The Primary Structure of a Low Eddy-current Loss Cogged Cylindrical Linear Motor

A technology of eddy current loss and linear motors, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of inefficient use of electromagnetic energy, many missing primary yoke cores, and limited application range, so as to facilitate heat dissipation and reduce primary Quality, guaranteed high-efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

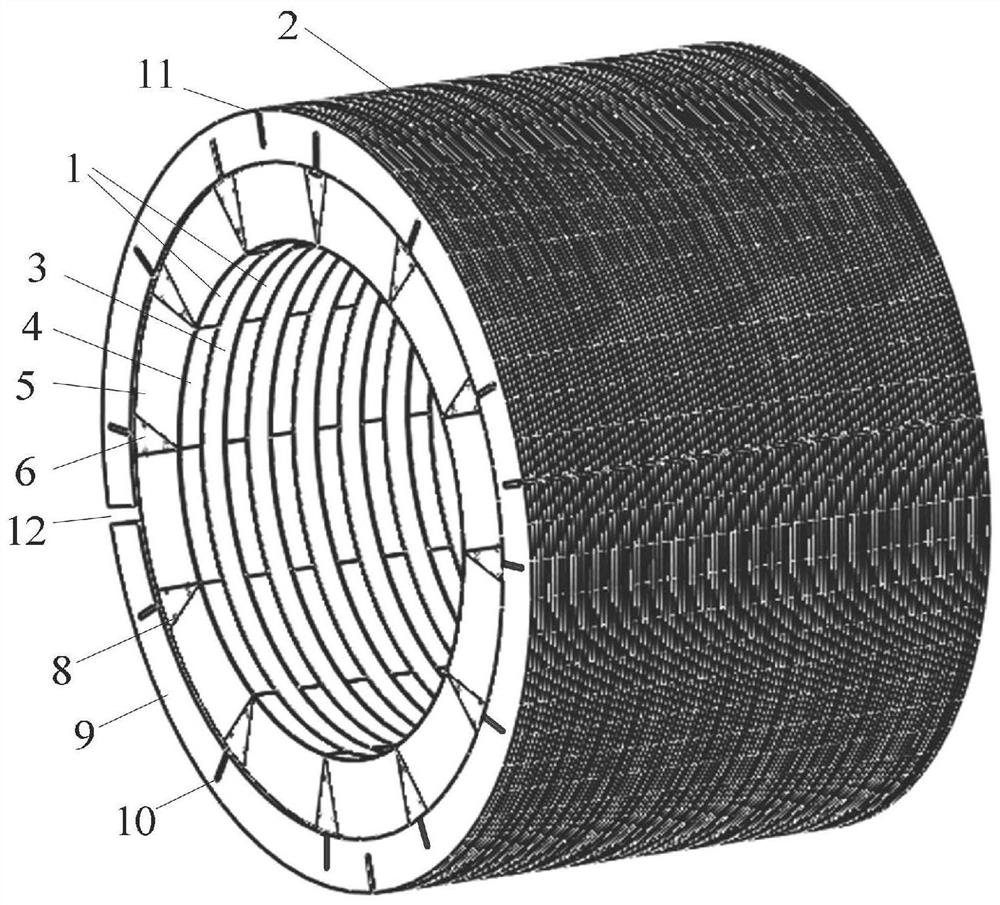

[0029] In this example, if figure 1 As shown, the primary structure of a cogging type cylindrical linear motor with low eddy current loss includes primary teeth 1, primary yoke 2 and multiple circular ring groups 3; wherein, primary teeth 1 and primary yoke 2 are separate components, And the primary yoke 2 is fitted on the outside of the primary tooth 1 and constitutes the primary iron core.

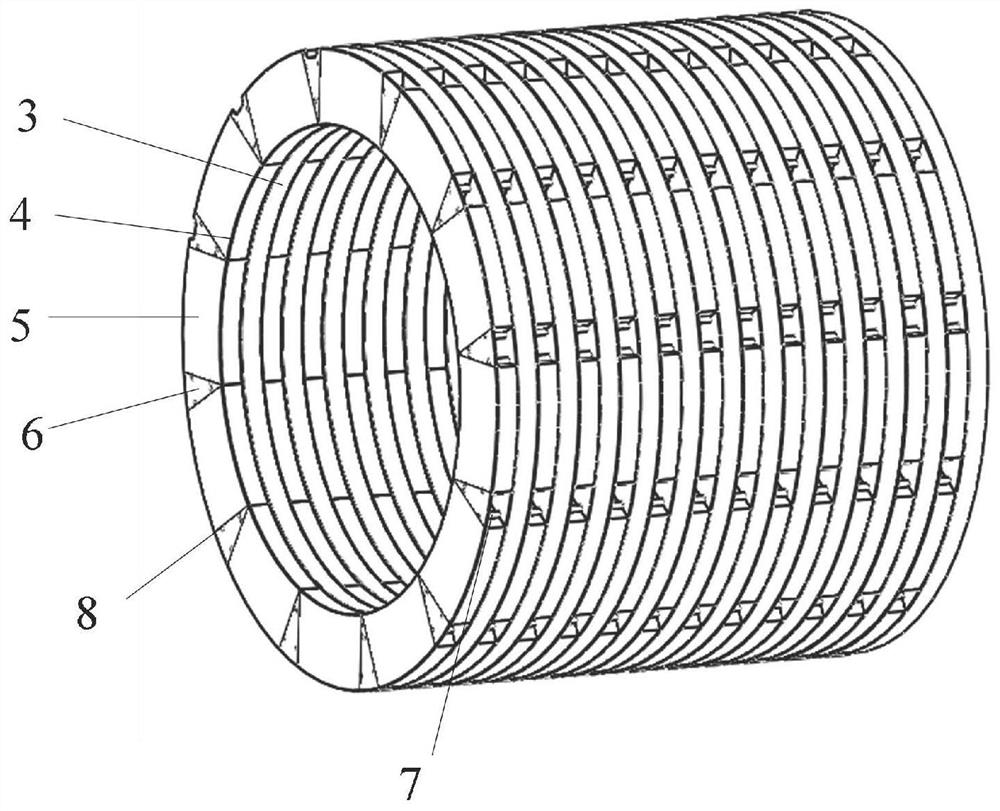

[0030] Such as figure 2 As shown, the primary tooth 1 includes a plurality of tooth core rings 4, and the scattered tooth core blocks 5 are clamped and positioned by two thin insulating plates 6, positioning pins 7 and positioning holes 8 to form a tooth core ring 4. One or more circular ring groups 3 are embedded between the two tooth core rings 4 . Both the tooth core rings 4 and the circular rings 3 are alternately clamped by two thin insulating plates 6 , and each circular ring 3 is located between the two tooth core rings 4 .

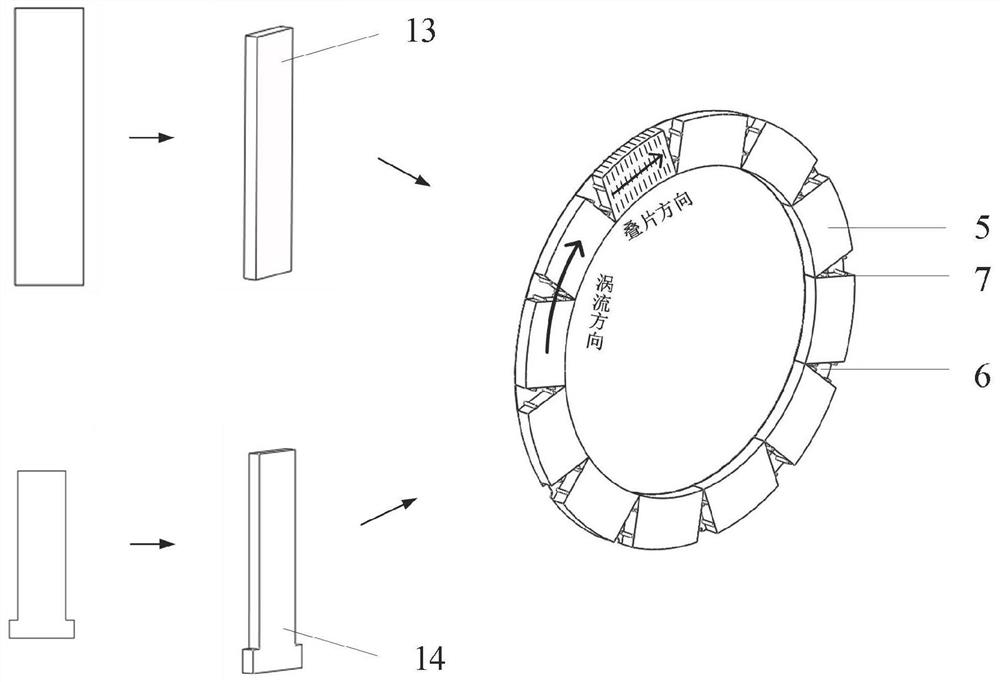

[0031] Such as image 3 As shown, the tooth core b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com