Centrally-distributed coreless winding

A hollow cup and winding technology, applied in the field of winding, can solve problems such as inability to effectively use the back EMF, achieve the effects of preventing potential safety hazards, improving the back EMF, and being easy to implement in engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

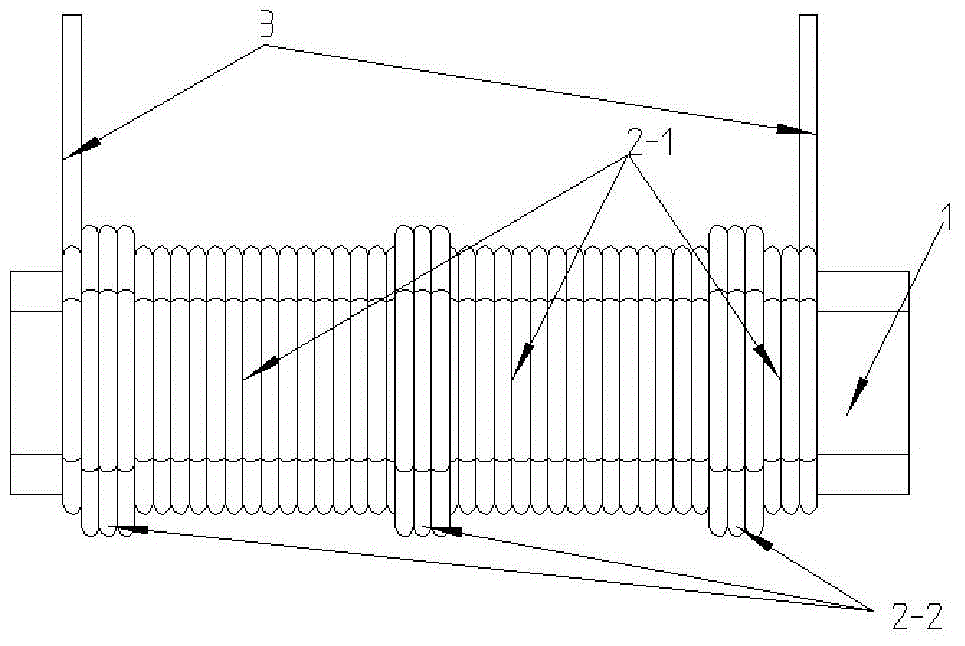

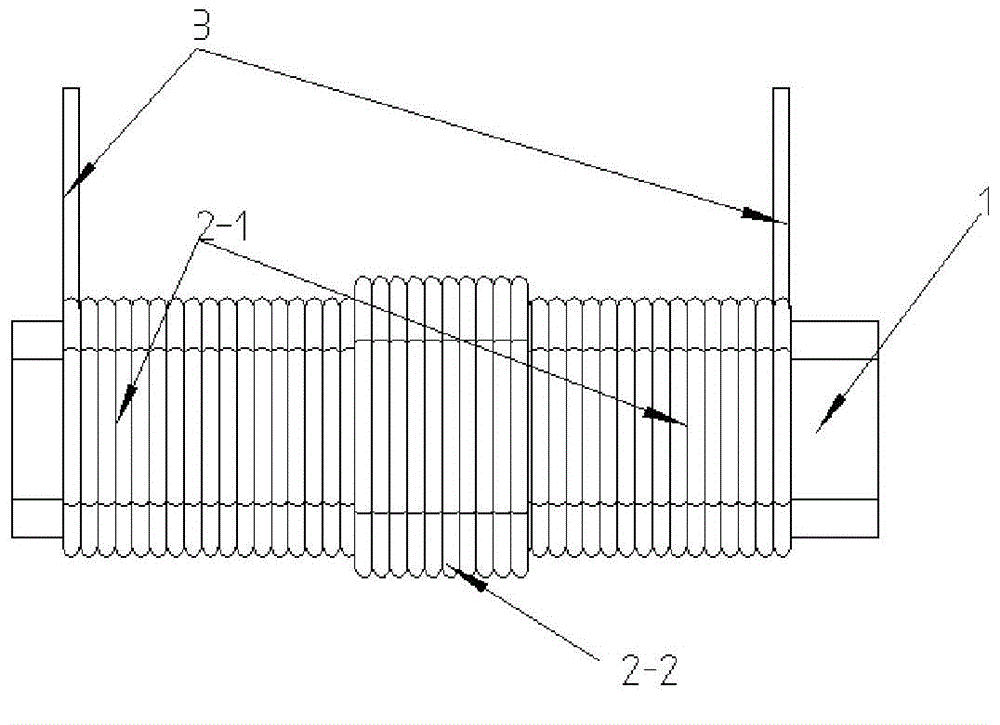

[0020] like image 3 As shown, a hollow cup winding with concentrated distribution includes a staggered conductor 2-2, a normal conductor 2-1 and a winding tap 3. The staggered conductor 2-2 is concentrated in the middle of the winding, and the normal The conductor 2-1 is distributed on both sides of the staggered conductor 2-2, the winding taps 3 are located at both ends of the normal conductor 2-1, and the conductor density of the middle part of the winding where the staggered conductor 2-2 is located is Greater than normal conductor 2-1.

[0021] The number of the staggered conductors 2-2 is 1 / 10 to 1 / 2 of that of the normal conductors 2-1. Preferably, the number of the staggered conductors 2-2 is 1 / 4 of that of the normal conductors 2-1.

[0022] The conductor density of the winding gradually decreases from the middle to both sides. The number of conductors of the staggered-layer conductor 2-2 is proportional to the inner diameter of the winding after winding.

[0023]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com