Rotor sheath of external rotor permanent magnet motor

A technology of rotor sheath and permanent magnet motor, which is applied to magnetic circuits, electrical components, electromechanical devices, etc., can solve the problems of reducing the service life of the rotor, reducing the strength of the sheath structure, and unable to dissipate heat, and achieves the effect of accelerating wind speed and heat dissipation. Good and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

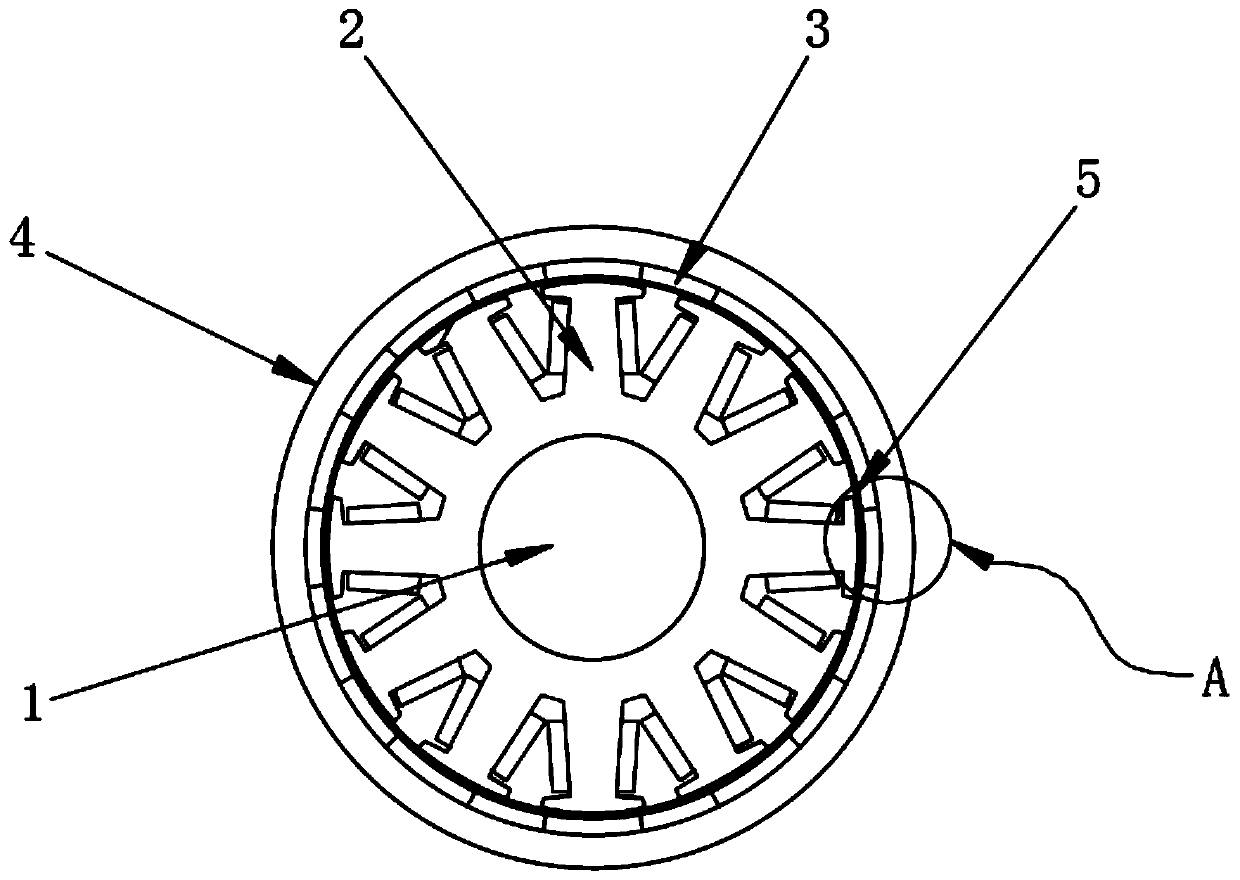

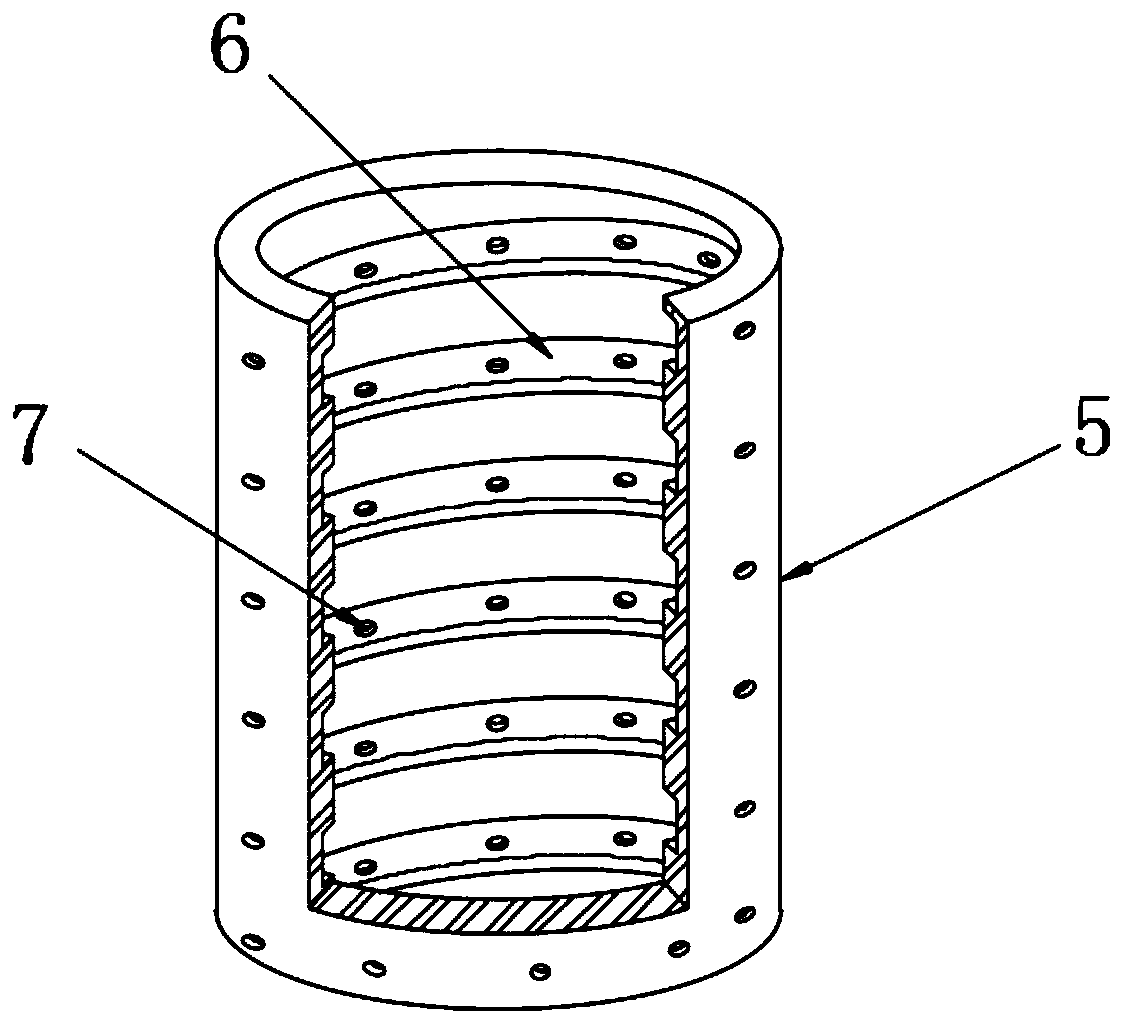

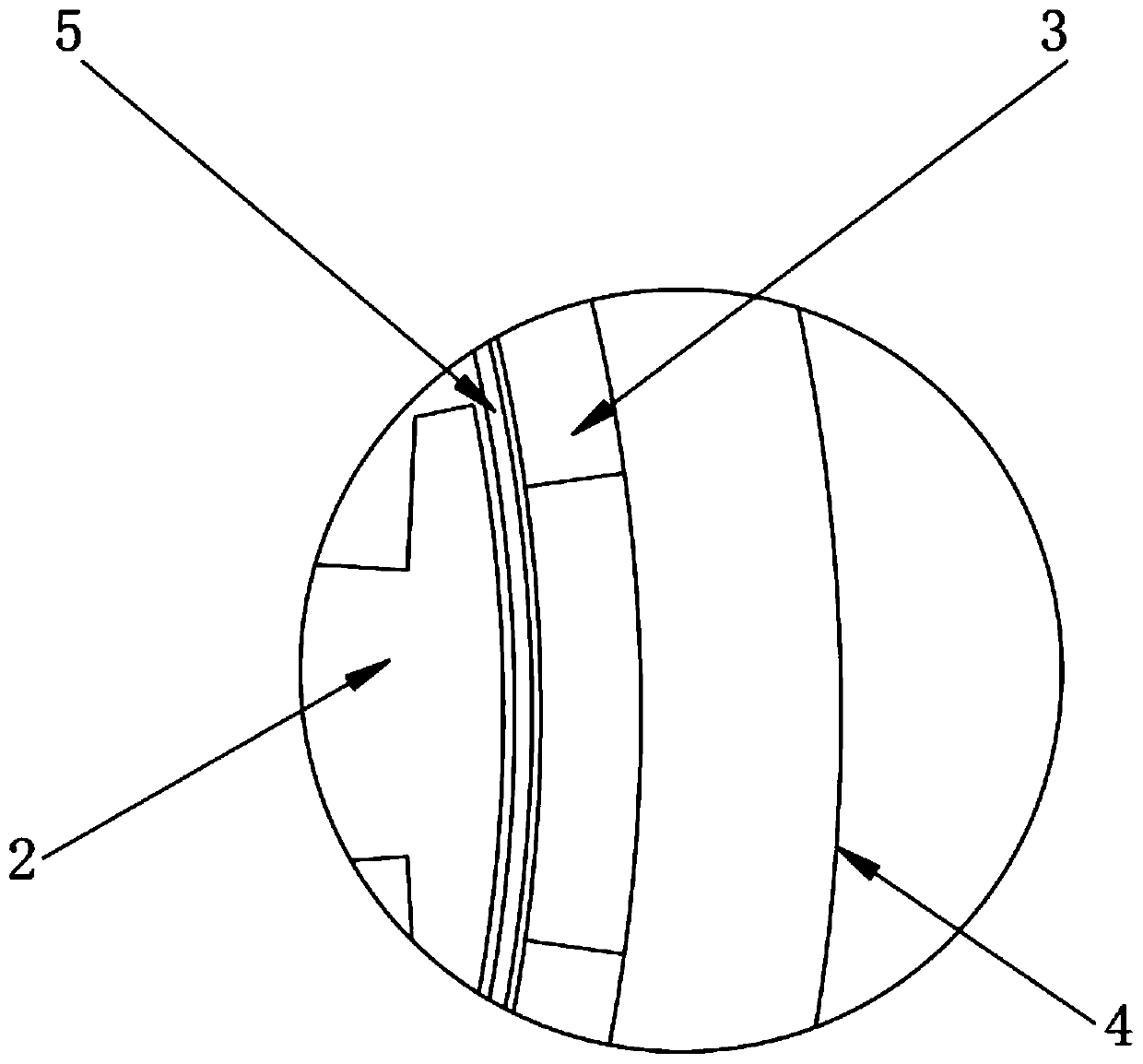

[0025] see Figure 1-3 , the present invention provides the following technical solutions: a rotor sheath of an outer rotor permanent magnet motor, including a rotating shaft 1, the outer wall of the rotating shaft 1 is provided with a stator 2, the rotating shaft 1 and the stator 2 are fixedly connected, and the stator 2 is provided with a rotor 4 on the outside, the rotor 4 is adapted to the stator 2, the inner wall of the rotor 4 is embedded with a permanent magnet 3, and a rotor sheath 5 is embedded in the interlayer between the permanent magnet 3 and the stator 2 , the inner wall of the rotor sheath 5 is provided with a spiral groove 6 from top to bottom, and the outer wall of the rotor sheath 5 is provided with a number of cooling slots 7, and the cooling slots 7 communicate with the spiral slot 6 .

[0026] In this embodiment, a spiral groove 6 is provided on the inner wall of the rotor sheath 5, and the helical groove 6 serves to accelerate the flow rate of the air ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com