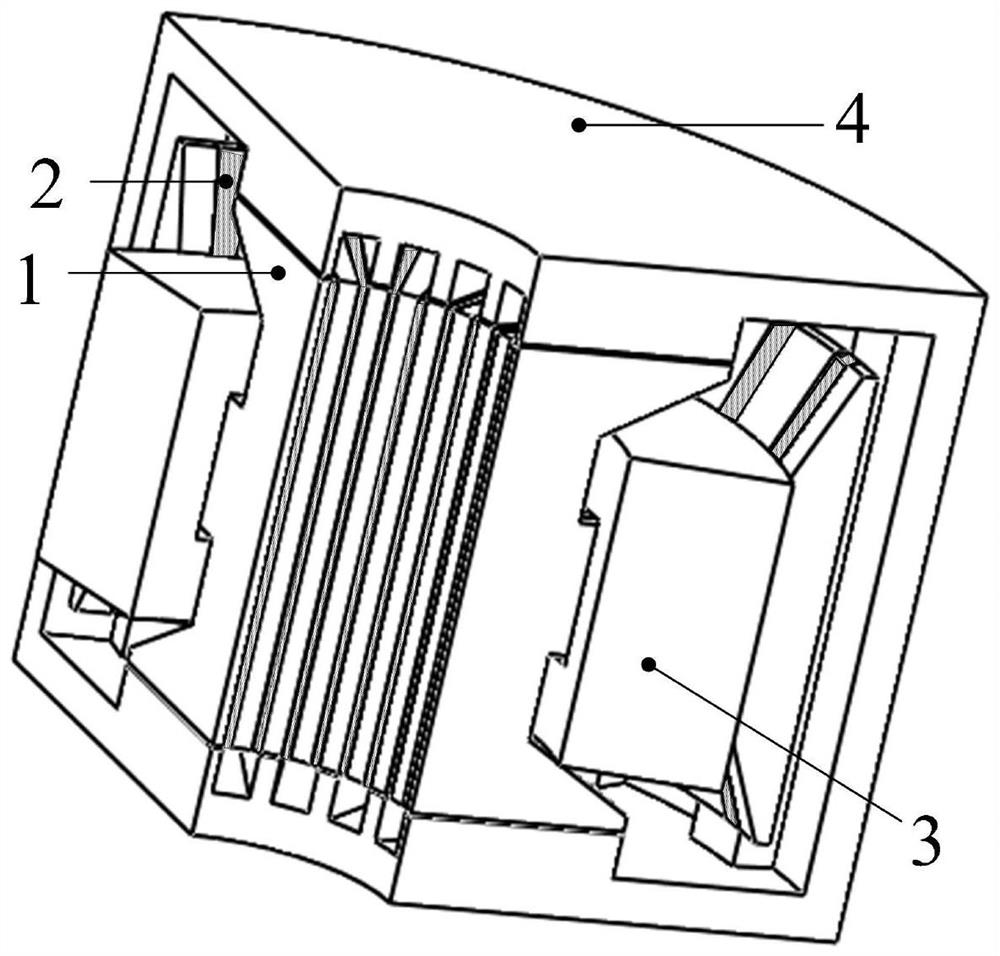

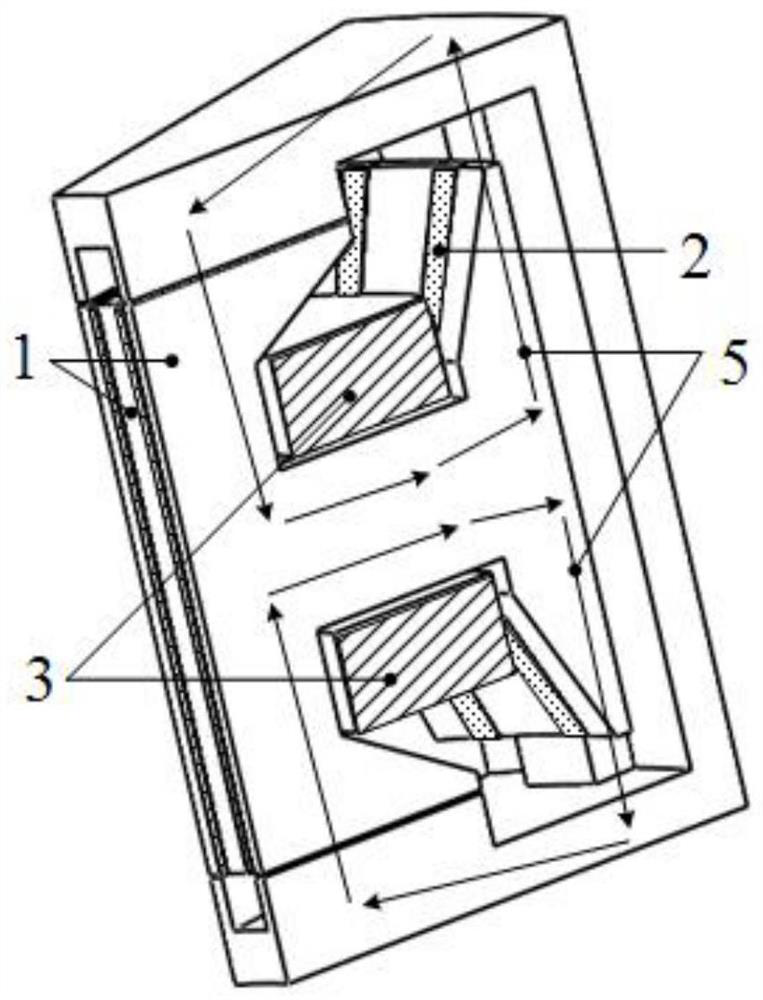

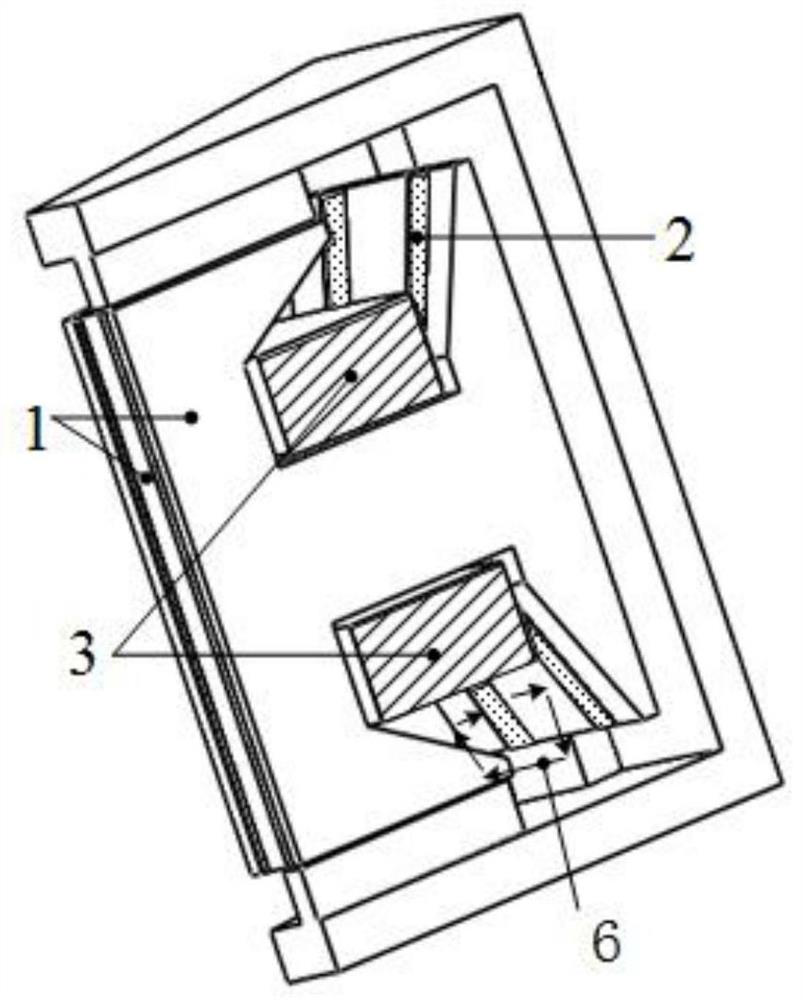

[0032] Such as Figure 1~5As shown, the present invention provides a radial-axial air gap type three-phase disc type transverse flux permanent magnet motor, which is characterized in that it includes a stator, a rotor 4 and three armature windings; the stator includes three Sector-shaped stator segments with the same structure, each stator segment includes p pieces of pole shoe permanent magnets 2, p+1 pieces of pole shoe stator core 1, p is an even number less than or equal to 2k, k is greater than or equal to 1 Positive integer; the stator core and the permanent magnets are alternately arranged along the circumferential direction of the stator segment to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com