Magnetic-field-enhanced permanent-magnetic switching flux linkage motor with high fault tolerance

A permanent magnet switch and fault-tolerant technology, which is applied to synchronous motors with rotating armatures and stationary magnets, electrical components, electromechanical devices, etc. Interference and other problems, to achieve the effect of improving anti-electromagnetic interference and electromagnetic compatibility, increasing the amount of change, and outputting high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

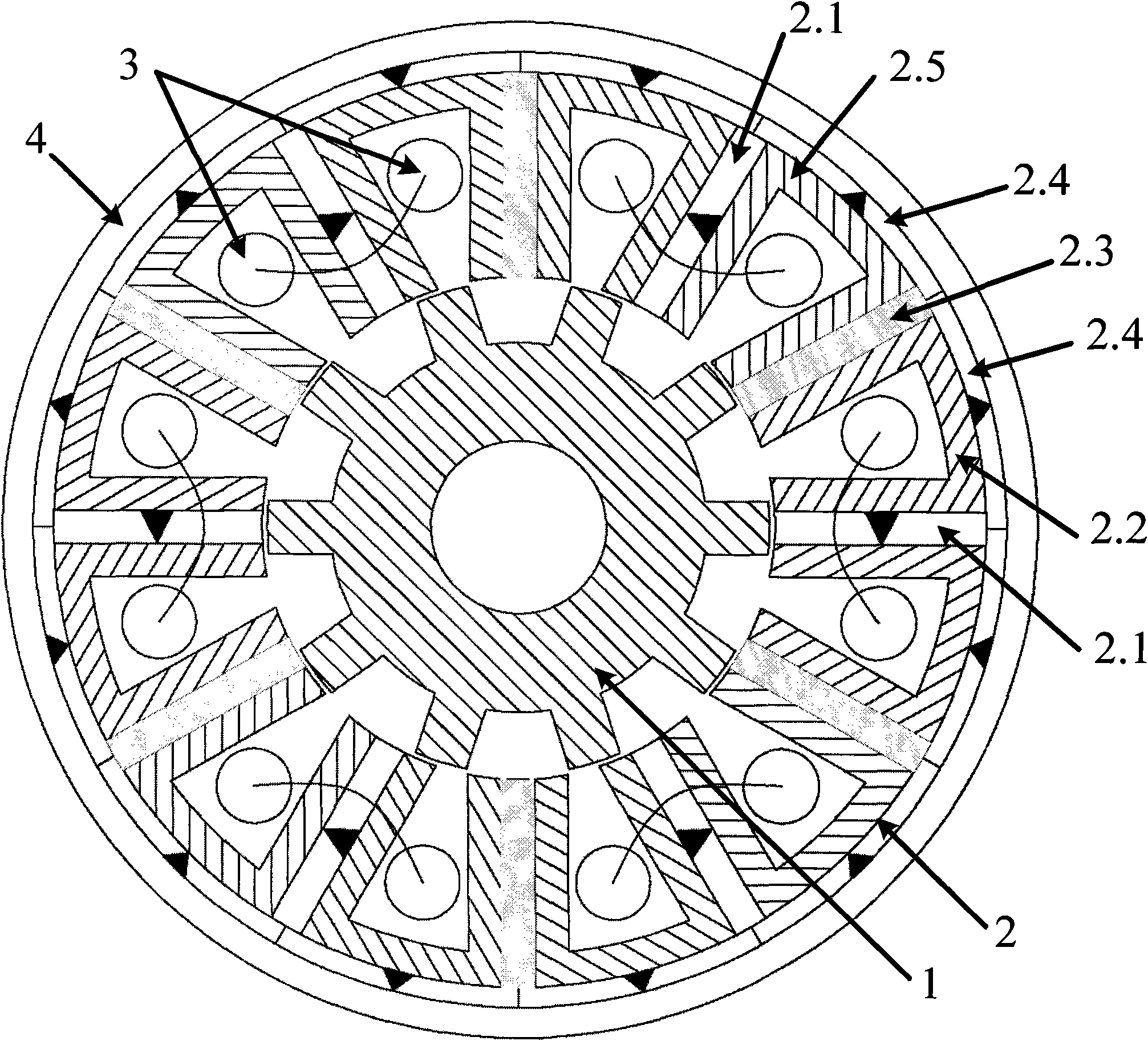

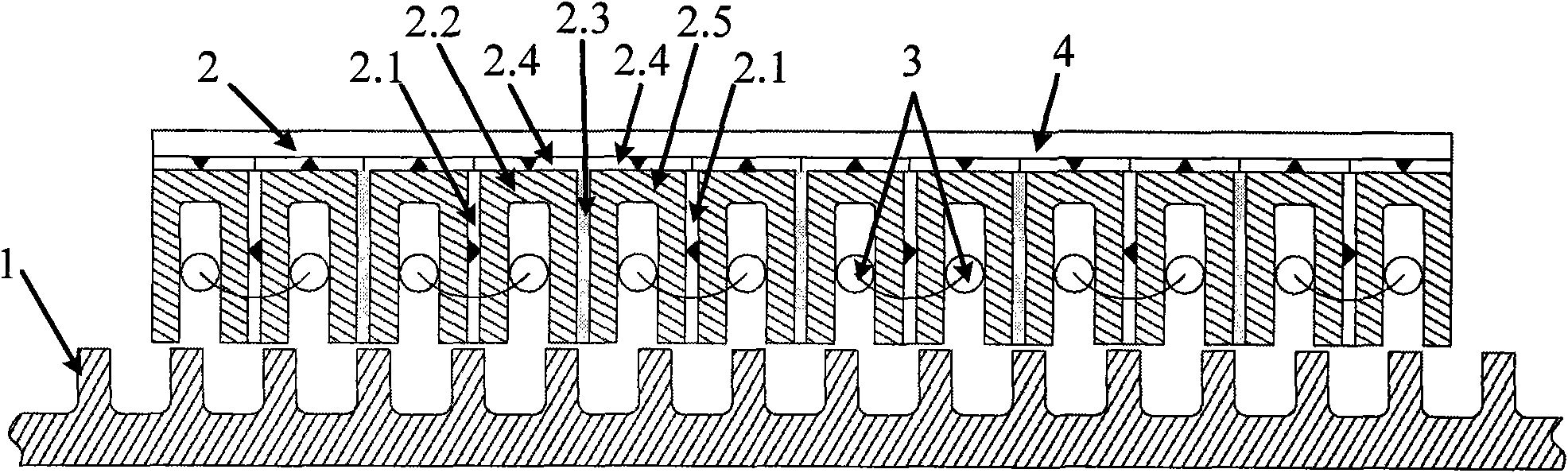

[0014] figure 1 It is a structure of a rotary high fault-tolerant magnetic field enhanced permanent magnet switch flux linkage motor, including a rotor 1, a stator 2, a three-phase armature winding 3 and a casing 4. The stator fixed in the casing includes the first permanent magnet 2.1, the first "U"-shaped iron core 2.2, the reluctance sheet 2.3 and the second "U"-shaped iron core 2.5 arranged in sequence, and the first "U"-shaped iron core The structure is the same as that of the second "U"-shaped iron core. The first permanent magnet is magnetized tangentially along the circumference. The "U" shaped iron core is formed by the side, and the auxiliary teeth are composed of the magnetic resistance piece and the "U" shaped iron core side close to the two sides of the magnetic resistance piece. In the example shown in the figure, the rotor has 10 teeth, and the stator has 6 armature teeth. Arranged at intervals with 6 auxiliary teeth, the three-phase armature winding 3 is a con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com